Patents

Literature

61results about How to "Reduce the possibility of explosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

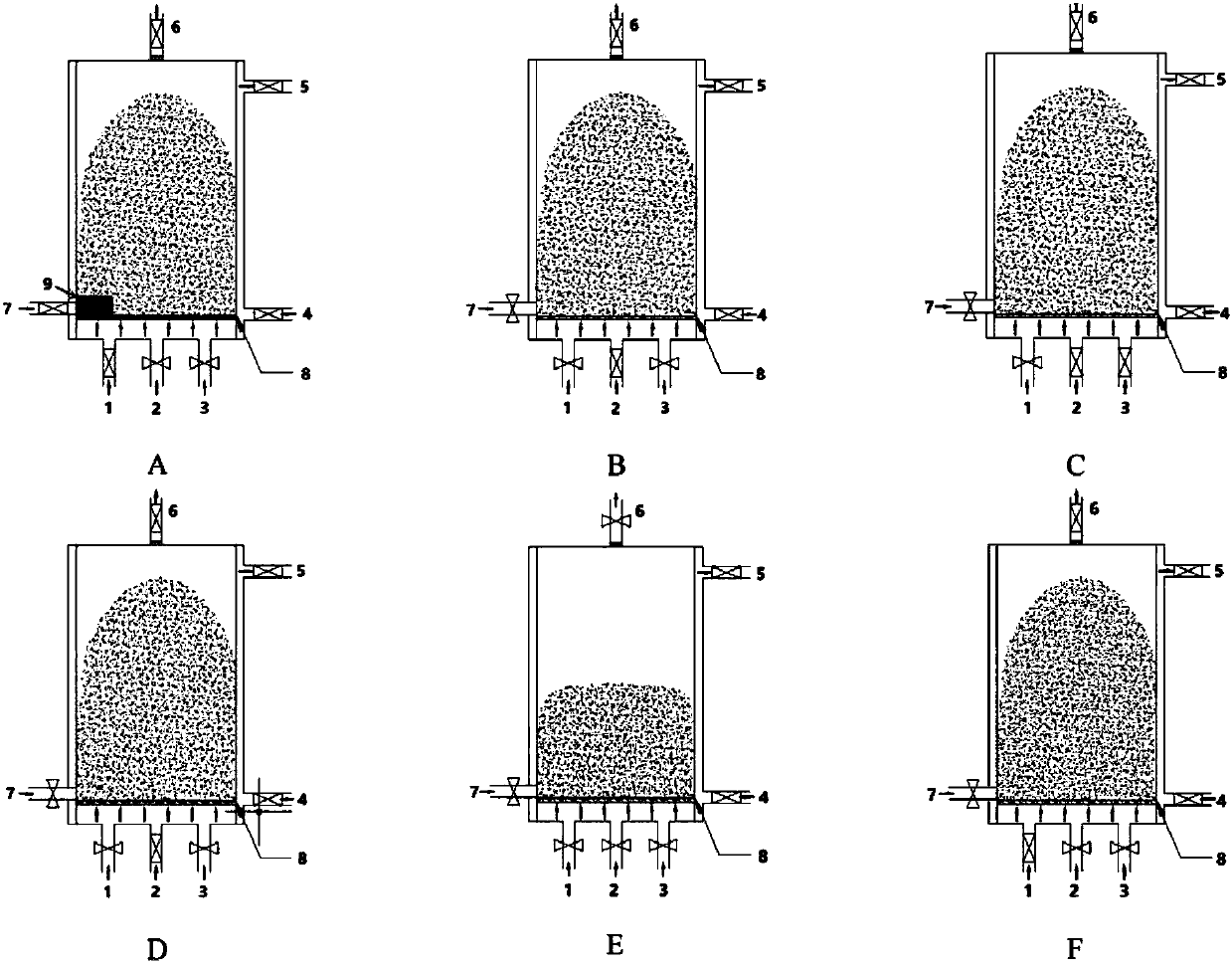

Preenrichment-three segment suspension roasting-magnetic separation treatment method of complex refractory iron ores

