Patents

Literature

127results about "Fire-box steam boilers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

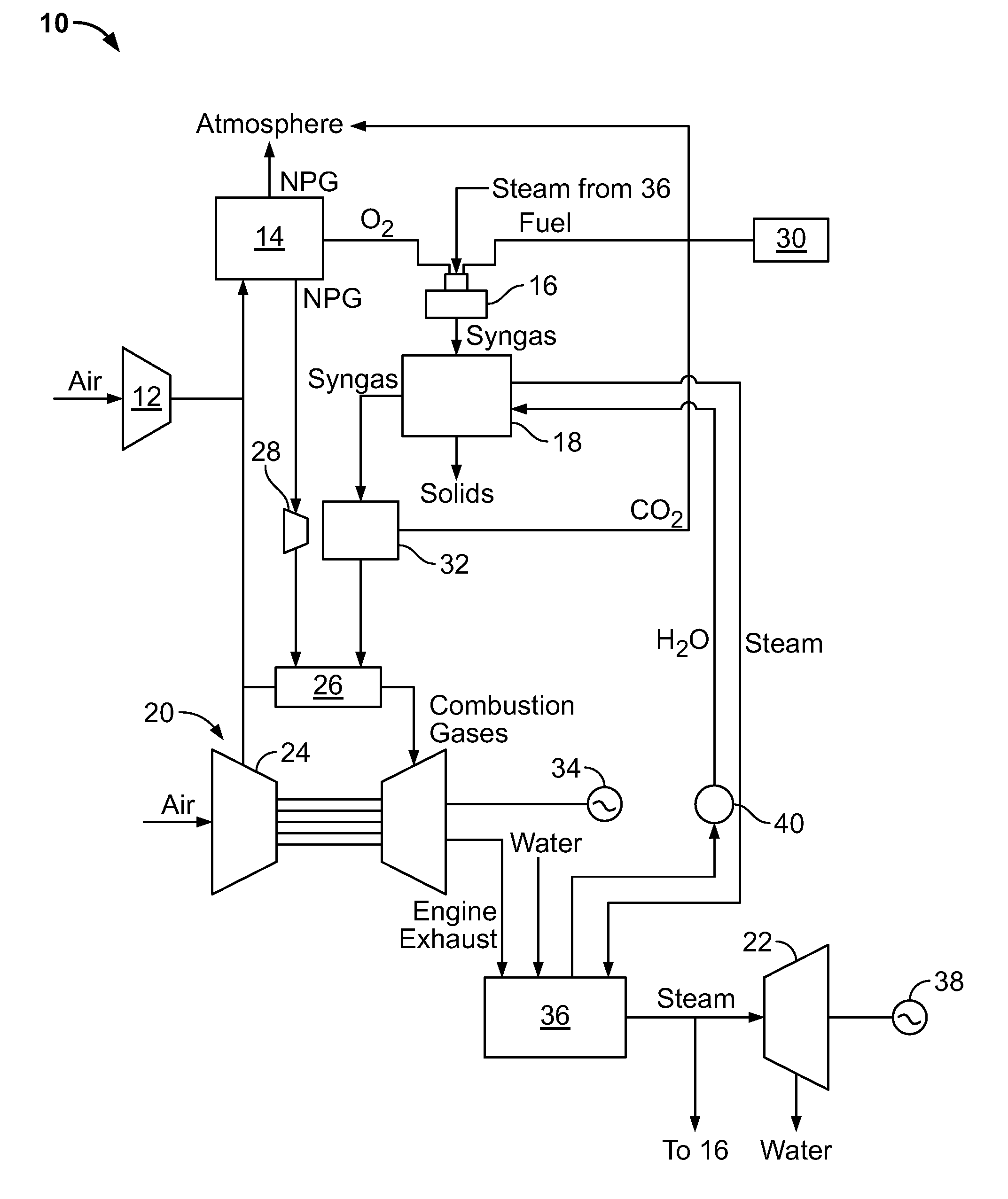

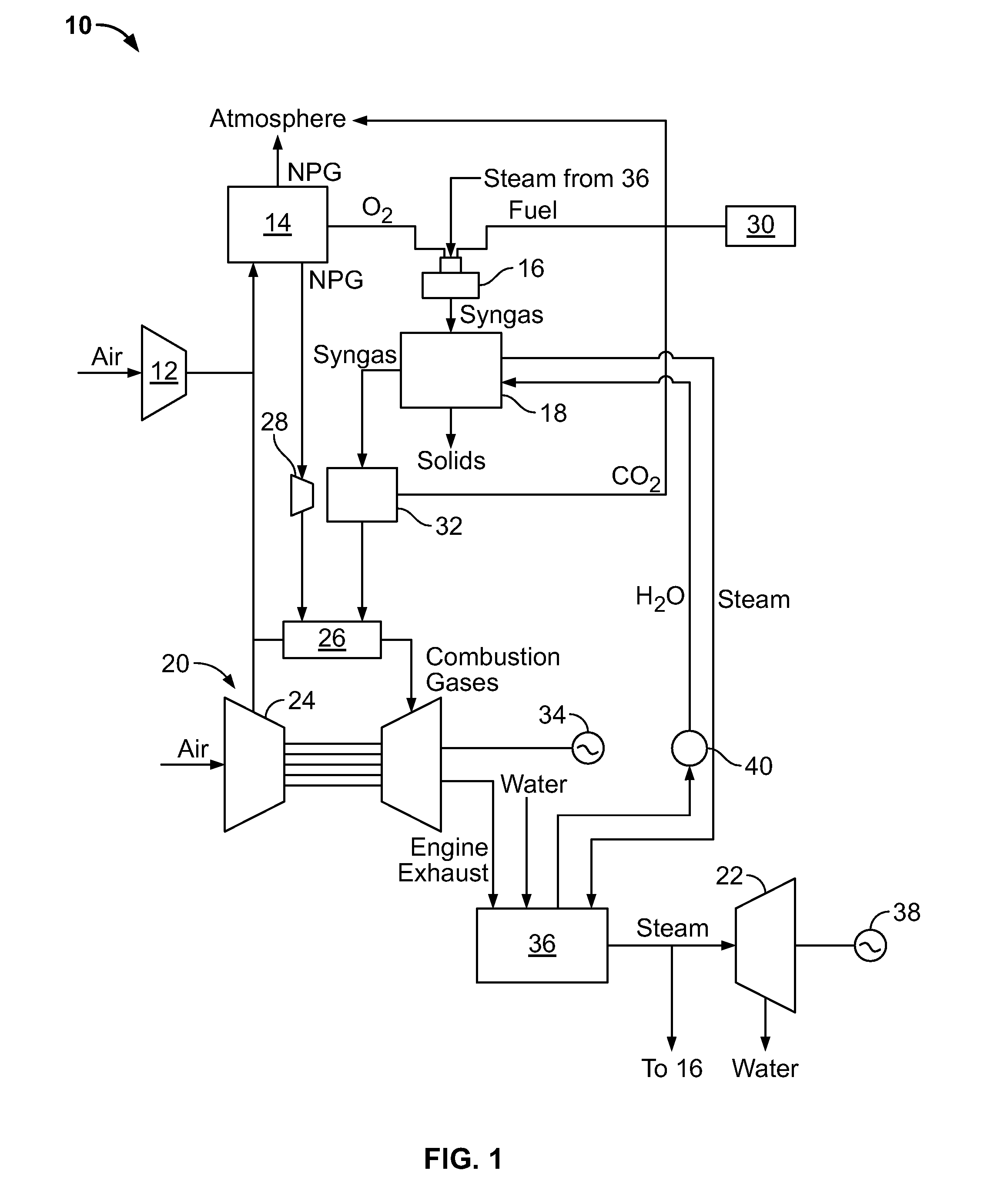

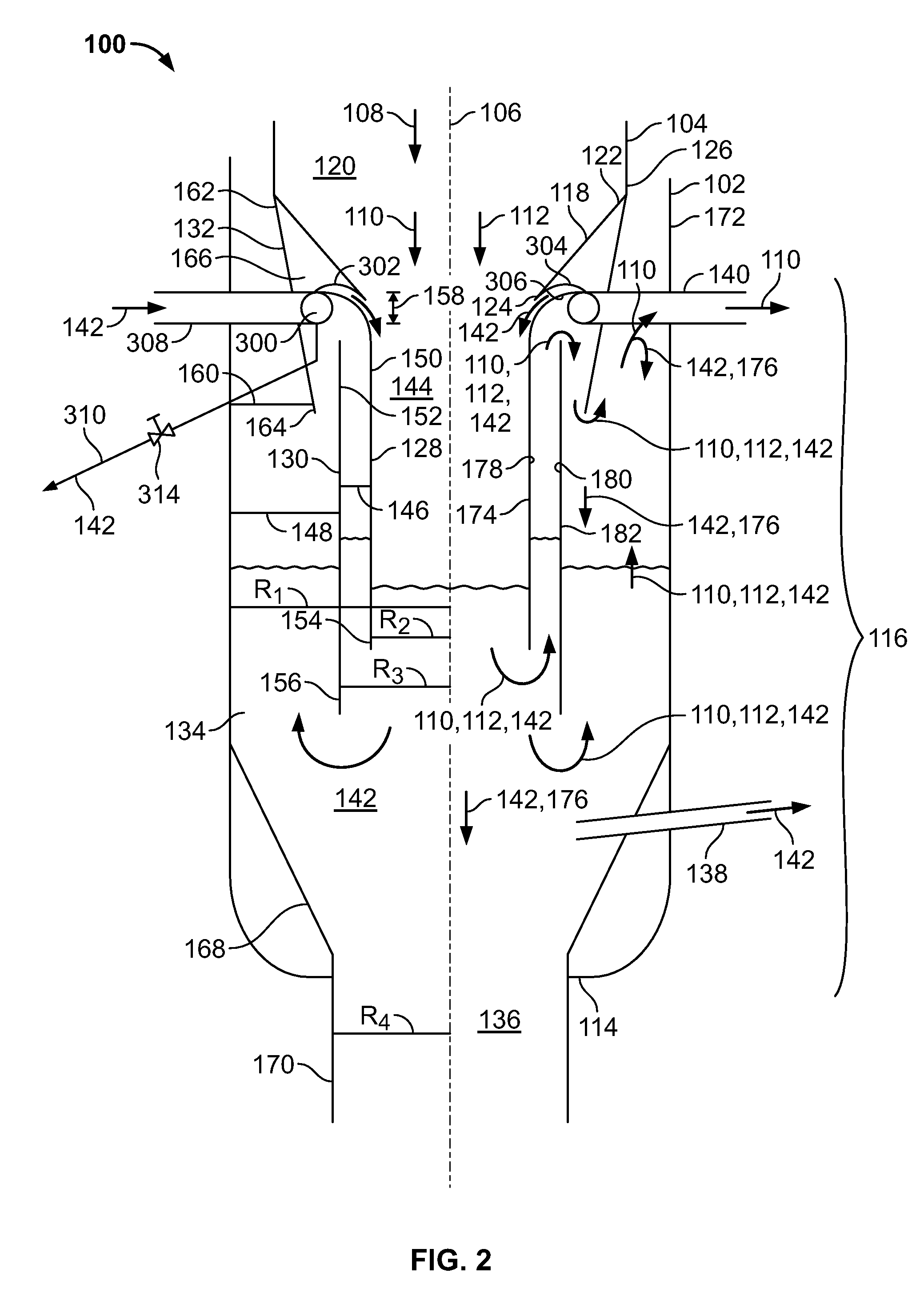

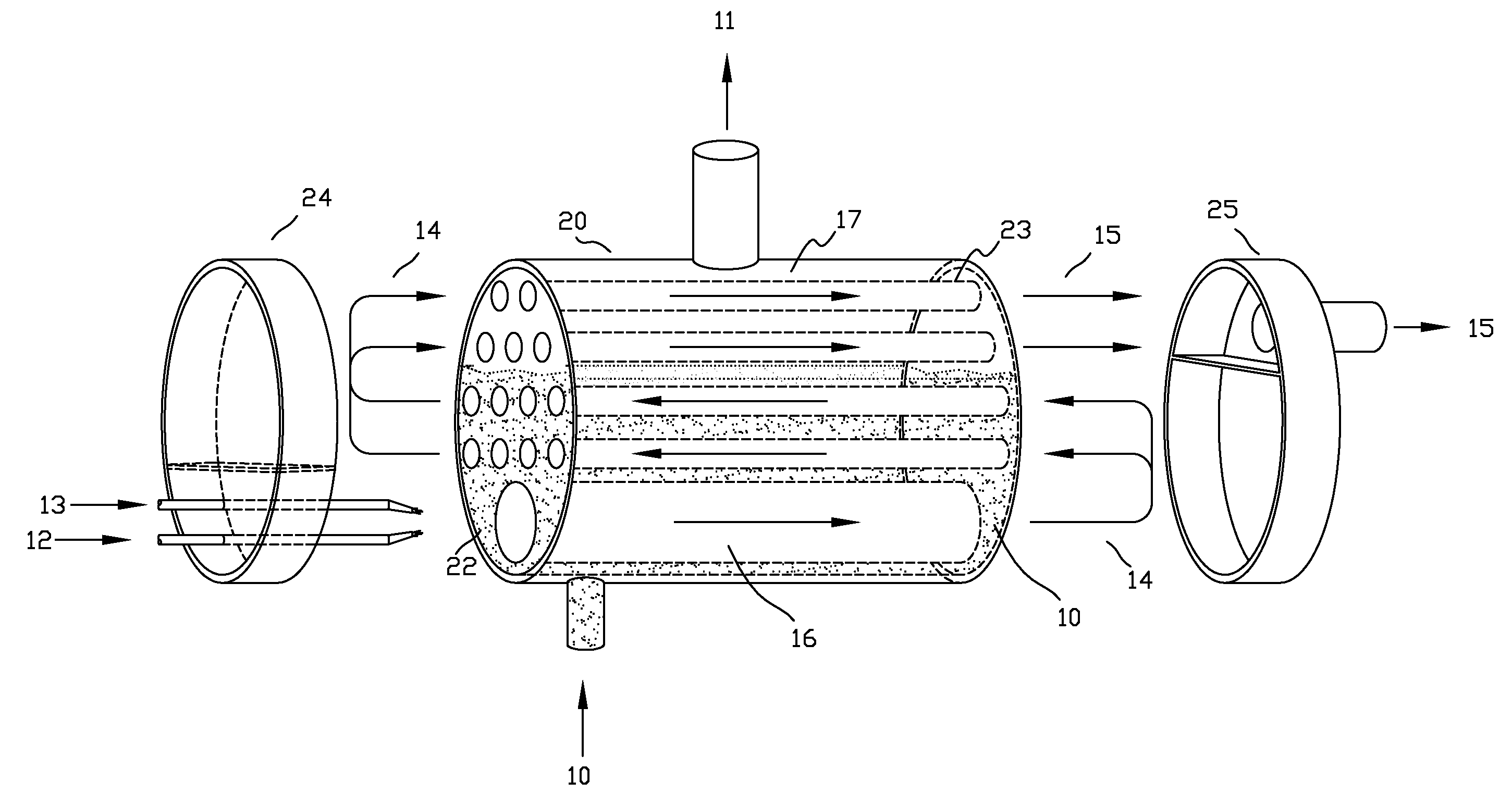

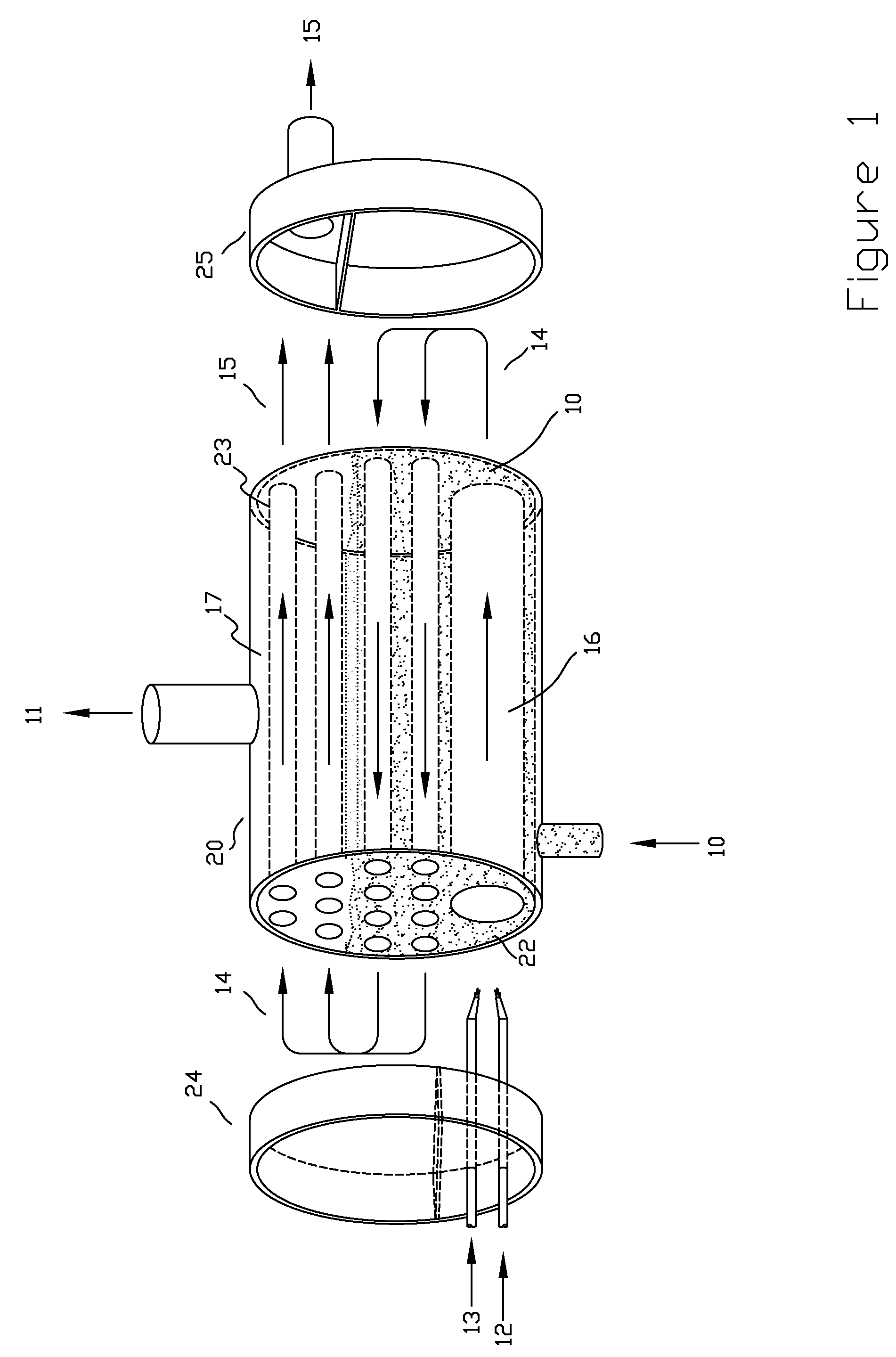

Methods and apparatus for cooling syngas within a gasifier system

A method for operating a syngas cooler is provided. The method includes channeling a flow of syngas into an annular cooling chamber having a longitudinal axis, injecting a cooling fluid into a manifold such that the cooling fluid is channeled substantially circumferentially about the annular cooling chamber, and discharging the cooling fluid from the manifold such that the cooling fluid contacts a surface of the cooling chamber at a predetermined angle relative to the axis of the cooling chamber.

