Steam generation device and method

A steam generating device and steam technology, which are used in steam generation, steam boilers, firebox-type steam boilers, etc., can solve the problems of poor safety and high operating costs, and achieve the effects of reducing the probability of explosion, reducing operating costs and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

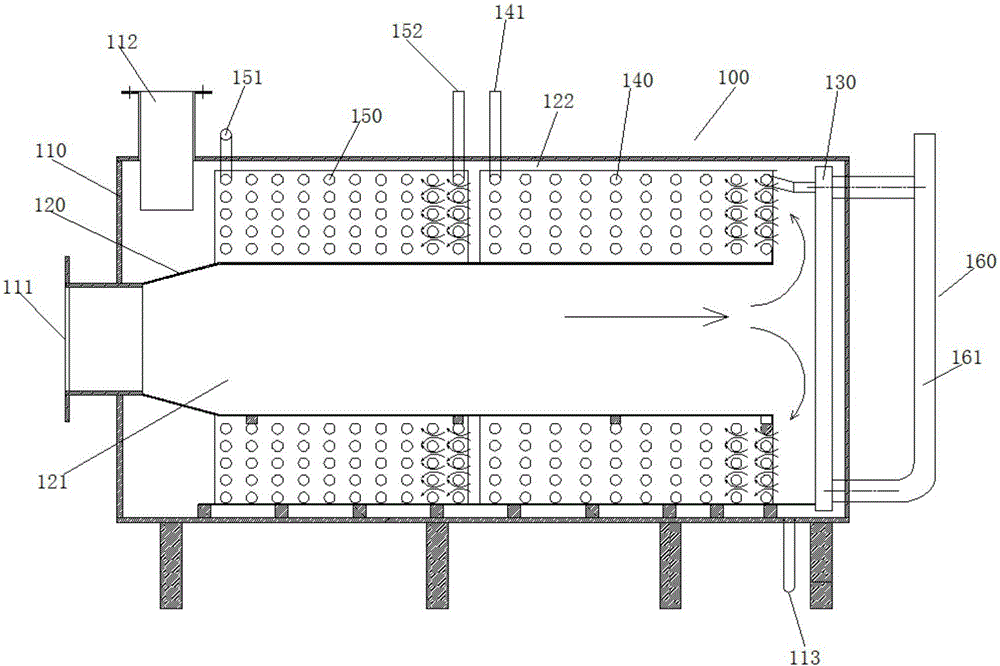

[0031] Such as figure 1 As shown, this embodiment provides a heating unit for a steam generator, which includes a closed casing 110, and a heating channel with both ends communicating with the outside is provided in the casing 110; A combustion channel 121 that injects flames inward in the horizontal direction, and a smoke flow channel 122 for exhausting combustion smoke. The discharge direction of the combustion smoke at the smoke flow channel 122 is opposite to the injection direction of the flame at the combustion channel 121; A first heating unit 130 is provided at the turning connection between the combustion channel 121 and the flue gas flow channel 122, a second heating unit 140 is provided at the flue gas flow channel 122, and both the first heating unit 130 and the second heating unit 140 are equipped with flow channels and communicate with each other.

[0032] In this embodiment, the first heating unit 130 and the second heating unit 140 are mainly heated by combust...

Embodiment 2

[0047] This embodiment provides a steam generator, including a generator body 100 . Its generator body 100 includes the heating unit in Embodiment 1.

[0048] In this embodiment, the bottom of the casing 110 is further provided with a sewage outlet 113 , and the sewage outlet 113 is located below the turn-back connection between the combustion channel 121 and the flue gas flow channel 122 .

[0049] In this embodiment, the setting of the sewage outlet 113 can conveniently clean up the combustion residue at the combustion channel 121; in addition, the sewage outlet 113 is located below the turning joint between the combustion channel 121 and the flue gas flow channel 122, because the combustion channel Driven by the internal airflow, the combustion residue at 121 will accumulate under the turn-back connection, so that the combustion residue can be better discharged.

[0050] In this embodiment, a sewage valve is provided at the sewage outlet 113 .

[0051] In this embodiment,...

Embodiment 3

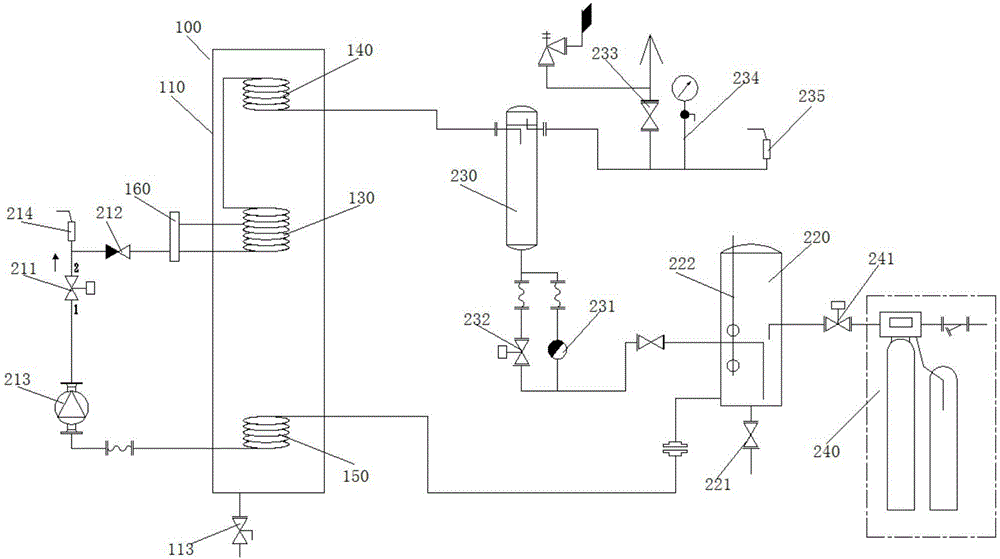

[0055] Such as figure 2 As shown, this embodiment provides a steam generating unit, and its specific structure can adopt the corresponding form in Embodiment 1 or 2. It includes a heating channel set in a closed casing 110, both ends of which communicate with the outside world, and the heating channel is provided with a first heating unit 130, a second heating unit 140 and a preheating unit 150 in the direction from the inlet to the outlet; The first heating unit 130, the second heating unit 140 and the preheating unit 150 are all provided with water flow passages, and the internal water flow passages of the preheating unit 150, the first heating unit 130 and the second heating unit 140 are connected in sequence, and the preheating unit 150 A pressure regulating valve 211 and a check valve 212 are also sequentially connected to the first heating unit 130 by pipelines.

[0056] In this embodiment, the check valve 212 can preferably isolate the preheating unit 150 from the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com