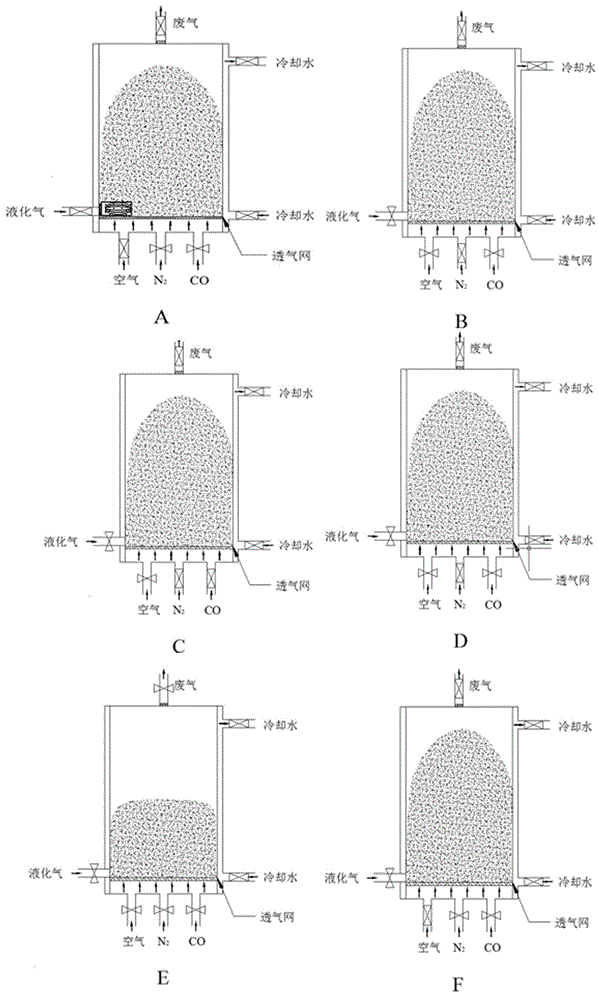

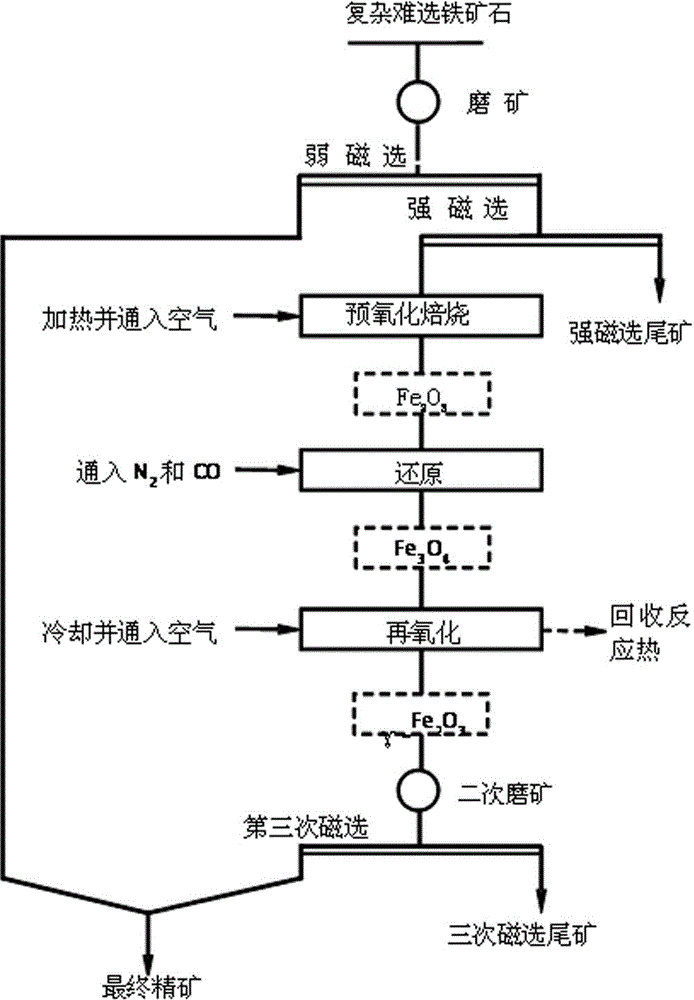

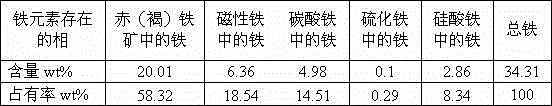

The invention discloses a preenrichment-three segment suspension roasting-magnetic separation treatment method of complex refractory iron ores, and belongs to the technical field of mineral processing. The method comprises the following steps: 1, levigating the complex refractory iron ores, carrying out weak magnetic separation, and carrying out strong magnetic separation on mine tailings; 2, putting concentrate obtained after strong magnetic separation in a suspension roasting furnace, and heating to 450-800DEG C in a suspension state in order to carry out pre-oxidation roasting; 3, introducing nitrogen to displace air, and introducing a reducing gas to carry out reduction in a suspension loose state; 4, introducing air when the temperature decreases to 250-400DEG C in order to oxidize, taking out the obtained material when the temperature decreases to below 100DEG C, and carrying out ore milling; and 5, carrying out third segment magnetic separation, and mixing concentrate obtained after three segment magnetic separation with concrete obtained after the weak magnetic separation to obtain finial concentrate. The method has the advantages of simple process, improvement of the recovery rate of the complex refractory iron ores, strong adaptability, safe and reliable process, uniform and stable product quality, energy saving and consumption reduction.

Owner:上海逢石科技有限公司

Production of instant water-gas slurry

InactiveCN101029260AEasy to oxidizeNot easily oxidizedLiquid carbonaceous fuelsLump/pulverulent fuel preparationMixed materialsBall mill

Production of quick-dissolving powdered water gas slurry is carried out by mixing various additive solutions with raw material coal proportionally, delivering mixed materials into ball mill, and dry grinding to obtain the final product. It has better stability, shorter working time, less producer and consumption and higher efficiency.