Owner:AIR PROD & CHEM INC

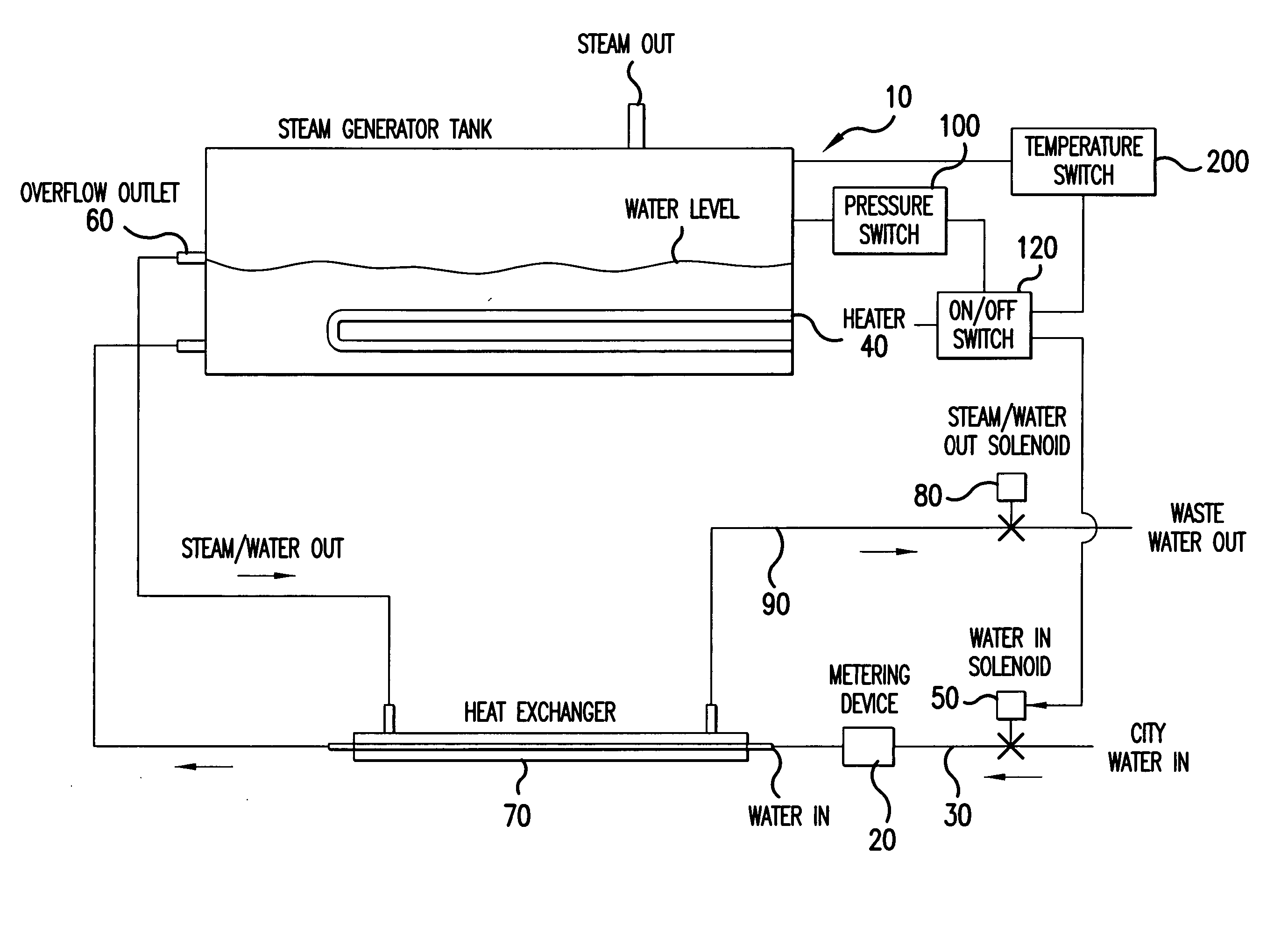

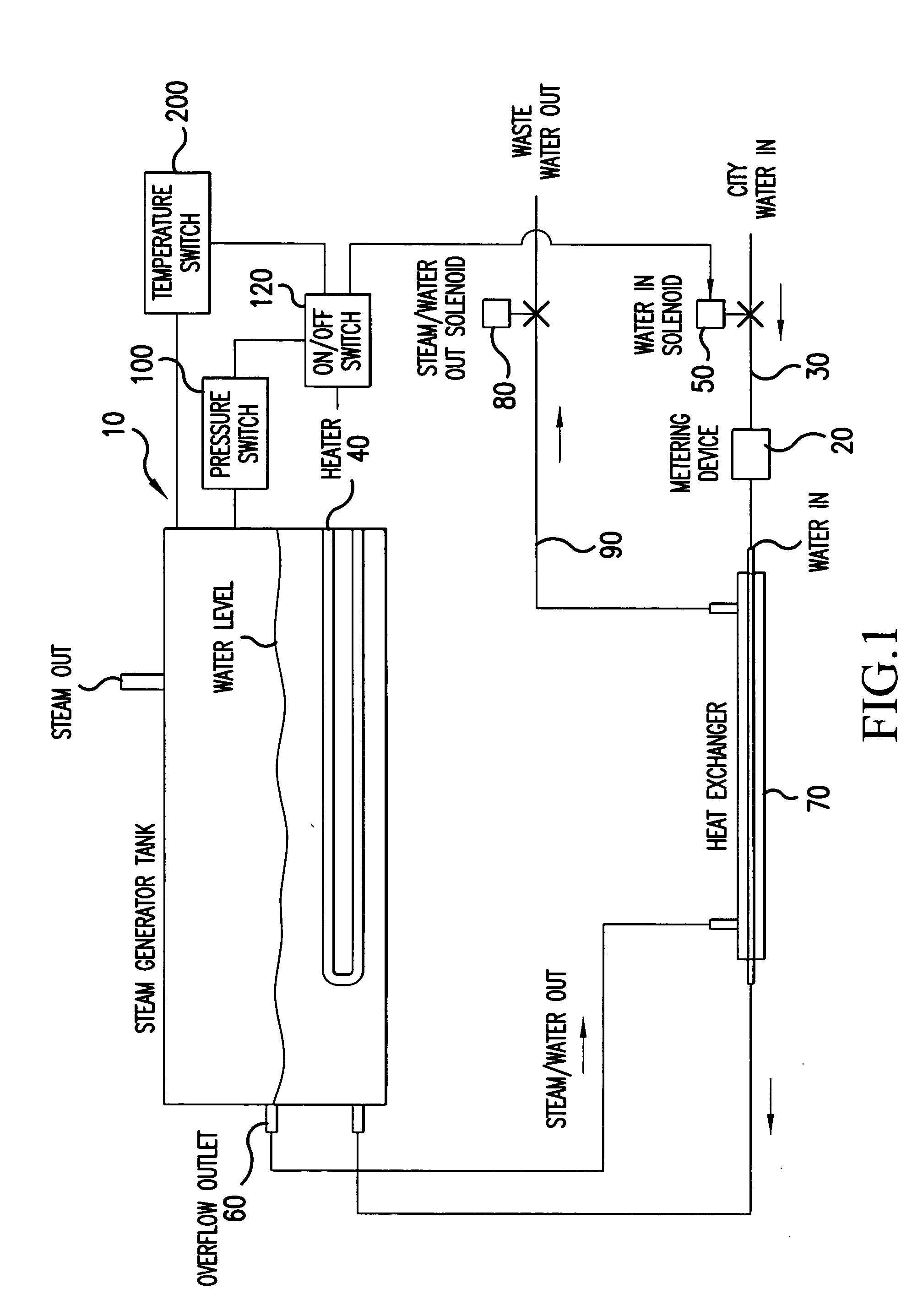

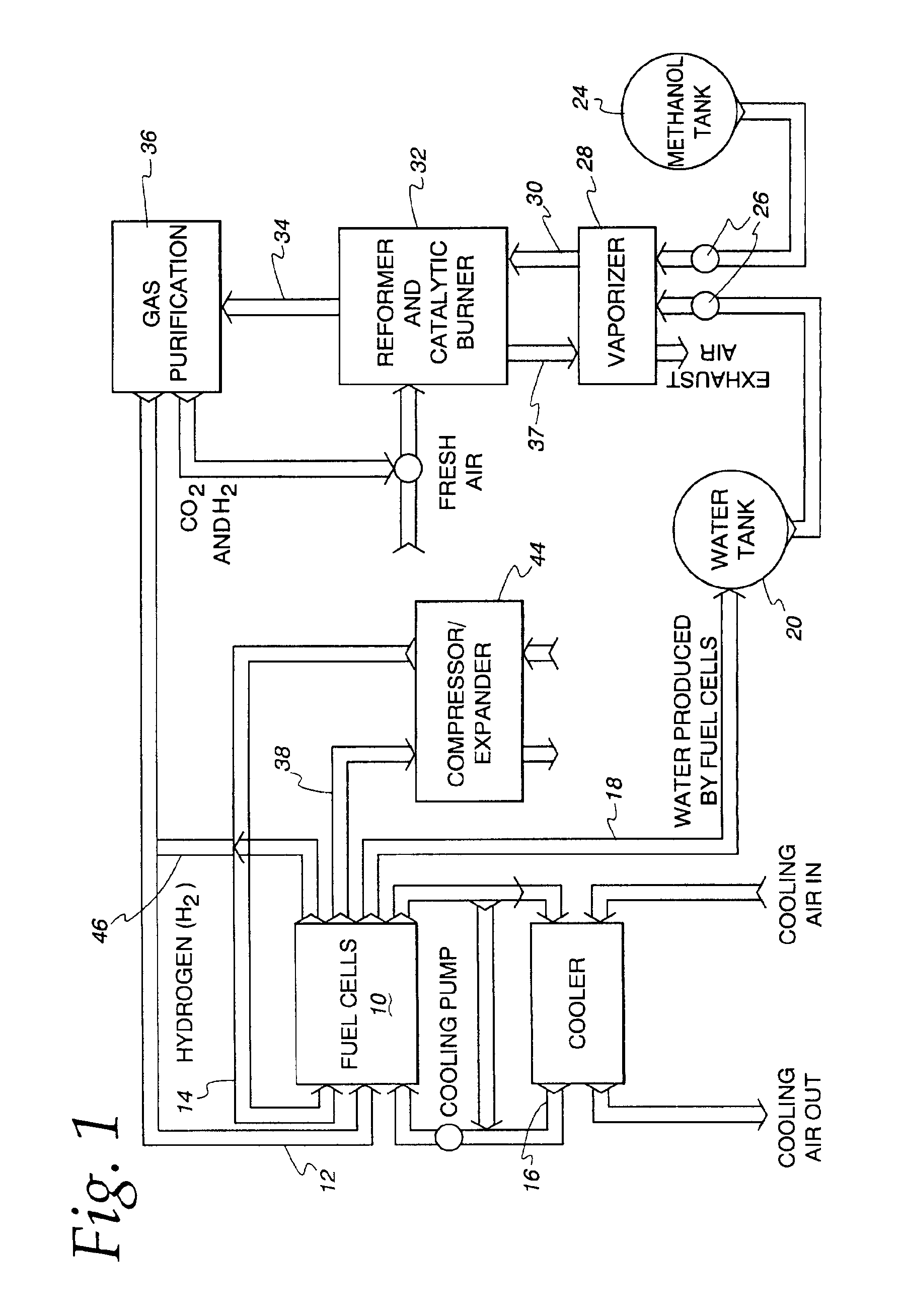

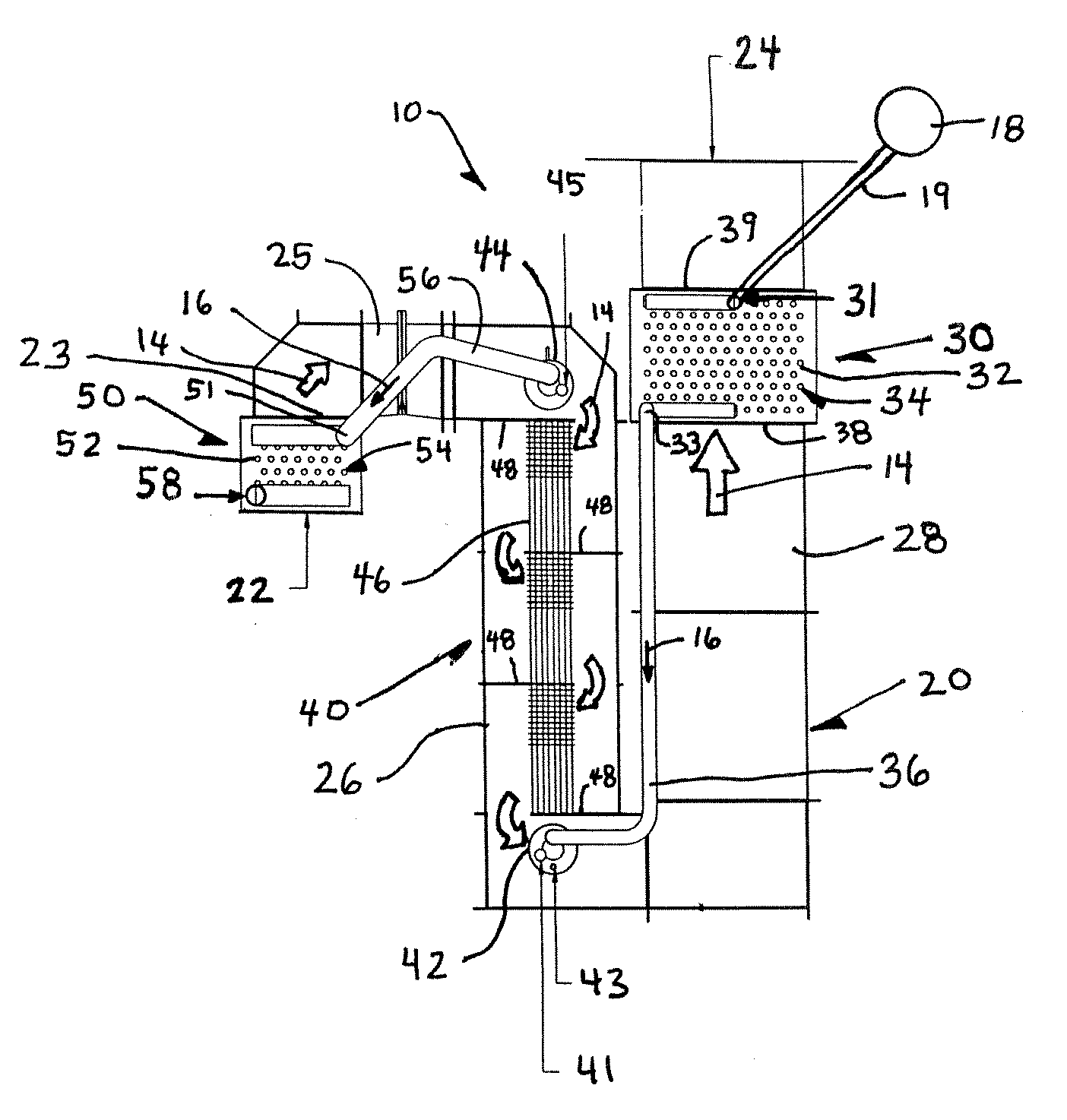

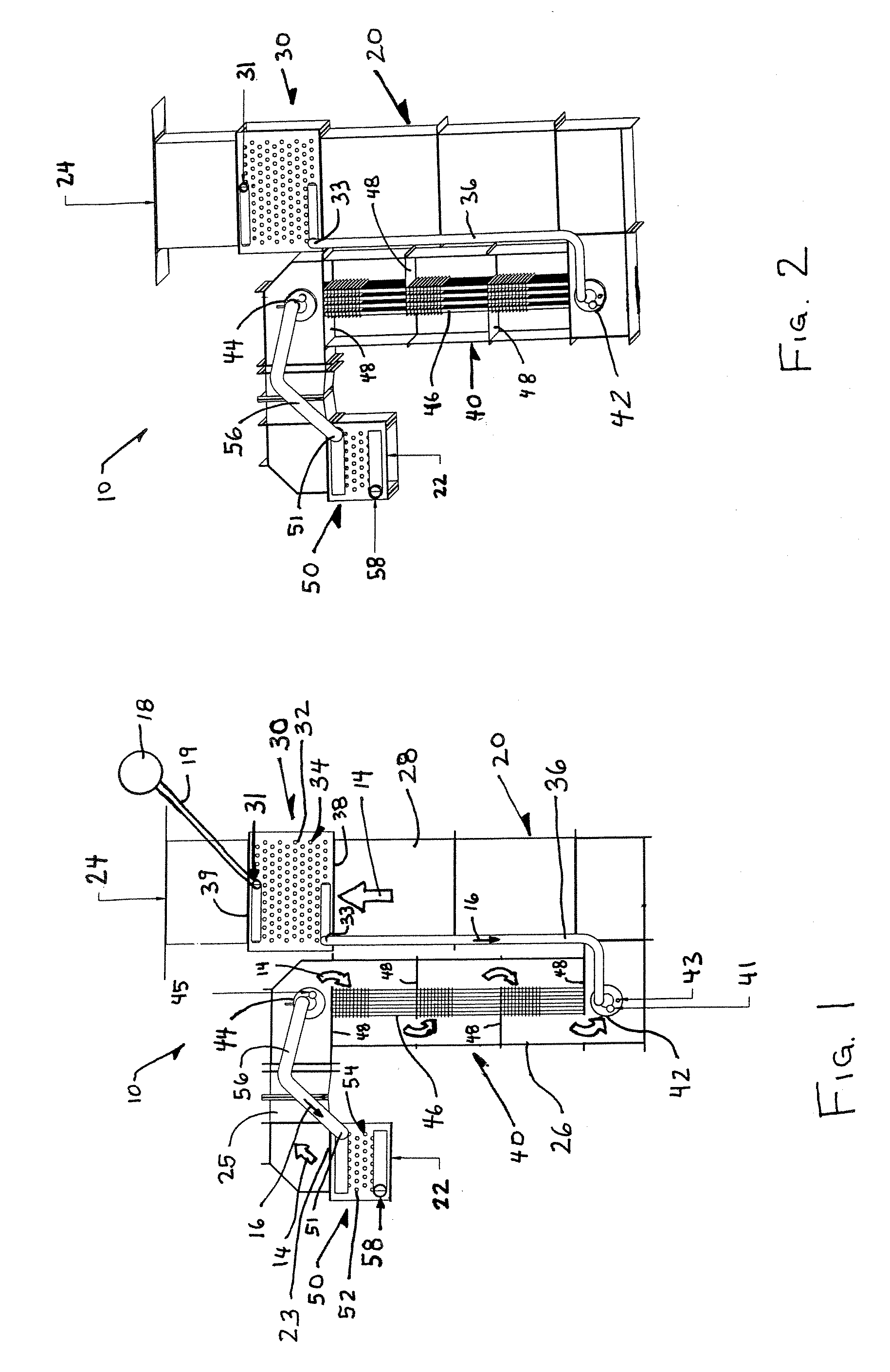

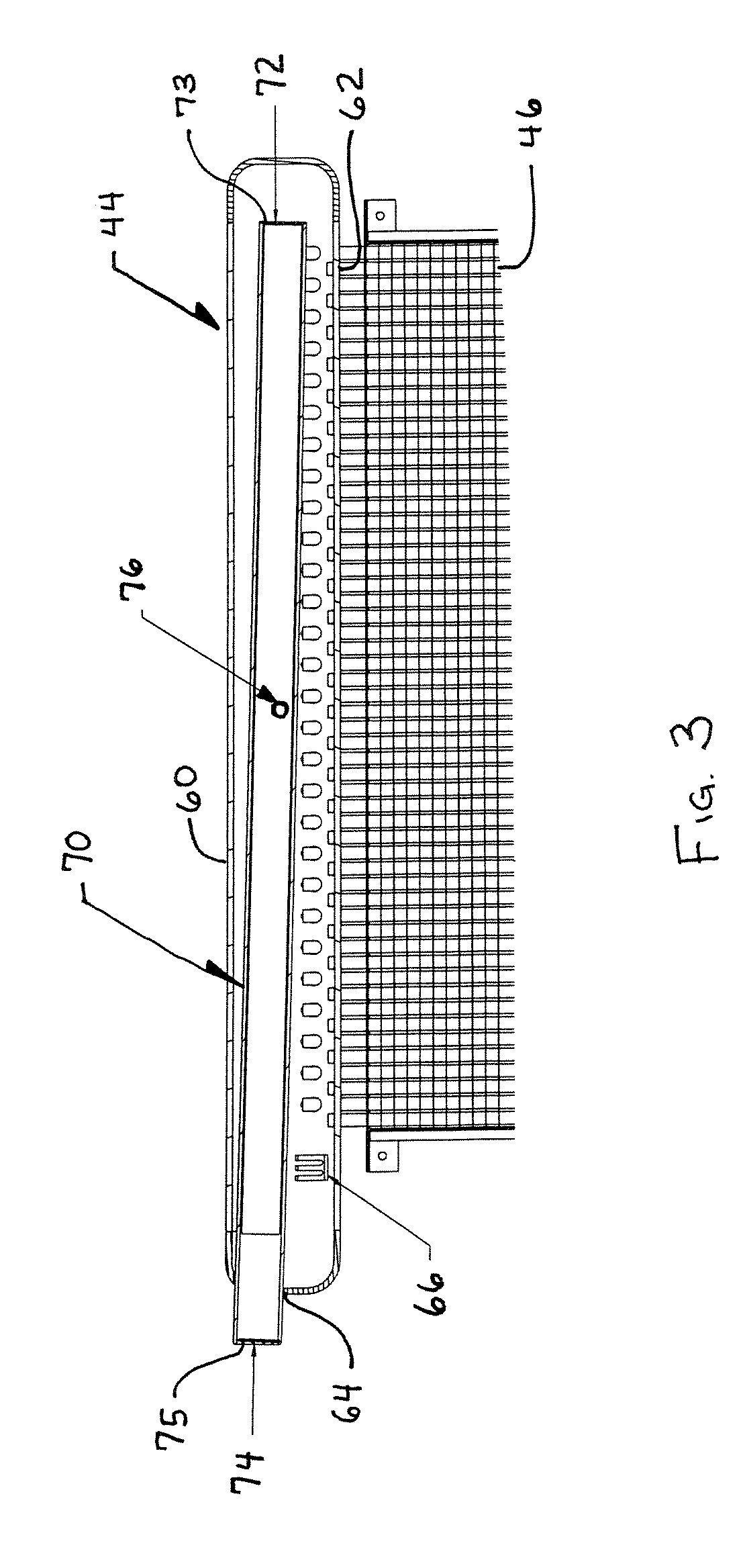

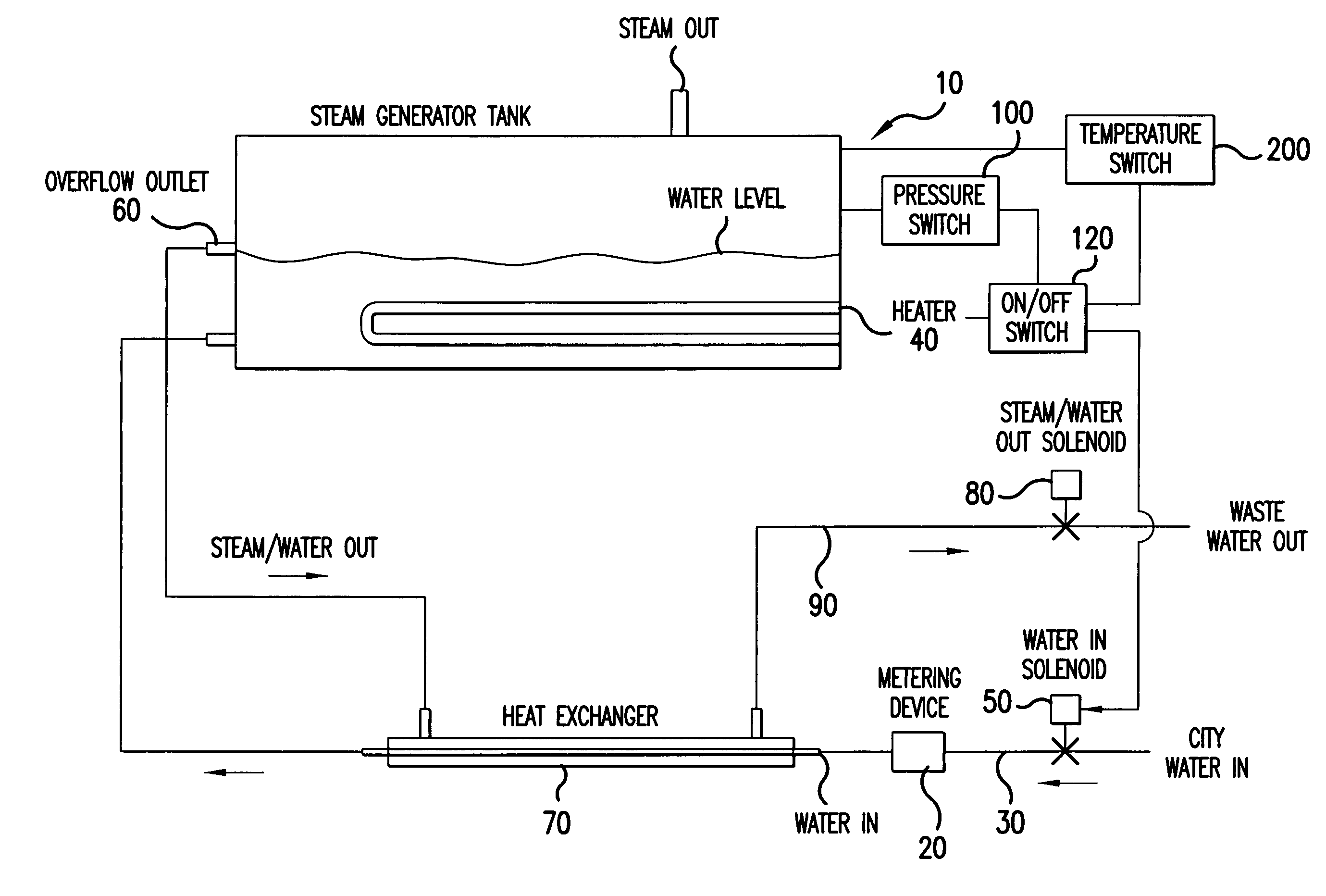

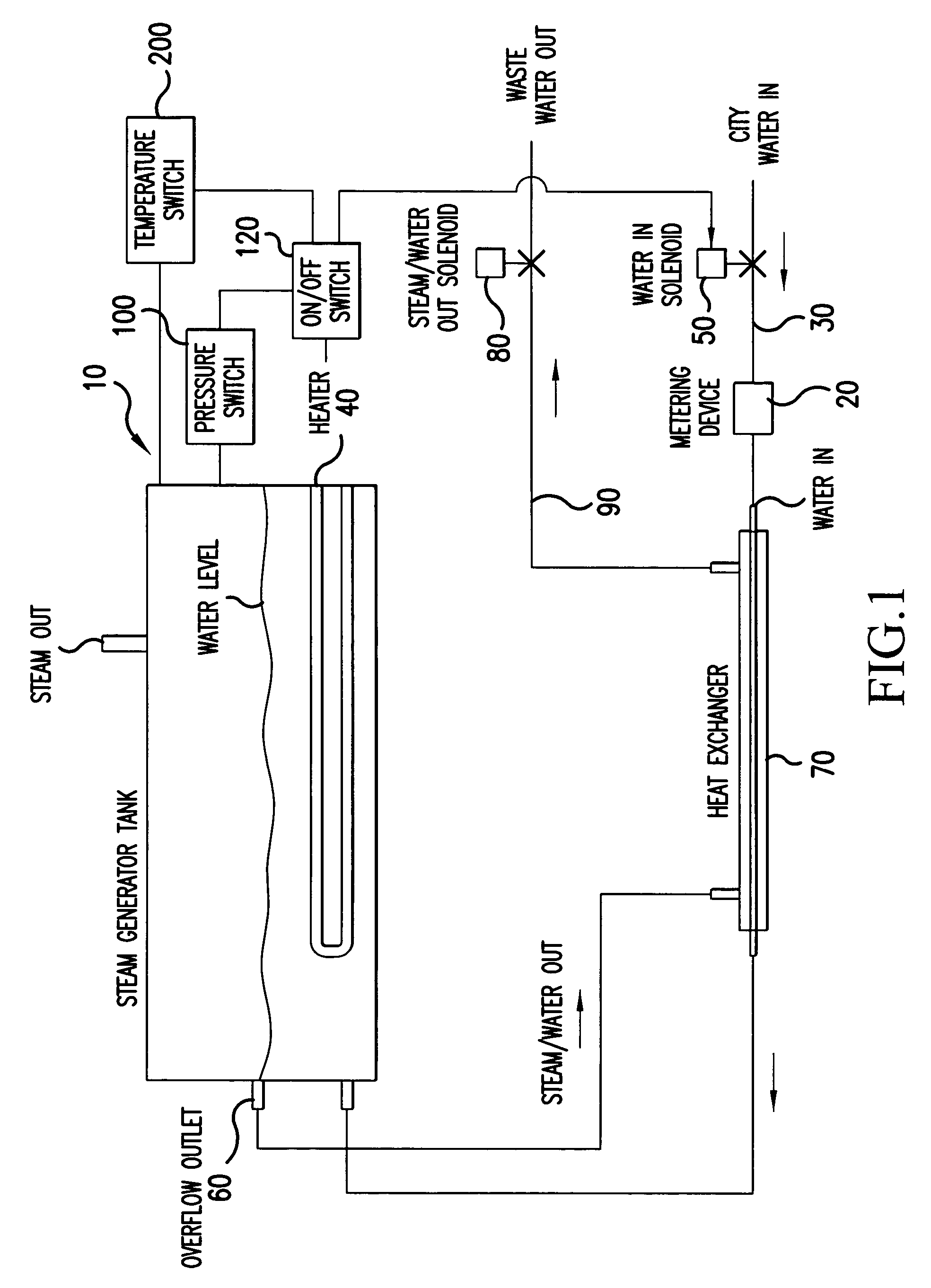

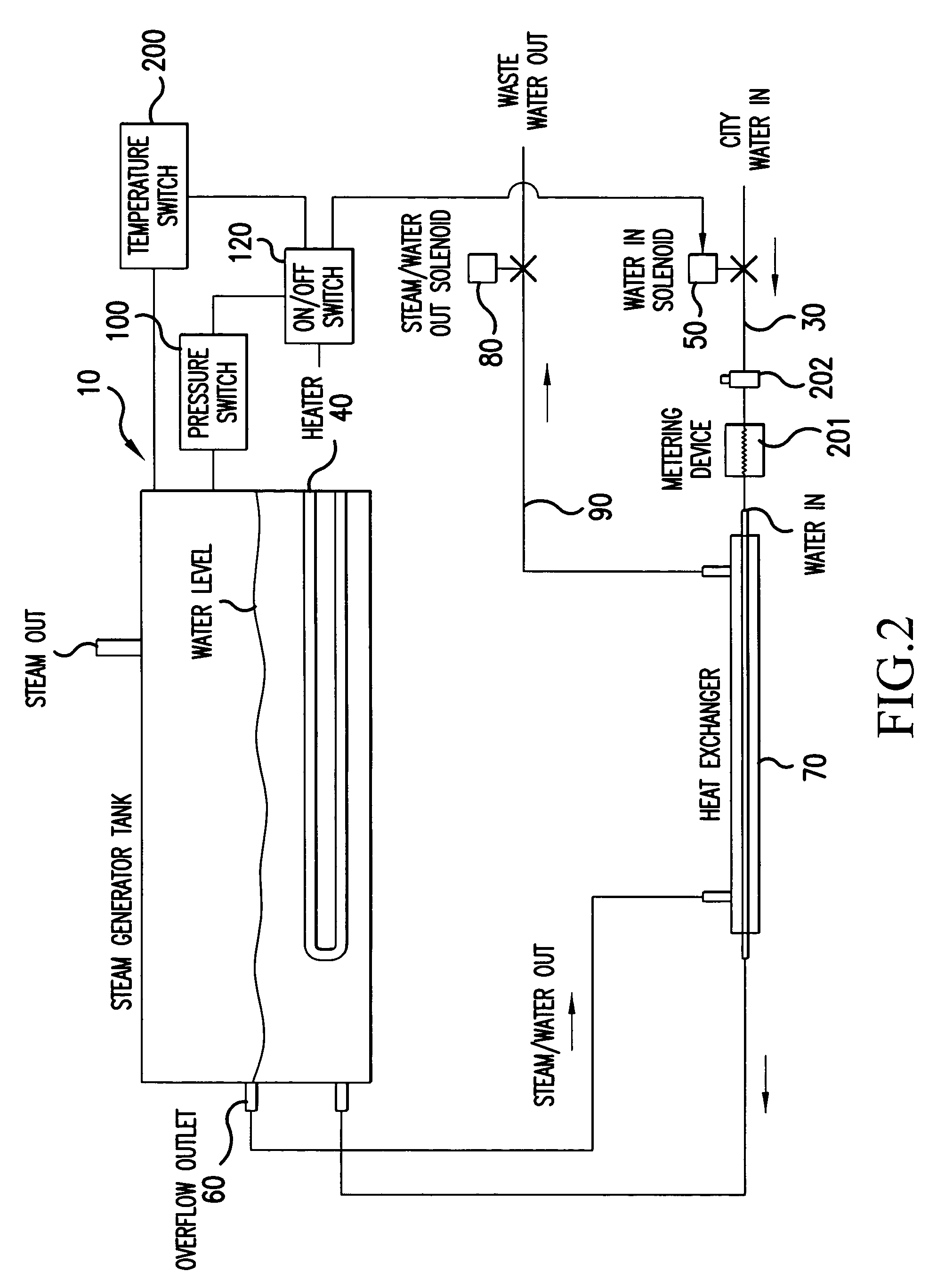

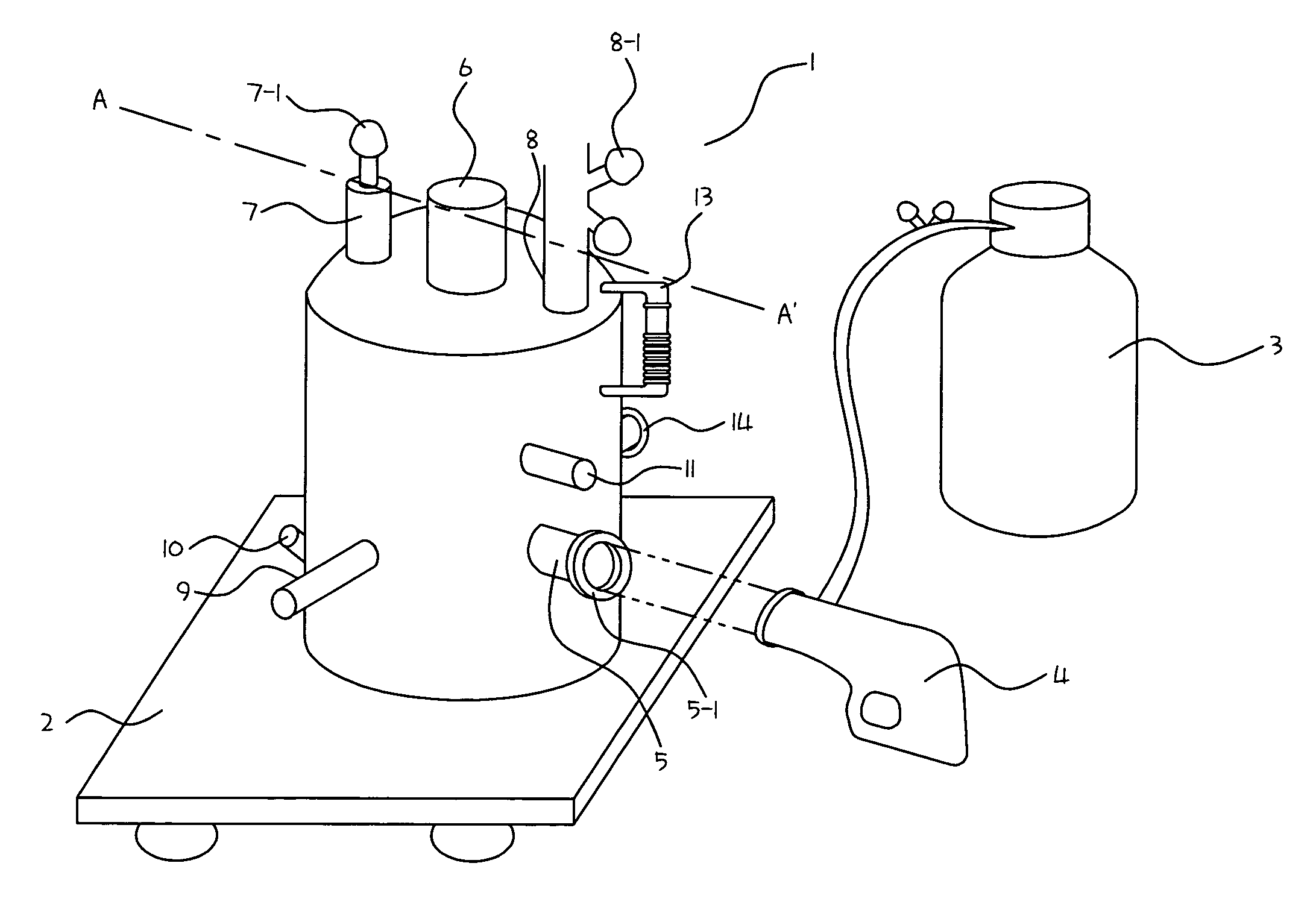

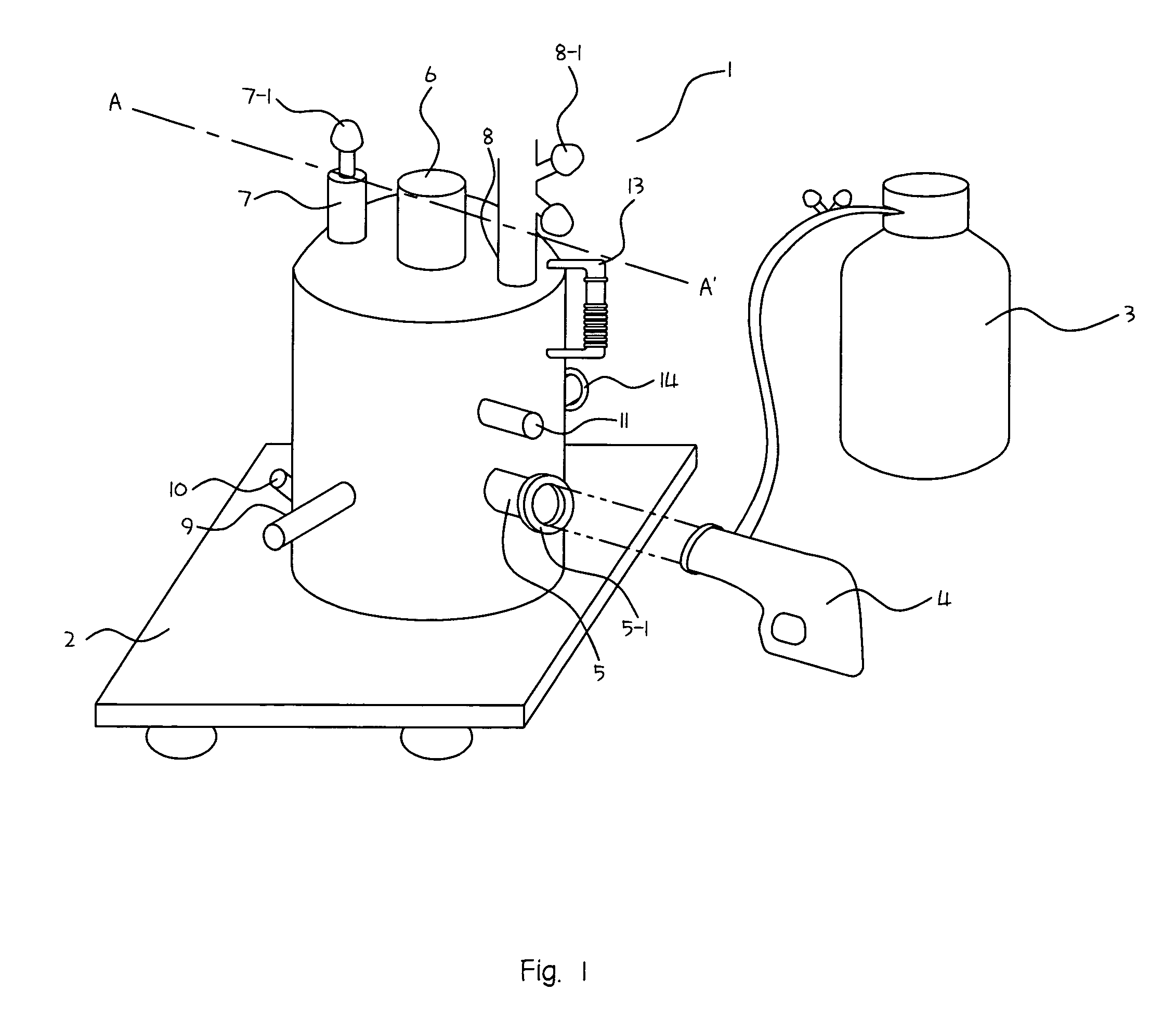

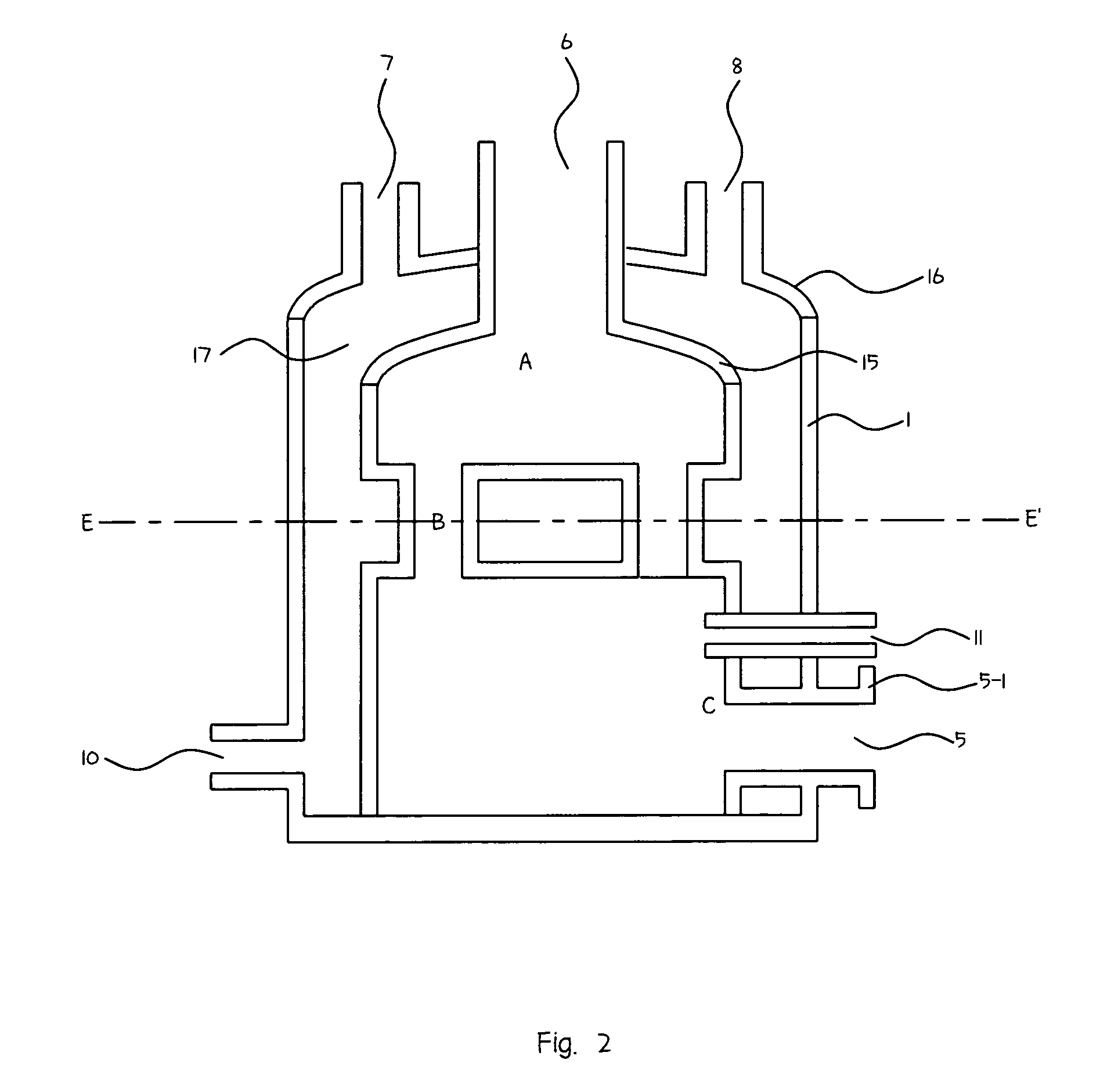

Self cleaning boiler and steam generator

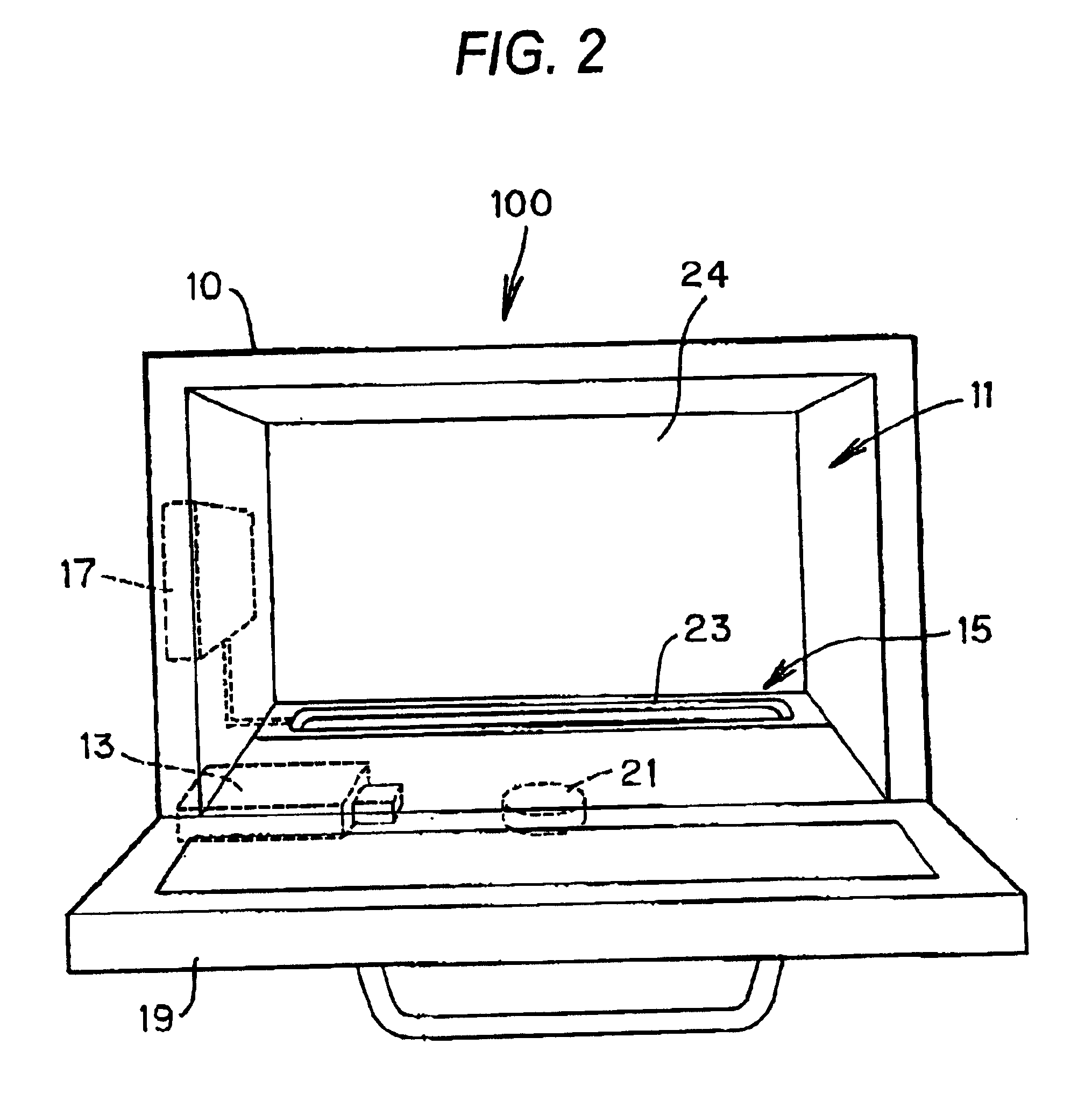

ActiveUS20050072382A1Increase supplyMaximize useSteam generation heating methodsGas pressure propulsion mountingEngineeringThermostat

A steam generator boiler for generating steam is connected to a supply conduit for supplying water to the boiler with a supply valve for controlling the supply of water through the supply conduit. A heater supplies heat to the boiler for generating steam with a discharge conduit for discharging excess impure water therefrom. A metering device is operatively connected to the supply conduit for regulating the flow of water to the boiler by calculating the amount of water required based on wattage or BTU's generated by the heater. A pressure switch or thermostat is provided for operating the boiler and the supply valve on the supply conduit for supplying water to the boiler to permit water to be added every time the heater is energized. In addition, a heat exchanger is provided for receiving discharged heated water from the steam generator and preheating water supplied to the steam generator.

Owner:AMERICAN GRIDDLE CORP

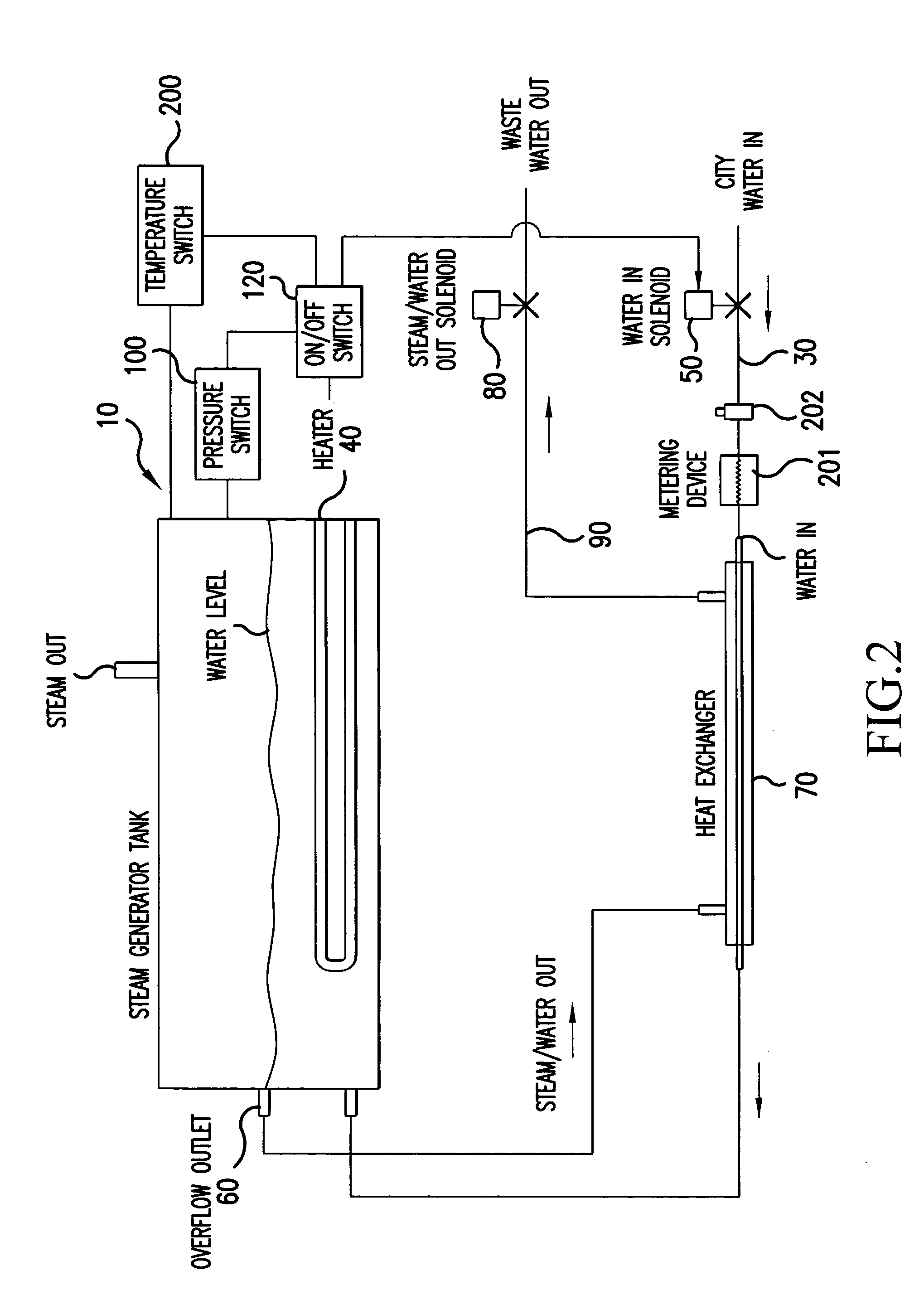

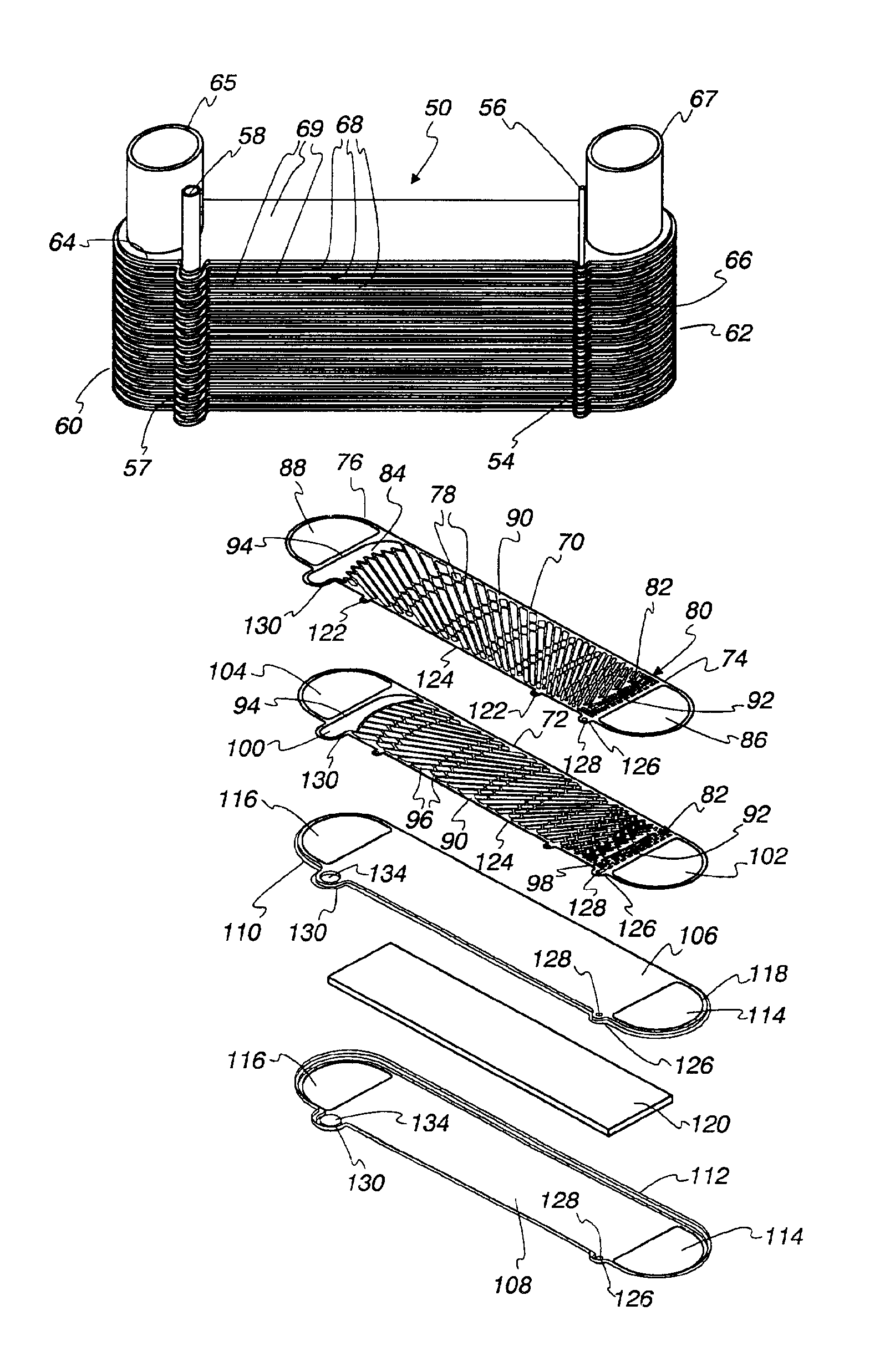

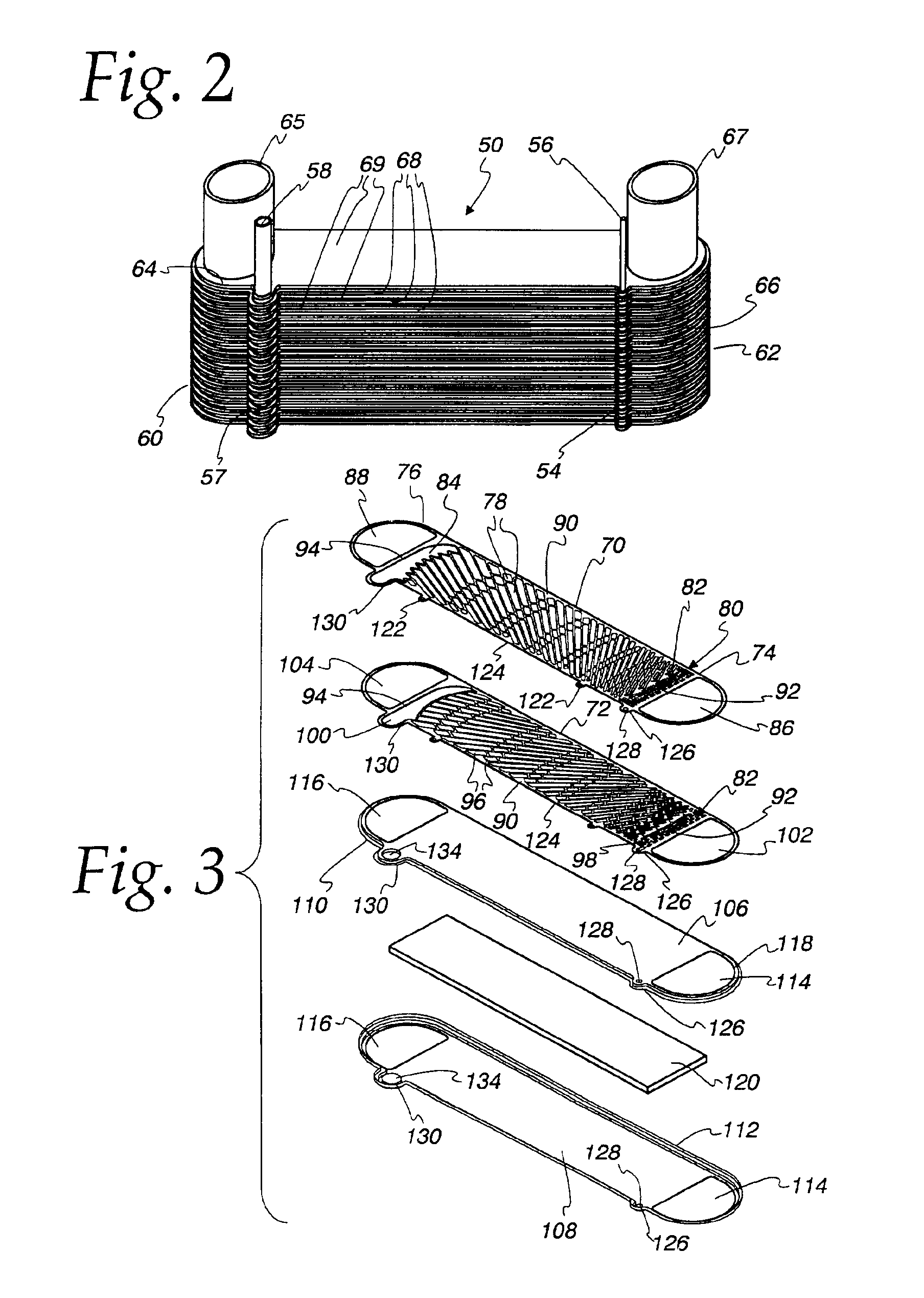

Method and apparatus for vaporizing fuel for a reformer fuel cell system

A vaporizer, a fuel cell system including the vaporizer, and a method of vaporizing fuel in a fuel cell system are disclosed. The fuel cell system includes a fuel reservoir (24) for storing a liquid fuel and a fuel cell (10) for consuming a fuel and generating electricity therefrom. A fuel vaporizer (28) is interposed between the fuel reservoir (24) and the fuel cell (10) for receiving liquid fuel and vaporizing it and delivering it ultimately to the fuel cell (10). The fuel vaporizer (28) includes a heat exchanger which includes a hot fluid inlet (65), a hot fluid outlet (67) and a core (50) interconnecting the inlet (65) and the outlet (68). The core (50) has alternating fuel flow structures (68) and hot fluid structures (69) with the fuel flow structures (68,69) having an inlet (56) and an outlet (58).

Owner:MODINE MFG CO +1

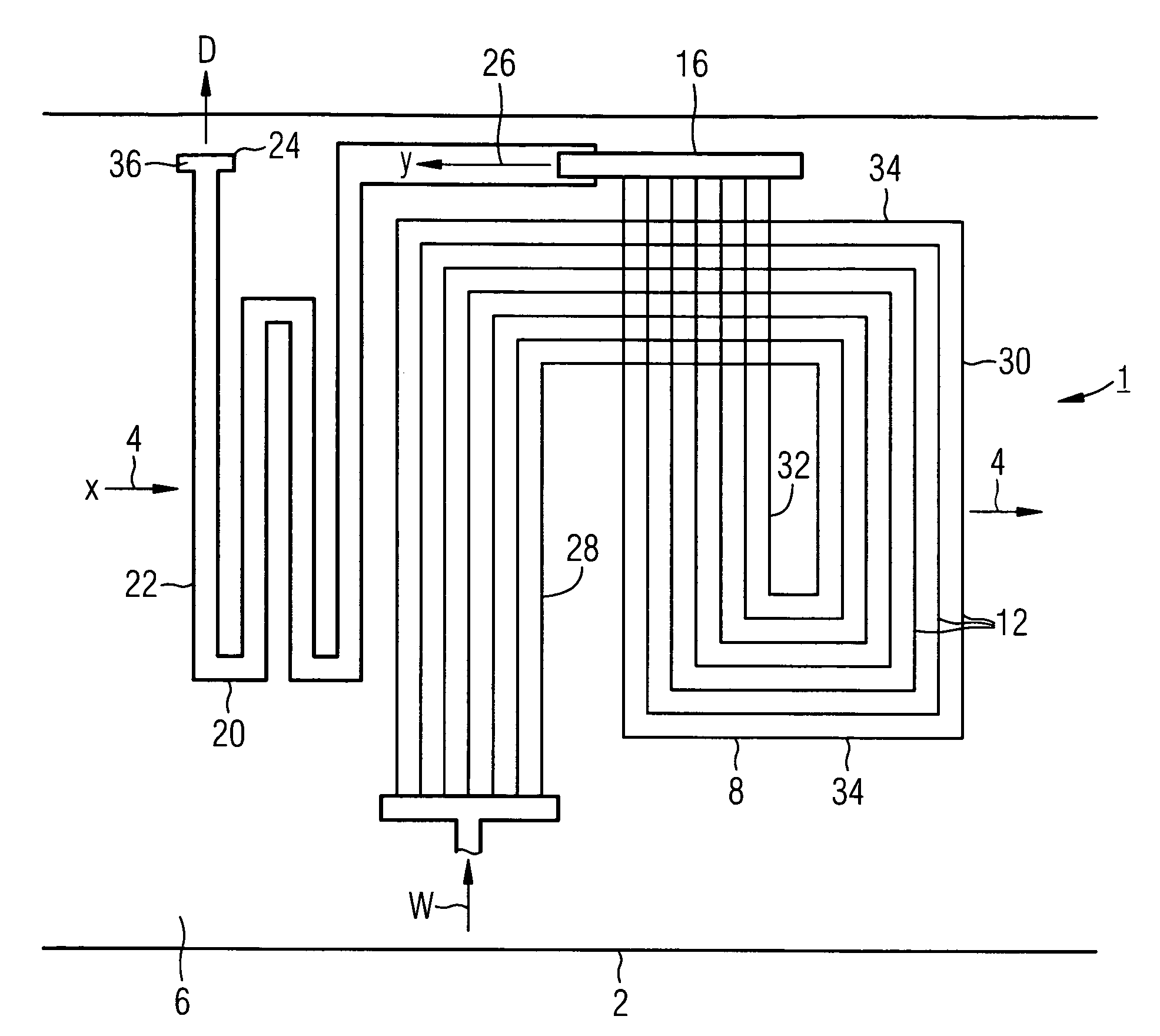

Method for starting a continuous steam generator and continuous steam generator for carrying out said method

The invention relates to a continuous steam generator provided with an evaporator through flow heating surface which is disposed in a heating gas channel which can be cross flown in an approximately vertical manner in a heating gas device, said evaporator through flow heating surface comprising a plurality of parallel connected steam generating pipes enabling a flow medium to flow through, and an overheating heating surface which is arranged downstream from the evaporator through flow heating surface comprising a plurality of parallel connected overheating pipes enabling the evaporated flow medium to flow through, also enabling production and operational costs to be reduced and enabling the temperature of the steam on the outlet of the overheating heating surface to be controlled in a comparatively simple and flexible manner. The steam end-point of the flow medium is displaced to the overheating pipe, if required. The continuous heating surfaces and the overheating heating surfaces are combined to form one functional unit such that the overheating heating surface can be used as a steam heating surface in a continuous steam generator which is particularly suitable for carrying out said method.

Owner:SIEMENS AG

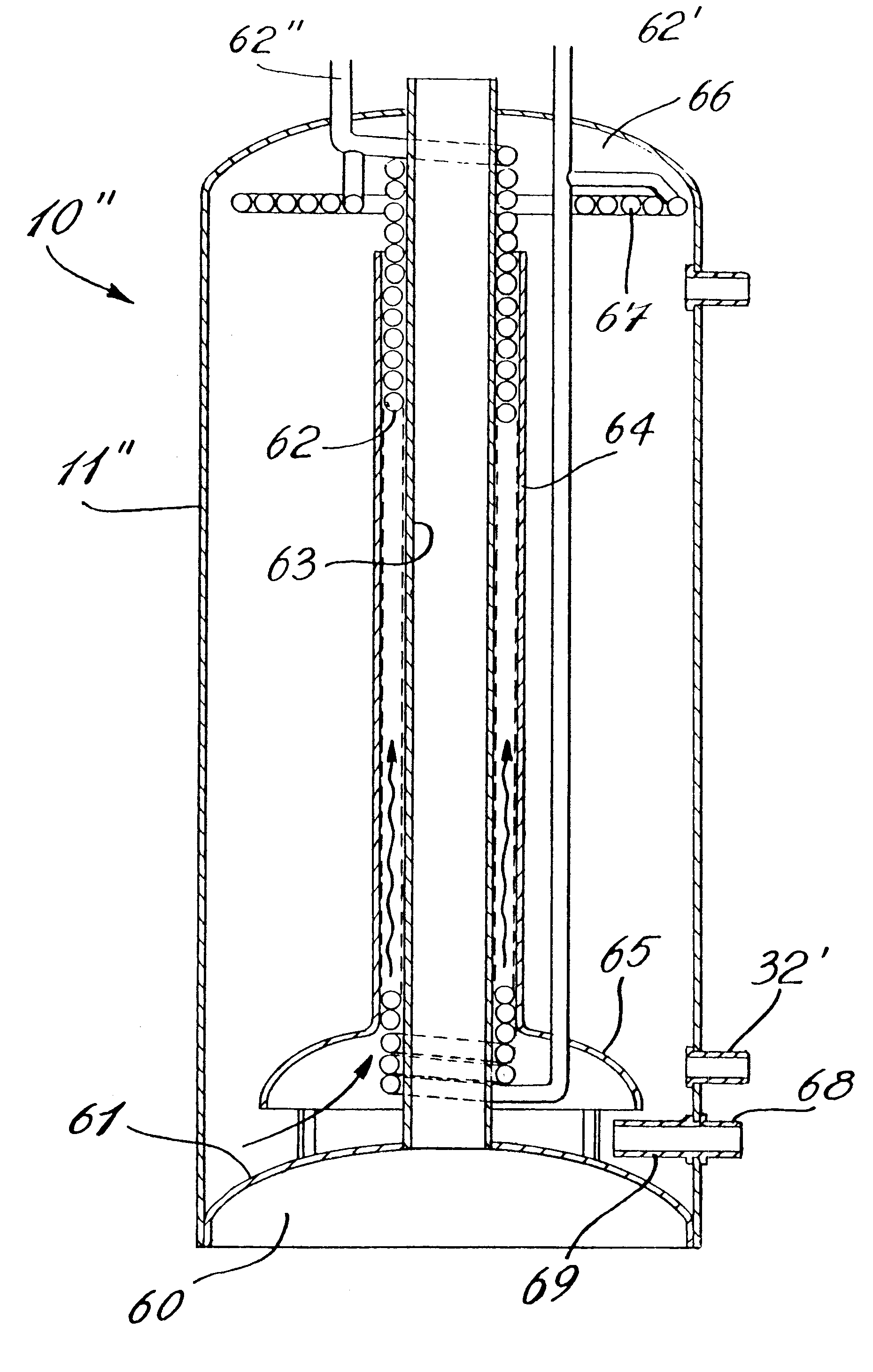

Heat exchanger having a counterflow evaporator

An evaporator including a lower drum, an upper drum, and at least one tube extending between the lower drum and the upper drum. The plurality of tubes have fluid passageways therein extending from the lower drum to the upper drum. A duct is provided having a heating gas passageway provided therein. The at least one tube extends through the heating gas passageway. The fluid passageways define an overall flow path from the lower drum to the upper drum extending in a direction substantially counter-current to an overall flow path defined by the heating gas passageway extending from a gas inlet of the heating gas passageway to a gas outlet thereof.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

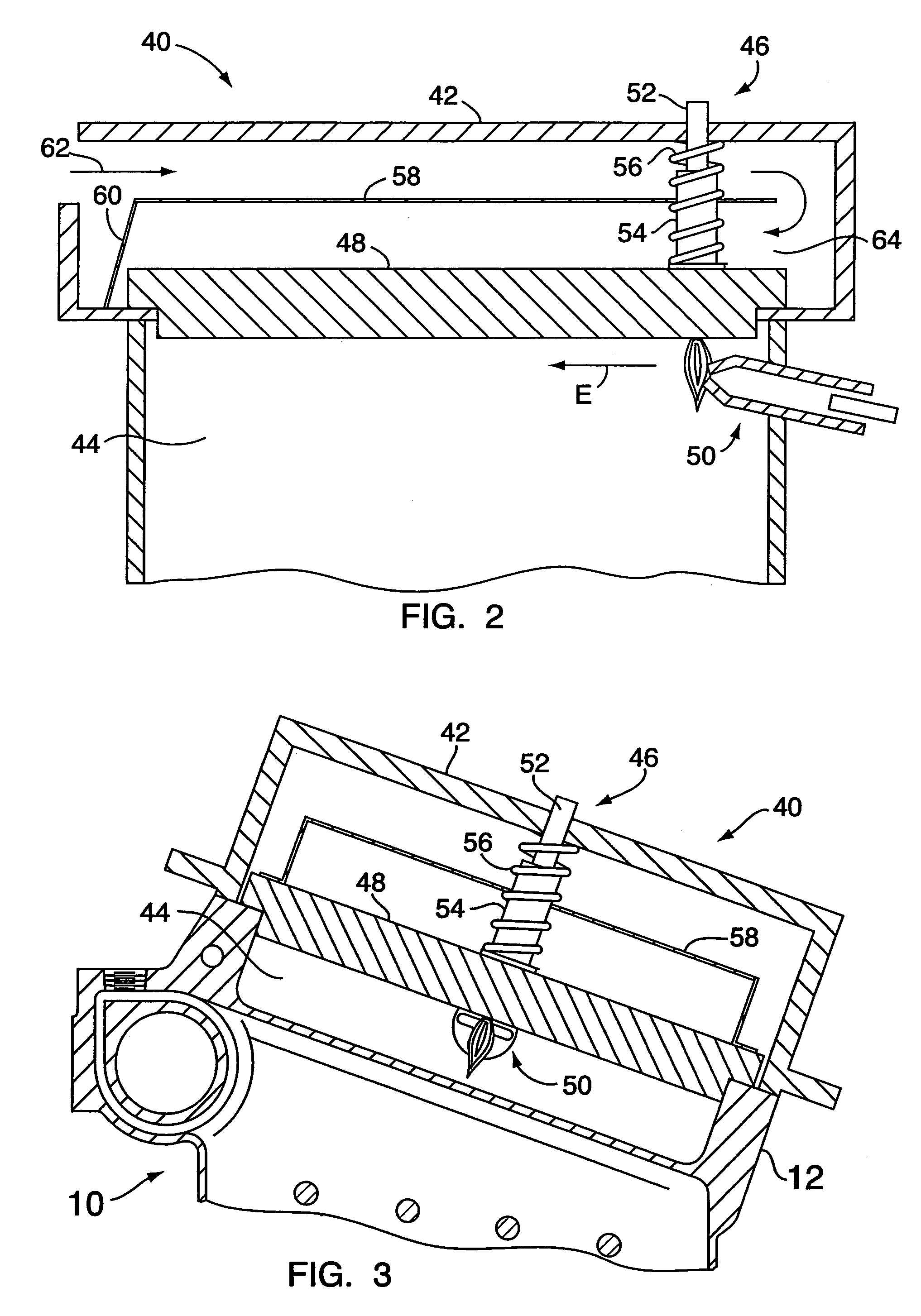

Self cleaning boiler and steam generator

ActiveUS7096828B2Increase supplyMaximize useFuel supply regulationSteam generation heating methodsEngineeringThermostat

A steam generator boiler for generating steam is connected to a supply conduit for supplying water to the boiler with a supply valve for controlling the supply of water through the supply conduit. A heater supplies heat to the boiler for generating steam with a discharge conduit for discharging excess impure water therefrom. A metering device is operatively connected to the supply conduit for regulating the flow of water to the boiler by calculating the amount of water required based on wattage or BTU's generated by the heater. A pressure switch or thermostat is provided for operating the boiler and the supply valve on the supply conduit for supplying water to the boiler to permit water to be added every time the heater is energized. In addition, a heat exchanger is provided for receiving discharged heated water from the steam generator and preheating water supplied to the steam generator.

Owner:AMERICAN GRIDDLE CORP

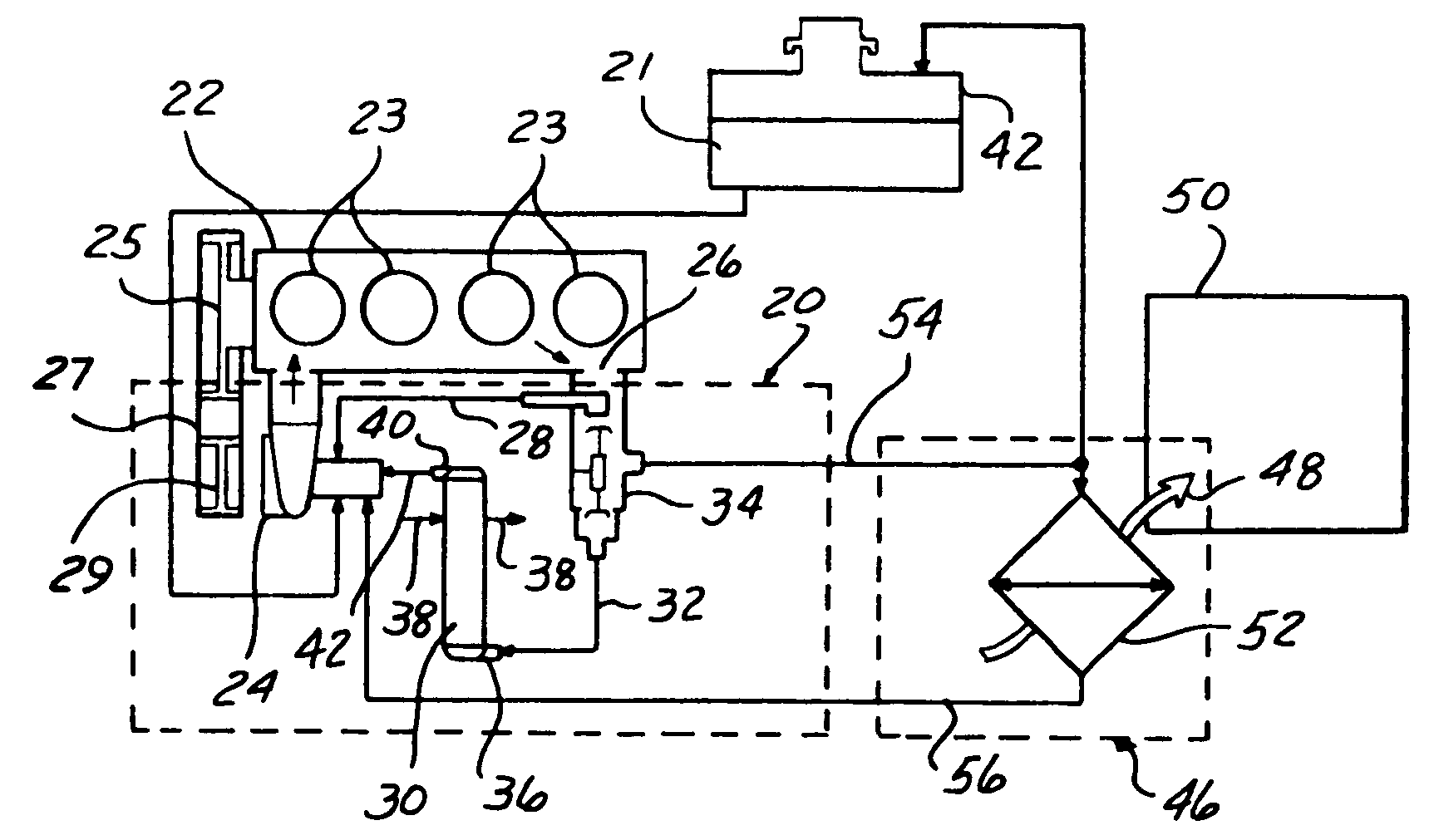

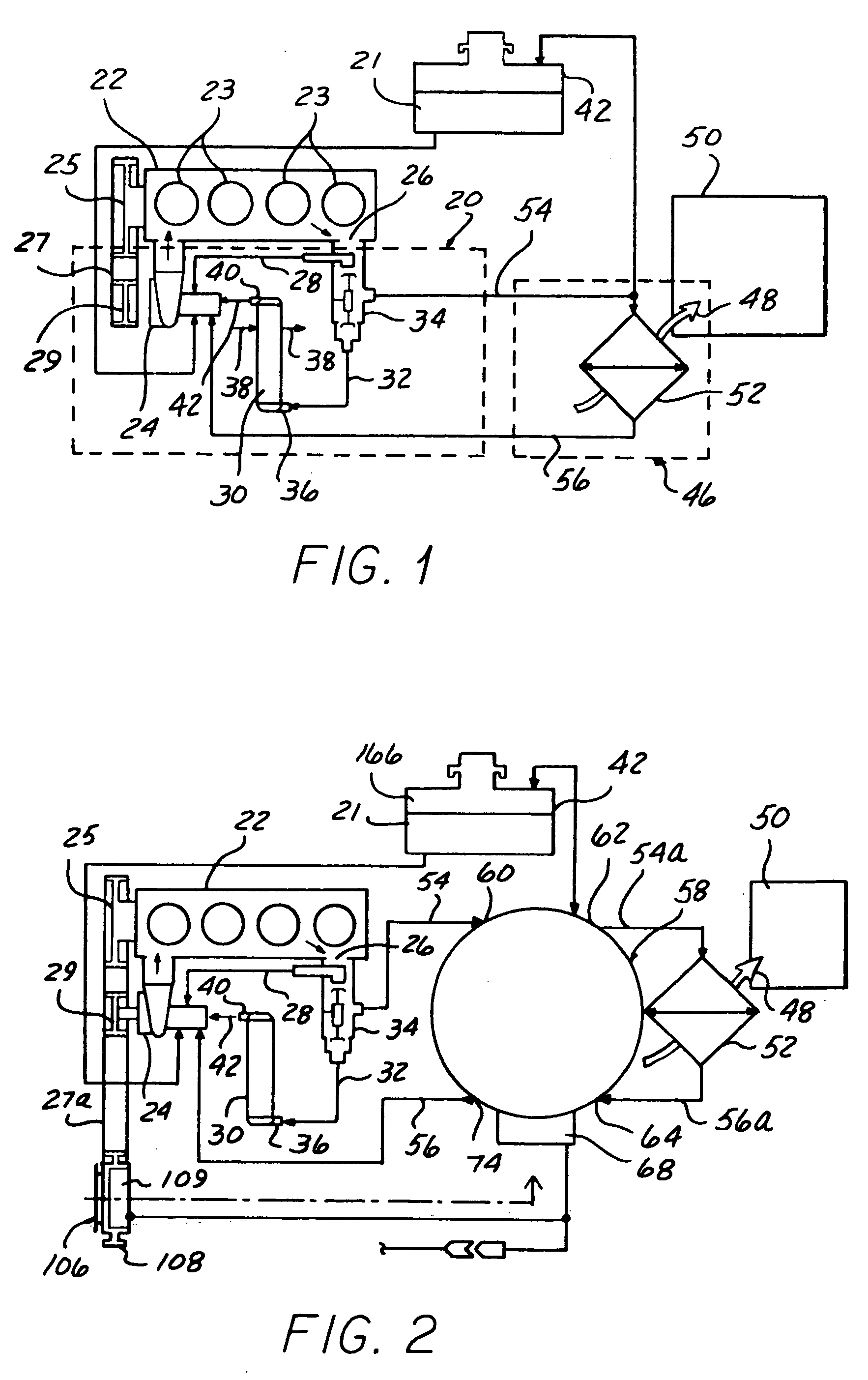

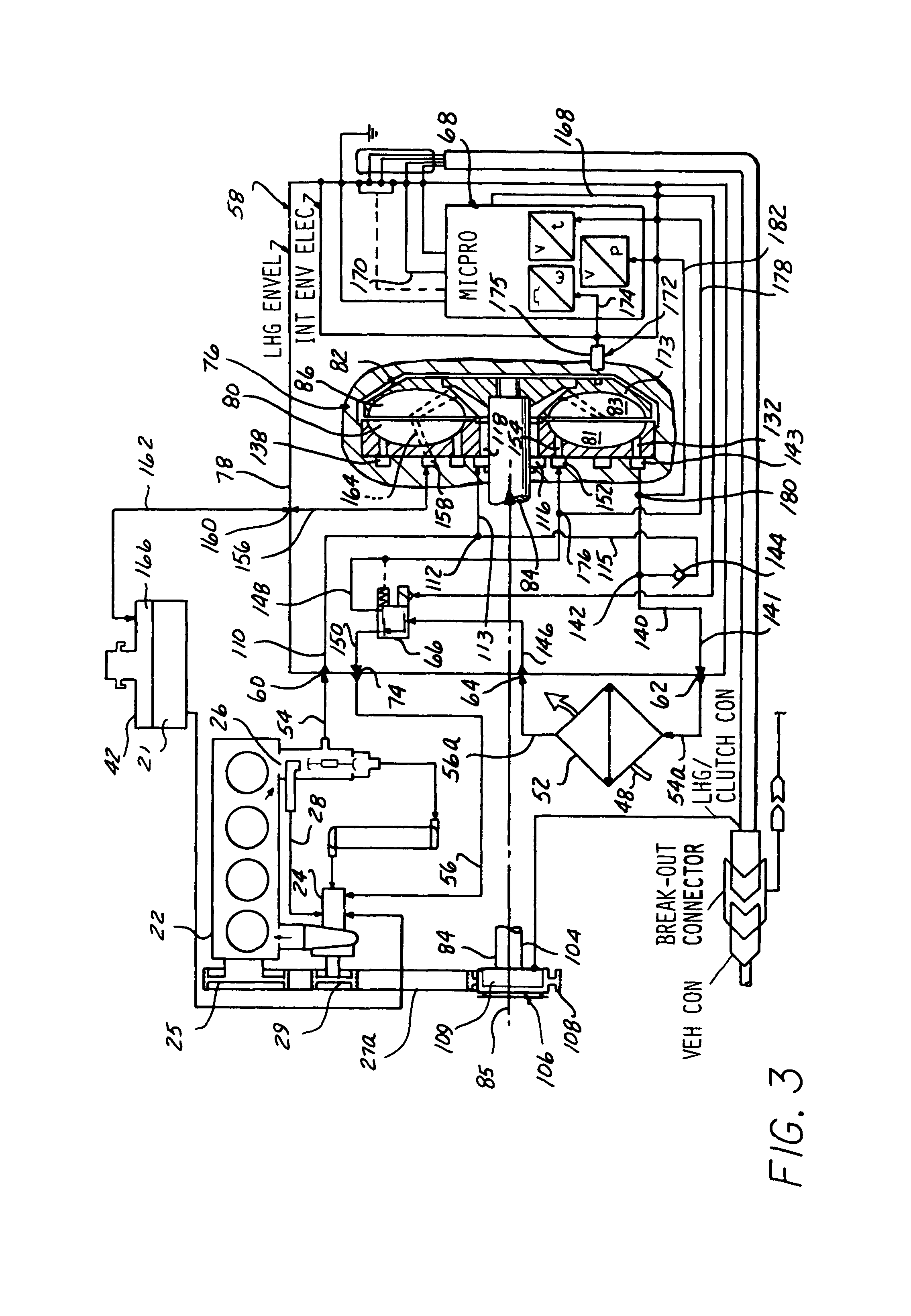

Vehicle supplemental heating system

A preferred embodiment supplemental heating system is fluidly connectable to a vehicle cooling system and includes a liquid heat generator operable for heating a cooling fluid delivered to the supplemental heating system from the vehicle's cooling system. The liquid heat generator includes a discharge passage connectable to a heater core of the vehicle and a inlet passage connectable to the vehicle's cooling system. The supplemental heating system further includes a control valve having an inlet connectable to an exit passage of a heater core of the vehicle, a discharge passage fluidly connected to the liquid heat generator, and a second discharge passage connectable to the vehicle's cooling system. The control valve is operable for controlling the proportion of cooling fluid exiting the heater core that is returned to the vehicle's cooling system and recirculated back to the liquid heat generator.

Owner:WEBASTO AG

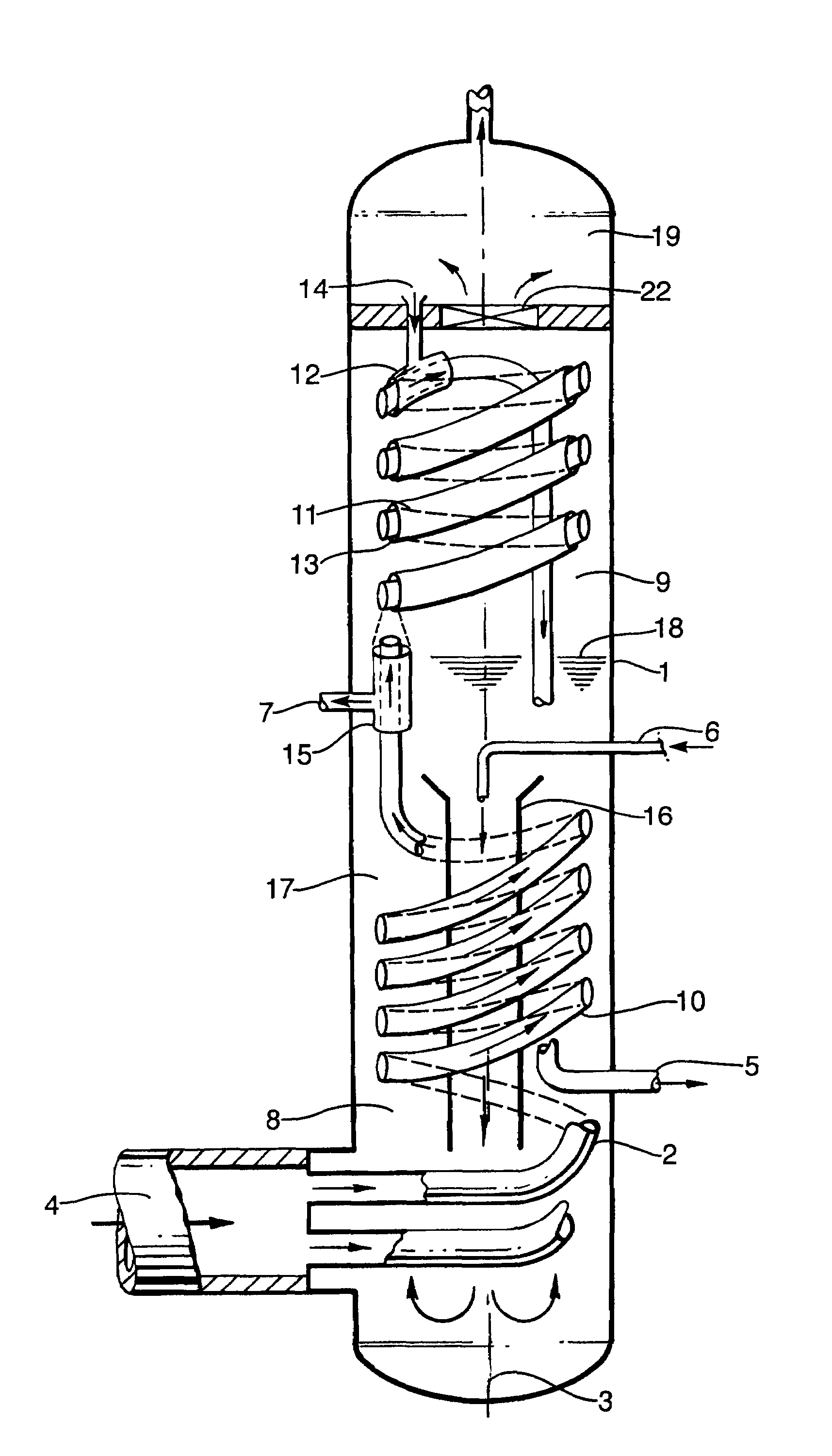

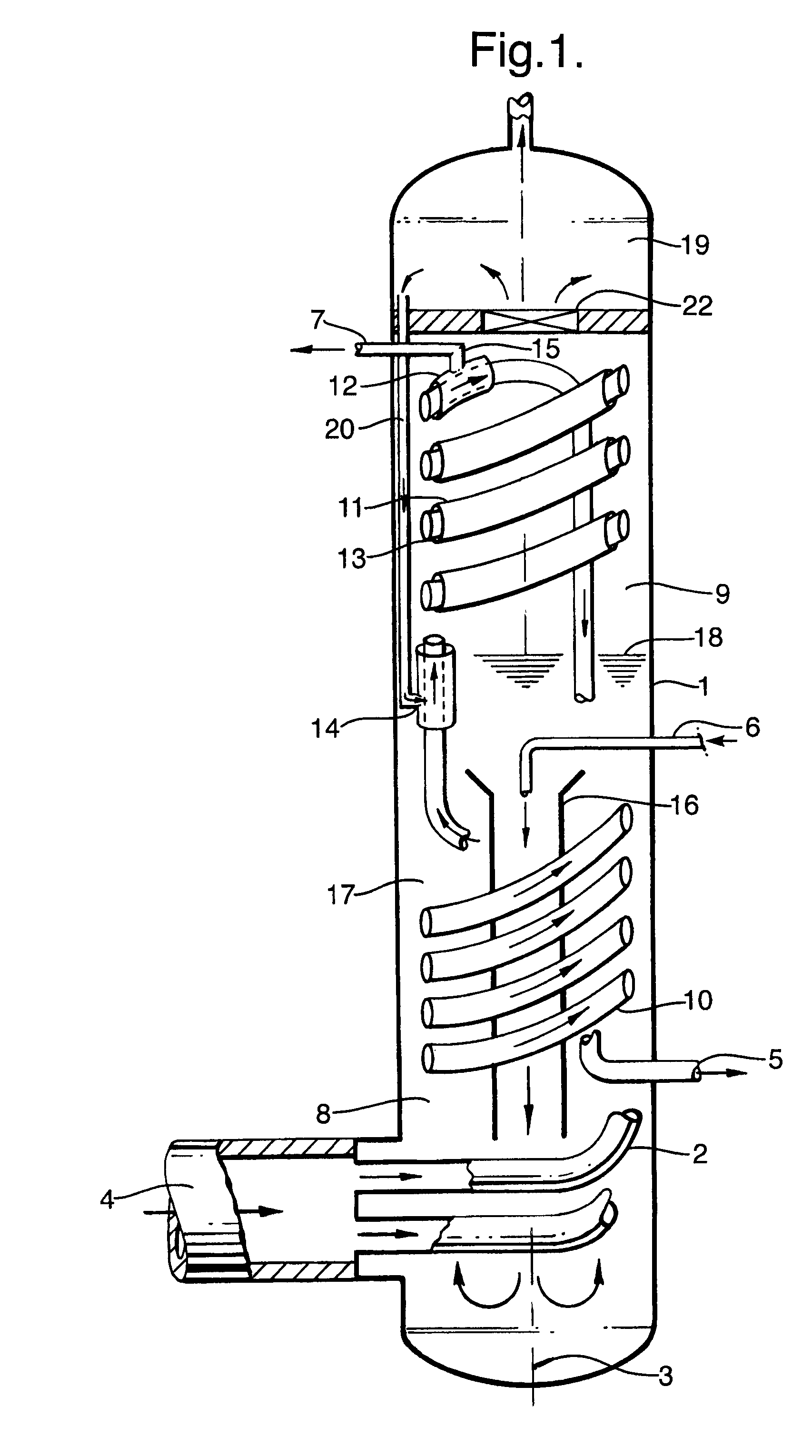

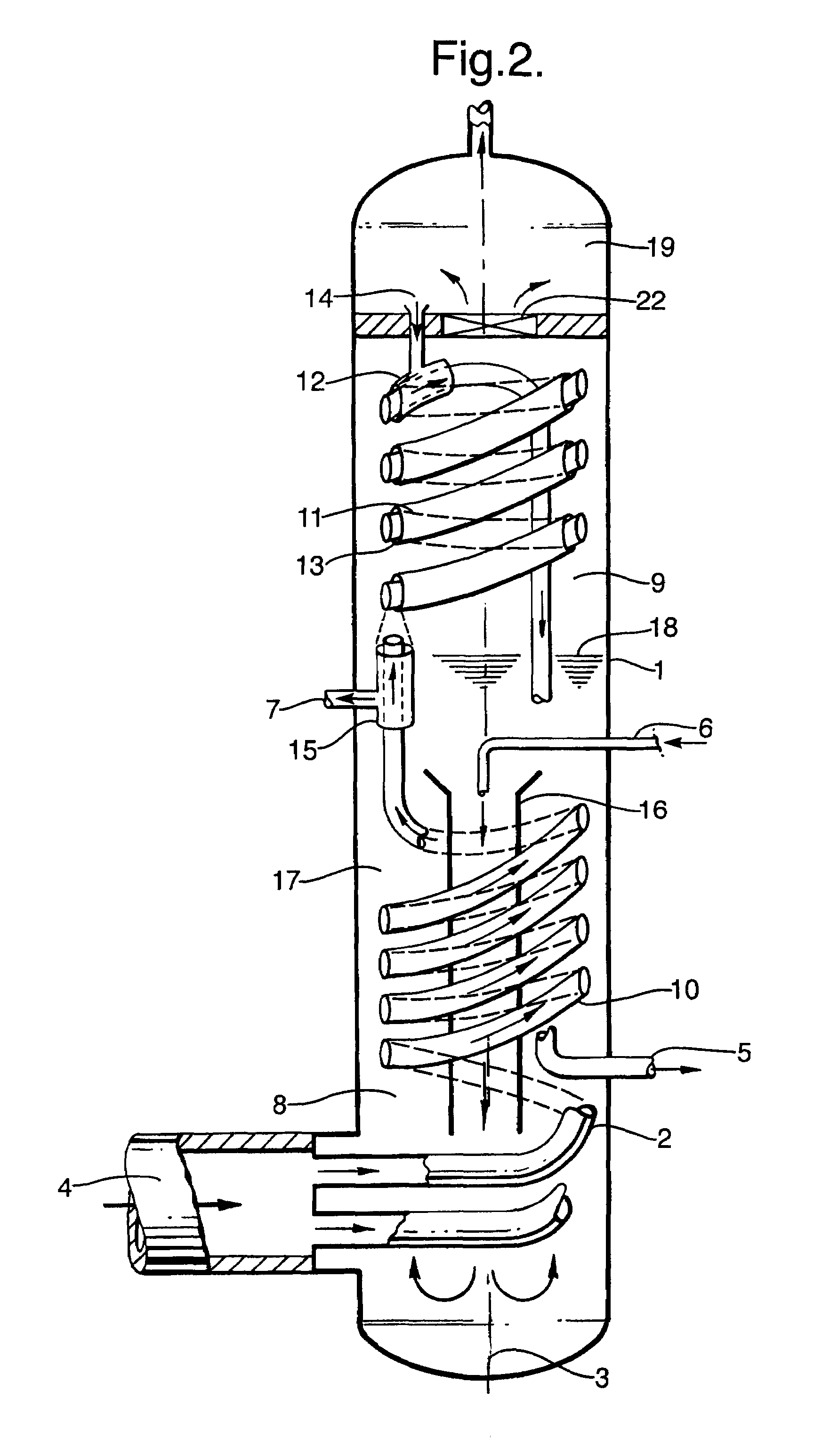

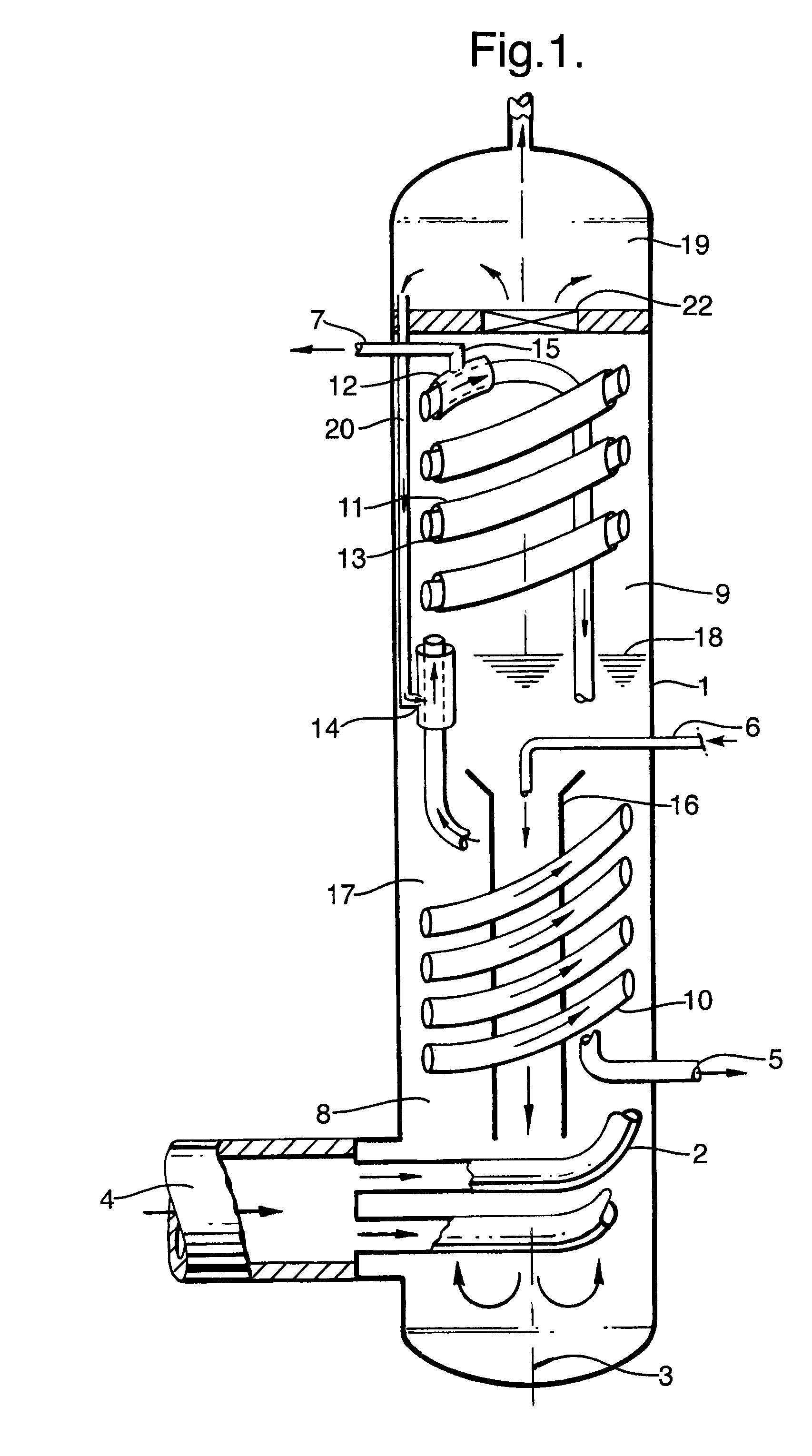

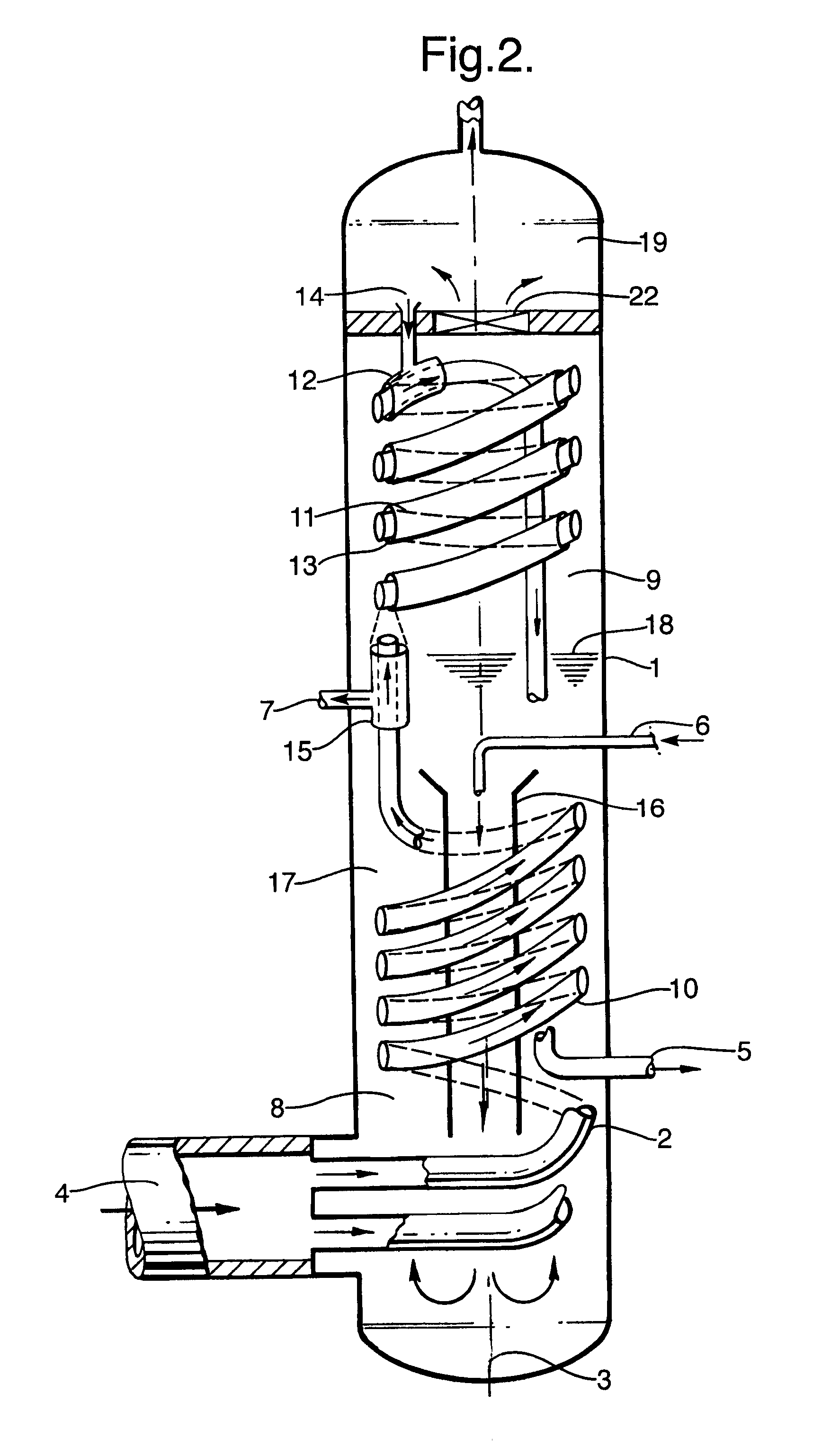

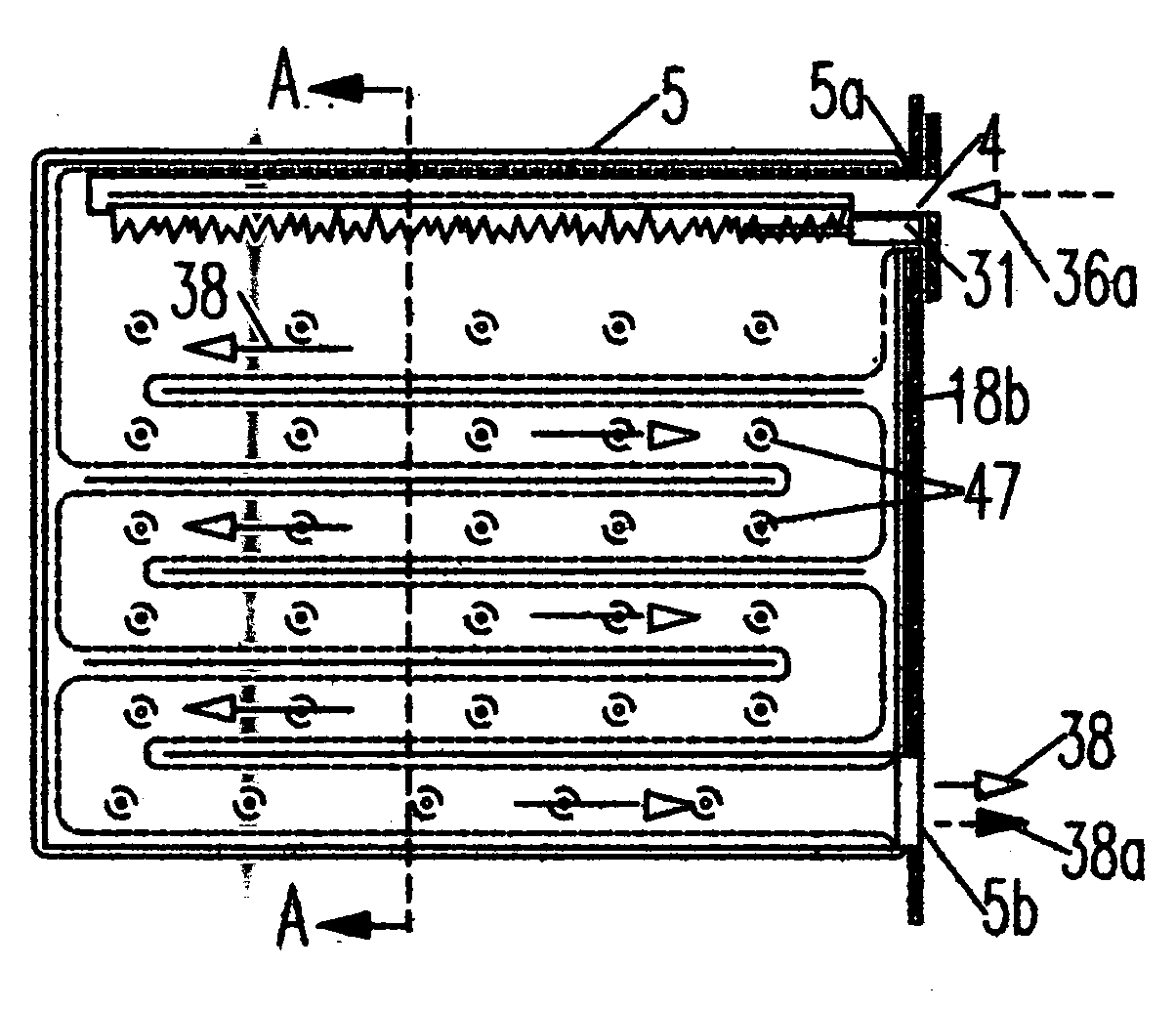

Boiler for making super heated steam and its use

ActiveUS7552701B2Avoid disadvantagesLocal overheating of the walls of the spirally conduit is avoidedStationary conduit assembliesWater-tube boilersWater bathsFresh water