Owner:陕西升基利科技有限公司

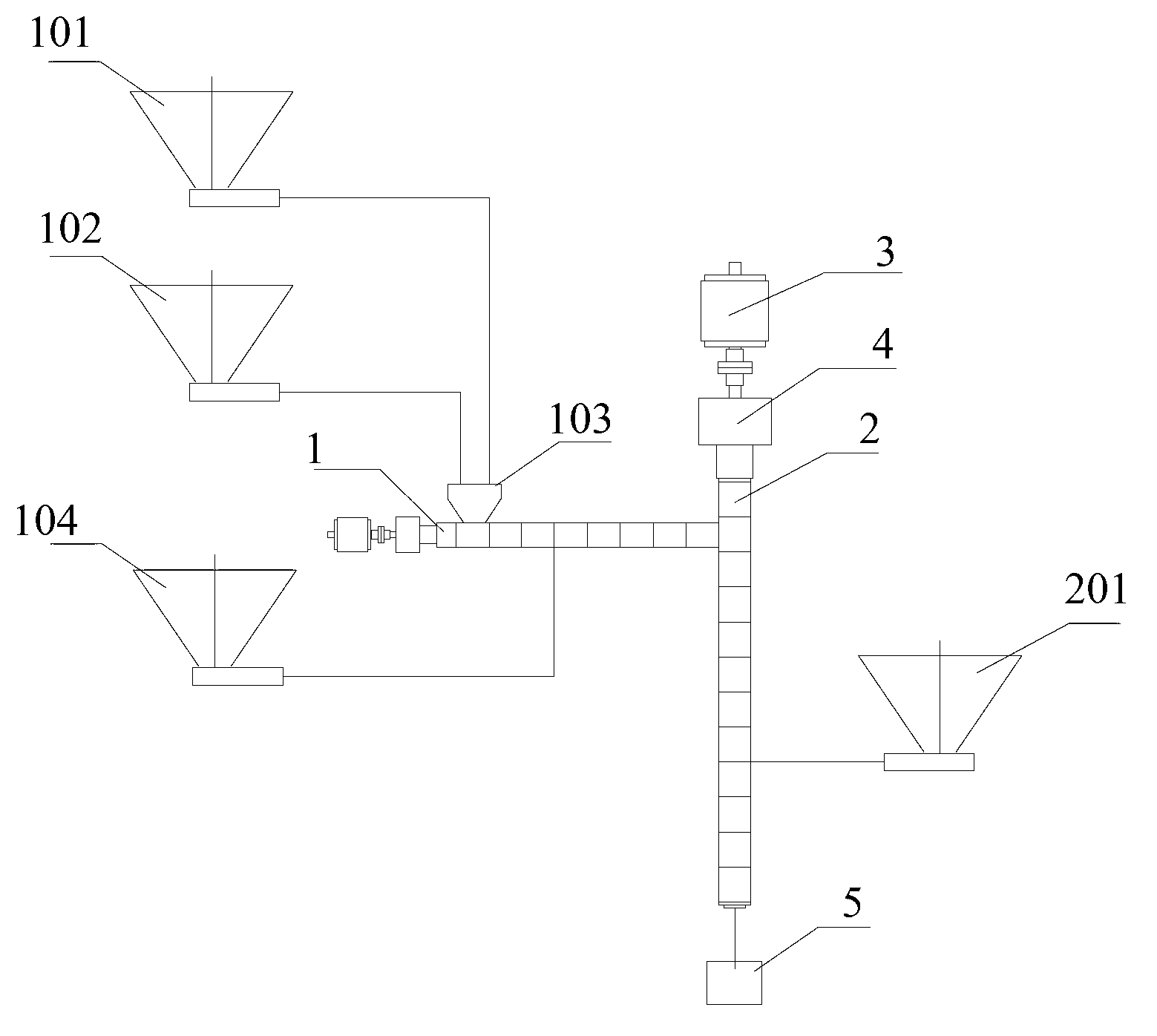

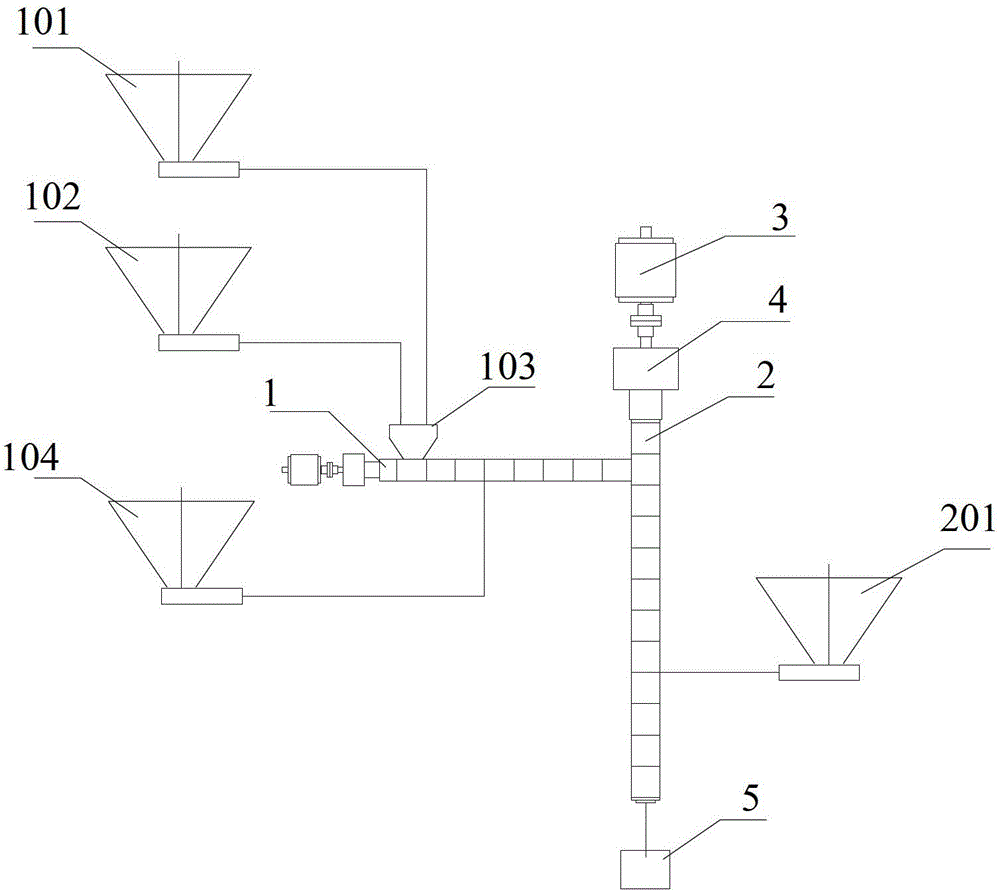

Production process and system of positive and negative electrode paste of lithium battery

ActiveCN103268931AQuality improvementImprove performanceElectrode manufacturing processesProduction rateMetallurgy

The invention discloses a production process and a production system of positive and negative electrode paste of a lithium battery. Positive and negative electrode materials are added to a first-order twin-screw extruder through a conveying device; then the materials are added to a second-order twin-screw extruder so as to be shorn and emulsified, and the consistency processing is performed; and finally, the materials are vacuum-degassed, cooled and shorn to obtain the positive and negative electrode paste. The dispersion degree of lithium ions in the paste is increased, the quality and performance of the battery in the subsequent production is effectively improved, the productivity is increased, and the cost input is reduced.