Owner:SHELL USA INC

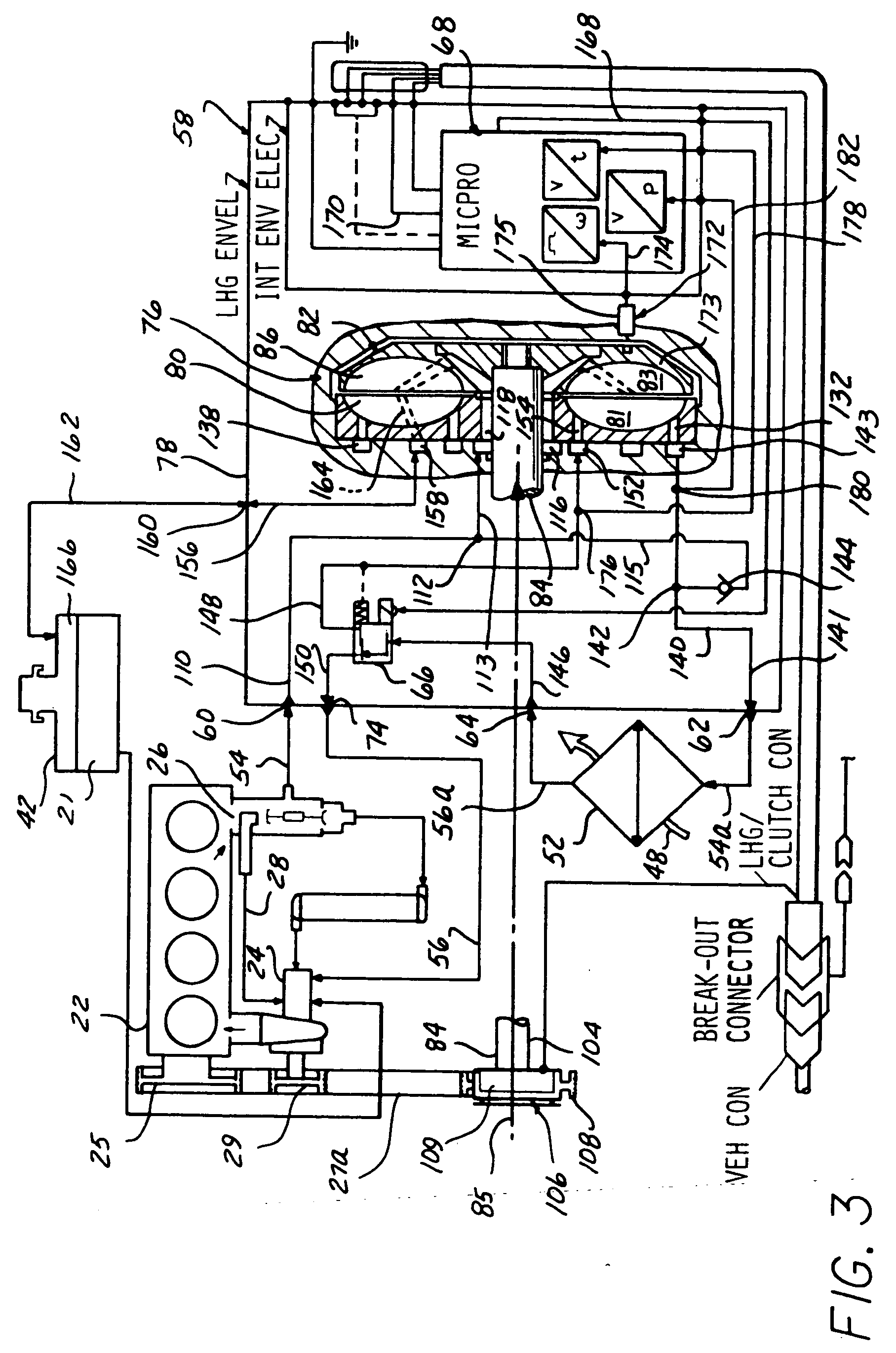

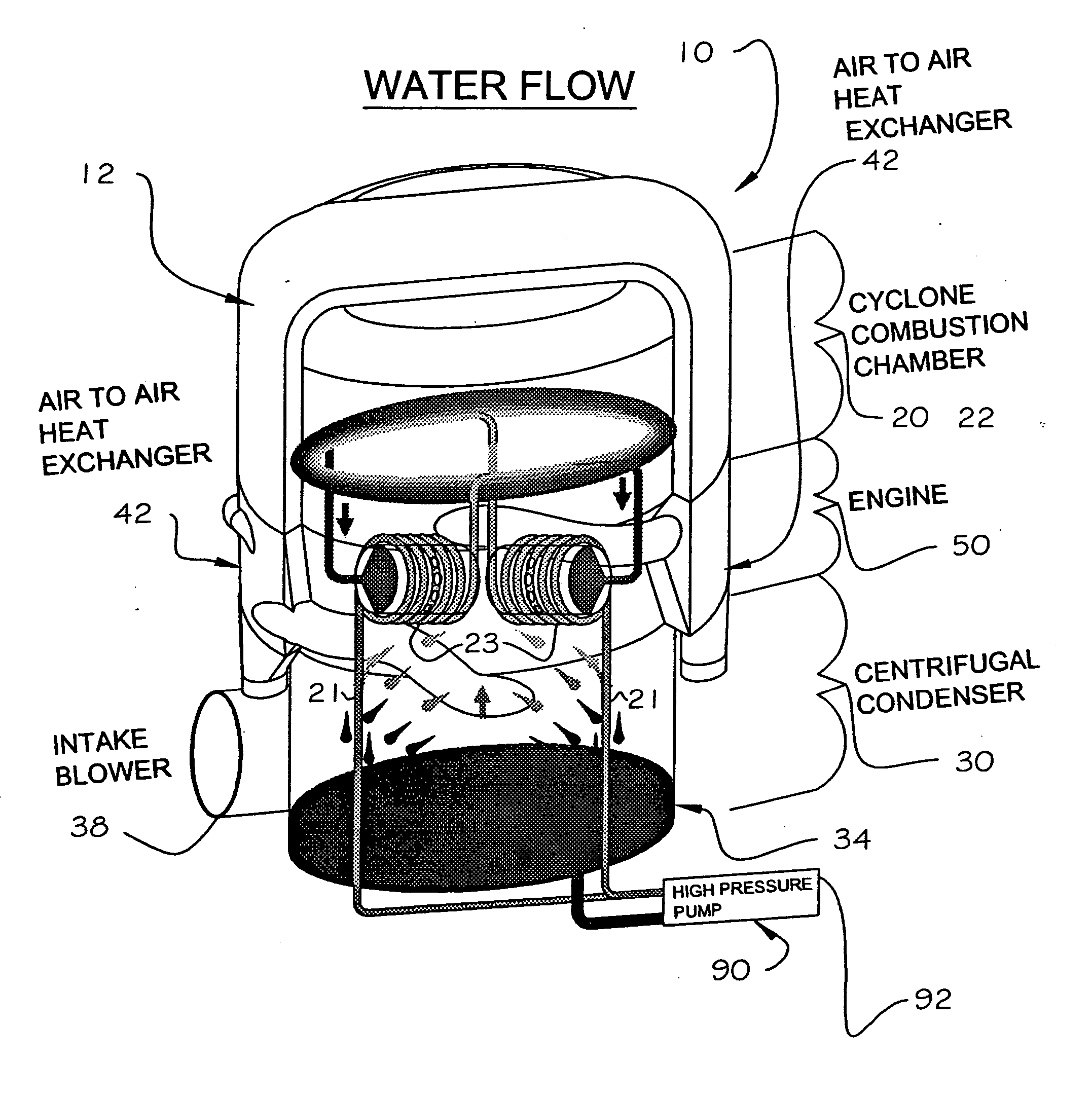

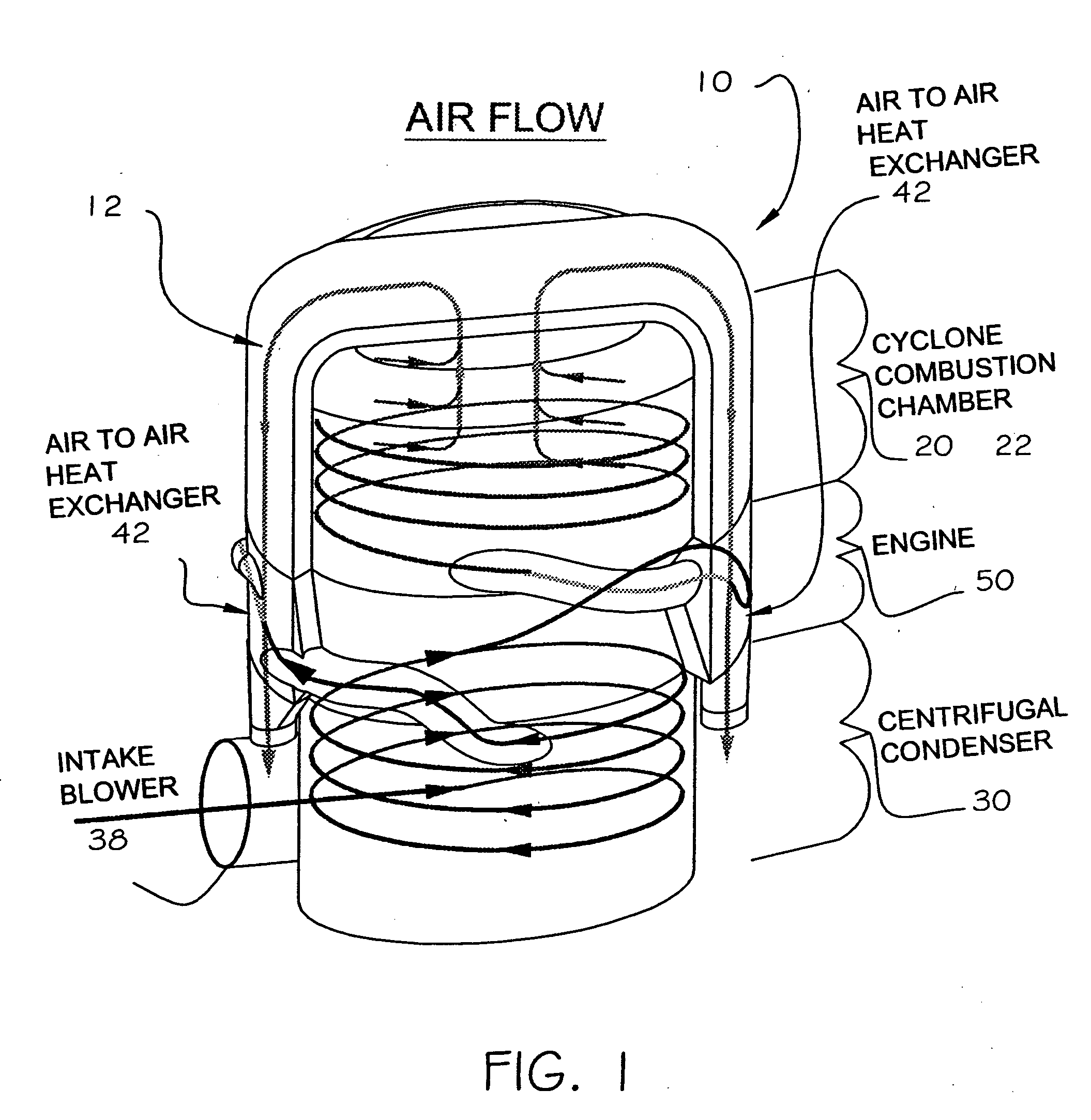

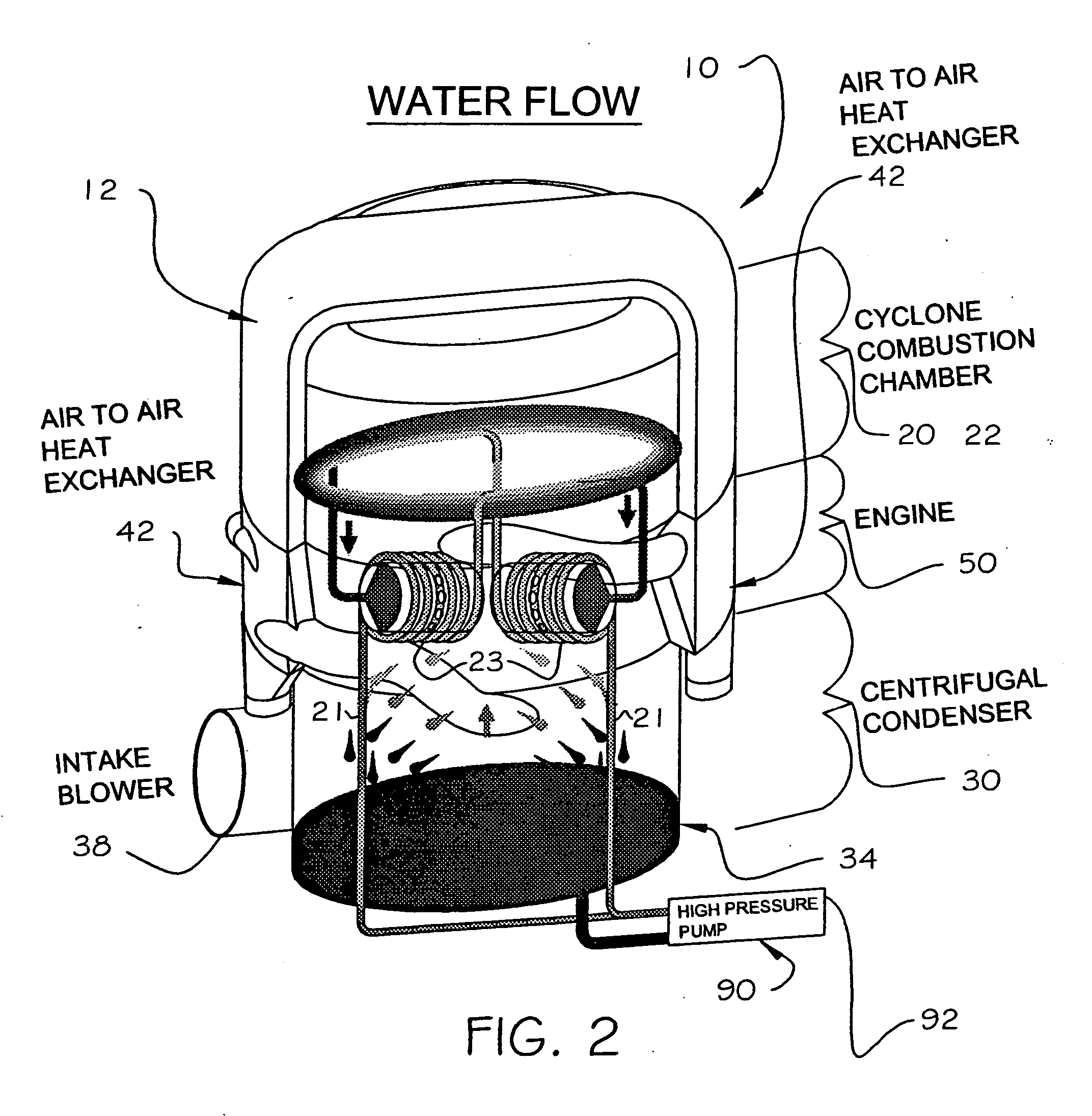

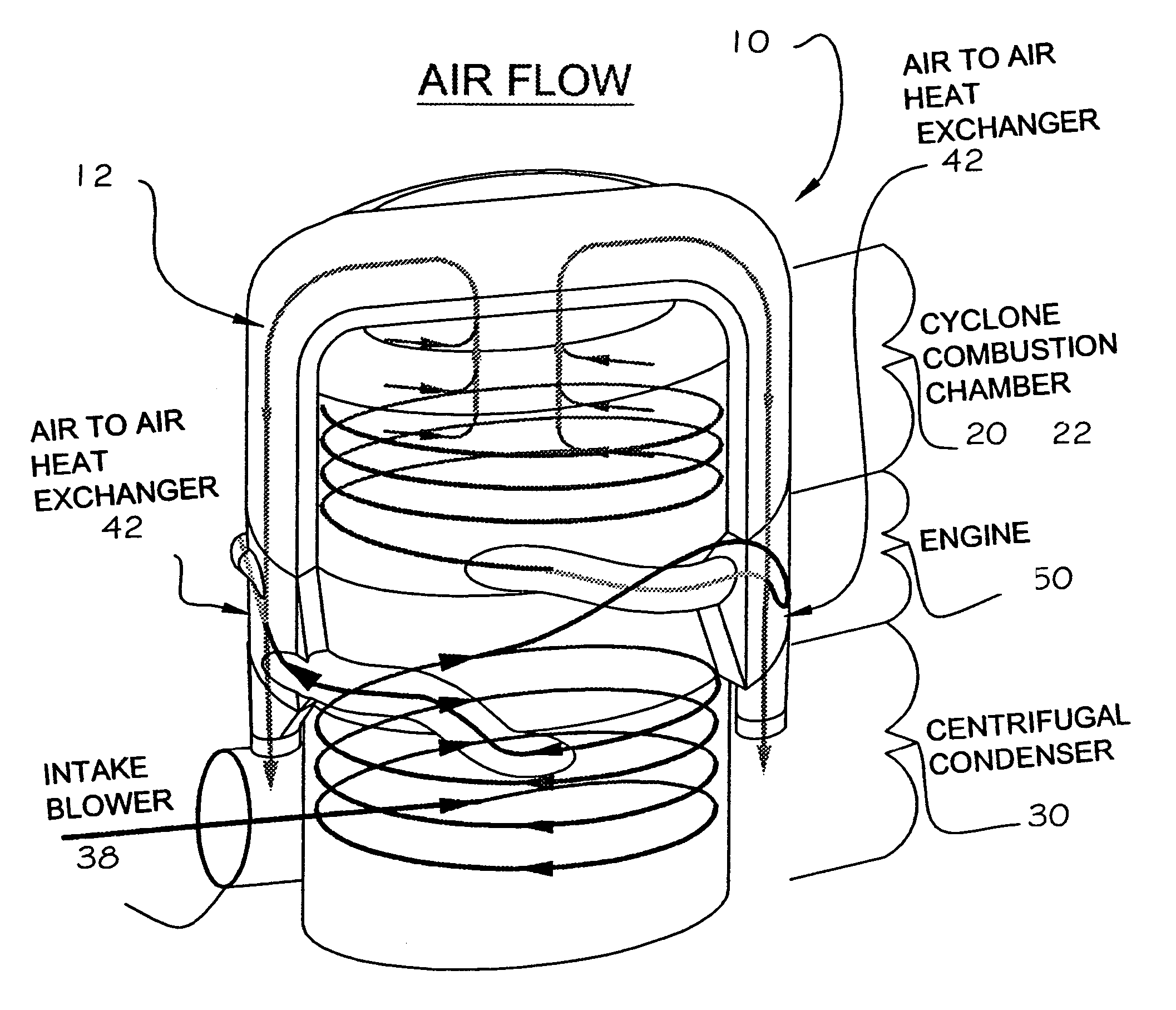

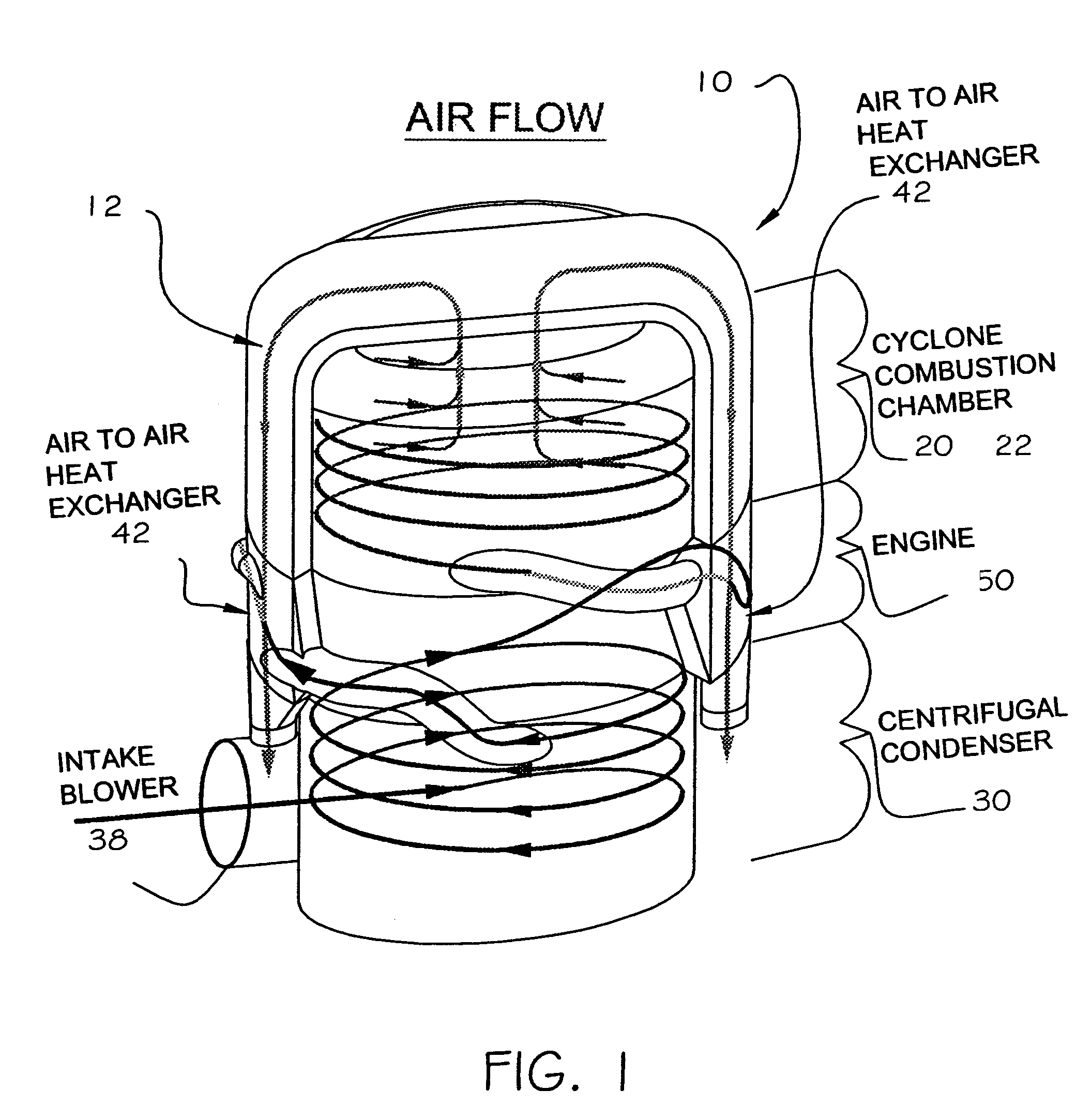

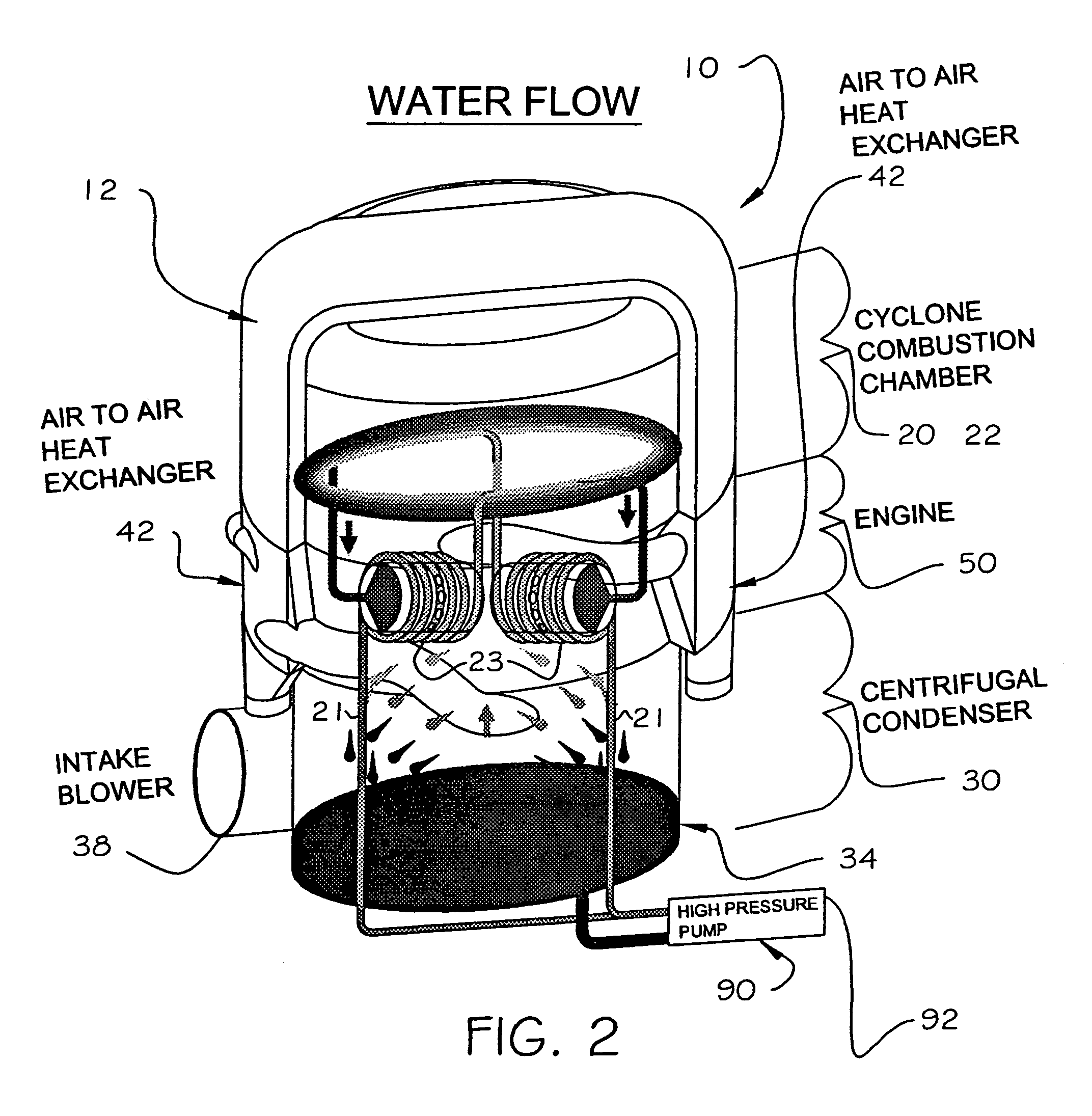

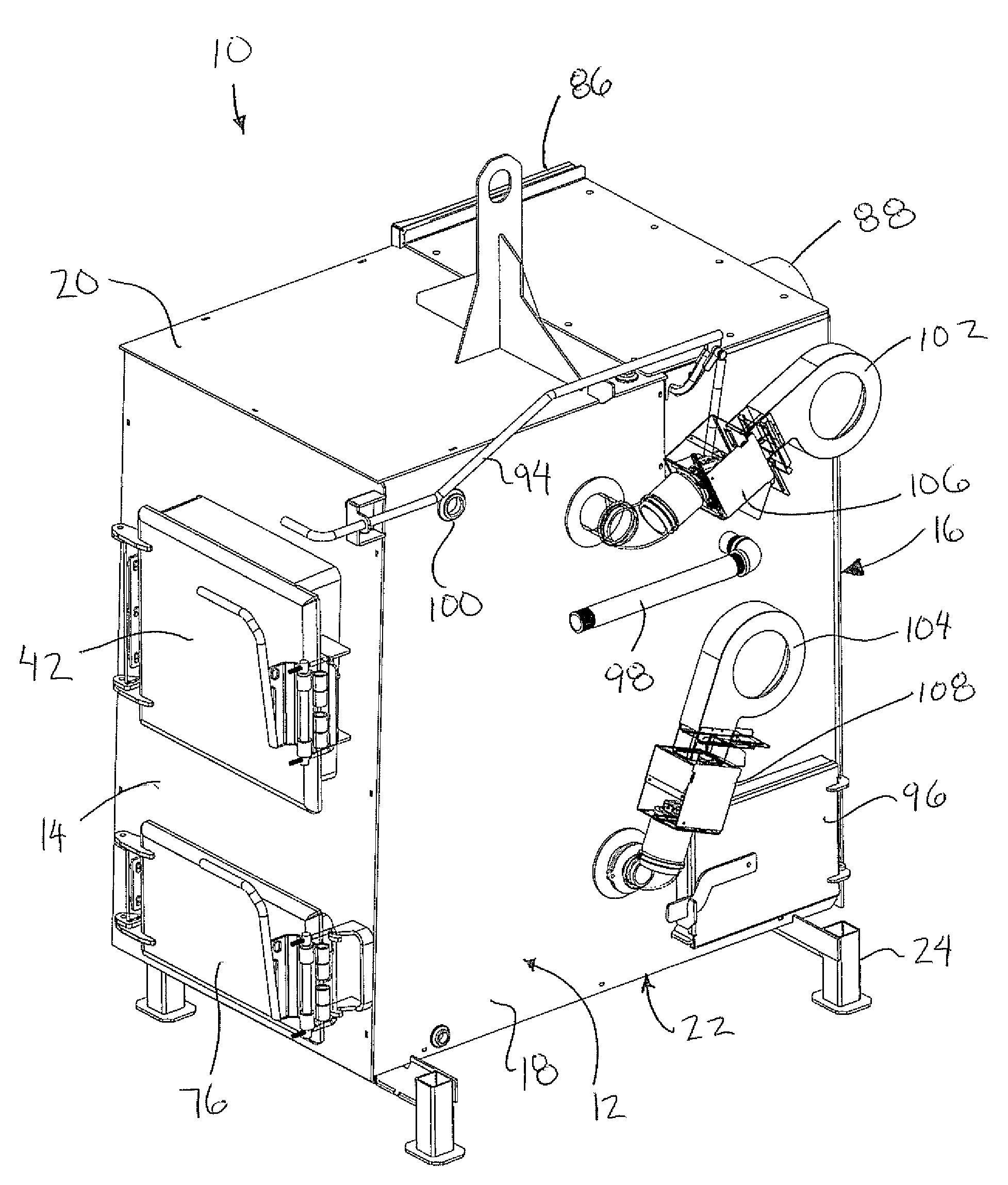

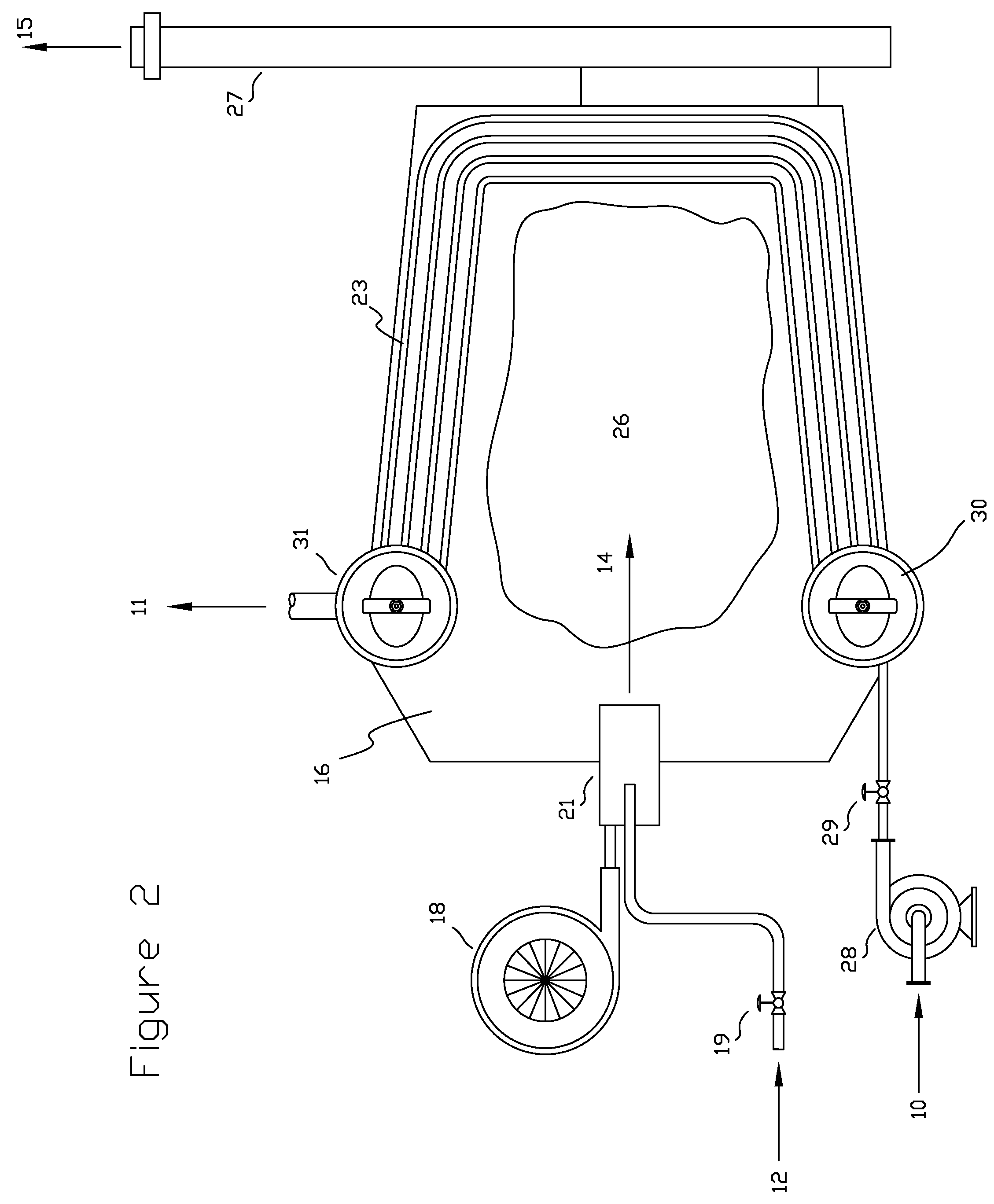

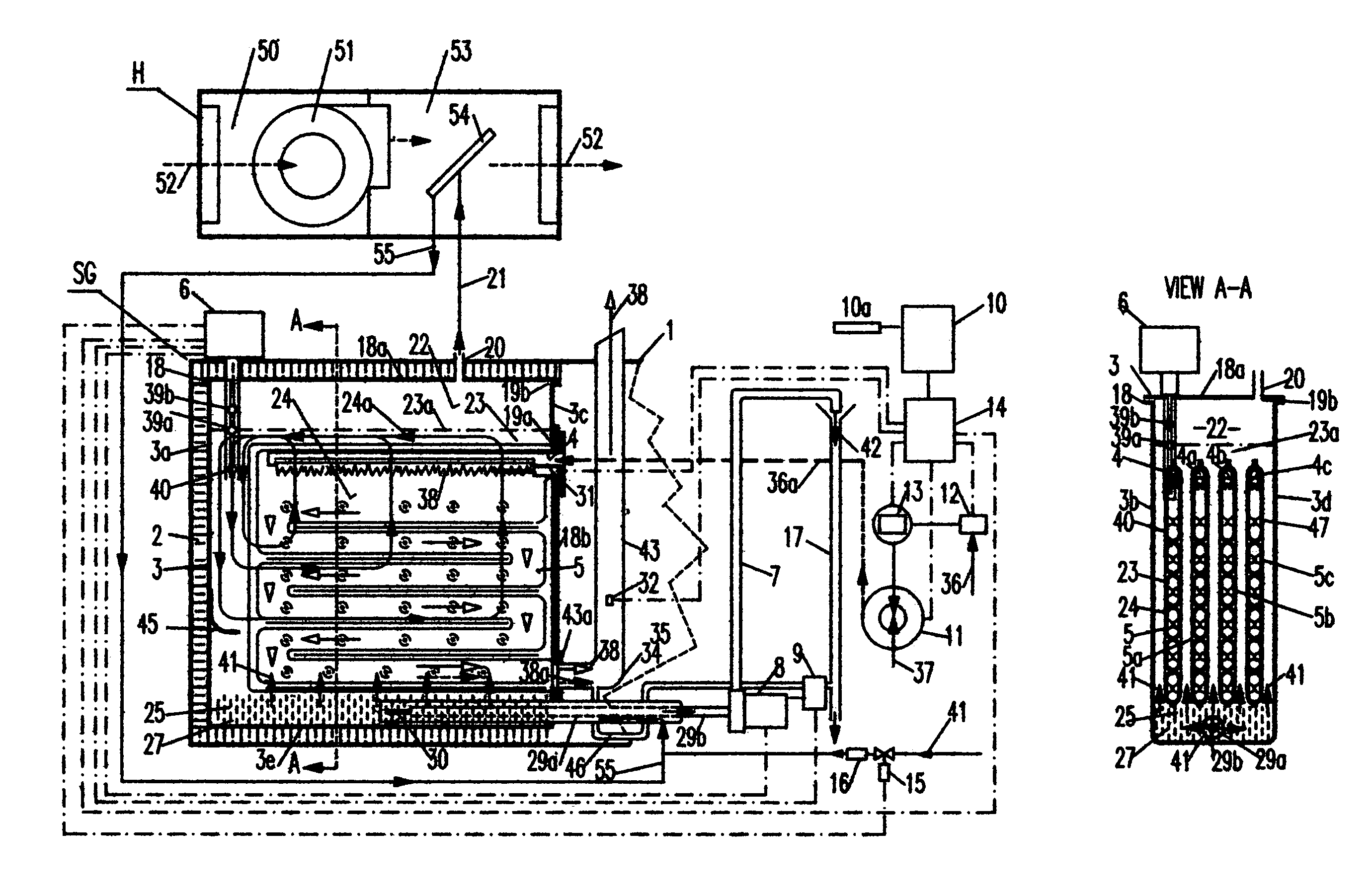

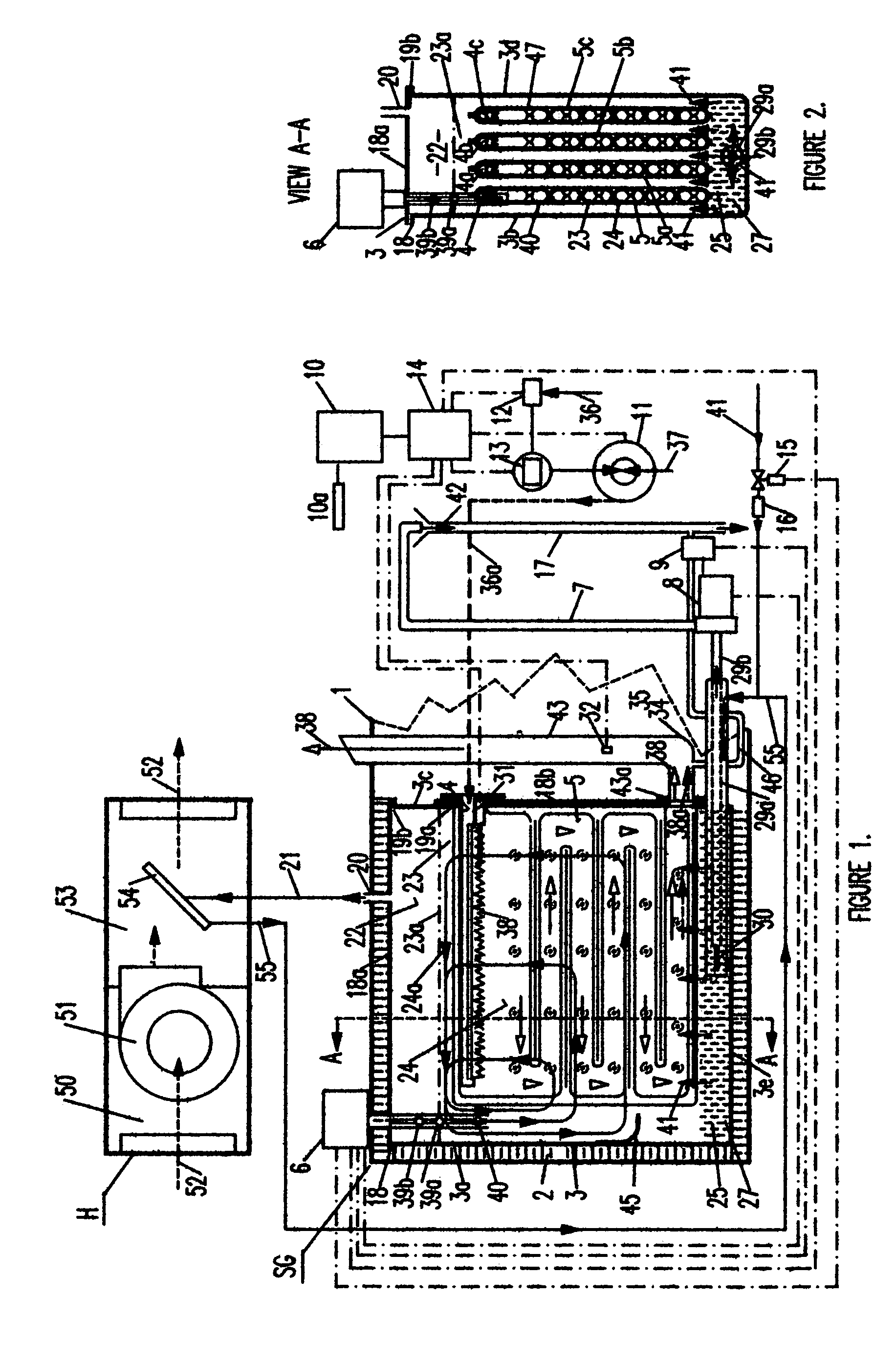

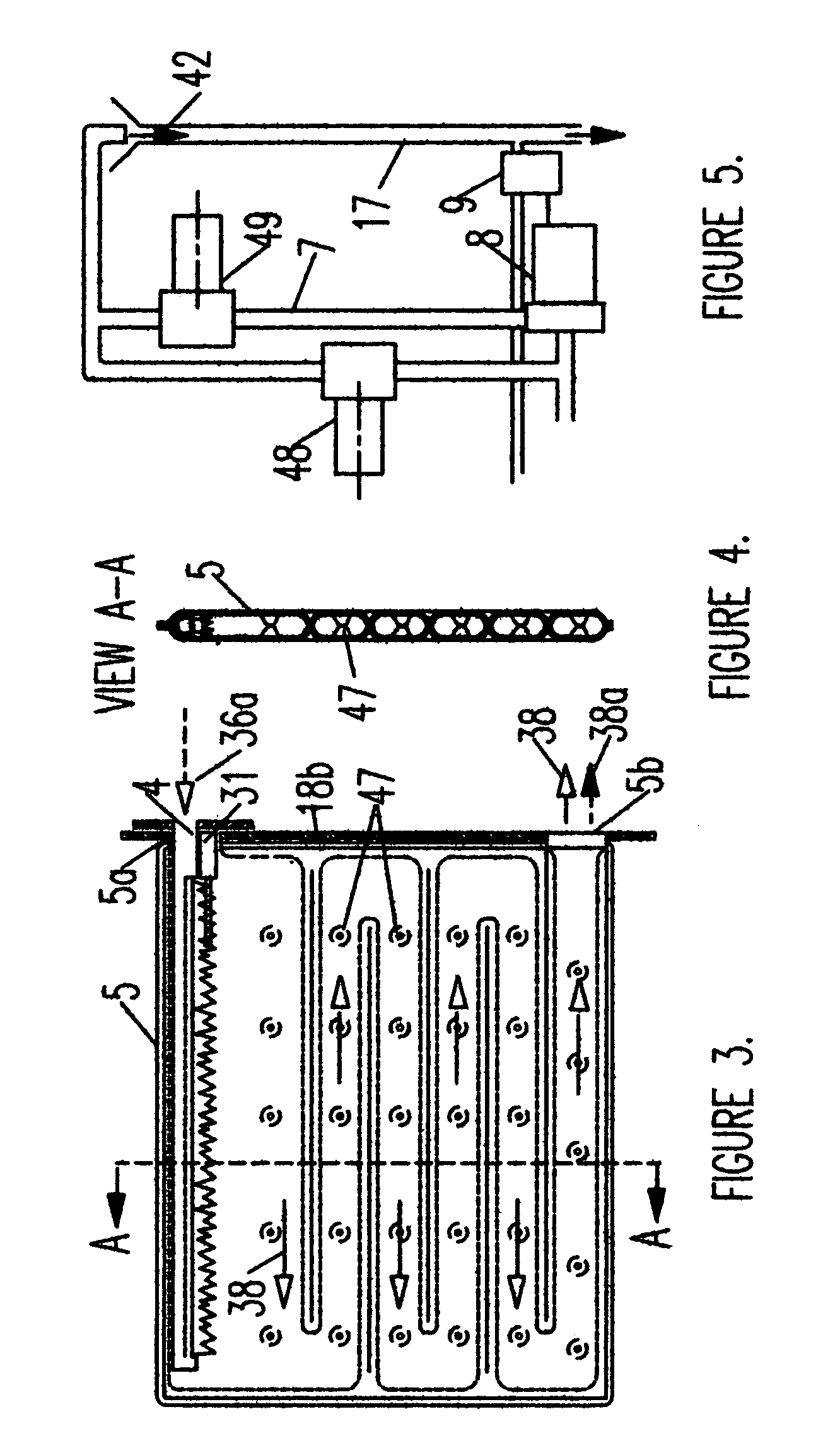

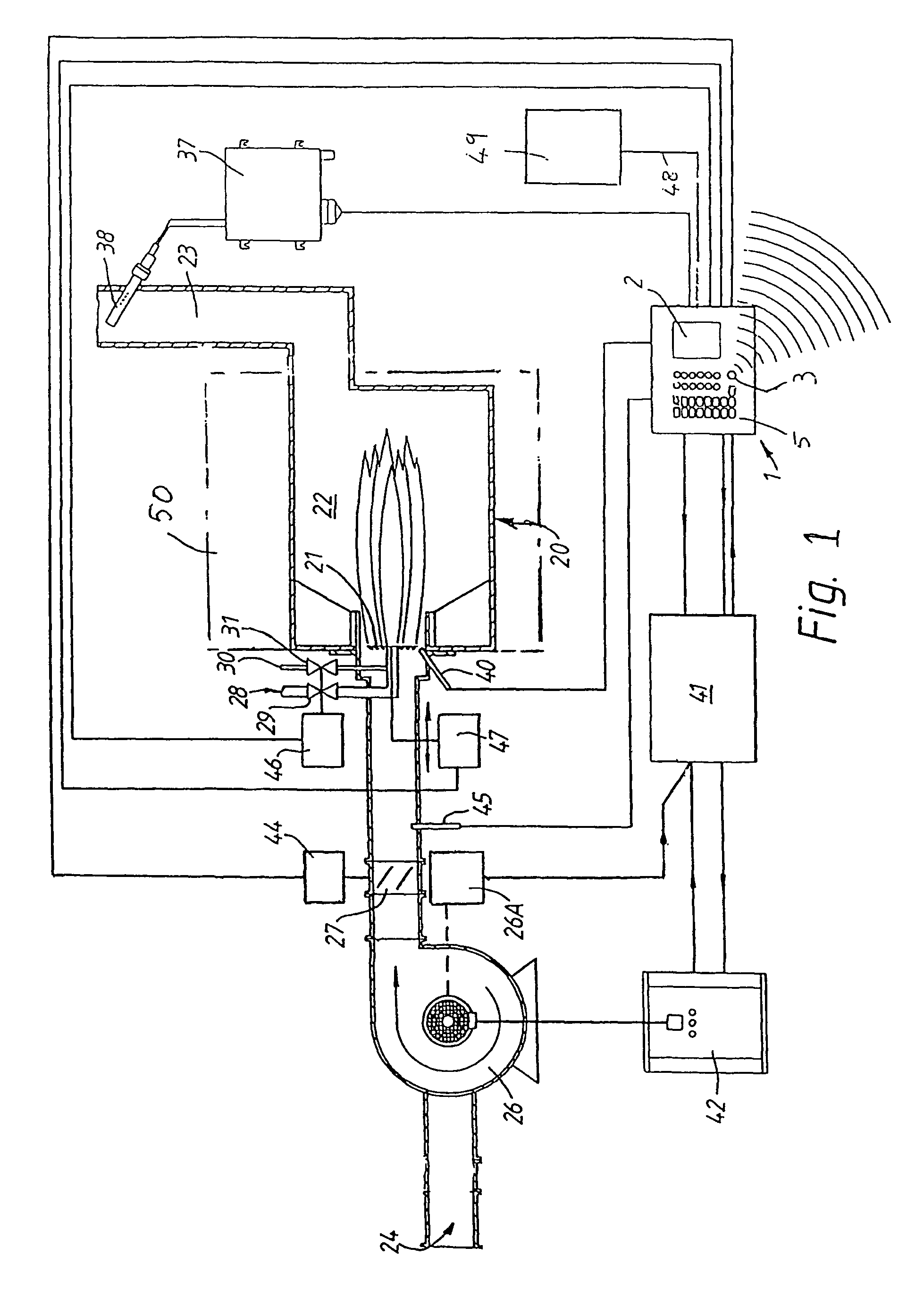

Heat regenerative engine

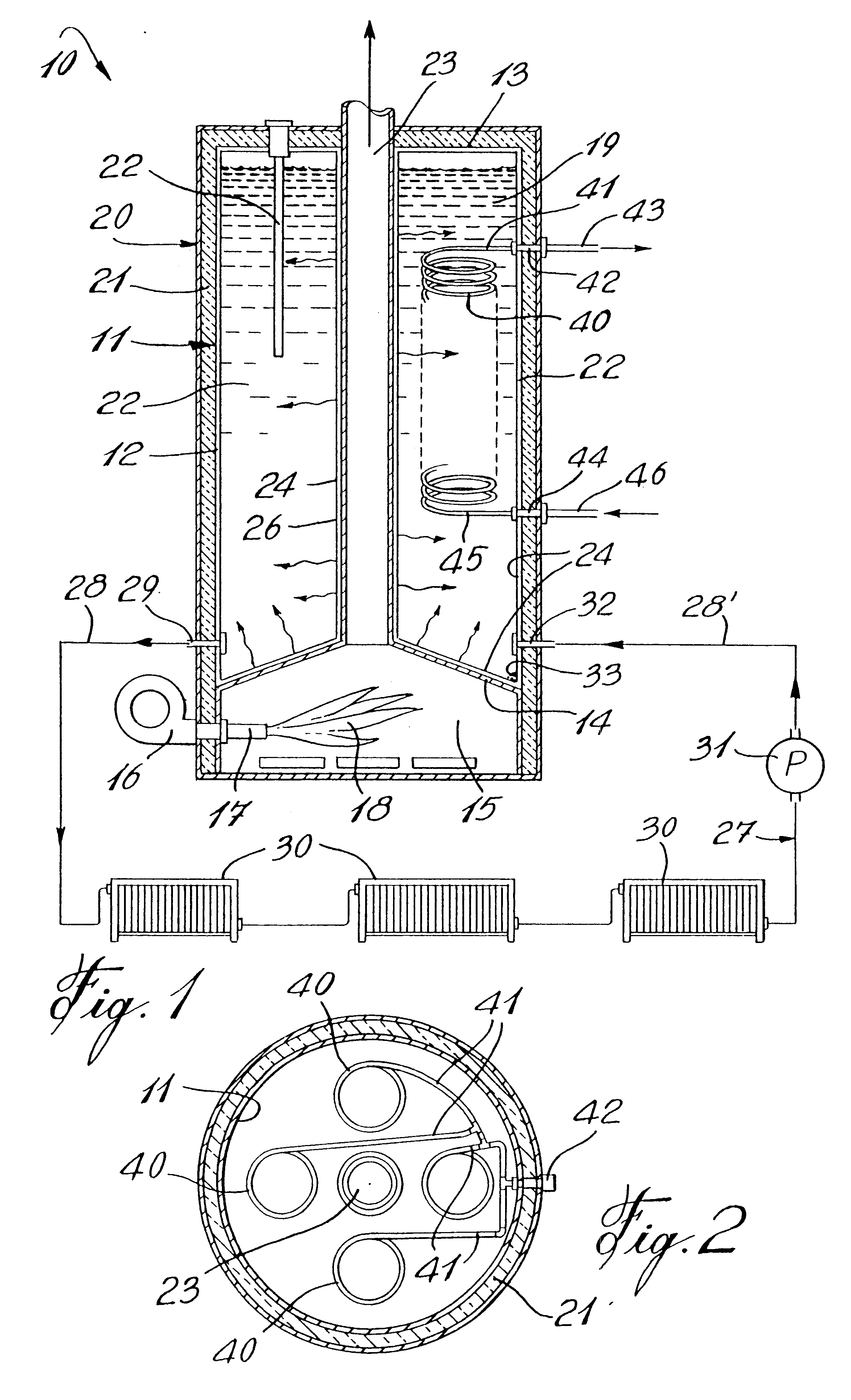

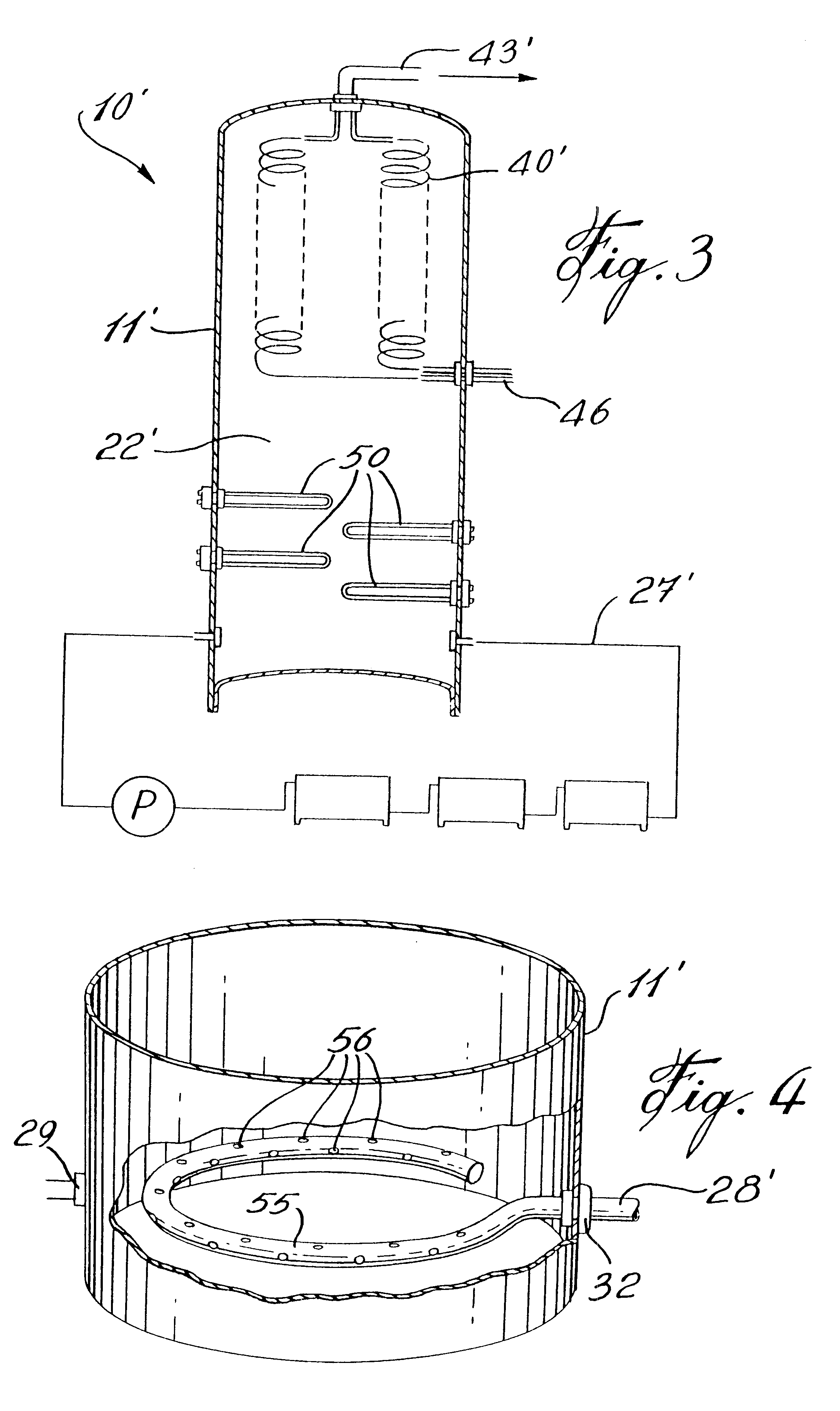

InactiveUS20060053793A1Improve efficiencyHighly compactSteam engine plantsFire-box steam boilersCombustion chamberWorking fluid

A heat regenerative engine uses water as both the working fluid and the lubricant. In operation, water is pumped from a collection pan and through a coil around a cylinder exhaust port, causing the water to be preheated by steam exhausted from the cylinder. The preheated water then enters a steam generator and is heated by a combustion chamber to produce high pressure super heated steam. Air is preheated in a heat exchanger and is then mixed with fuel from a fuel atomizer. An igniter burns the atomized fuel as the flames and heat are directed in a centrifuge within the combustion chamber. The speed and torque of the engine are controlled by a rocker and cam arrangement which opens a needle-type valve to inject high pressure super heated steam into a cylinder having a reciprocating piston therein. The injected steam expands in an explosive action on the top of the piston at high pressure forcing the piston down and drivingly rotating a linked crank cam and crankshaft. Exhaust steam is directed through a centrifugal condenser having an arrangement of flat plates. Cooling air from blowers circulates through the flat plates to condense the steam to a liquid state. The water condensation is returned to the collection pan for subsequent use in steam generation.

Owner:CYCLONE POWER TECH

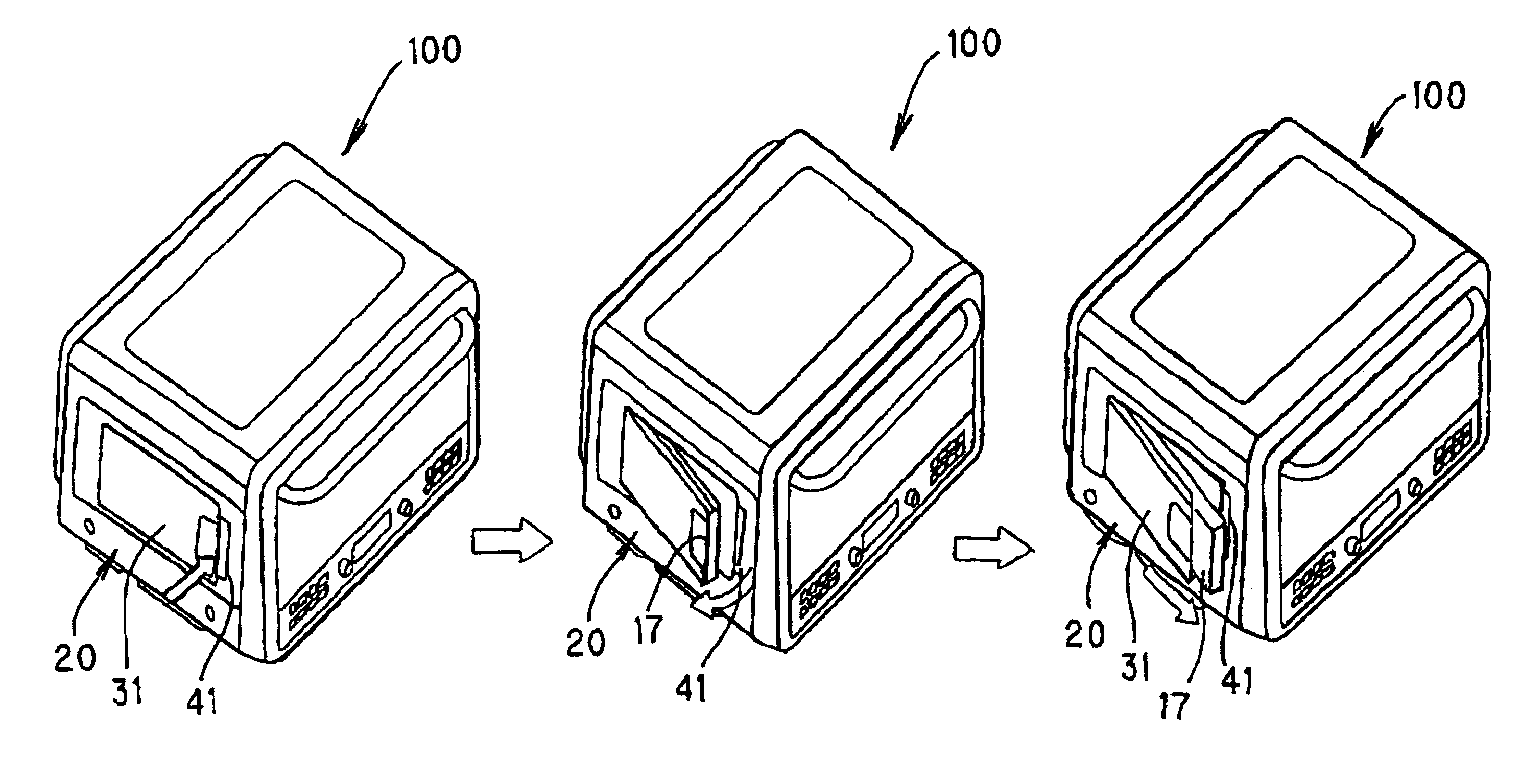

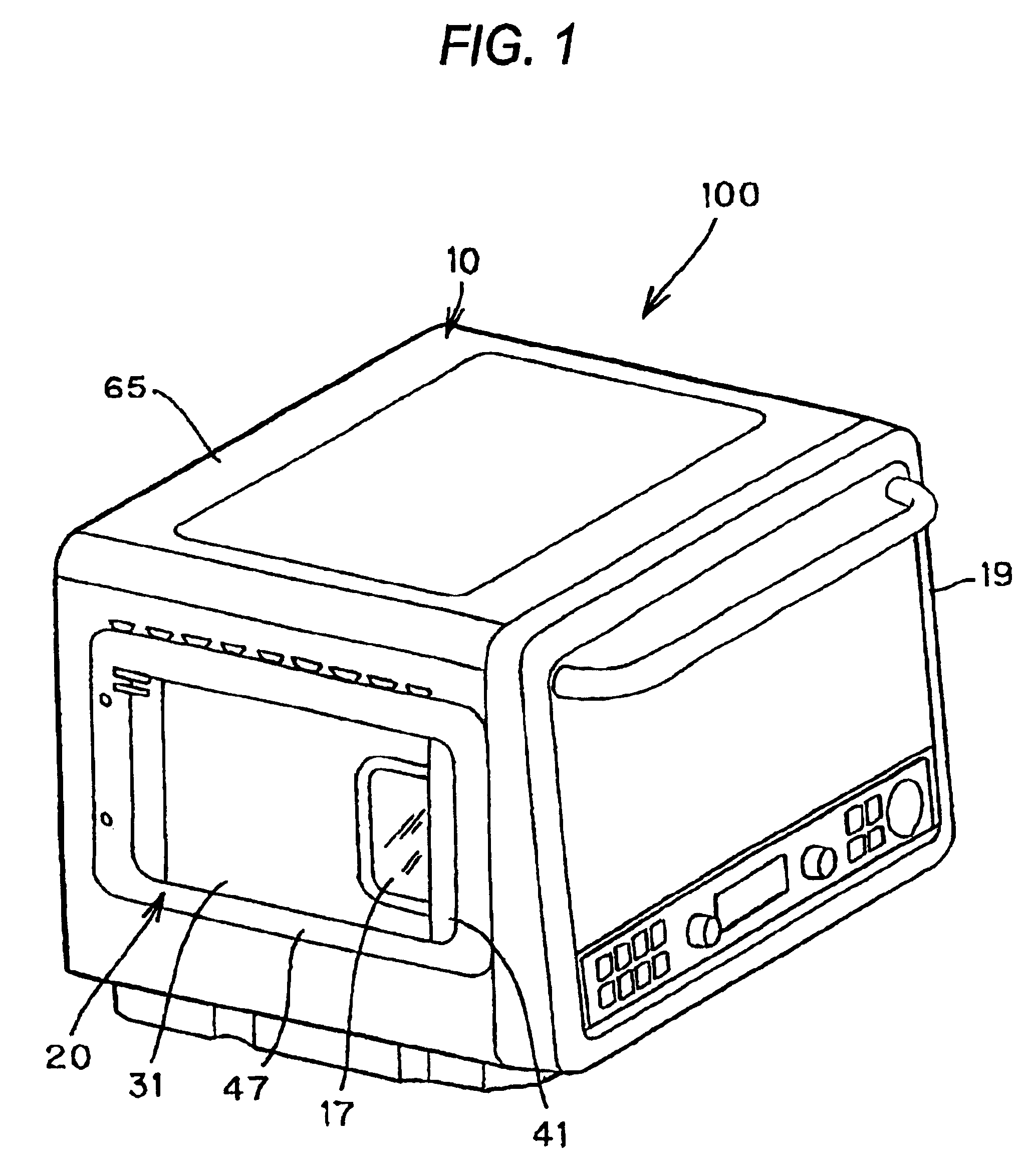

Water supply tank unit

ActiveUS6843207B2Steady attachment stateMoistening function of the heating apparatusDomestic stoves or rangesElectrical heating fuelWaste managementWater supply

A water supply tank unit, attached to a heating apparatus having a moistening function, comprising an open / close member biased in a direction of departing from a unit body attached to the heating apparatus, and a water supply tank held in the open / close member so as to be attachable / detachable, wherein the water supply tank and the open / close member have protrusions respectively so that the protrusions climb over each other and are locked to each other in a process of attaching / detaching the water supply tank.

Owner:PANASONIC CORP +1

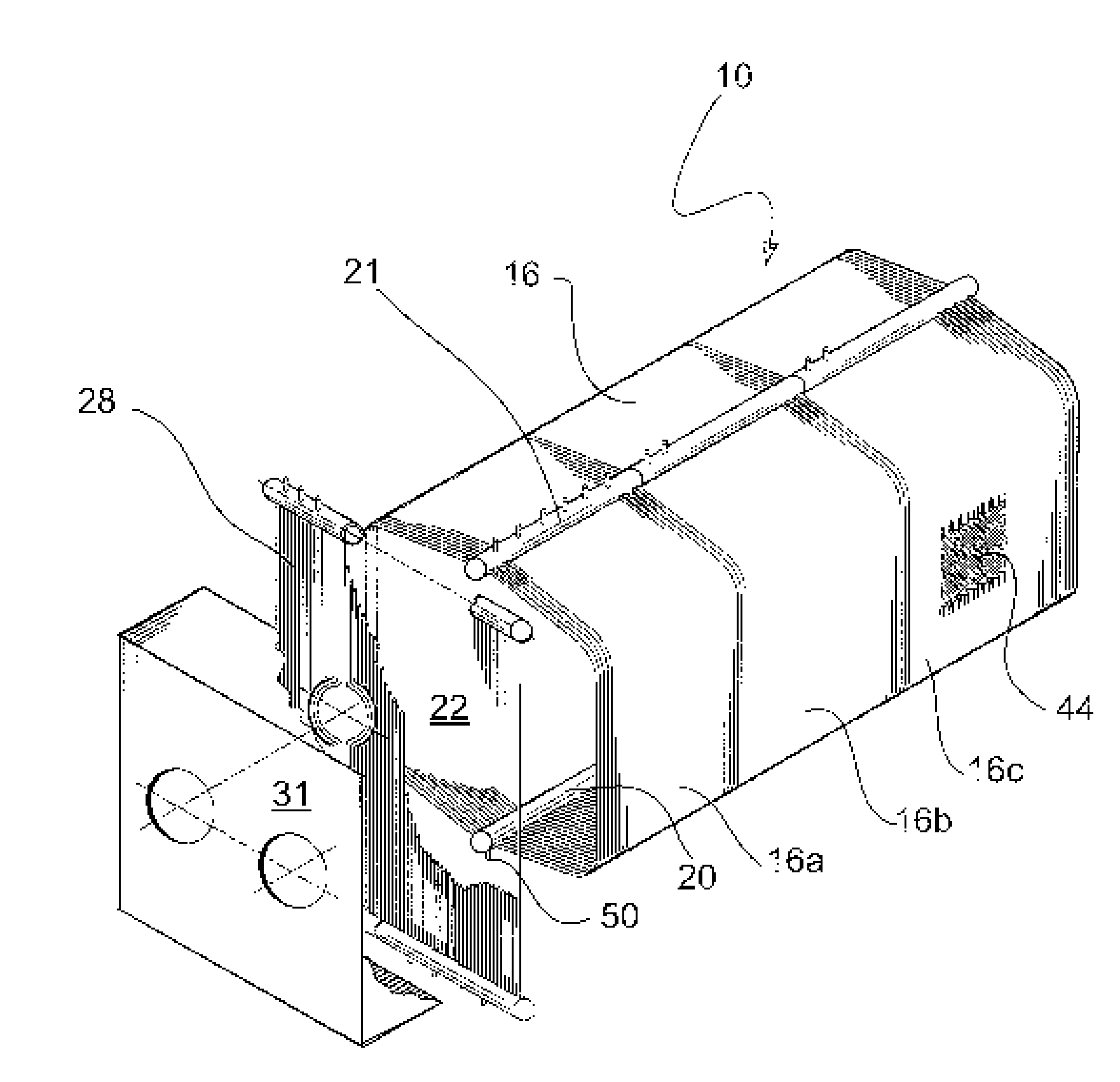

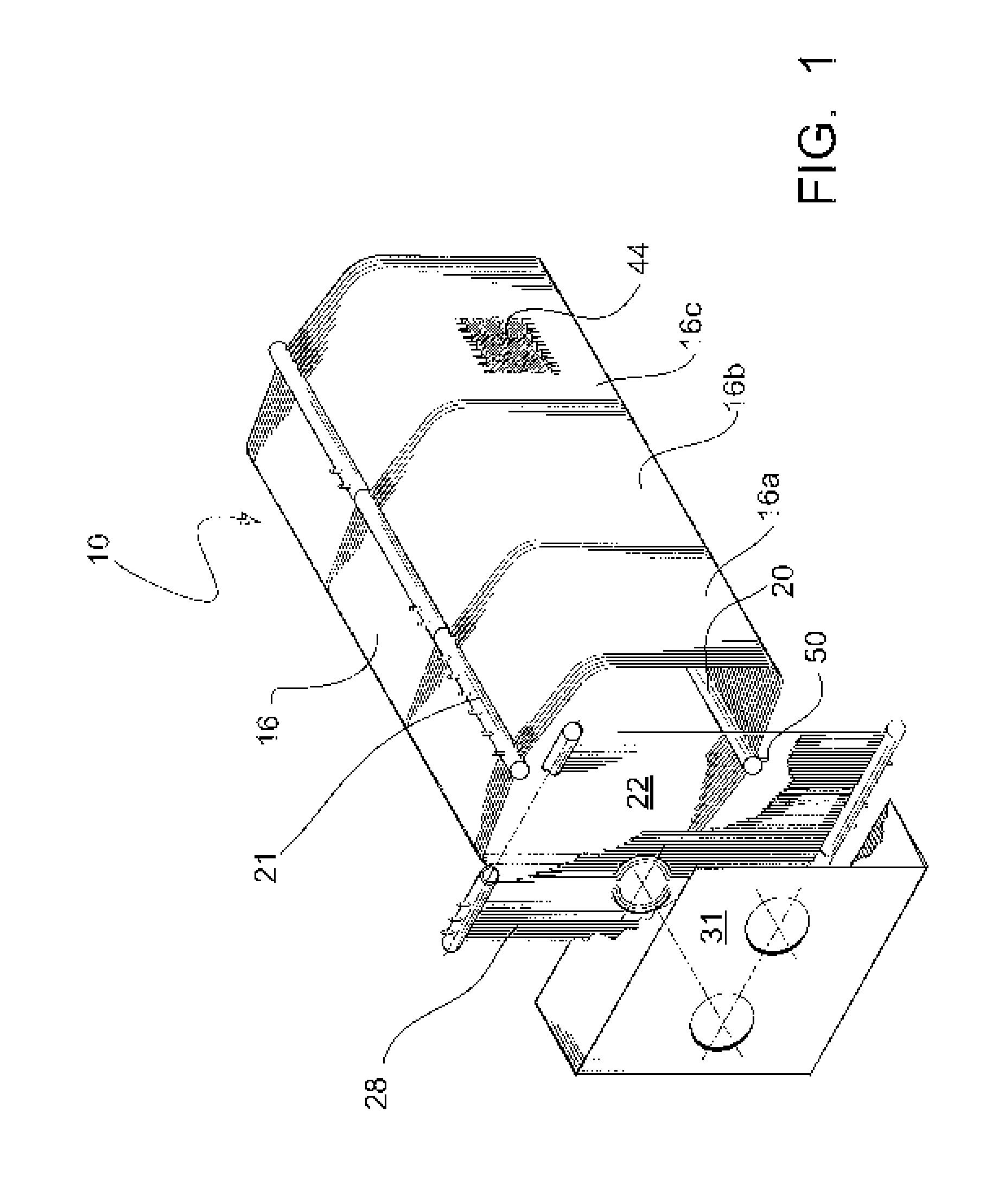

Heat regenerative engine

A heat regenerative engine uses water as both the working fluid and the lubricant. In operation, water is pumped from a collection pan and through a coil around a cylinder exhaust port, causing the water to be preheated by steam exhausted from the cylinder. The preheated water then enters a steam generator and is heated by a combustion chamber to produce high pressure super heated steam. Air is preheated in a heat exchanger and is then mixed with fuel from a fuel atomizer. An igniter burns the atomized fuel as the flames and heat are directed in a centrifuge within the combustion chamber. The speed and torque of the engine are controlled by a rocker and cam arrangement which opens a needle-type valve to inject high pressure super heated steam into a cylinder having a reciprocating piston therein. The injected steam expands in an explosive action on the top of the piston at high pressure forcing the piston down and drivingly rotating a linked crank cam and crankshaft. Exhaust steam is directed through a centrifugal condenser having an arrangement of flat plates. Cooling air from blowers circulates through the flat plates to condense the steam to a liquid state. The water condensation is returned to the collection pan for subsequent use in steam generation.