Owner:FOSHAN GOLD SILVER RIVER INTELLIGENT EQUIP CO LTD

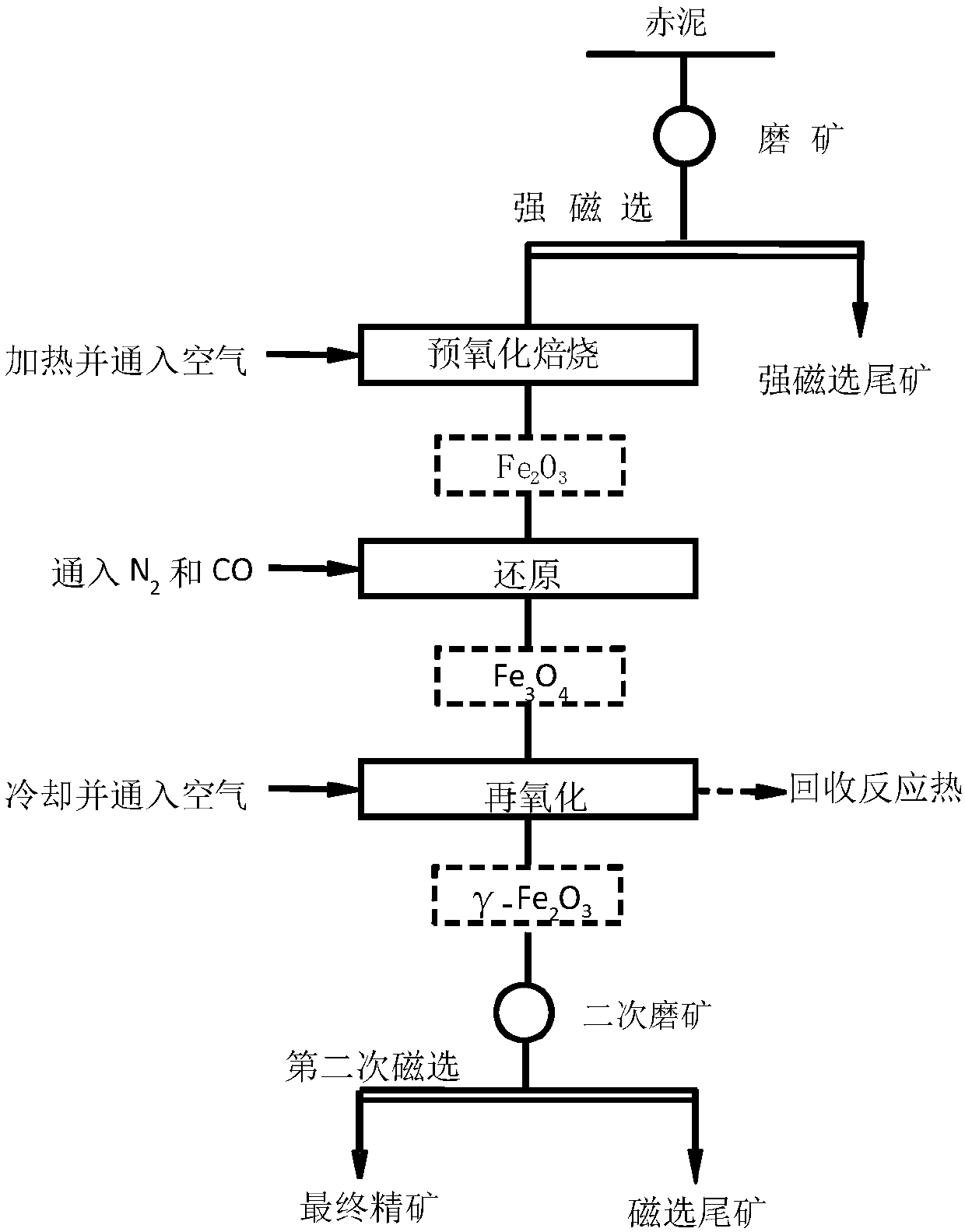

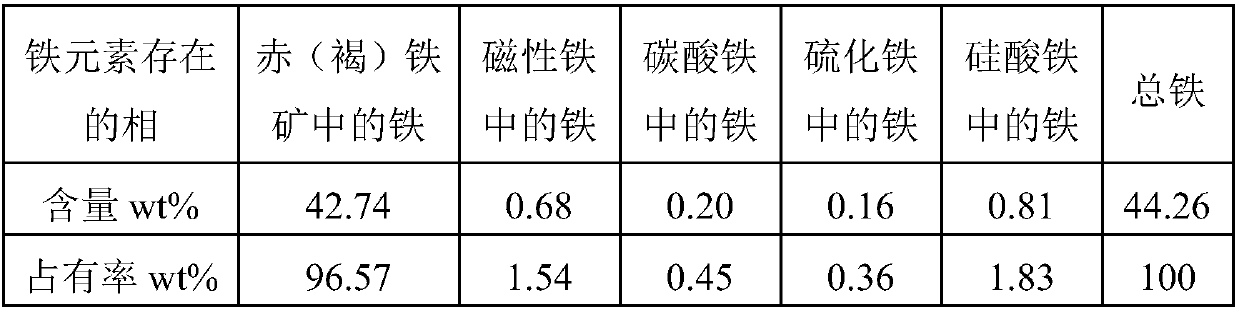

Method for recovering iron from red mud

InactiveCN107760862AStrong magnetismStrong sorting methodMagnetic separationAir atmosphereHigh energy

The invention relates to a method for recovering iron from red mud. The method for recovering the iron from the red mud belongs to the technical field of mineral processing, and comprises the steps ofin a suspension roaster, pre-oxidizing a magnetic-separated red mud material in an air atmosphere, and completely transforming spathic iron and brown iron ore in the red mud material into hematite; utilizing self-stored heat of a material obtained through pre-oxidization treatment for reducing the material in a reducing gas atmosphere so as to completely reduce hematite in the material into Fe3O4; re-oxidizing the obtained material in an air atmosphere, and transforming at least part of Fe3O4 in the material into gamma-Fe2O3; and carrying out magnetic separation on the material obtained through the treatment in the steps. The method provided by the invention solves the problems of long calcination time, high temperature, higher reducing gas CO content, loss of valuable elements, high energy consumption and the like in an existing process method for treating the red mud so as to recover fine iron powder.