Owner:CYCLONE POWER TECH

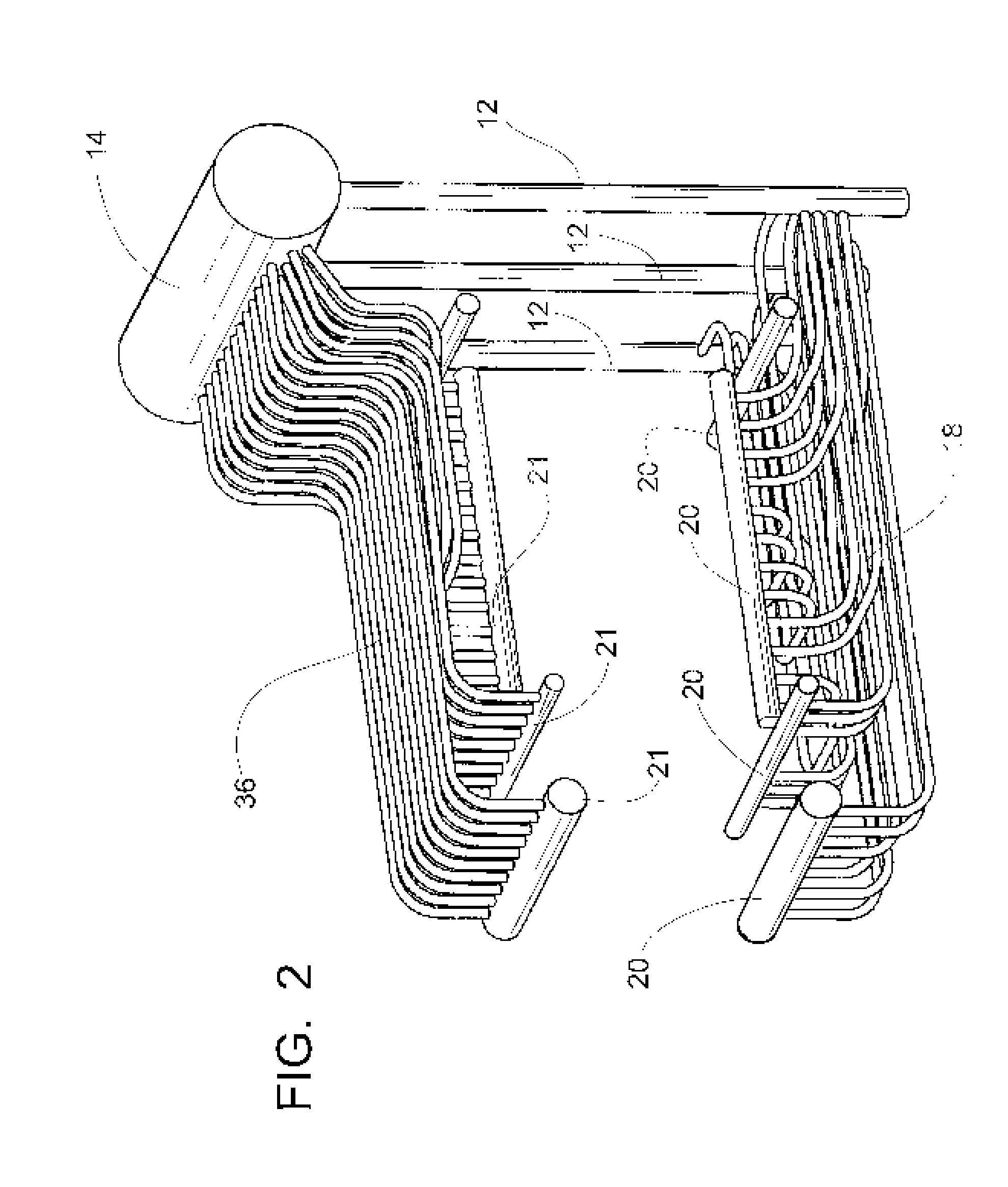

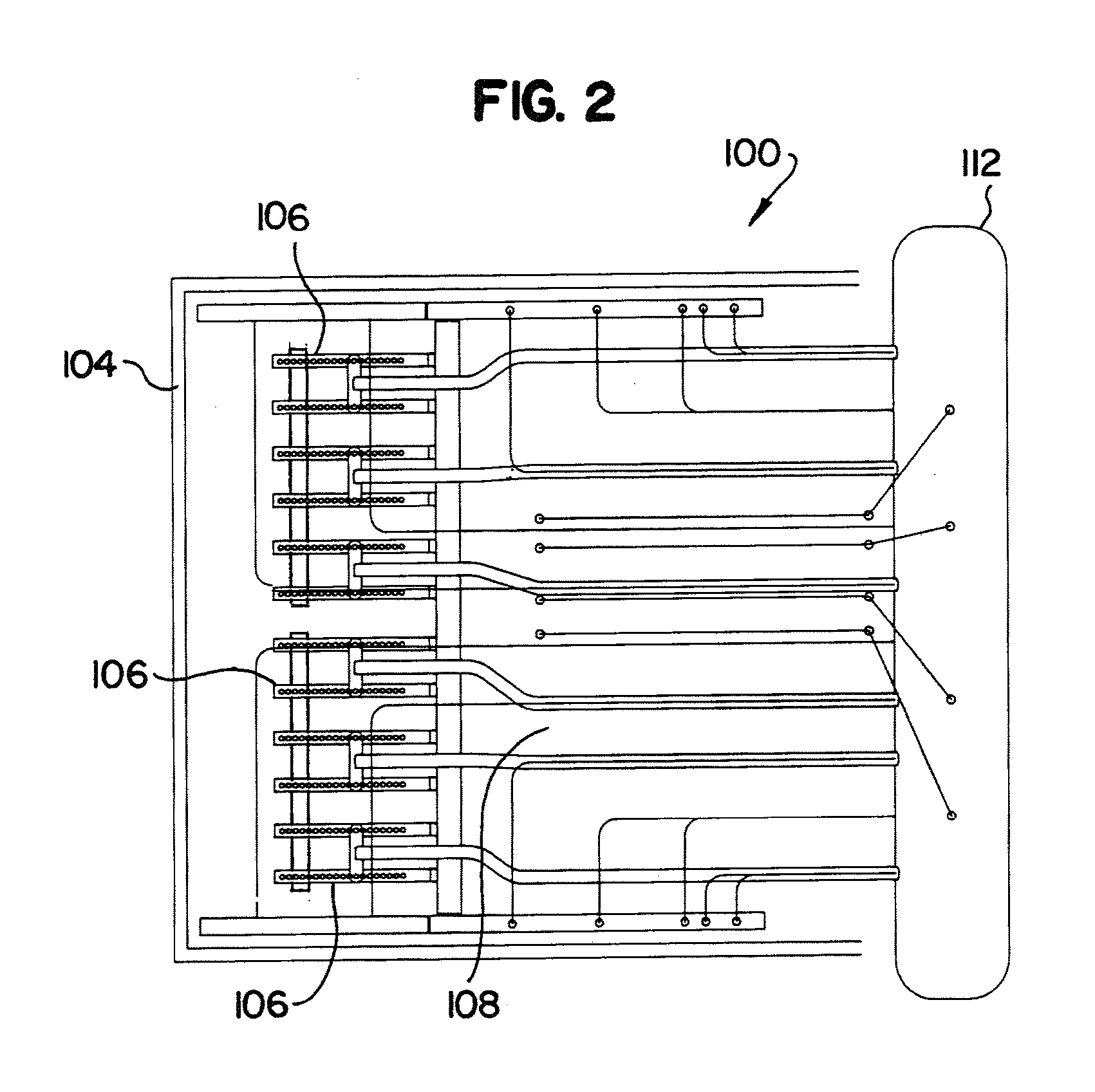

Tube assembly for a boiler

InactiveUS7137360B1Improve boiler efficiencyGood coefficientBoiler water tubesEnergy industryFlue gasEngineering

A boiler is described comprising a housing with a flue gas inlet for receiving a hot gas flame and an outlet for venting a hot gas produced by the hot gas flame, and a tube assembly mounted within the housing. The tube assembly comprises a lower manifold for receiving a liquid, an upper manifold for receiving a heated version of the liquid; and, a plurality of tubes disposed between the lower and upper manifolds. Each tube is shaped to provide a hot gas pathway that travels in a parallel fashion along at least a lower portion of the longitudinal extent of each tube in the tube assembly to the outlet, whereby the liquid introduced into the lower manifold travels in the plurality of tubes and receives heat from the hot gas along the extent of the hot gas pathway.

Owner:PRIME BOILERS

High efficiency, glass-lined, combination space and hot water heater

InactiveUS6334411B1Improve efficiencyOvercome disadvantagesBoiler water tubesSpeed sensing governorsWater sourceCoupling

A combination space and hot water heater is comprised of an inner tank having an outer casing spaced therebout with insulation being interposed between the casing and the inner tank. The inner tank has a glass-lined inner surface and a heater is provided within the inner tank for heating a same volume of water within the inner tank. An anode is provided within the inner tank. A closed water circulating circuit is connected to the inner tank for circulating hot water from the tank through heat exchange means connected in the closed water circulating circuit. Preferably, but not exclusively, the heat exchange devices are radiators. The inner tank contains a predetermined same volume of recirculating water wherein minimal deposits are accumulated in the inner tank by not admitting fresh water thereby substantially preventing the build-up of deposits on heat exchange elements within the tank and the formation of harmful bacteria in radiators and corrosion and further wherein a high constant efficiency is achieved and the life expectancy of the hot water heater is substantially prolonged. At least one heat exchange coil is disposed in the inner tank and immersed in the water contained therein. The heat exchange coil is connected at one end to an outlet coupling to which a domestic hot water line is connected. An opposed end of the heat exchange coil is connected to an inlet coupling. The inlet coupling is connected to a pressurized water supply.

Owner:MICLAU S R I

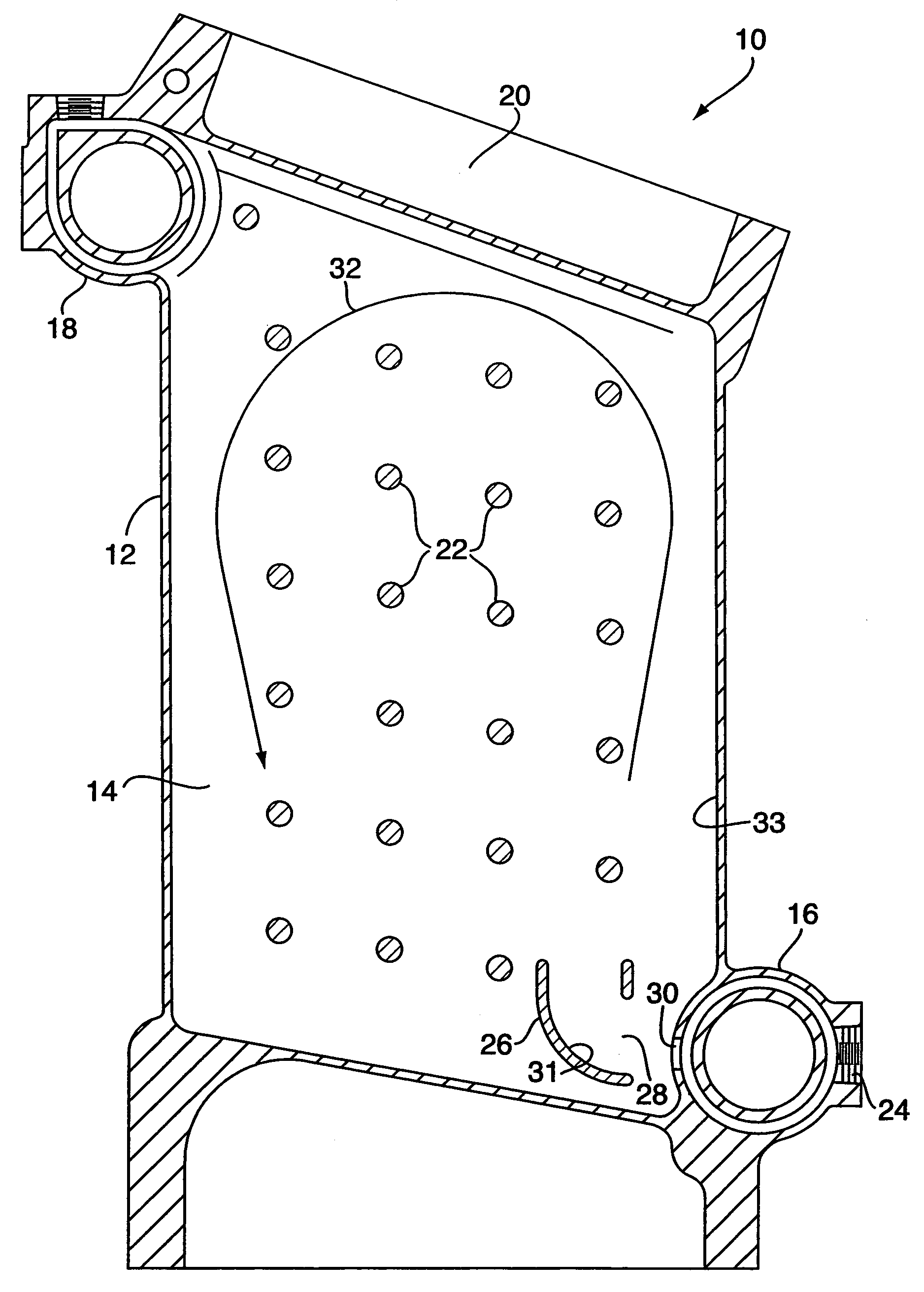

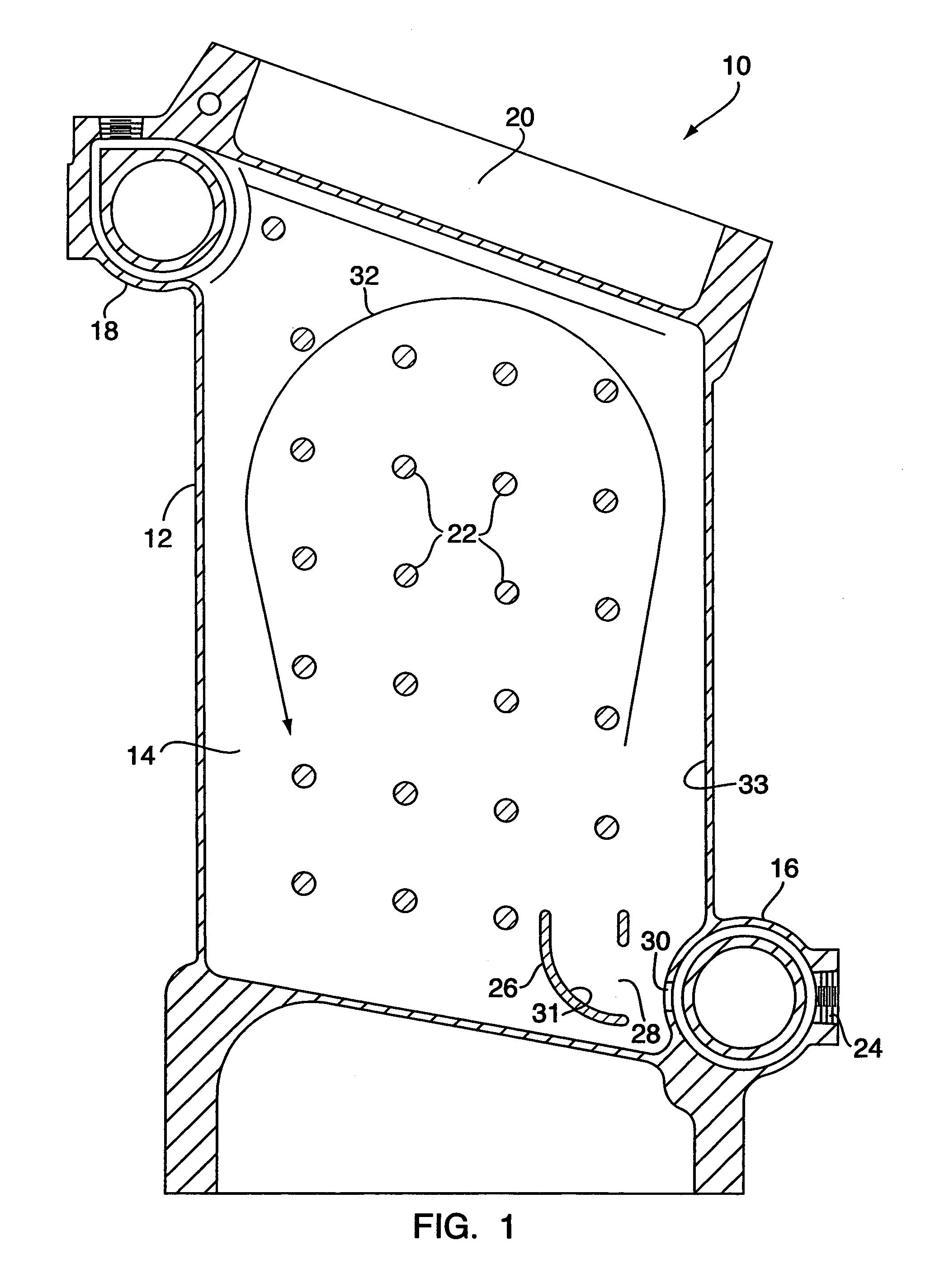

Boiler and burner apparatus

InactiveUS7036462B2Reduce sensitivityImprove efficiencyWater-tube boilersWater heatersCombustorEngineering

A boiler apparatus includes a housing defining an interior boiler chamber and a burner element arranged to be in thermal communication with the boiler chamber. An ignition device is provided for instigating combustion of an inlet gas stream, and is arranged adjacent one edge of the burner element. A gas restricting device is utilized for restricting contact between the burner element and the inlet gas stream such that the inlet gas stream is initially incident upon the one edge of the burner element, thereby forcing the inlet gas stream to propagate across the burner element from the one edge.

Owner:MESTEK

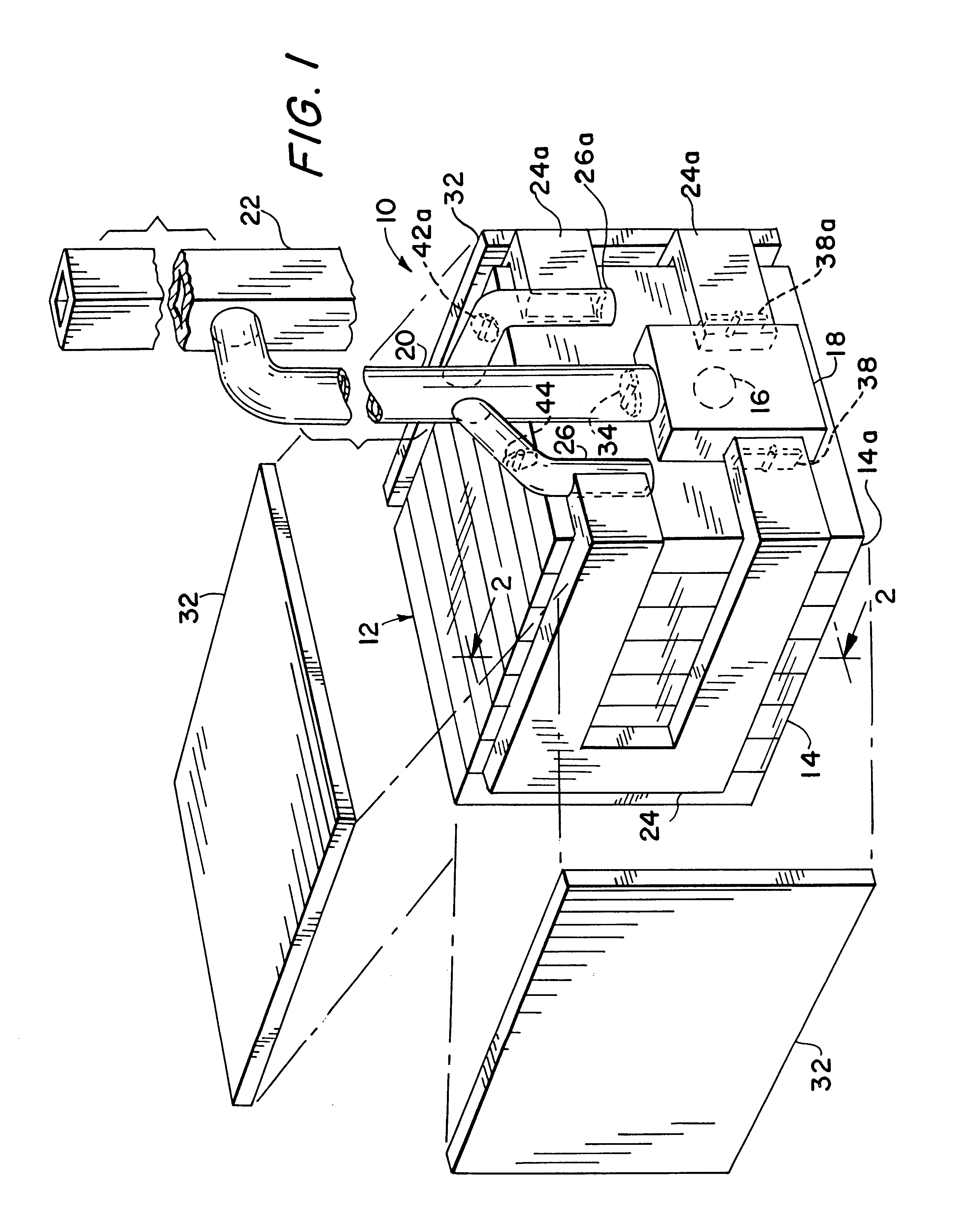

Natural Circulation Industrial Boiler for Steam Assisted Gravity Drainage (SAGD) Process

A gravity feed, natural circulation boiler for an SAGD process using low quality feedwater for carbonatious material recovery, has a large diameter steam drum with downcomers. A furnace of the boiler has individually replaceable membrane wall modules, each with upper and lower headers and membrane roof, wall and floor parts connected to the drum and defining a fire box having an inlet end and an outlet end. The furnace includes a membrane front wall connected to the drum with a windbox upstream of the front wall. Burners at the inlet end of the firebox heat the firebox and riser pipes are connected between the steam drum and the upper header for supplying steam to the steam drum when the firebox in heated, the downcomer pipes being connected to the lower header for supplying water from the stream drum under gravity feed so that each module defines a single circuit. Furnace outlet screen bank and subsequent generating banks each with upper and lower headers and associated feeder and riser tubes complete the boiler.

Owner:BABCOCK & WILCOX CANADA LIMITED

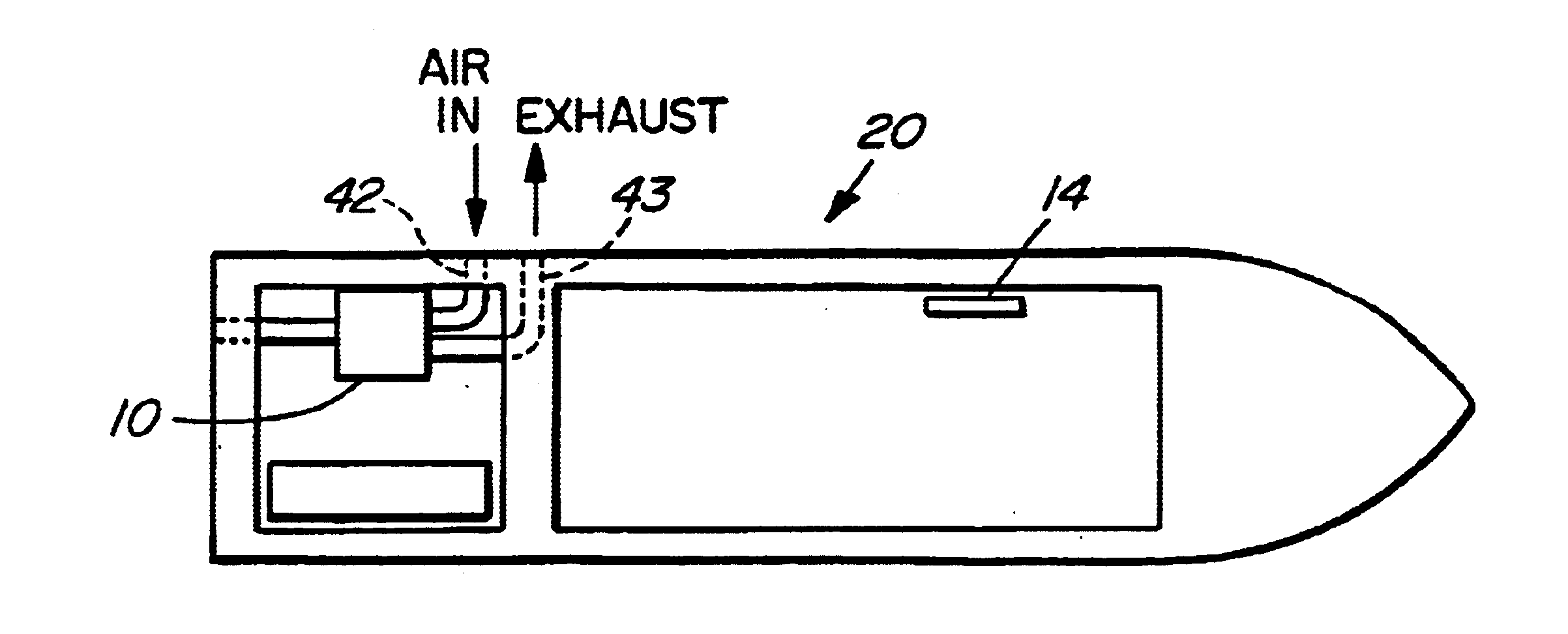

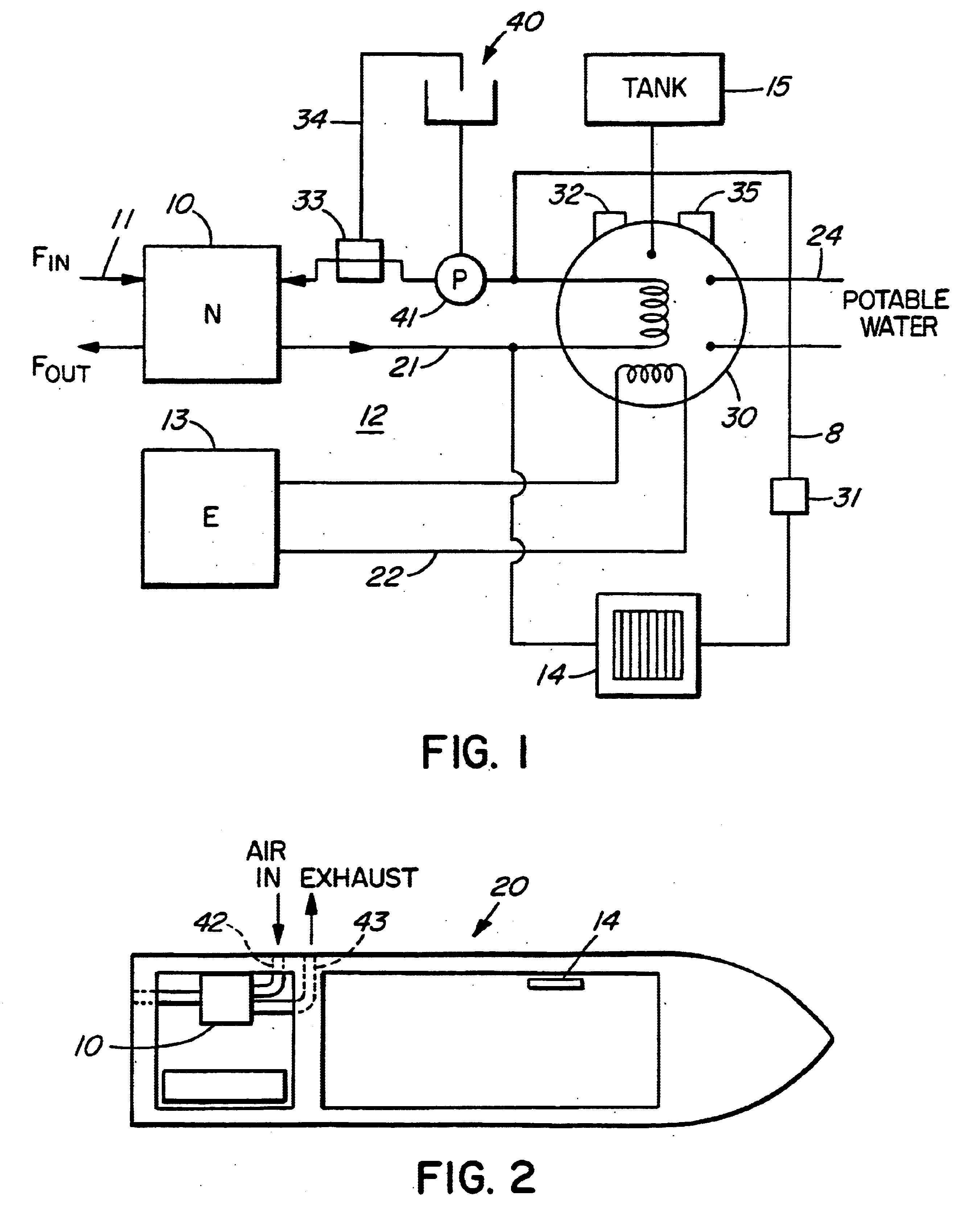

Narrowboat auxiliary heater and method of controlling same

A hot water system for a narrowboat which system comprises an auxiliary heater used to heat a potable water tank and further is used to heat living areas of the narrowboat. The auxiliary heater and a temperature measuring device are operably connected to the water tank which terminates operation of the heater when the temperature reaches a predetermined and comfortable level selected by the user. Likewise, a room water circuit is operably attached to the auxiliary heater and is operated by a thermostatically controlled solenoid valve which terminates hot water flow through a radiator within the living areas when the temperature reaches a value selected by the user.

Owner:INT THERMAL INVESTMENTS

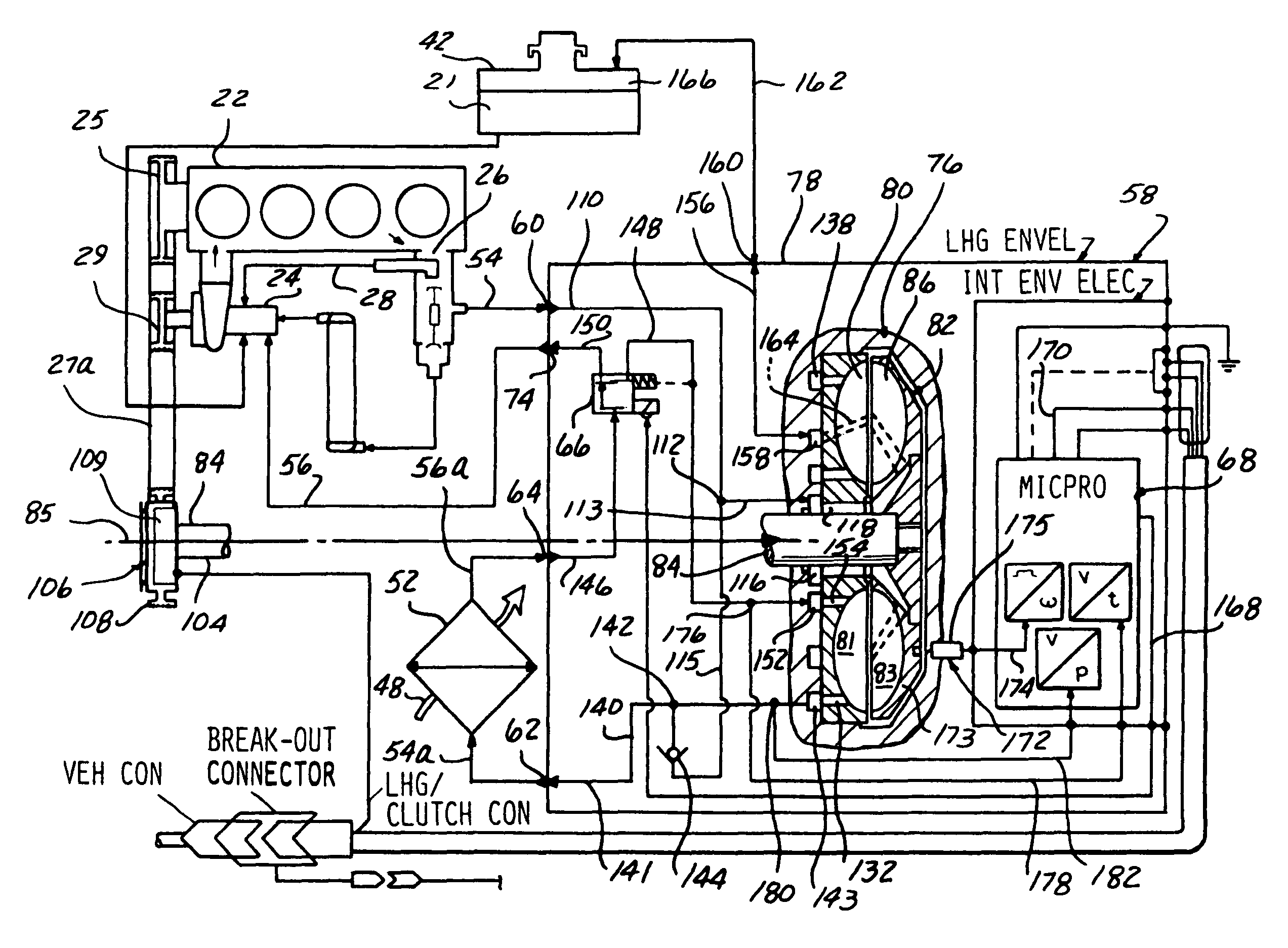

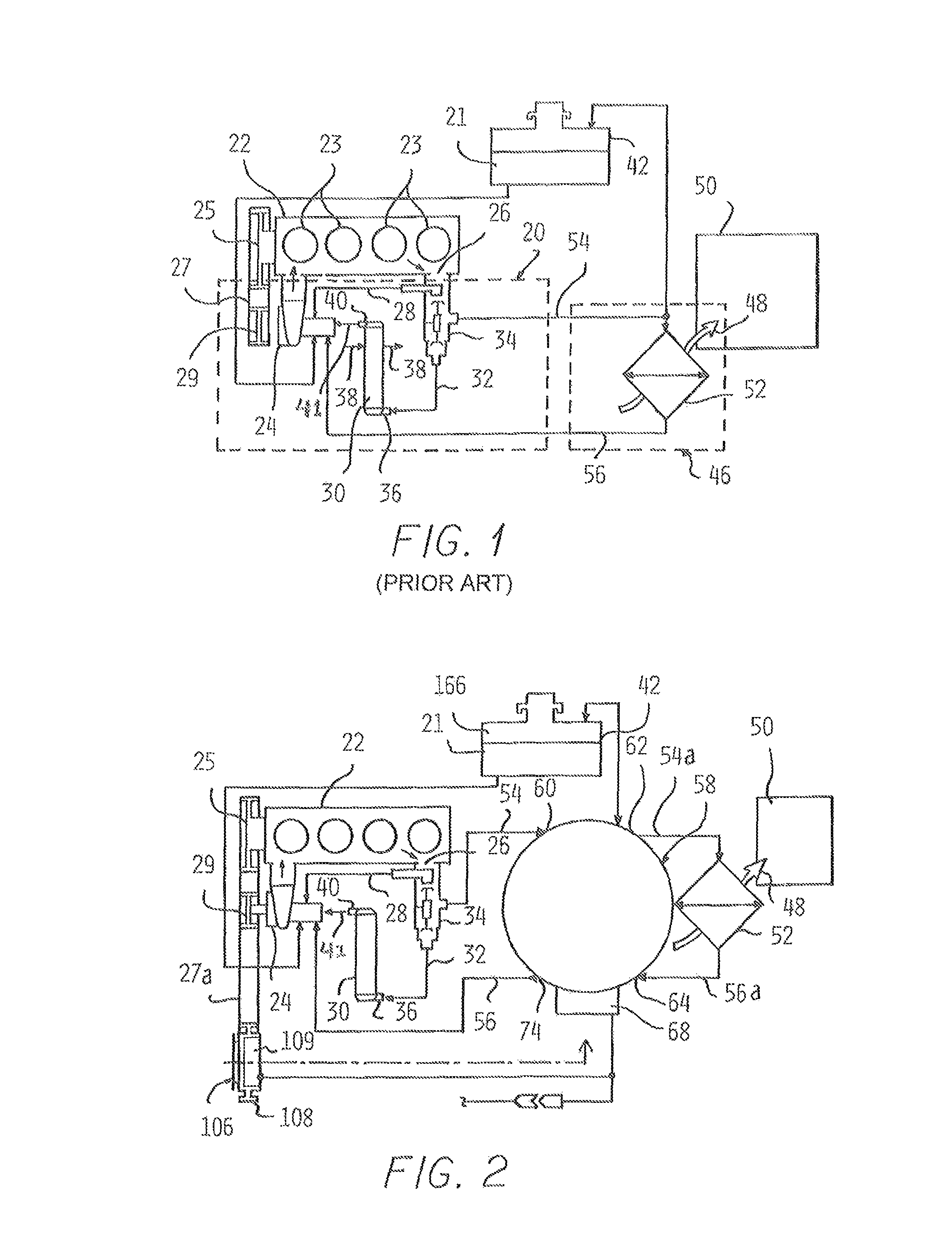

Vehicle supplemental heating system

A preferred embodiment supplemental heating system is fluidly connectable to a vehicle cooling system and includes a liquid heat generator operable for heating a cooling fluid delivered to the supplemental heating system from the vehicle's cooling system. The liquid heat generator includes a discharge passage connectable to a heater core of the vehicle and a inlet passage connectable to the vehicle's cooling system. The supplemental heating system further includes a control valve having an inlet connectable to an exit passage of a heater core of the vehicle, a discharge passage fluidly connected to the liquid heat generator, and a second discharge passage connectable to the vehicle's cooling system. The control valve is operable for controlling the proportion of cooling fluid exiting the heater core that is returned to the vehicle's cooling system and recirculated back to the liquid heat generator.

Owner:WEBASTO AG

Portable high pressure steam generator for car washing with gas heater

InactiveUS6925968B1Easy to cleanSmall volumeFluid heatersCleaning apparatus for vehicle exteriorsGas heaterEngineering

A portable steam generator for automobile washing is provided. The steam generator of the current application is to produce a steam of pressure 6 KG / cm2 at a rate of 30 kg / hr. The steam generator uses natural gas as a heat source. The inner structure of the steam generator is designed to increase the contact of the heat with the steam generating chamber while minimizing heat exchanging tubes inside the chamber. The steam generator weights only 25 Kg and has dimension of 572 mm in height by 400 mm in outer diameter. Whole unit including gas burner is mounted on one structure.

Owner:HWANG PIL SUN +2

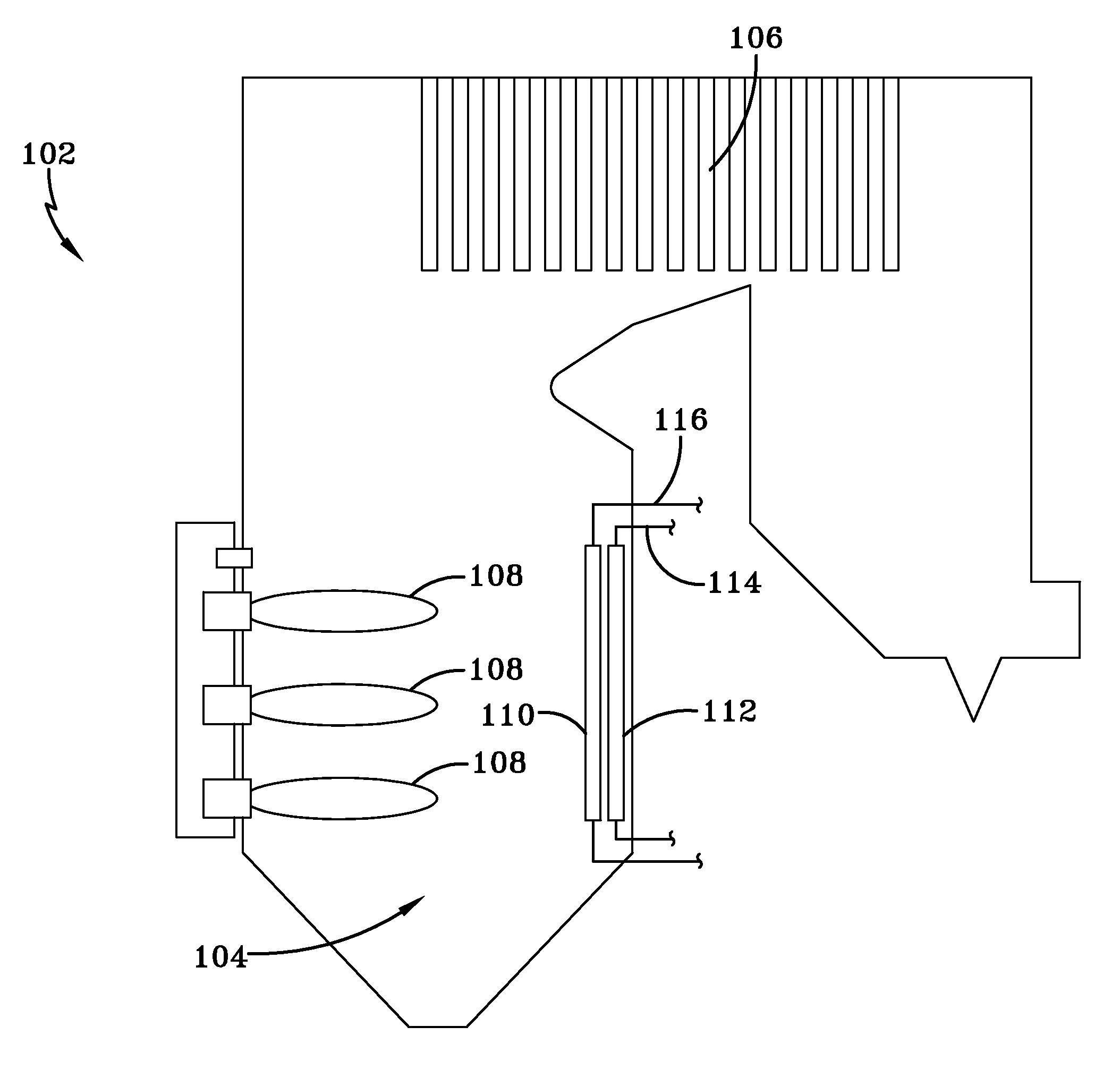

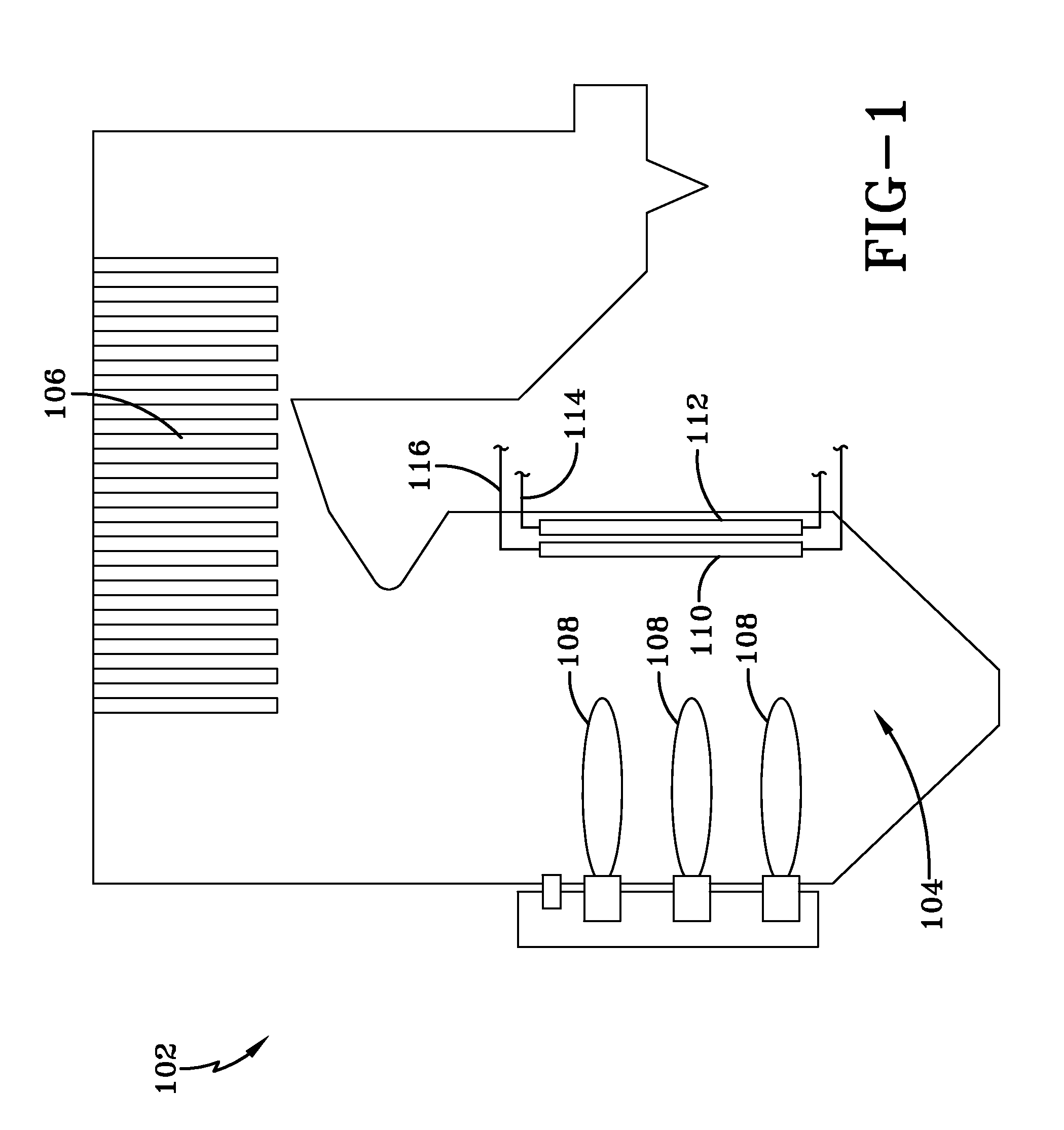

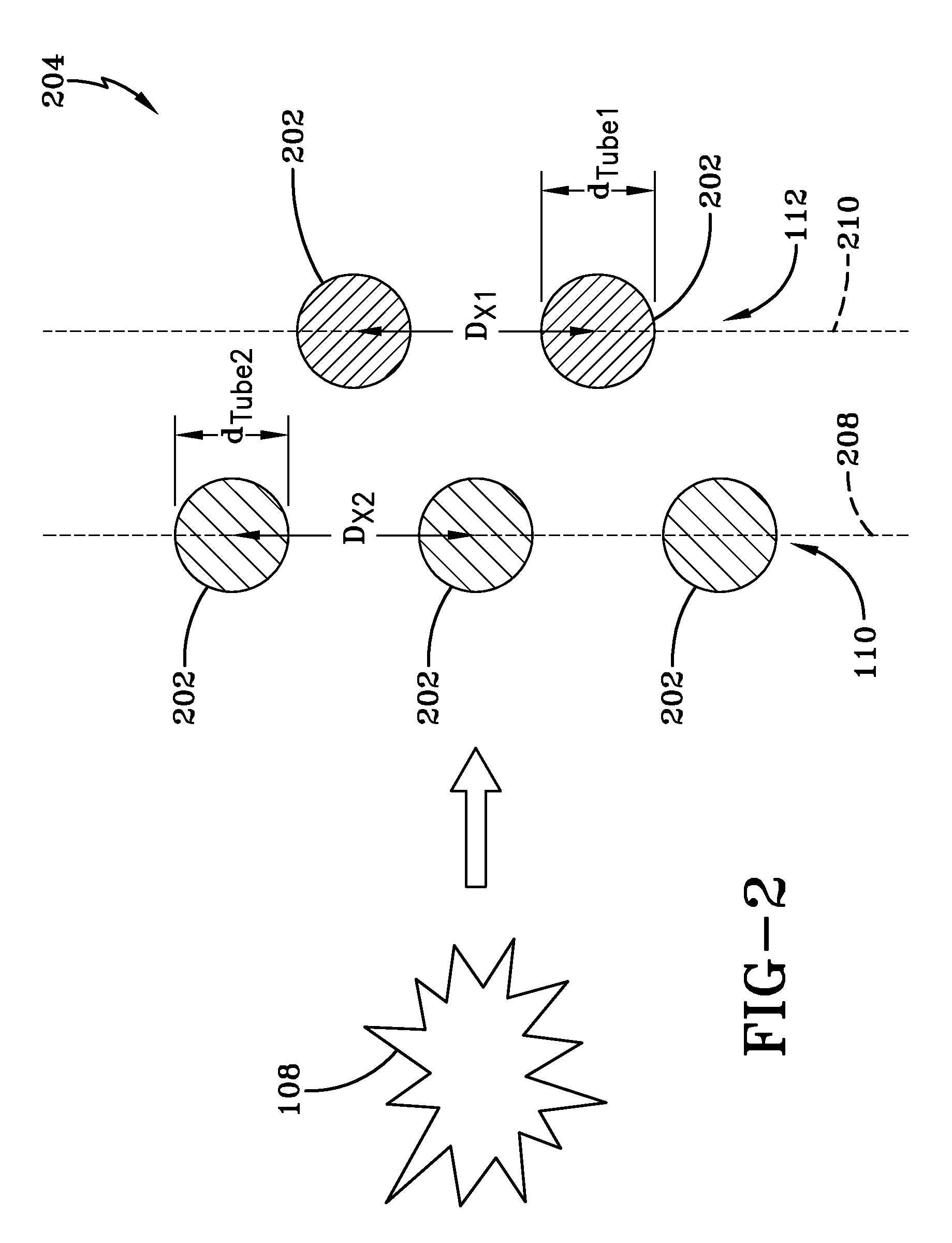

Oxy/fuel combustion system having combined convective section and radiant section

InactiveUS20100077968A1Low costDecreases overall capital and operating costBoiler water tubesWater-tube boilersCombustion systemCombustion

A heat transfer system having a a radiant source, a first heat exchanger configured to permit a first fluid to flow therethrough, and a thermal shield configured to provide controlled radiative heat from the radiant source to the first exchanger. The radiant source is a flame. The thermal shield is a second heat exchanger configured to permit a second fluid to flow therethrough or a non-contact thermal shield fabricated from a material arranged to provide controlled radiative heat exposure from the radiant source to the first exchanger. Oxy / coal combustion systems are also disclosed.

Owner:AIR PROD & CHEM INC

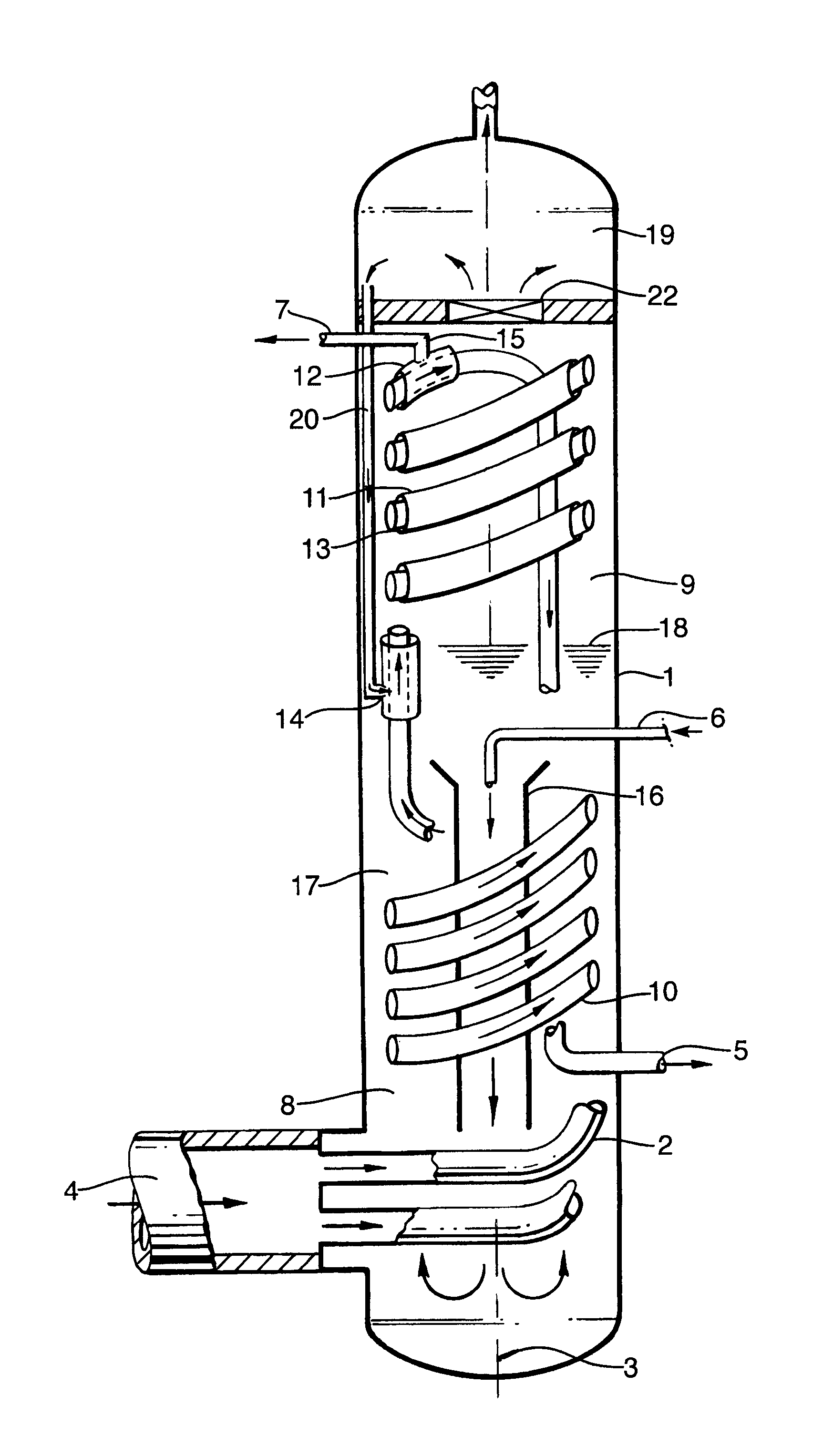

Boiler for making super heated steam and its use

ActiveUS20070283907A1Avoid disadvantagesLocal overheating of the walls of the spirally conduit is avoidedStationary conduit assembliesWater-tube boilersWater bathsEngineering

A boiler for making super heated steam by indirect heat exchange of water against a hot gas, said boiler being a vertically oriented vessel comprising a spirally formed conduit around the vertical axis of the vessel, which vessel is provided with an inlet for hot gas fluidly connected to the lower end of the conduit for upwardly passage of hot gas through the spirally formed conduit, an outlet for cooled gas fluidly connected to the upper end of the conduit, an inlet for fresh water and a vessel outlet for super heated steam, said vessel further provided with a water bath space in the lower end of the vessel and a saturated steam collection space above said water bath space, said spirally formed conduit comprising of a spirally formed evaporating section located in the water bath space and a spirally formed super heater section at the upper end of the vessel, wherein the conduit of the super heater section is surrounded by a second conduit forming an annular space between said super heater conduit and said second conduit, said annular space being provided with an inlet for saturated steam fluidly connected to the saturated steam collection space and an outlet for super heated steam located at the opposite end of said annular space and fluidly connected to the vessel outlet for super heated steam, wherein outlet or inlet are positioned in water bath space.