Owner:NORTHEASTERN UNIV

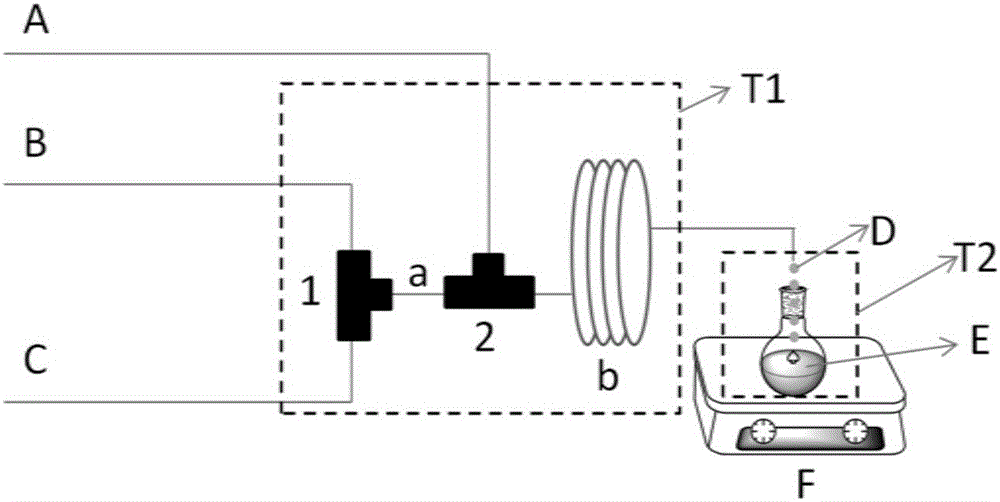

Method for preparing diazonium salt by utilizing micro-reactor

InactiveCN105693549ASolve the problem of clogged microchannelsEasy to operateOrganic chemistryNitriteOil water emulsion

The invention provides a method for preparing diazonium salt by utilizing a micro-reactor. The method comprises the following steps: firstly, preparing a nitrite solution and an organic amine into oil-water emulsion through a micro-mixer; enabling the oil-water emulsion to react with an introduced acid in a micro-channel to obtain the diazonium salt. The size of the salt formed by the contact of the oil-water emulsion and the acid is very small, and the salt can be consumed rapidly when reacting with nitrous acid, so that a pipeline is not blocked. The method provided by the invention is convenient and rapid to operate and short in reaction time; the defect that the diazonium salt is decomposed, caused by the fact that the temperature is too high, is avoided, and industrial production can be realized.