Owner:SHELL USA INC

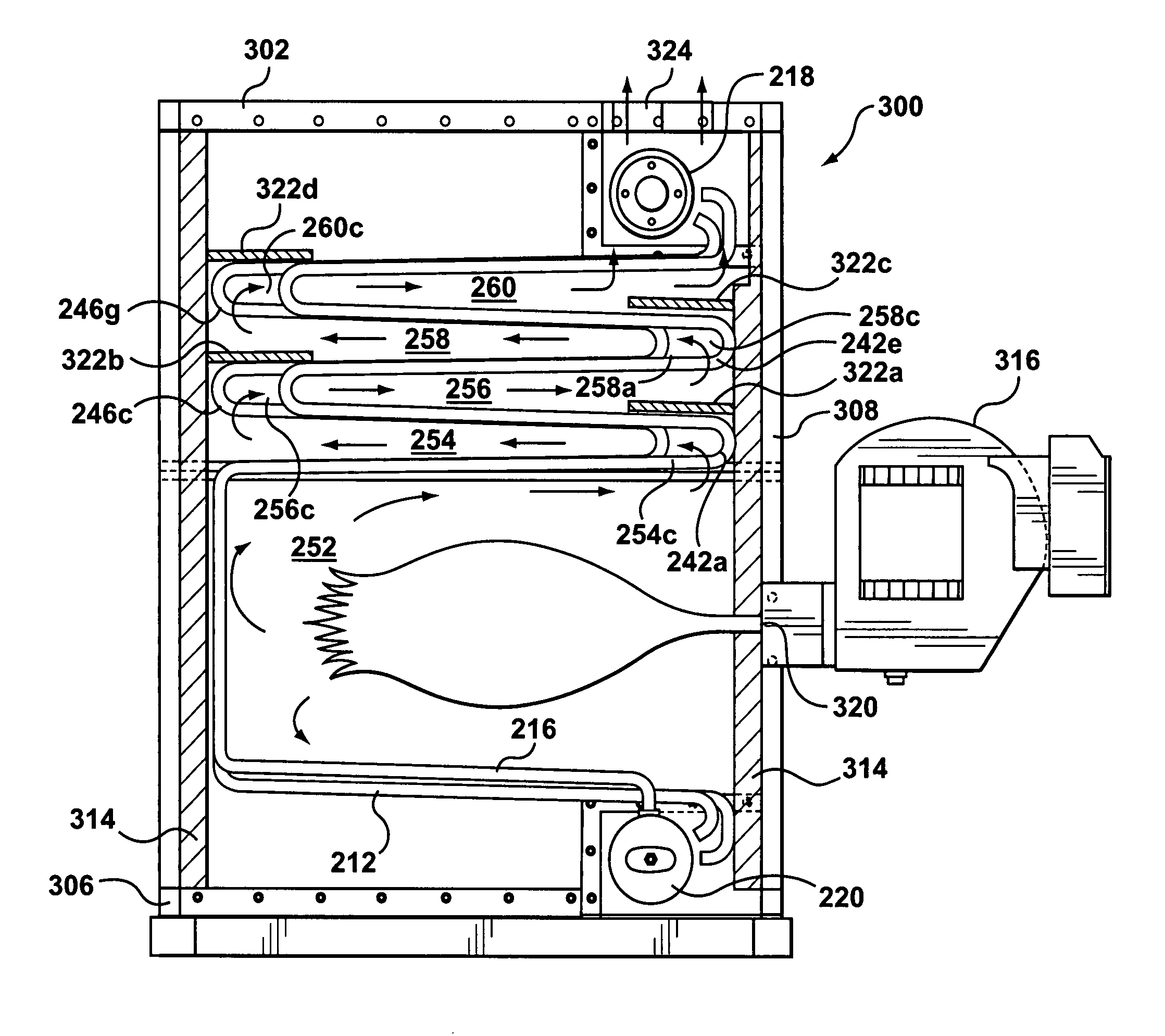

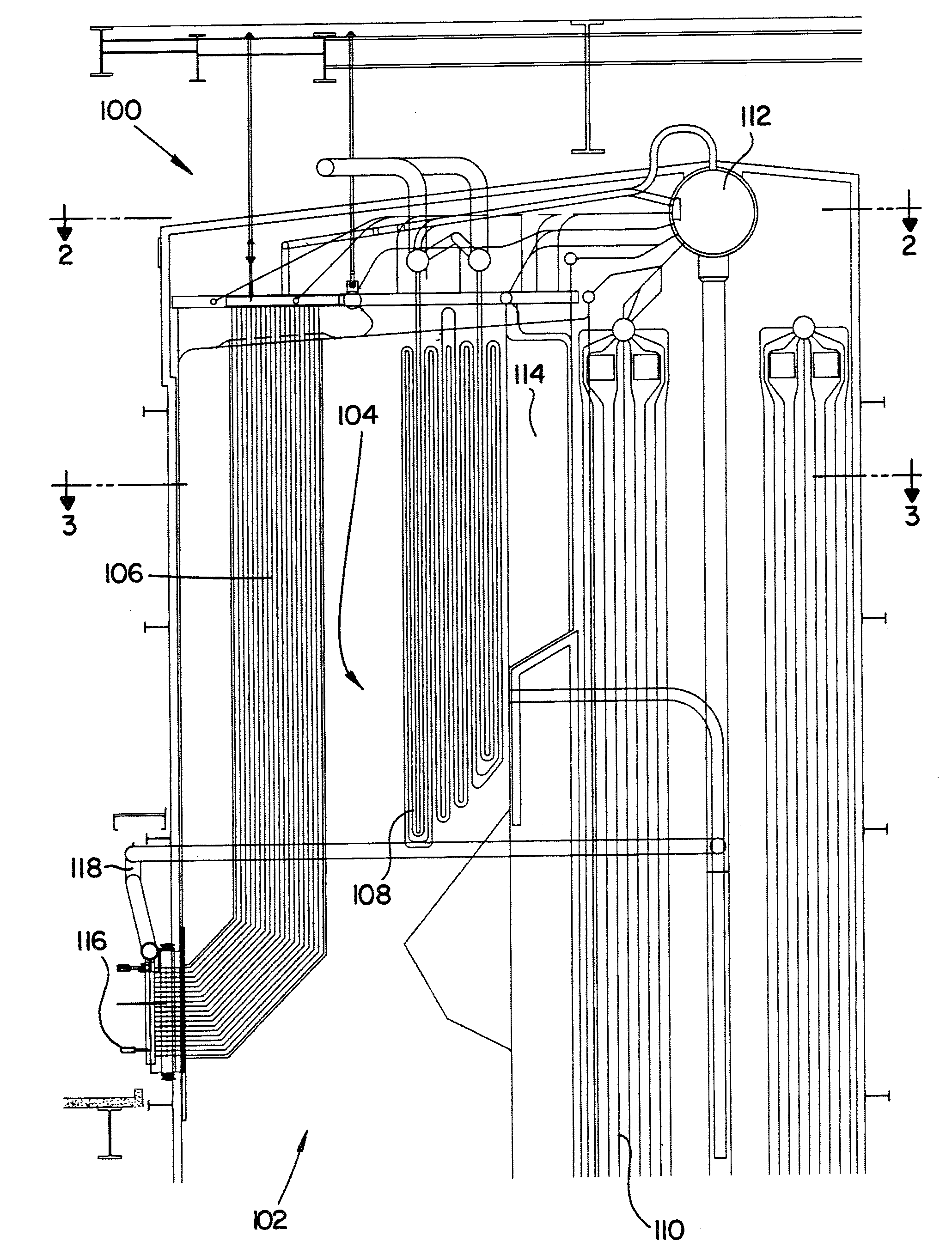

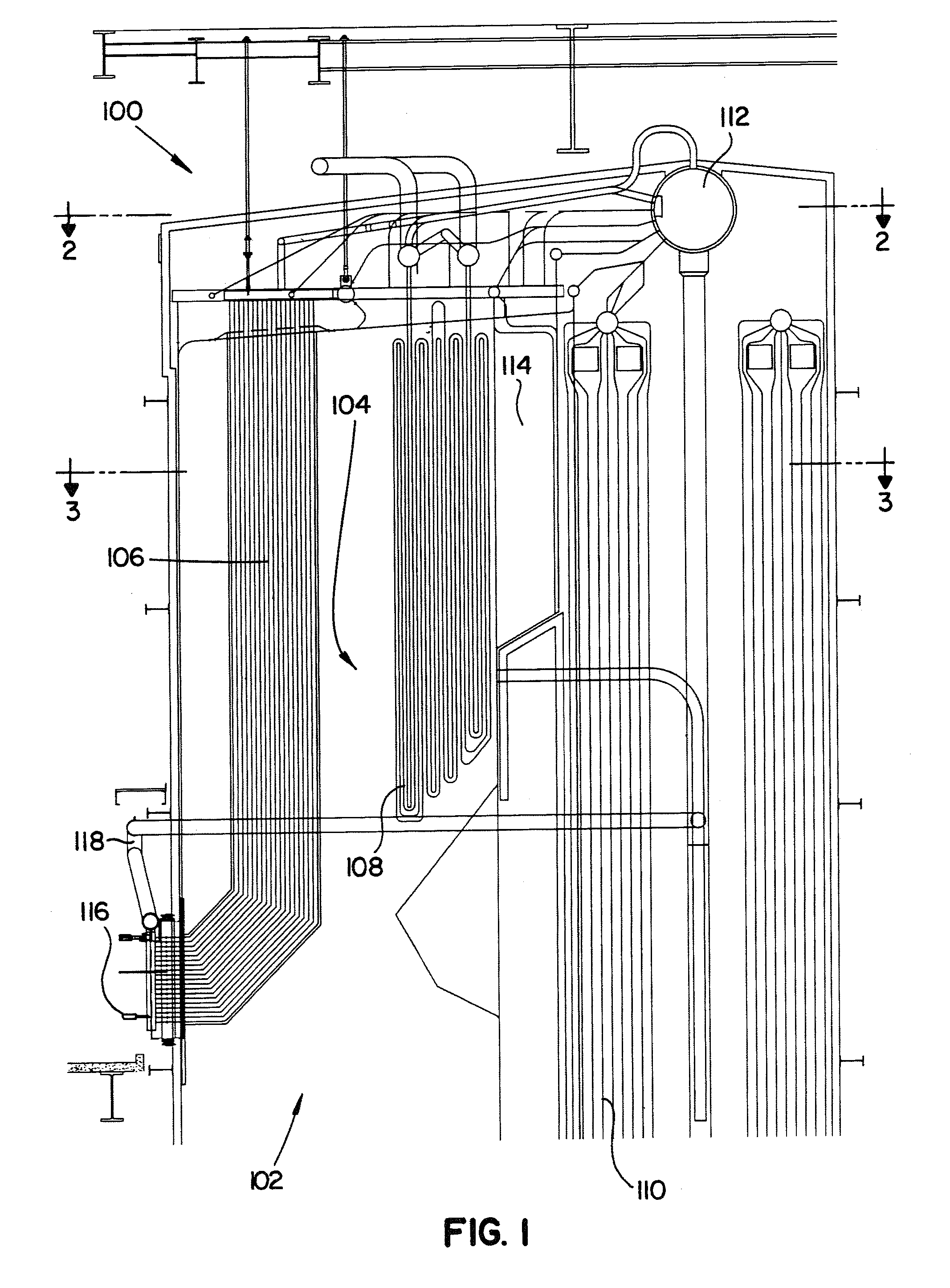

Municipal solid waste fuel steam generator with waterwall furnace platens

ActiveUS20090084327A1Improve heat transfer performanceFurnace exit gas temperatureSolid waste disposalBoiler cleaning apparatusCombustionProcess engineering

A steam generator includes a furnace configured and adapted to generate a stream of furnace exit gases from the combustion of municipal solid waste fuel. At least one superheater is disposed within an upper portion of the furnace or backpass. The superheater is configured and adapted to superheat fluids within the superheater by facilitating heat transfer between fluids within the superheater and furnace exit gases outside the superheater. At least one waterwall furnace platen is disposed within the furnace upstream from the superheater, the waterwall furnace platen is configured and adapted to lower furnace exit gas temperature at the superheater by facilitating heat transfer between fluids within the waterwall furnace platen and furnace exit gases outside the waterwall furnace platen.

Owner:RILEY STOKER +1

Flue gas energy transfer system

A flue gas energy transfer system for increasing the efficiency of hot-water and / or steam boiler. They system utilizes an arrangement of heat transfer ducts with damper elements for the selective diverting exhaust combustion gases. The heat transfer ducts transmit the exhaust gases for contiguous contact with the boiler for conductive heat transfer. The heated gases are retained within the transfer duct after boiler shutdown for maintaining an elevated water temperature.

Owner:ZAYAS CARLOS

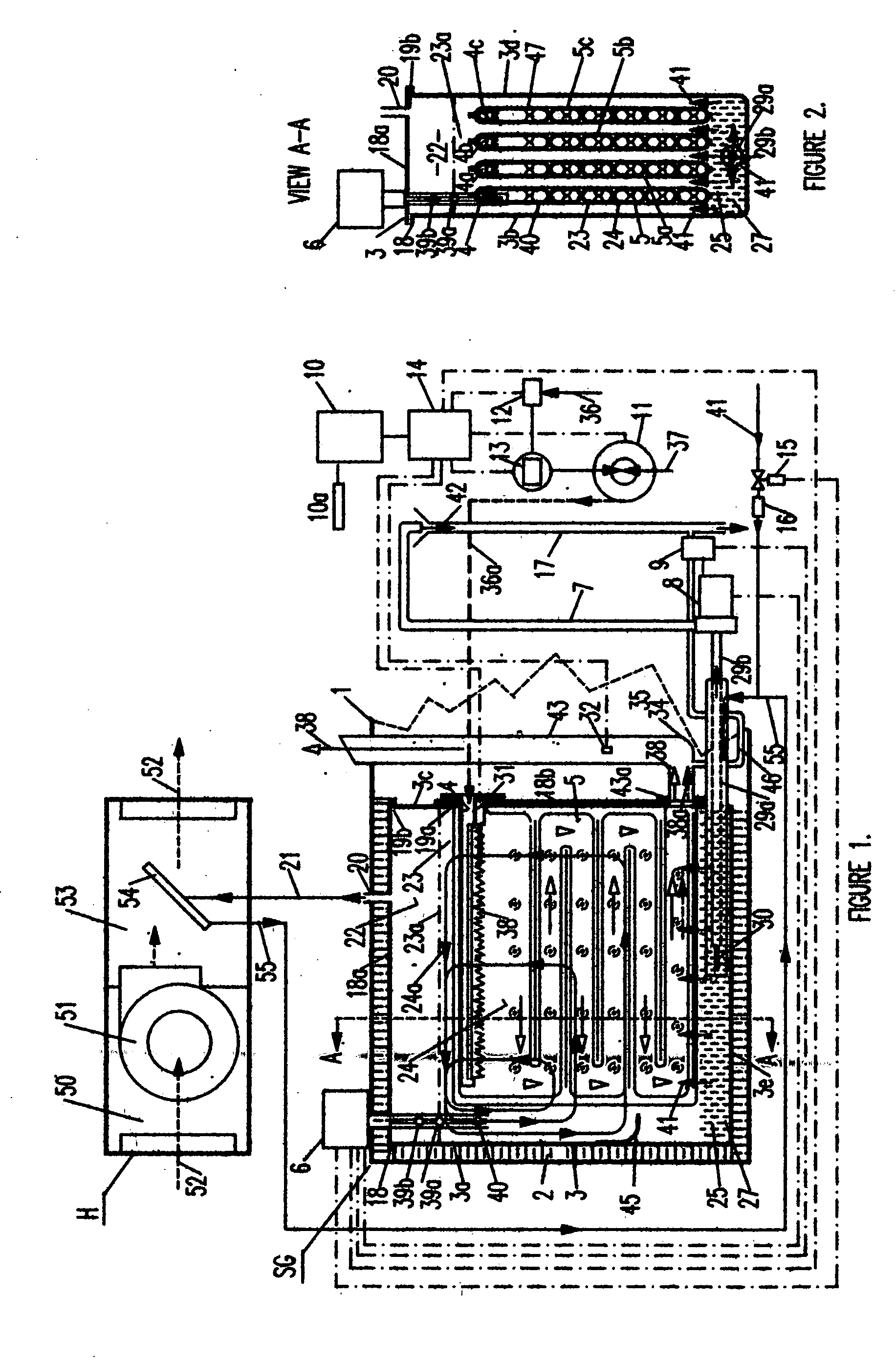

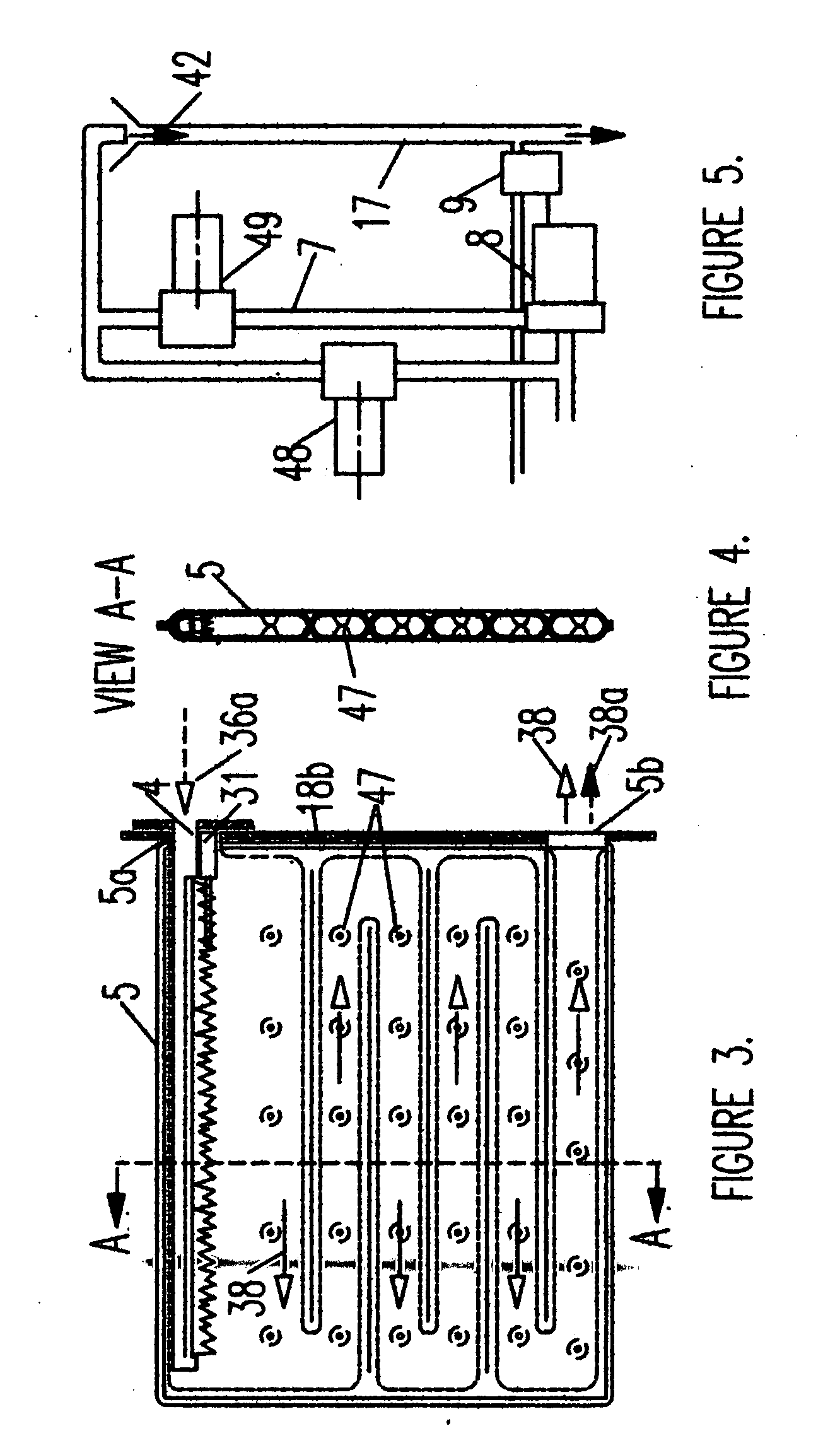

Compact high efficiency gas fired steam generator-humidifier

InactiveUS20060249099A1Low pour pointEliminate condensation of moistureBoiler water tubesSteam separation arrangementsHigh rateOperating energy

A compact gas fired steam generator comprises a water tank with designated steam separation zone, boiling zone and a solids separation zone, a burner for burning gaseous fuel with air for producing combustion products and a flat tubular type heat exchanger immersed in water in the water tank. The combustion products are passing through the heat exchanger in an indirect heat transfer relationship with water in boiling zone thereby boiling, circulating and evaporating the water in boiling zone and in an indirect heat transfer relationship with cold make up water passing upwardly through solids separation zone thereby preheating cold make up water and cooling combustion products and recovering latent heat and condensing moisture present in combustion products. The cooled combustion products are discharged to outdoors and the collected condensed moisture is discharged to drain. The produced steam is separated from the boiling water in steam separation zone, the solids present in the boiling water are separated from the circulating boiling water and accumulated in solids separation zone and the accumulated solids are cooled by the incoming cold make up water and intermittently discharged from solids separation zone by a water pump together with the incoming cold make up water to drain. The high rate internal circulation of boiling water, the extended self cleaning heat transfer surfaces of the flat tubular type heat exchanger immersed in the boiling water, the recovery of latent heat from flue gases and the discharge of cooled solids with cold make up water provide an exceptionally compact steam generator with overall thermal efficiency of up to 95% and with maintenance free unattended operation. The compact steam generator can be used in humidifying of space air in buildings, in heating of air in domestic central air heating systems and in industrial processes requiring clean steam.

Owner:BESIK FERDINAND K

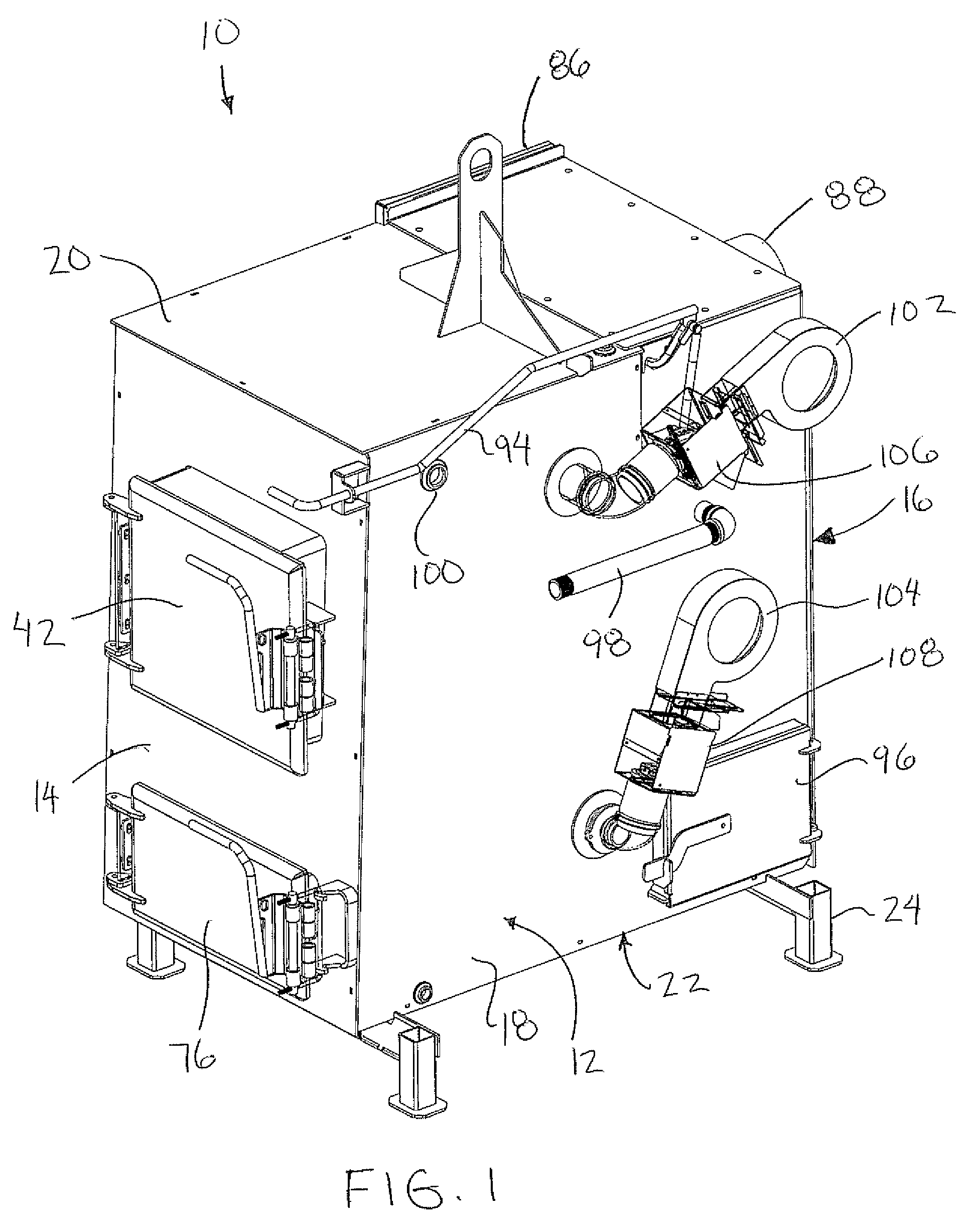

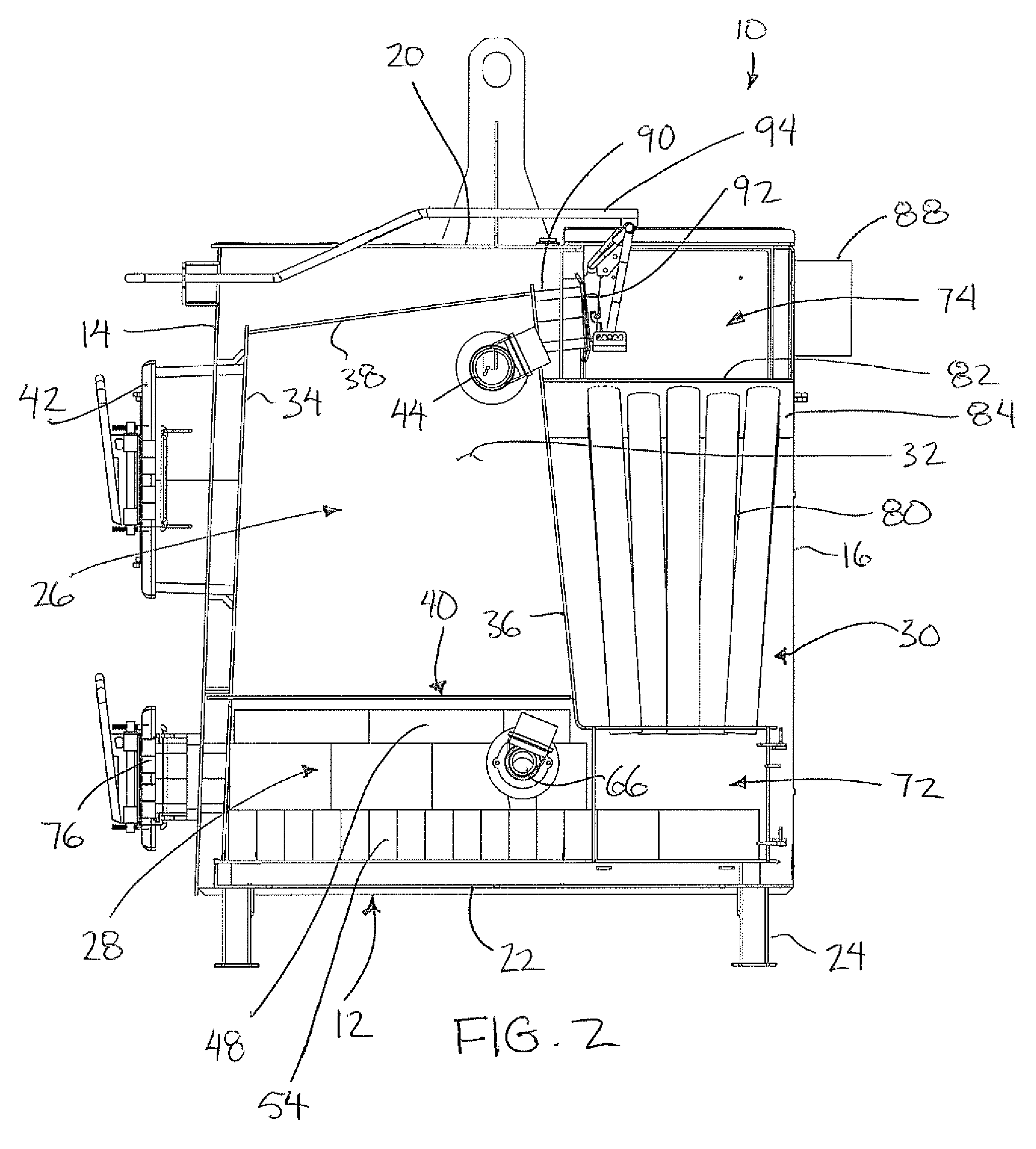

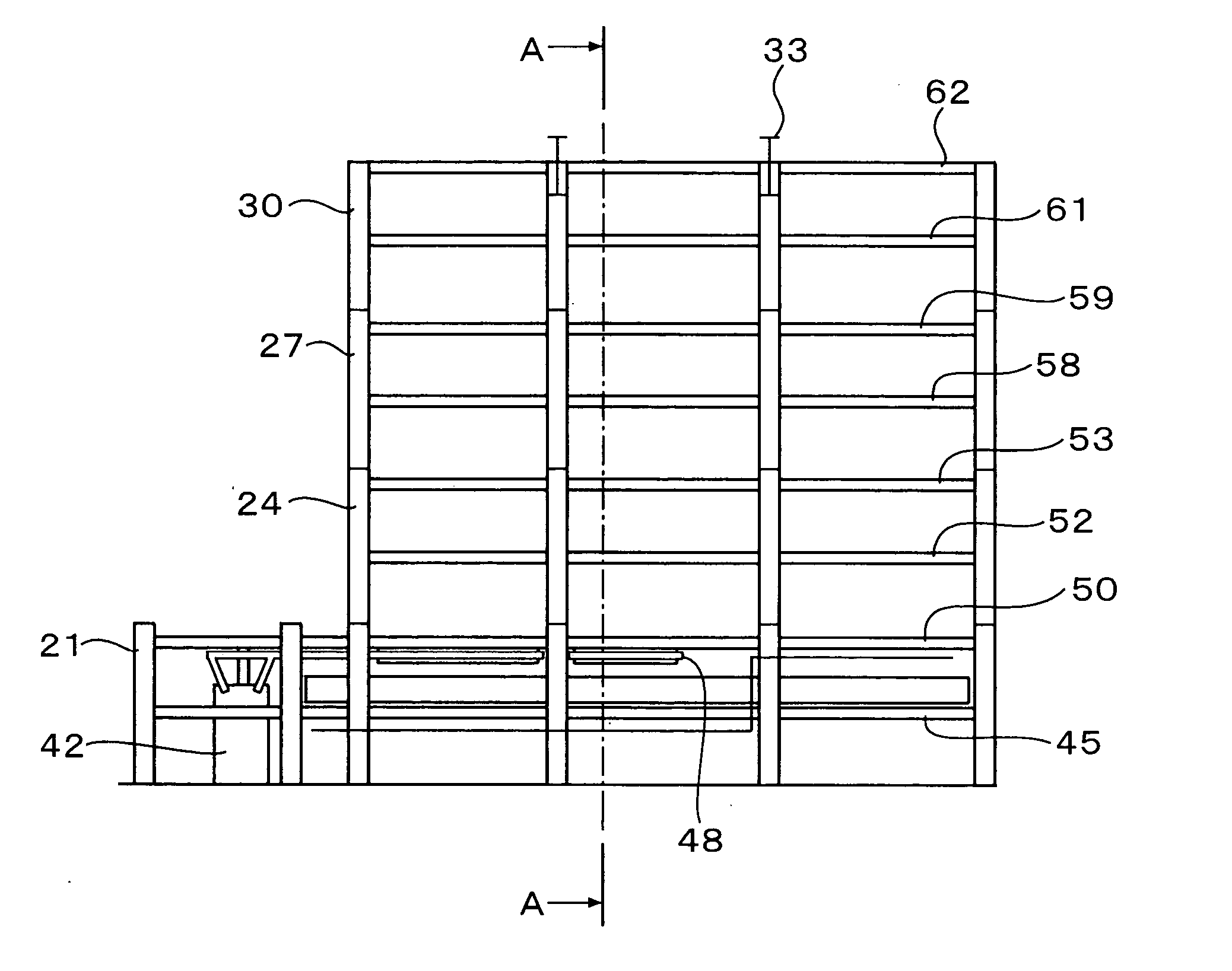

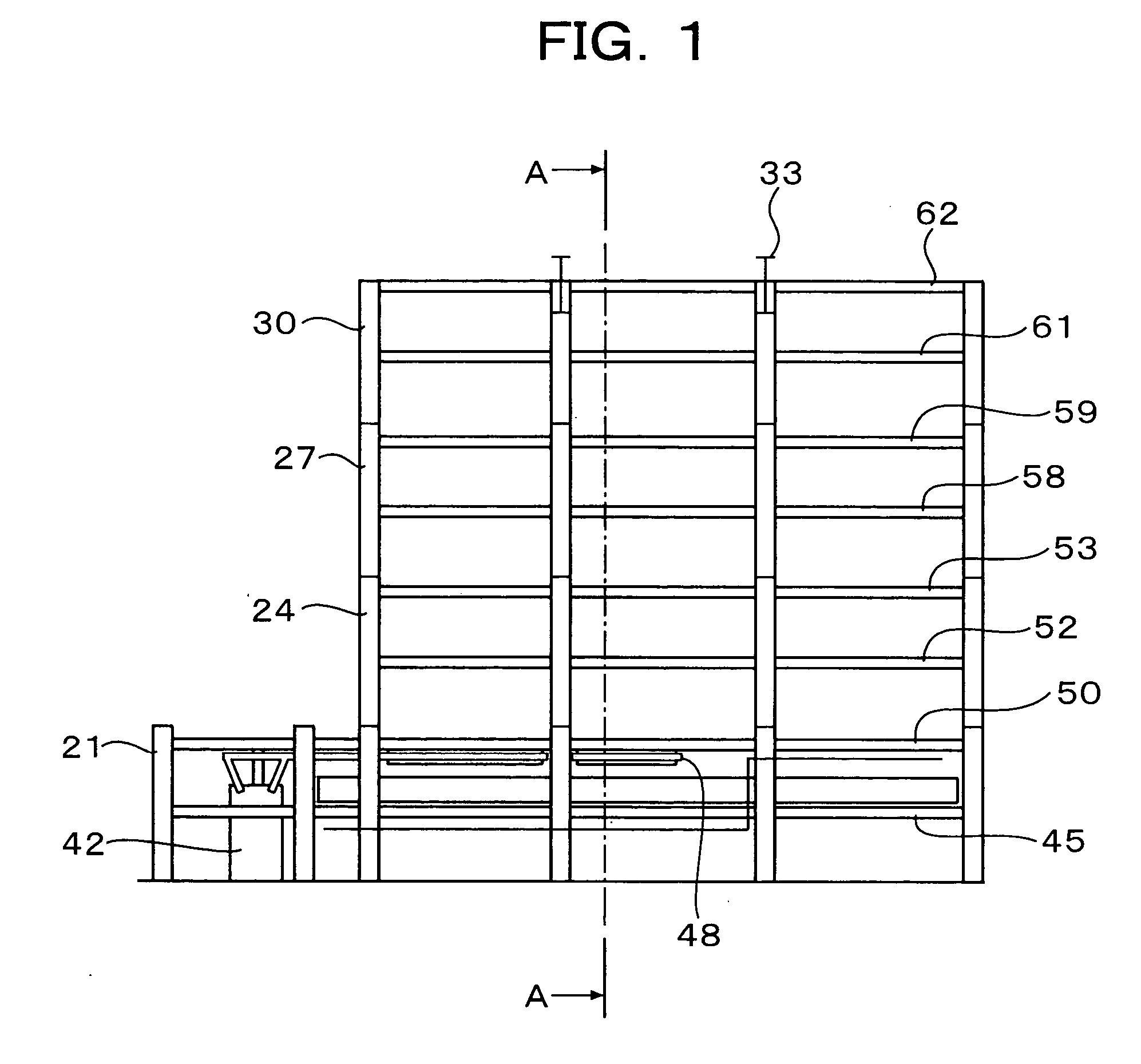

Solid Fuel Boiler Assembly

InactiveUS20100083883A1Prevent air flowImprove sealingAir supply regulationBoiler controlCombustion chamberSolid fuel

A boiler assembly including primary and secondary combustion chambers includes primary and secondary air controls for controlling combustion air to the chambers respectively. The air controls are operable between open positions to allow combustion in the chambers and a closed position in which the combustion air passages are fully sealed to fully interrupt combustion responsive to heating demands. The air controls are supported externally on the main housing of the boiler assembly so as to be modular and readily releasable from the main housing and the respective combustion air passages. The primary combustion chamber communicates with the secondary combustion chamber at a location partway in between introduction of the secondary combustion air and the exhaust passage.

Owner:HOFER NEIL +1

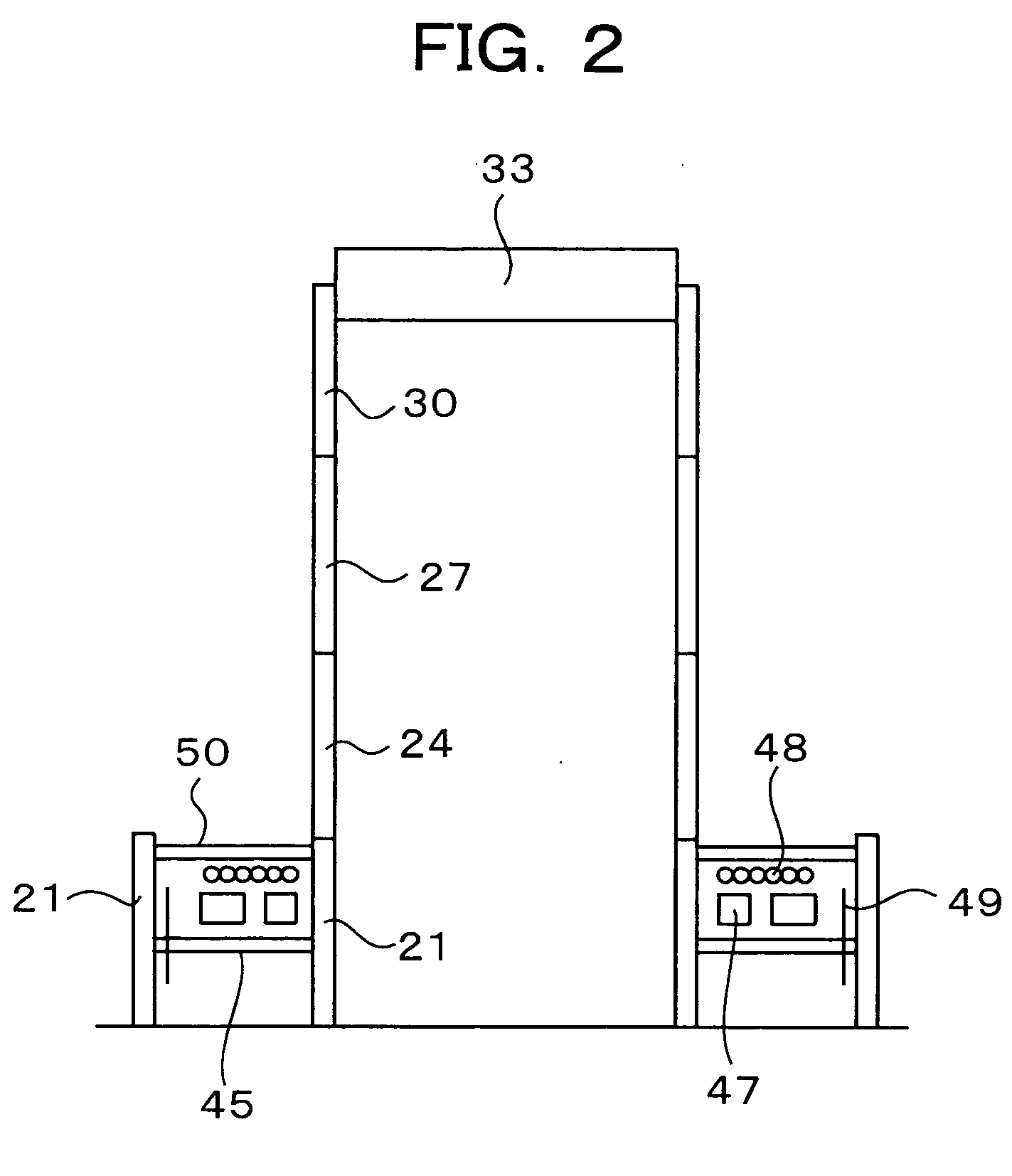

Installation construction method for boiler facilities

ActiveUS20070089296A1Shorten the construction periodBoiler supporting/setting arrangementsAssembly machinesEngineeringBuilding construction

Owner:MITSUBISHI POWER LTD

System and Method for Zero Emissions, Hydrogen Fueled Steam Generator

InactiveUS20080223315A1Easy to completeEfficient heatingBoiler flue tubes/fire tubesSteam superheatersOxygenCarbon-based fuel

As we move towards a hydrogen economy or use hydrogen as an energy carrier, the need to get heat energy and steam out of the hydrogen is arising more frequently. This invention addresses that need without the atmospheric pollutants which would result from burning carbon based fuels or hydrogen freely in the air. Presented is an invention which has very high overall efficiency and generates no oxides of carbon and nearly zero nitrogen oxide compounds. The generated steam can be used for comfort heating, process heating, electric generation and other common applications requiring steam. The invention can also be used for generation of hot water. The process of steam generation is accomplished by precisely metering the mixing and oxidation of hydrogen and oxygen under controlled conditions. The result of this oxidation reaction is simply only water and heat, which are used to generate steam.

Owner:DOLAND GEORGE

Compact high efficiency gas fired steam generator-humidifier

InactiveUS7281498B2Maintenance freeEliminate condensationBoiler water tubesFuel injection apparatusHigh rateOperating energy

Owner:BESIK FERDINAND K

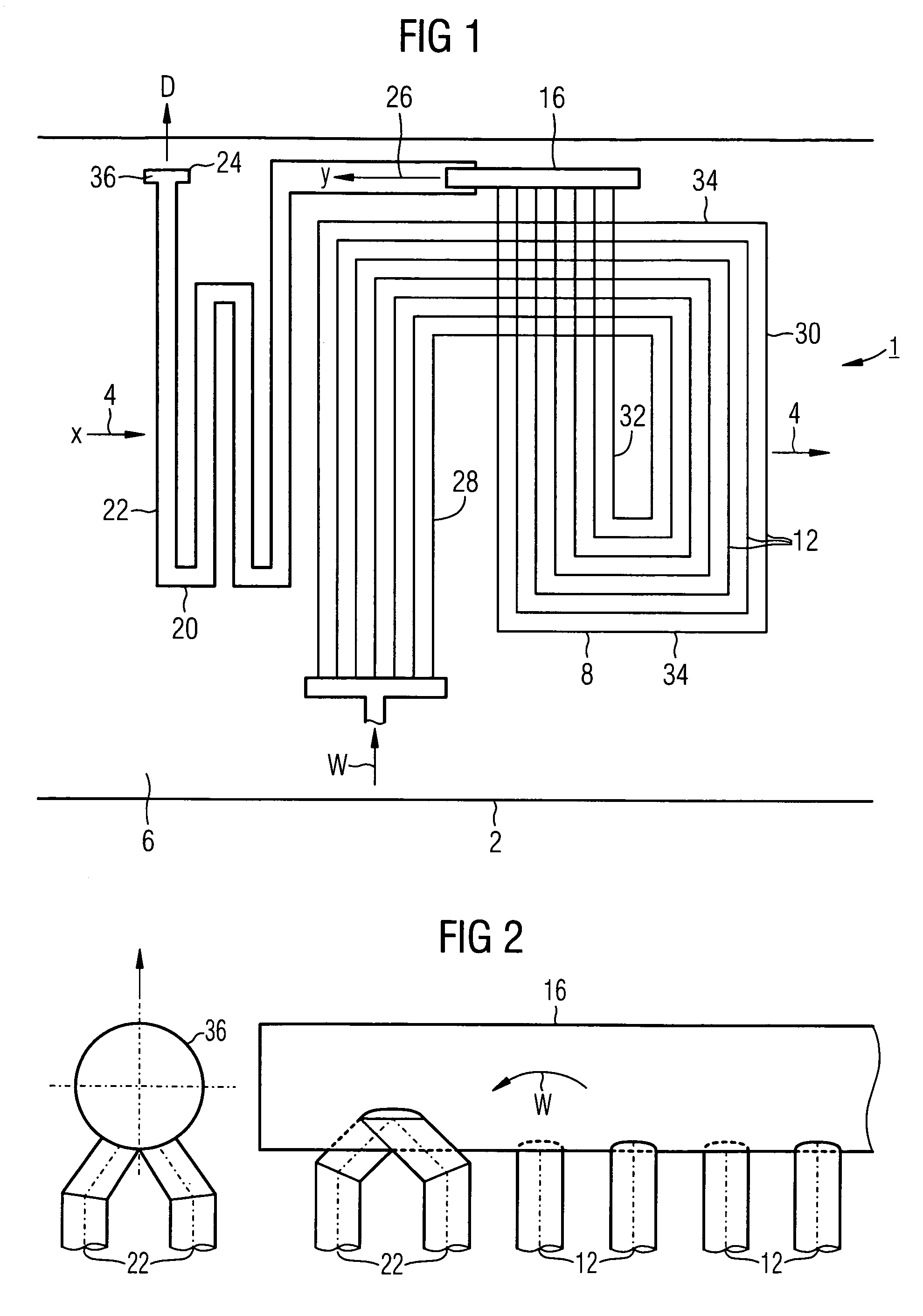

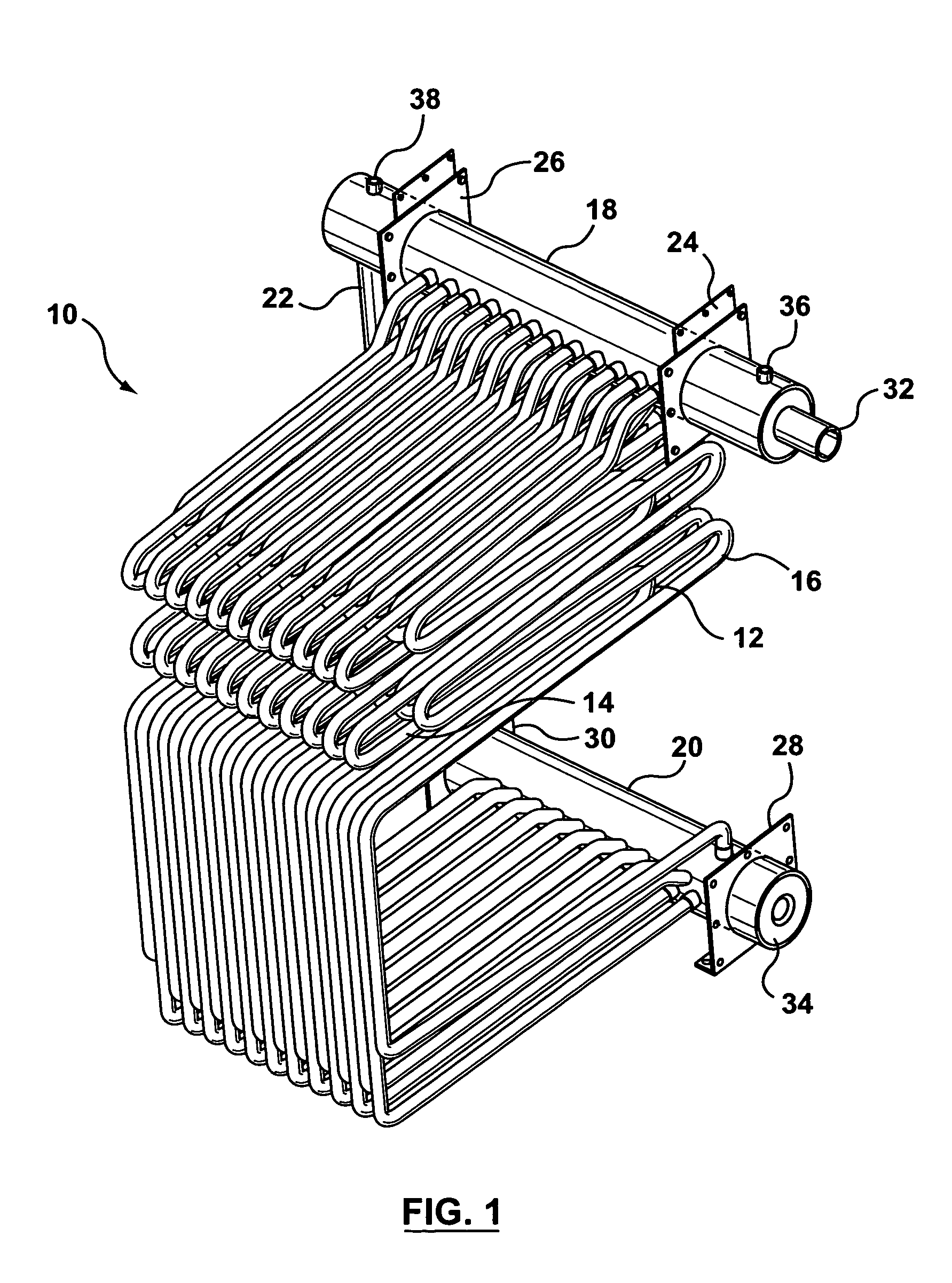

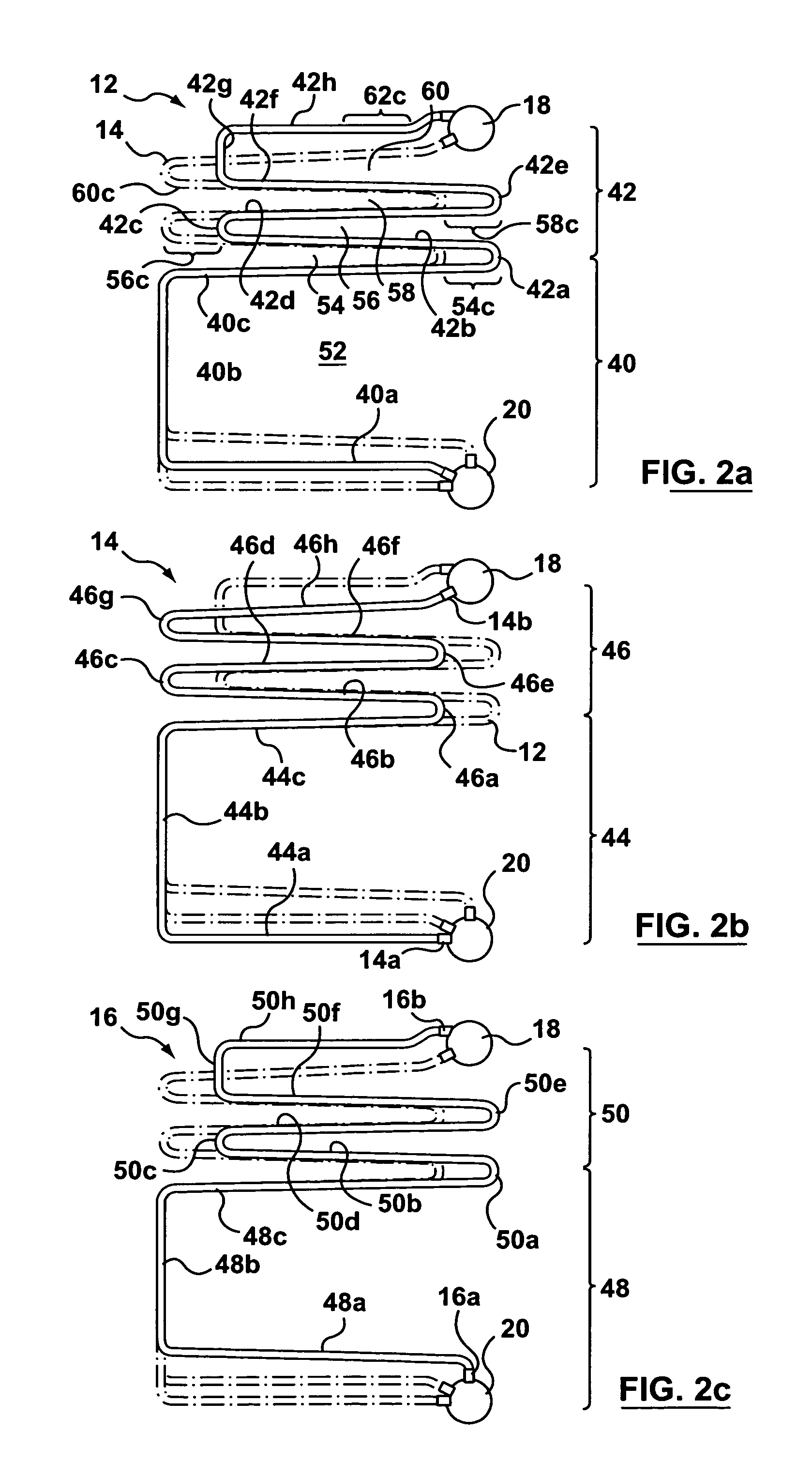

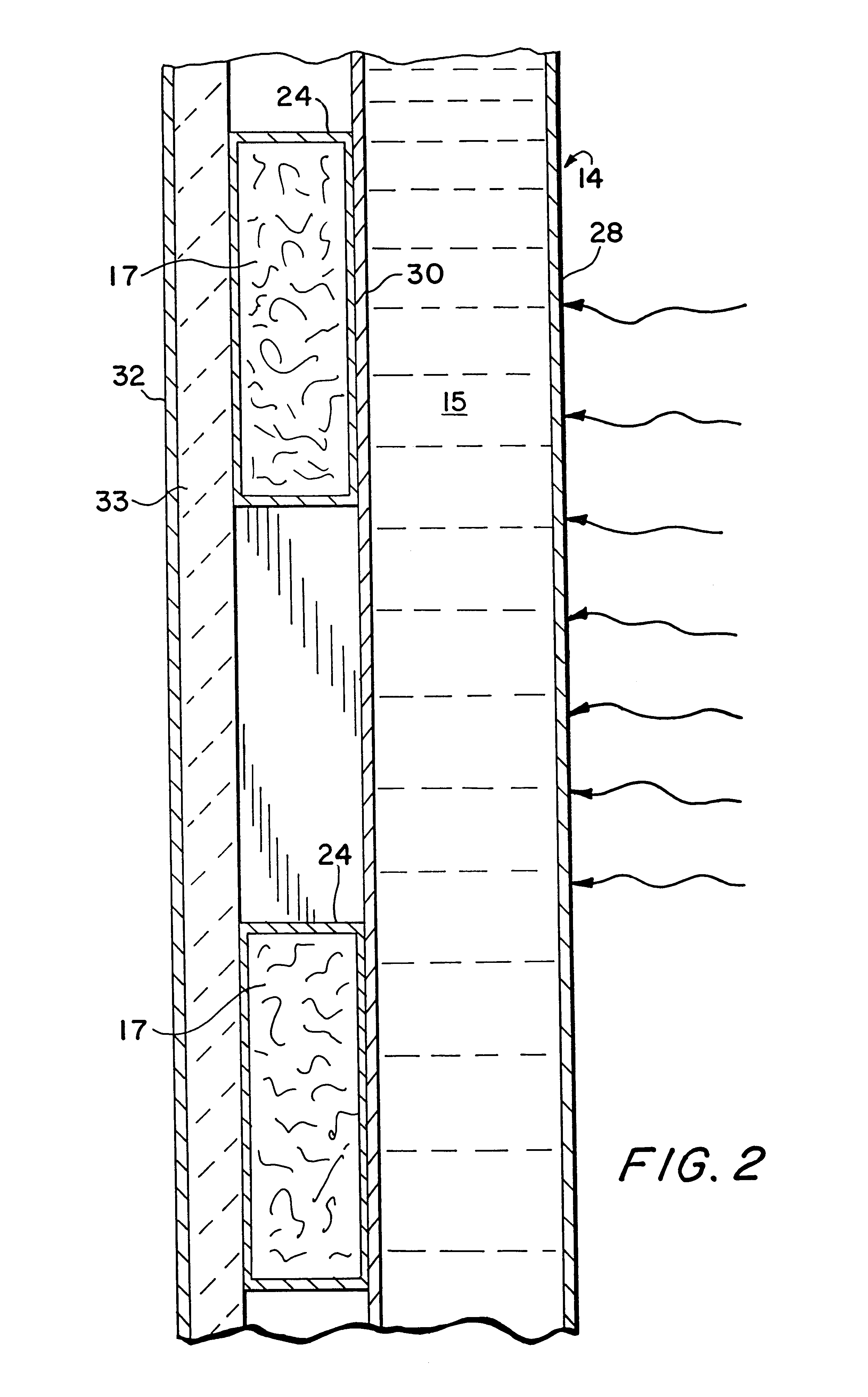

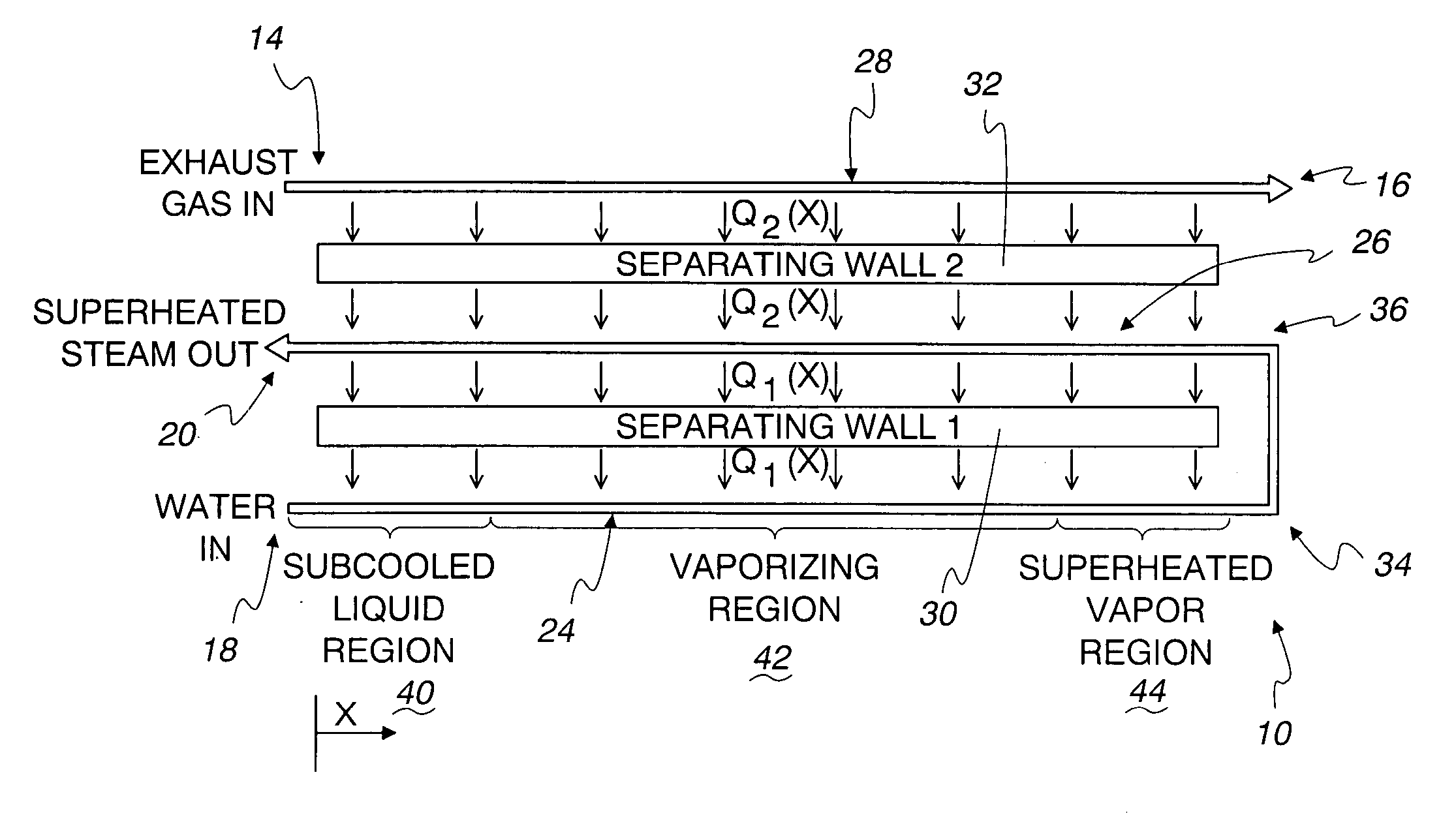

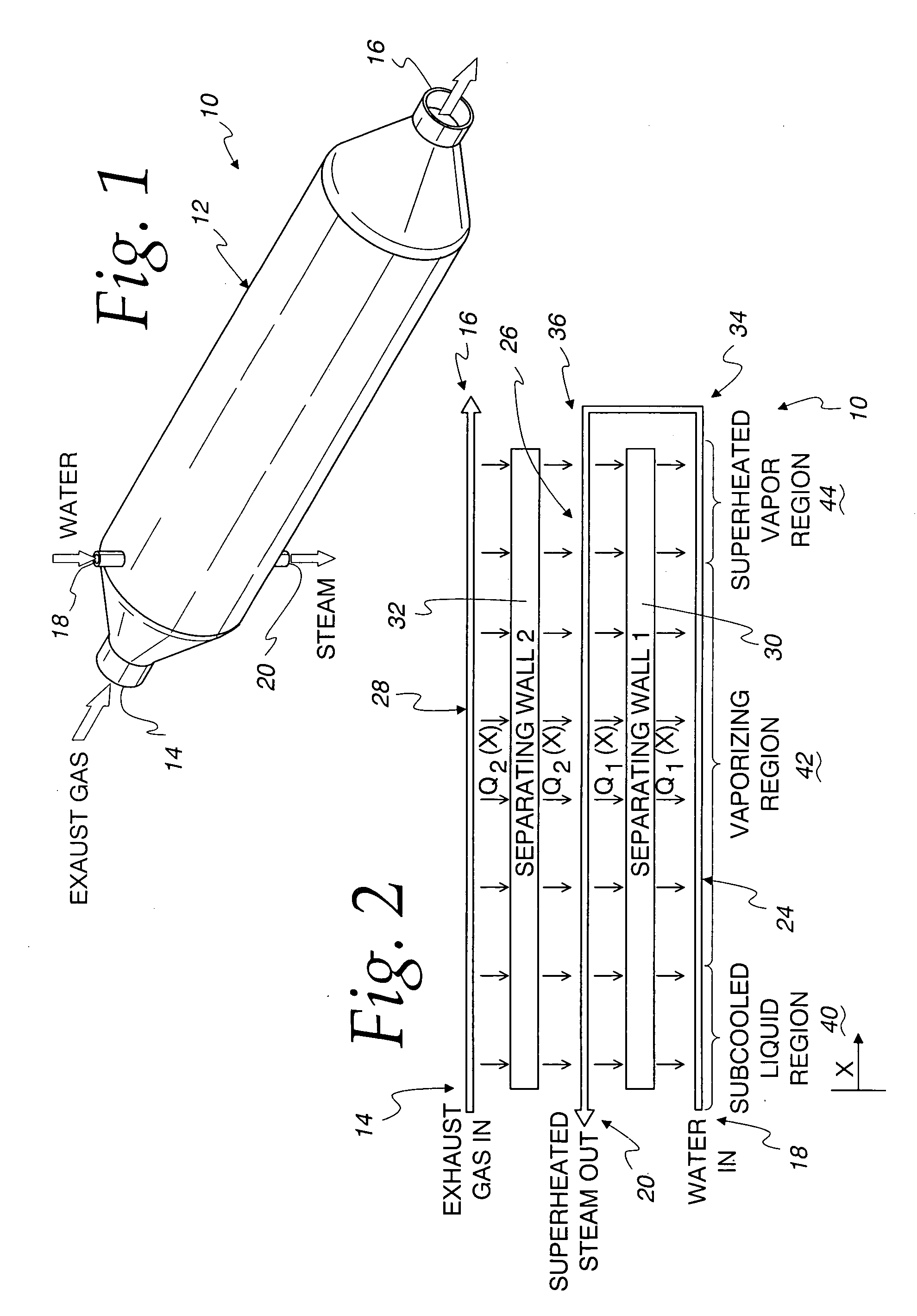

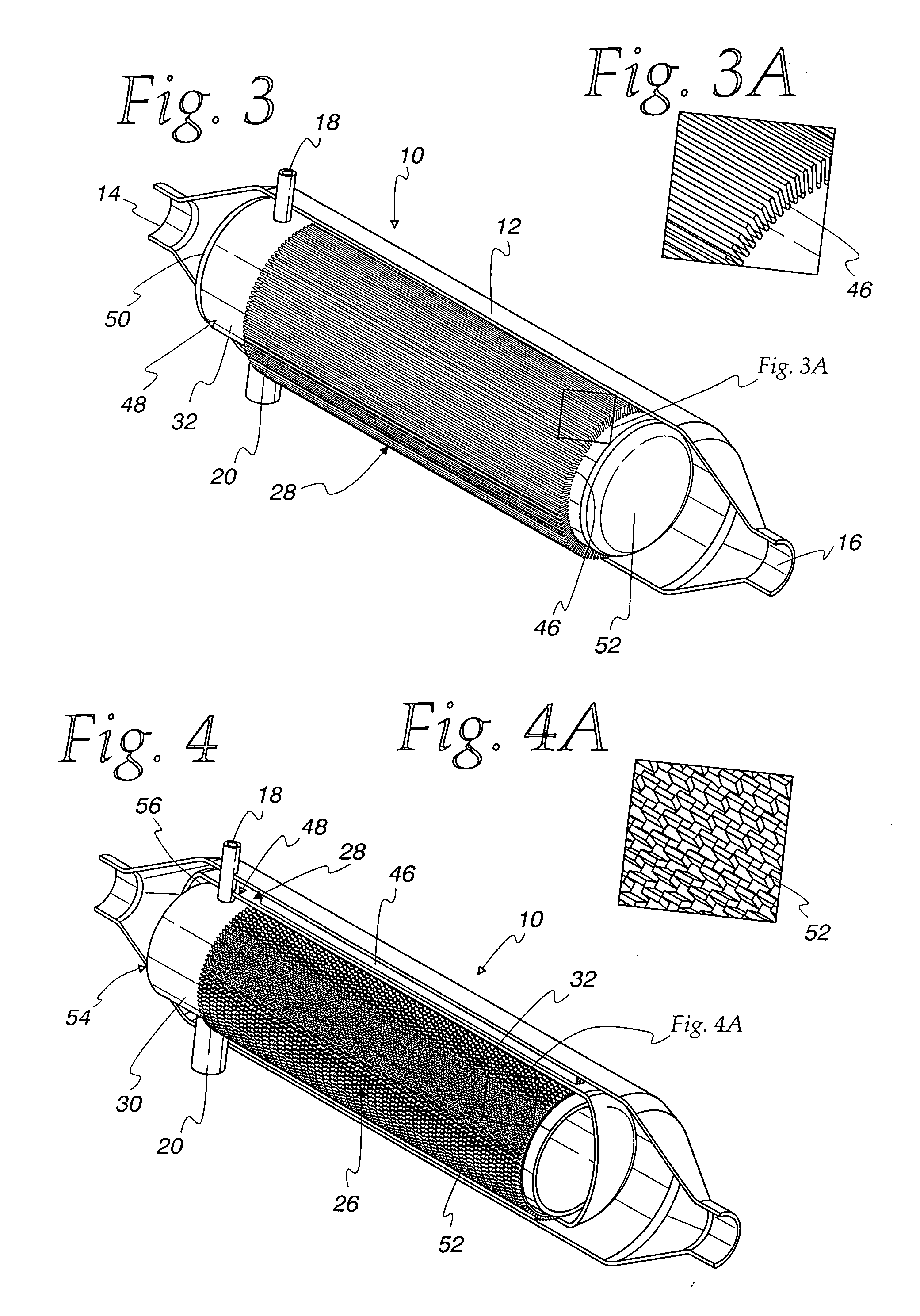

Water vaporizer with intermediate steam superheating pass

InactiveUS20070039725A1Reduce thermal stressEliminate pressure-induced stressSteam generation heating methodsCombustion technology mitigationThermal energyEngineering

A vaporizing heat exchanger (10, 68) is provided for vaporizing a fluid flow using a thermal energy containing flow. Flow paths (24, 26, 28) for each of the fluid flow and the thermal energy containing flow are located relative to each other such that the fluid flow makes multiple passes wherein the fluid is vaporized and subsequently superheated.

Owner:MODINE MFG CO

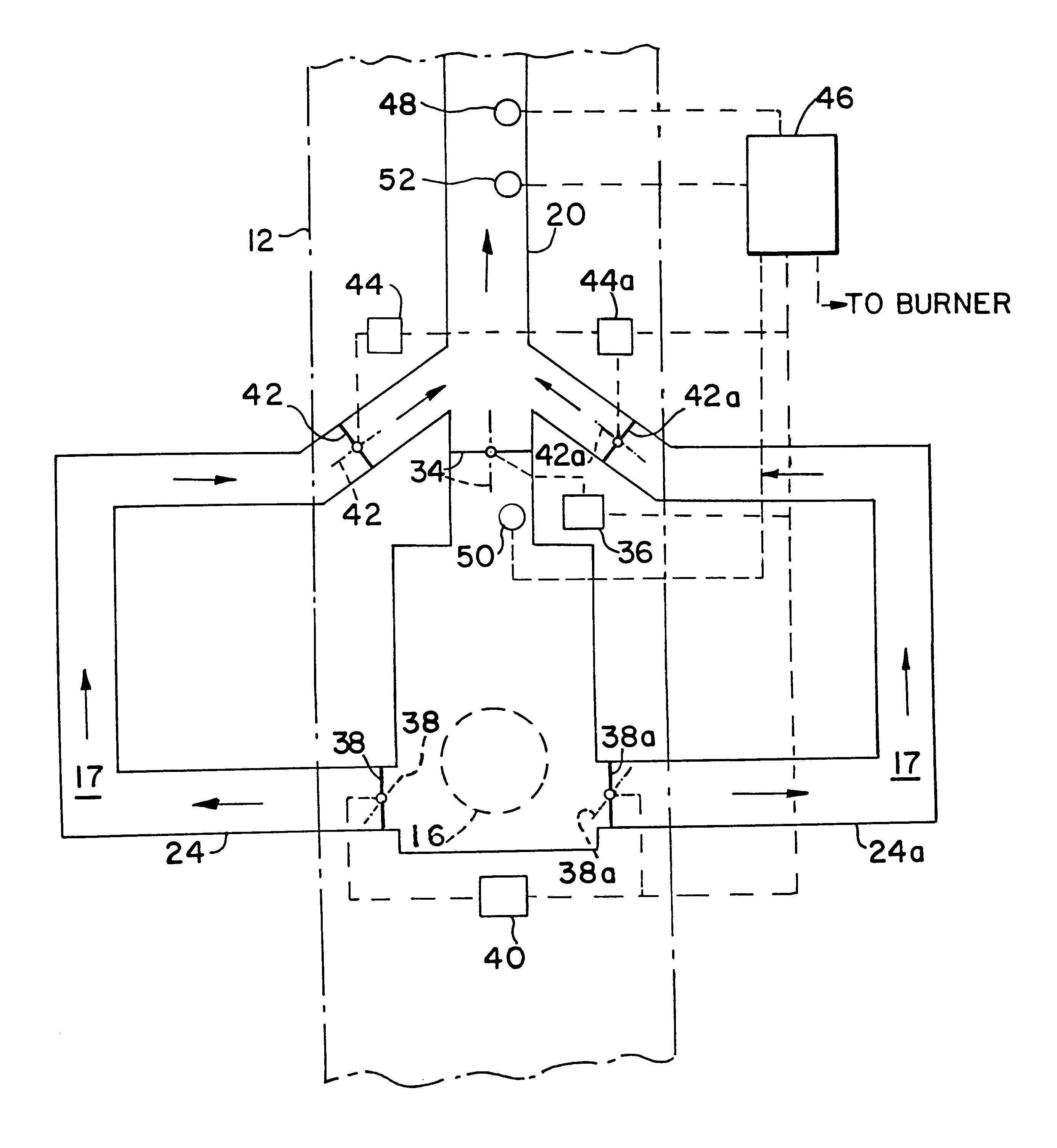

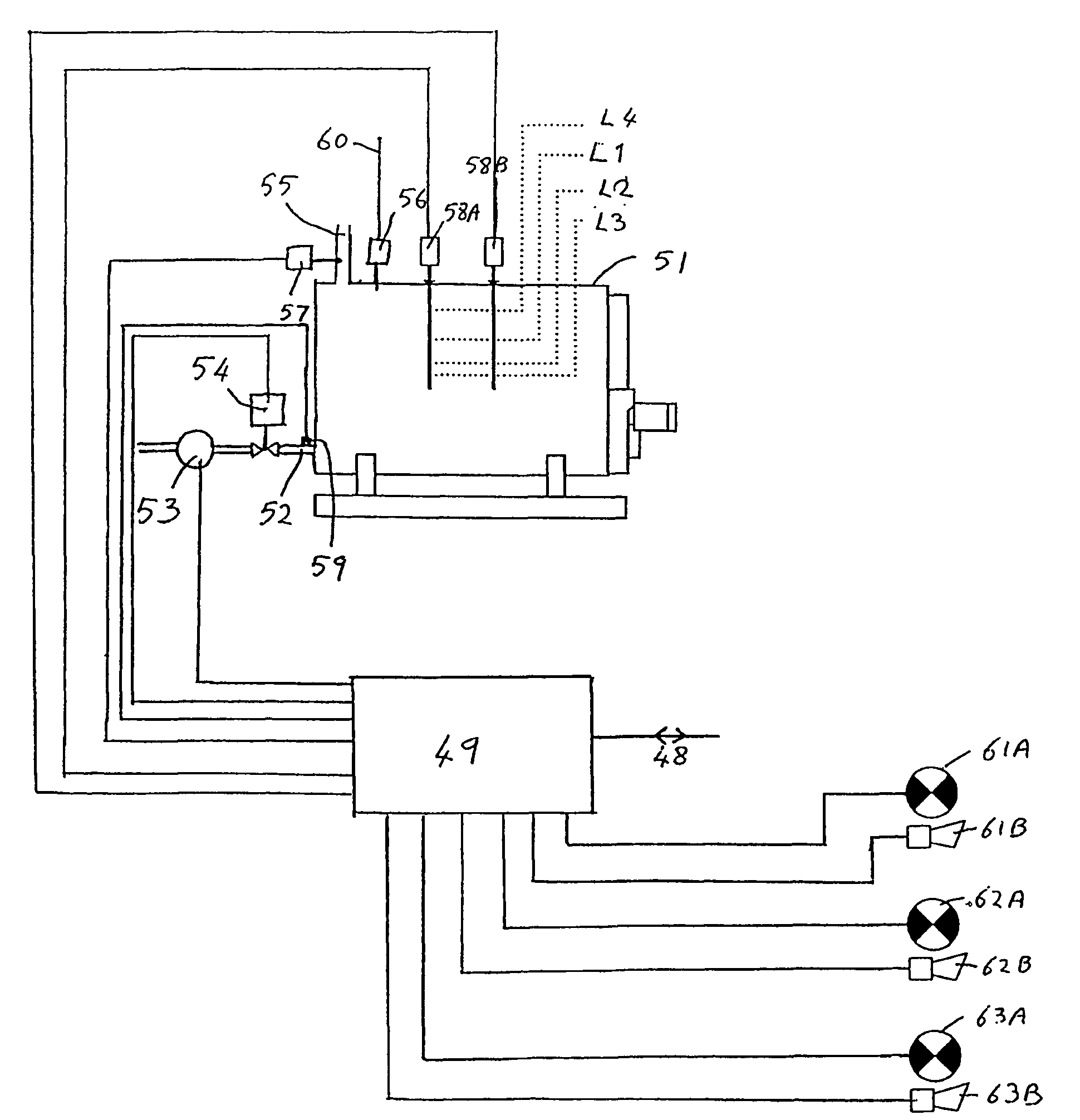

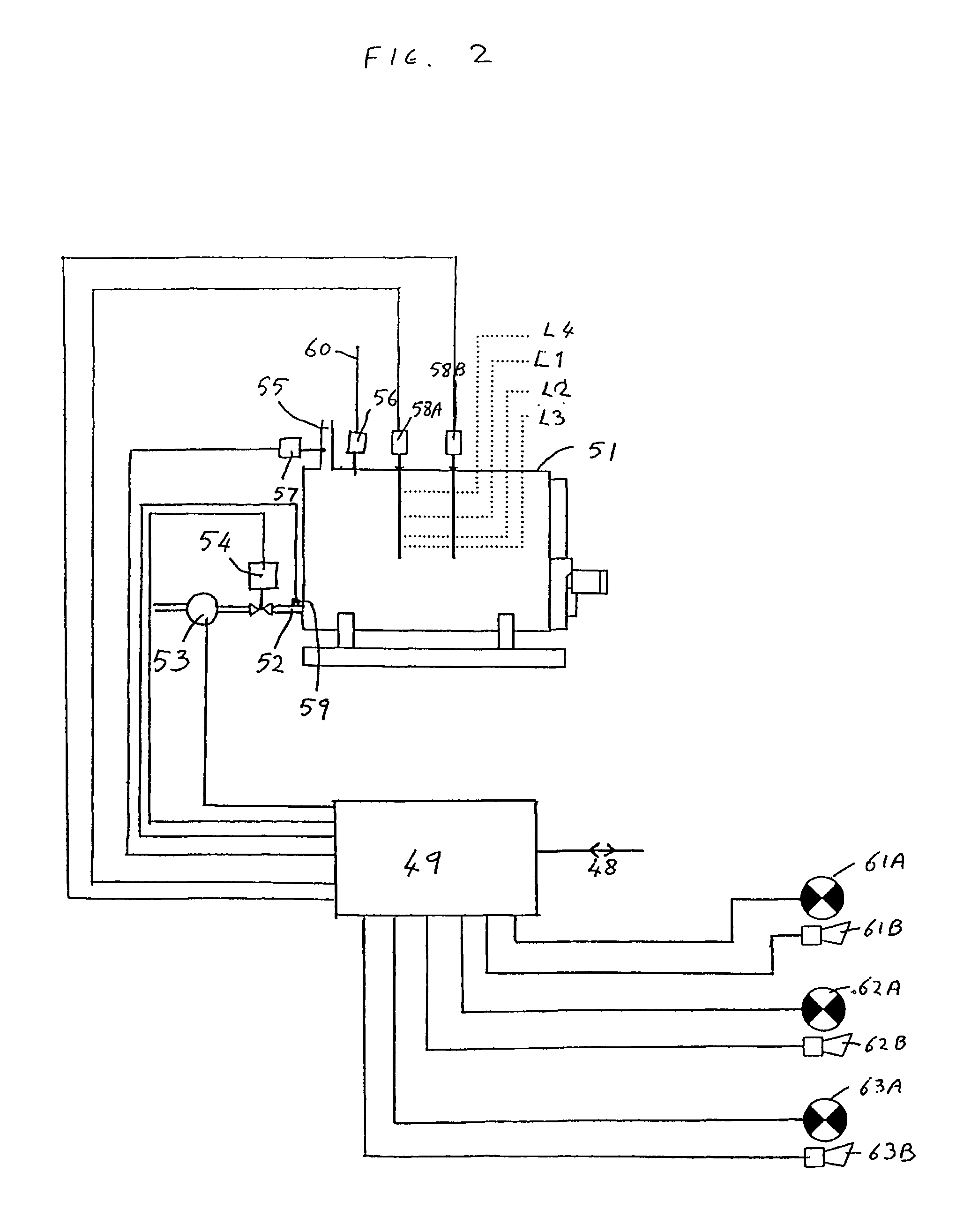

Pressurized steam boilers and their control

InactiveUS7249573B2Reduce probabilityImproved and simplifiedMachines/enginesFuel injecting pumpsCombustorEngineering

A method of controlling the operation of a pressurised steam boiler (50) heated by a burner (20), which includes the steps of a) monitoring the level of water in the boiler (50), b) monitoring the pressure of steam in the boiler (50), c) monitoring the firing rate of the burner (20), and d) controlling the flow rate of water into the boiler (50) having regard to the signals resulting from a) and b) and, at least for some signal conditions, also having regard to signals resulting from c). The level of water is detected by a pair of capacitance probe assemblies (58A and 58B).

Owner:AUTOFLAME ENG

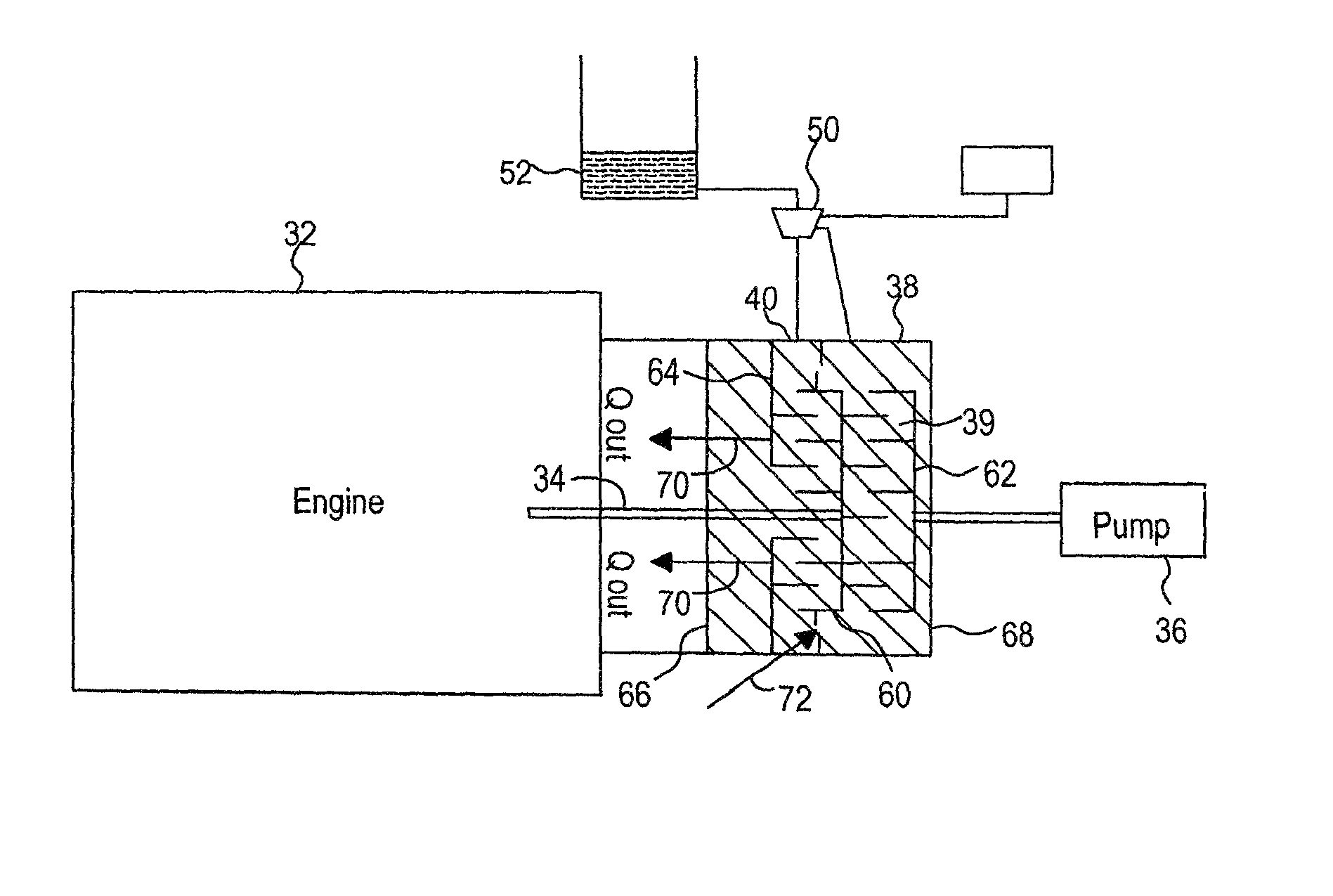

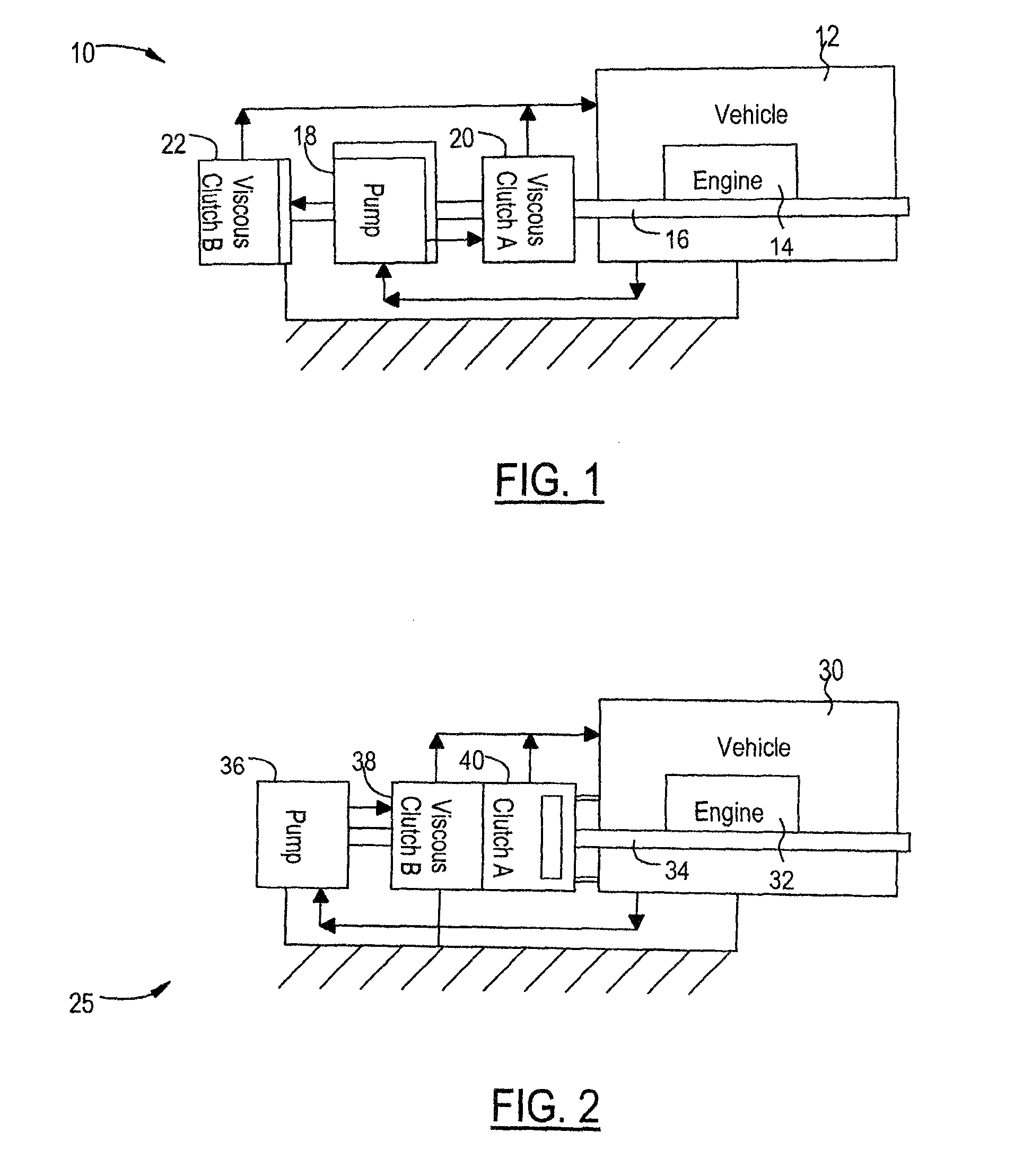

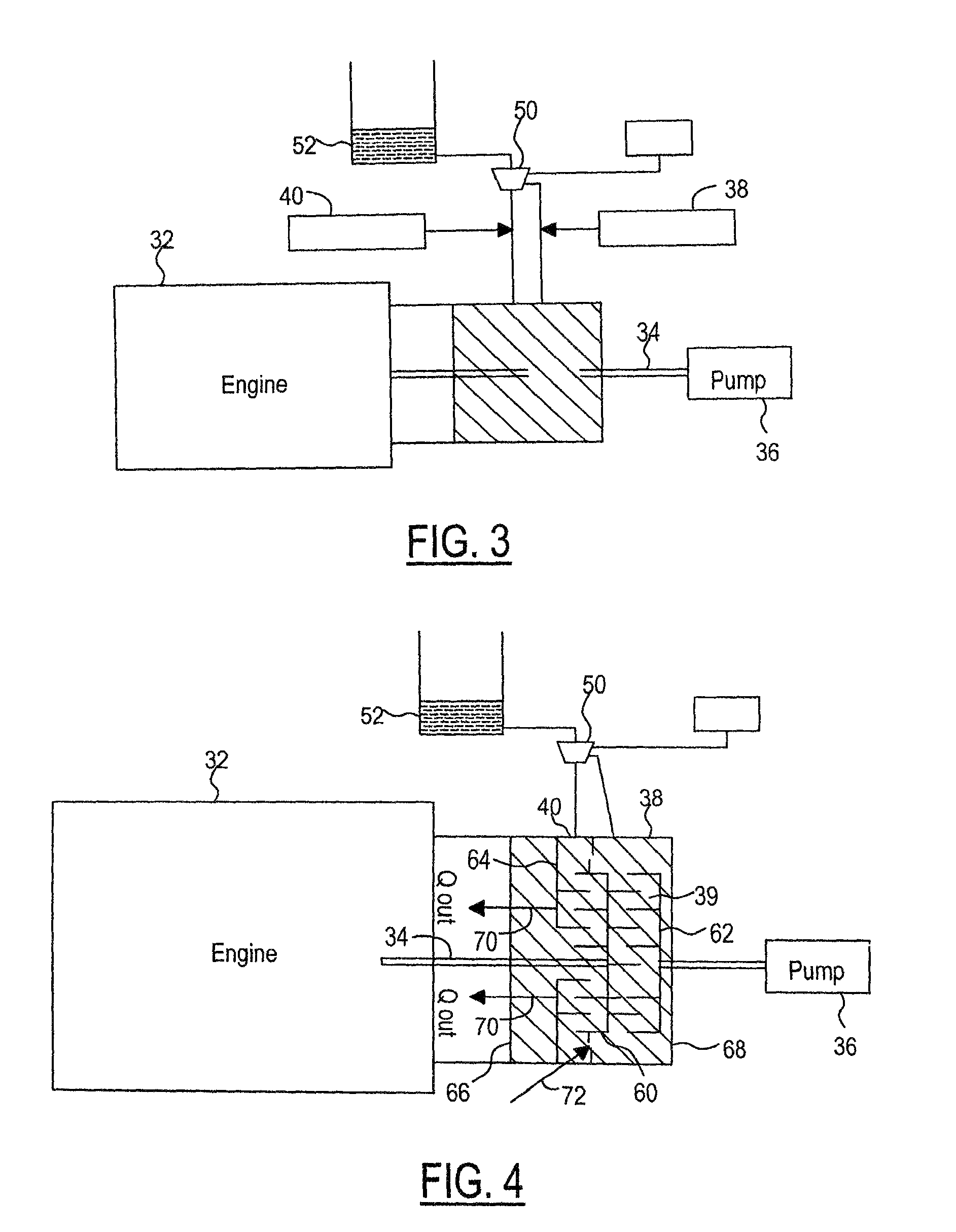

Viscous coolant heater with variable coolant pump drive

A system for supplying supplemental heat to a vehicle, particularly a vehicle with a diesel engine, A driven viscous plate with different viscous clutch faces on either side is provided between the engine and the coolant pump. One side clutches to the engine structure (ground) to generate heat, and the other side clutches to the coolant pump to vary the pump drive. The two sides are controlled by a valve operated by signals from the engine computer. The valve varies the supply of viscous fluid from a common reservoir independently to both sides of the driven viscous plate. The signal from the engine control unit is based on the instantaneous desired supplemental heat and coolant flow. In another embodiment, two separate viscous clutches are utilized and positioned on opposite sides of the coolant pump.

Owner:BORGWARNER INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com