Owner:上海睿瓦科技有限公司

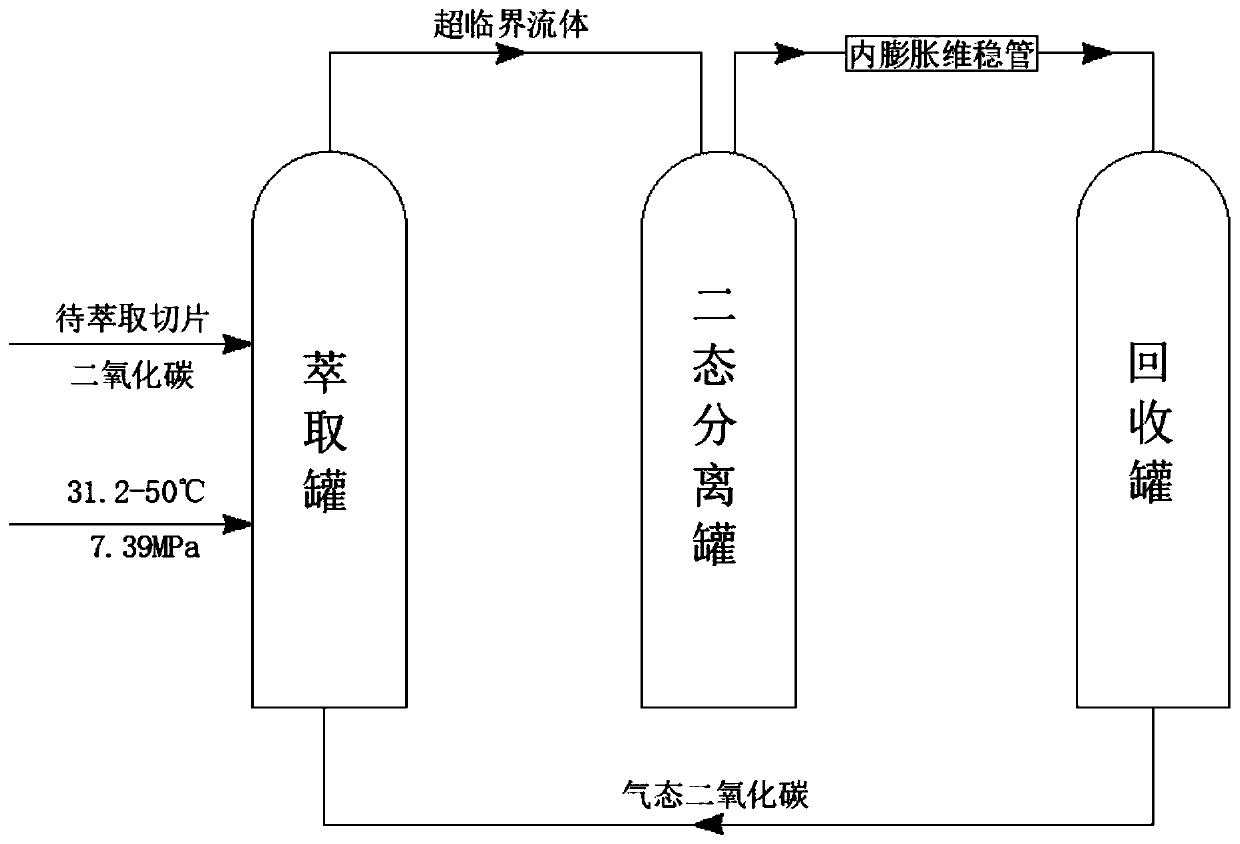

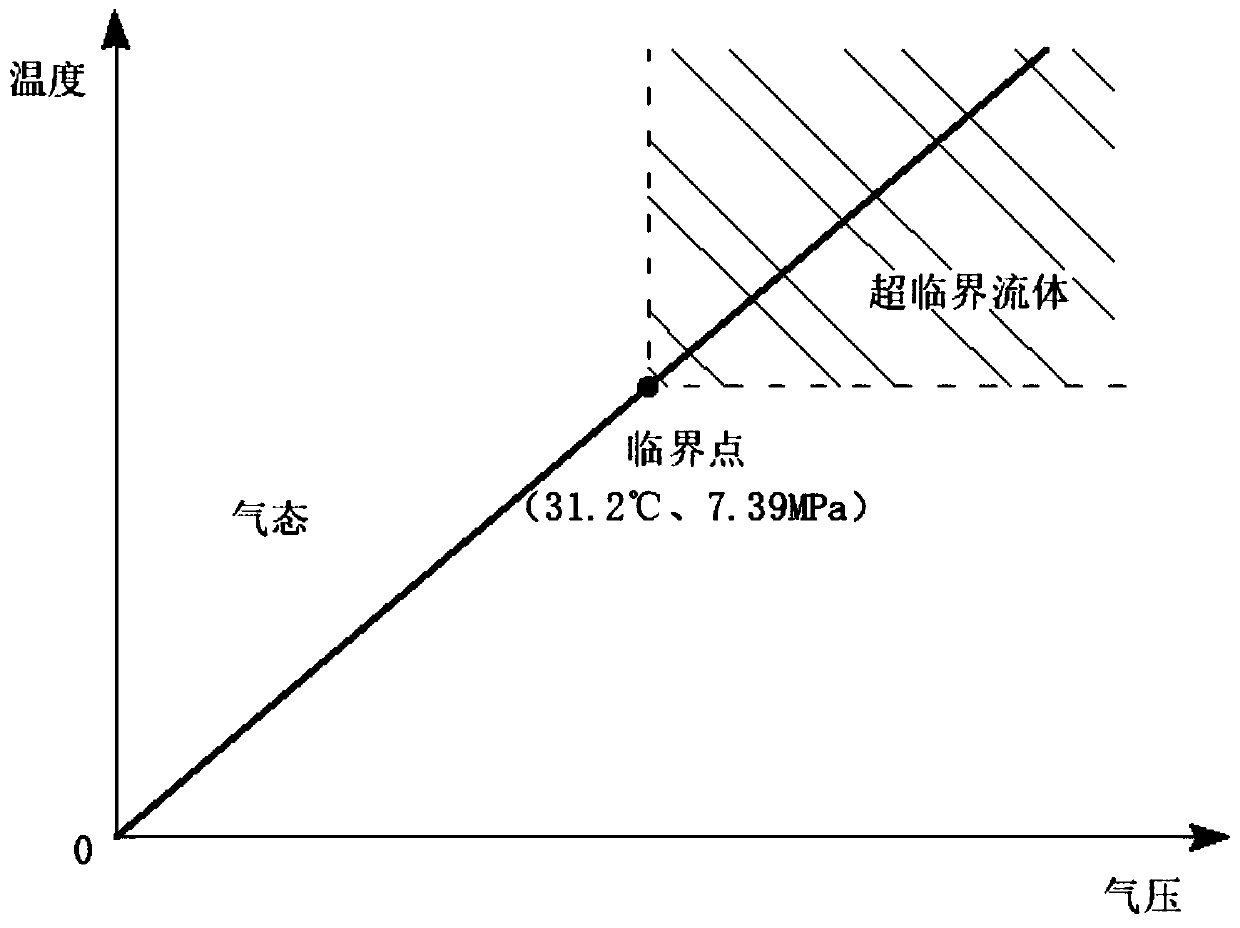

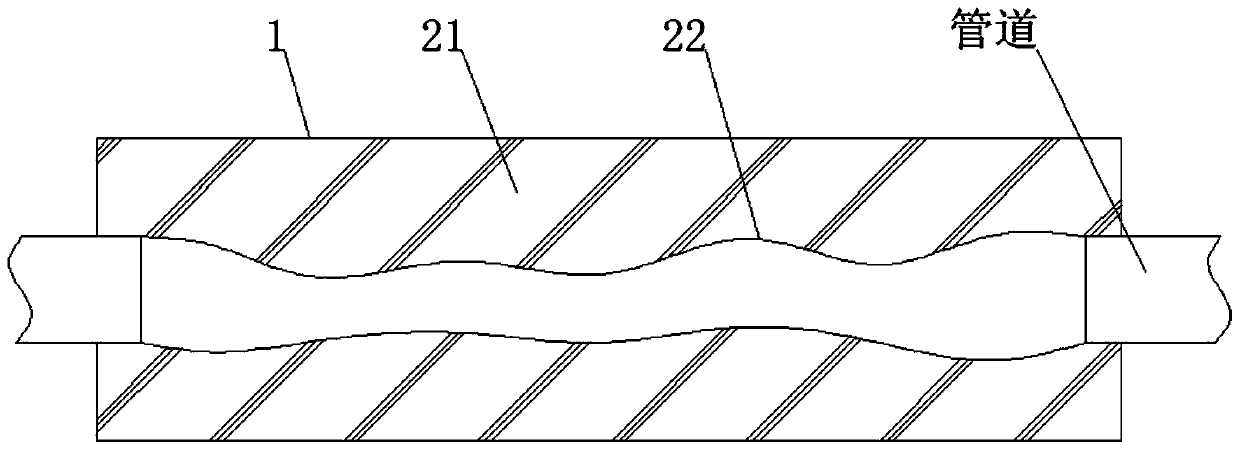

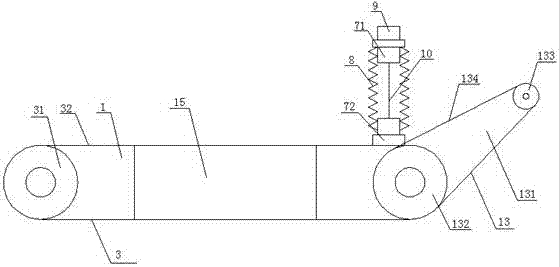

Supercritical extraction technology imitating ultrasonic high-speed separation

ActiveCN110743193ASpeed up circulationAvoid strandedCo-current extractionSolid solvent extractionPhysicsMicro ultrasound

The invention discloses a supercritical extraction technology imitating ultrasonic high-speed separation, and belongs to the field of supercritical extraction. According to the supercritical extraction technology imitating ultrasonic high-speed separation, through a micro ultrasonic bag arranged on the lower portion of a binary separation tank, an ultrasonic cavity is formed, through a gas opening, the ultrasonic cavity can be filled with gas continuously, the gas can be pumped out of the ultrasonic cavity continuously, thus continuous switch of expanding and shrinkage of transformation bulgeparts can be effectively controlled, then a micro-elastic baseboard is driven to shake continuously, thus a binary intermediate shakes, due to temperature rise and decompression, carbon dioxide in thebinary intermediate returns to a gas state, and through shaking, the movement speed of gaseous carbon dioxide molecules can be effectively improved, so that release of gaseous carbon dioxide is effectively accelerated, then the efficiency of medicine extraction is significantly improved, meanwhile, by arranging an inner expansion stabilizing pipe with variable volume, the flow speed of the gaseous carbon dioxide can be improved, the possibility that the binary separation tank internally explodes due to the fact that gas is not discharged in time is effectively avoided, and the safety is improved.

Owner:南通科鑫超临界设备有限公司

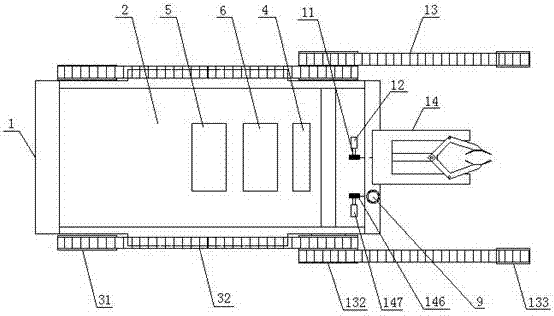

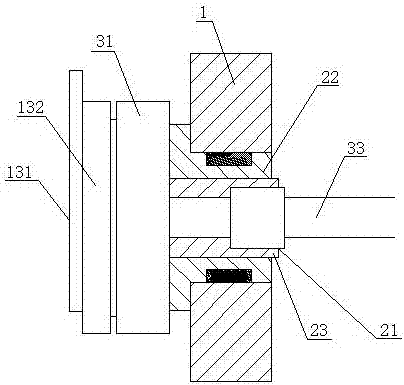

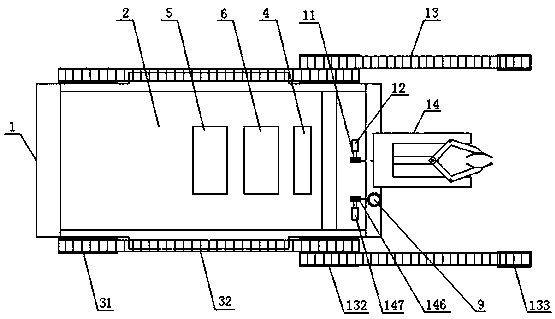

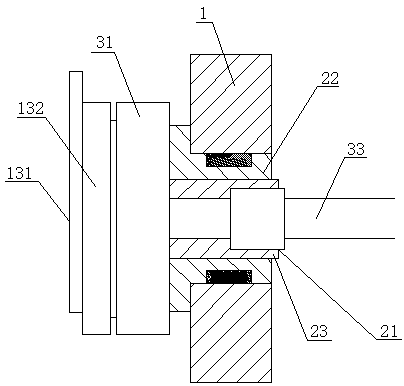

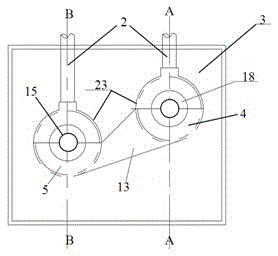

Tunnel poisonous gas detecting device for mine engineering

ActiveCN107054486ASmooth trafficReduce the possibility of explosionMaterial heat developmentItem transportation vehiclesIntrinsic safetyCommunications system

The invention discloses a tunnel poisonous gas detecting device for mine engineering. The tunnel poisonous gas detecting device comprises a vehicle body; crawler-type travelling mechanisms are symmetrically mounted on the two sides of the vehicle body; mounting holes are formed in the two sides of the vehicle body correspondingly and communicate with an explosive-proof cavity of the vehicle body; a main drive shaft and the mounting holes are connected through shaft seats I fixedly mounted in the mounting holes; shaft sleeves are embedded in the shaft seats I; a gas detection sensor is further mounted at the front end of the vehicle body through a lifting column; the gas detection sensor is wirelessly connected with an intrinsically safe type wireless communication module mounted in the explosive-proof cavity through an intrinsically safe type communication system; and an upper lifting column body moves up and down under driving of a stranded wire I. According to the tunnel poisonous gas detecting device, the possibility that explosion is caused by the travelling mechanisms in travelling is effectively avoided, safety performance is improved, meanwhile, and the situation that the gas detection sensor can detect the state and concentration of poisonous gas of different heights is achieved, so that the gas detection sensor effectively avoids top obstacles, and smooth passing of the vehicle body is guaranteed.

Owner:内蒙古智盛达能源有限公司

Mechanical latching mechanism of explosion-proof switching box

ActiveCN102360970AReduce the possibility of explosionReasonable structural designElectric switchesSwitch boxDust explosion

Owner:久益环球(青岛)电气有限公司

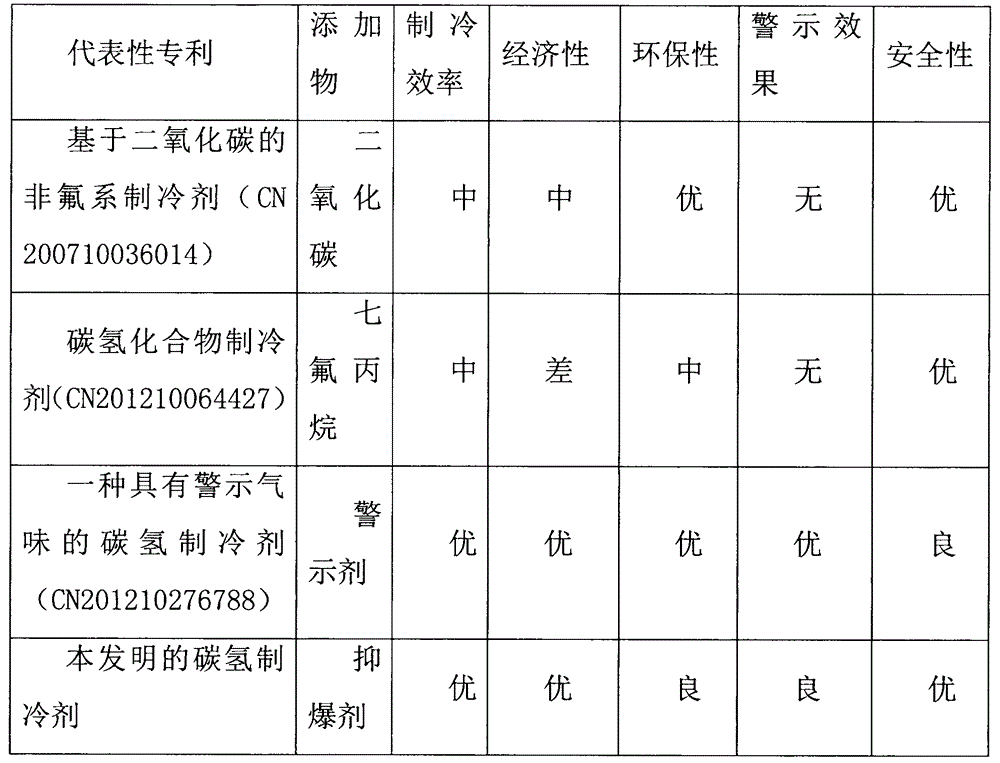

Hydrocarbon refrigerant with intrinsic safety

The invention discloses a hydrocarbon refrigerant with intrinsic safety. The hydrocarbon refrigerant is characterized by comprising a low carbon alkane refrigerant and 1%-5% of an explosion suppressant (according to the total mass of the low carbon alkane refrigerant), wherein the low carbon alkane refrigerant (by mass%) is formed by mixing of 60%-100% of propane and 0%-40% of isobutane, the explosion suppressant accounts for 1-5% (according to the total mass of the low carbon alkane refrigerant), and the explosion suppressant (according to the mass% of the explosion suppressant) is any one of or formed by mixing of more than one of tetramethyl lead, tetraethyl lead and pentacarbonyl iron in arbitrary proportion. The hydrocarbon refrigerant provided by the invention not only has high refrigeration efficiency, excellent environmental protection performance, but also has reliable essential safety, effectively eradicates the possibility of hydrocarbon refrigerant explosion, and is applicable to air conditioners, refrigerators and freezers and other refrigeration equipment.

Owner:南京苏佰能能源科技有限公司

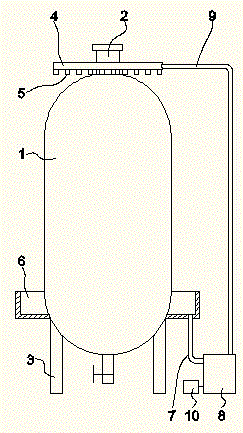

Chemical stock tank cooling system

InactiveCN105857975AReduce the possibility of explosionRelieve pressureLarge containersTank wagonsCompound (substance)Water collection

The invention discloses a chemical raw material tank cooling system, which comprises a tank body, the top of the tank body is provided with a feed port, the bottom of the tank body is provided with a bracket, and the top of the tank body is provided with an annular water pipe. The lower end of the annular water pipe is provided with a plurality of spray ports; the top of the support is provided with an annular sump close to the outer wall of the tank, and the bottom of the sump is provided with an outlet pipe, which is connected to the water pump. The water pump is connected to the annular water pipe through the water inlet pipe. The chemical raw material tank cooling system of the present invention has reasonable structural design, fast cooling speed, and high cooling efficiency. The present invention has the advantages of simple structure, convenient use and maintenance, low cost, and high work efficiency.

Owner:WUXI AOYUTE NEW TECH DEV

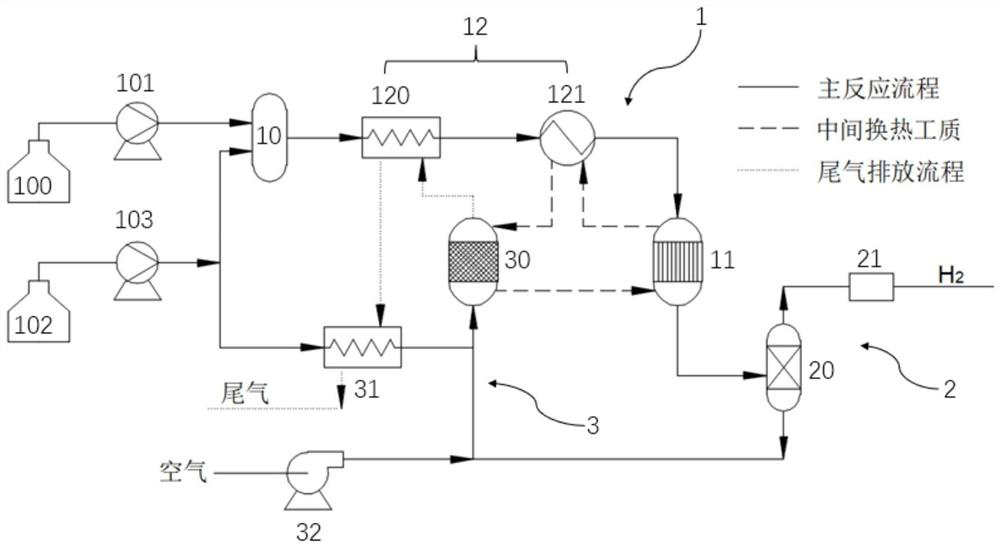

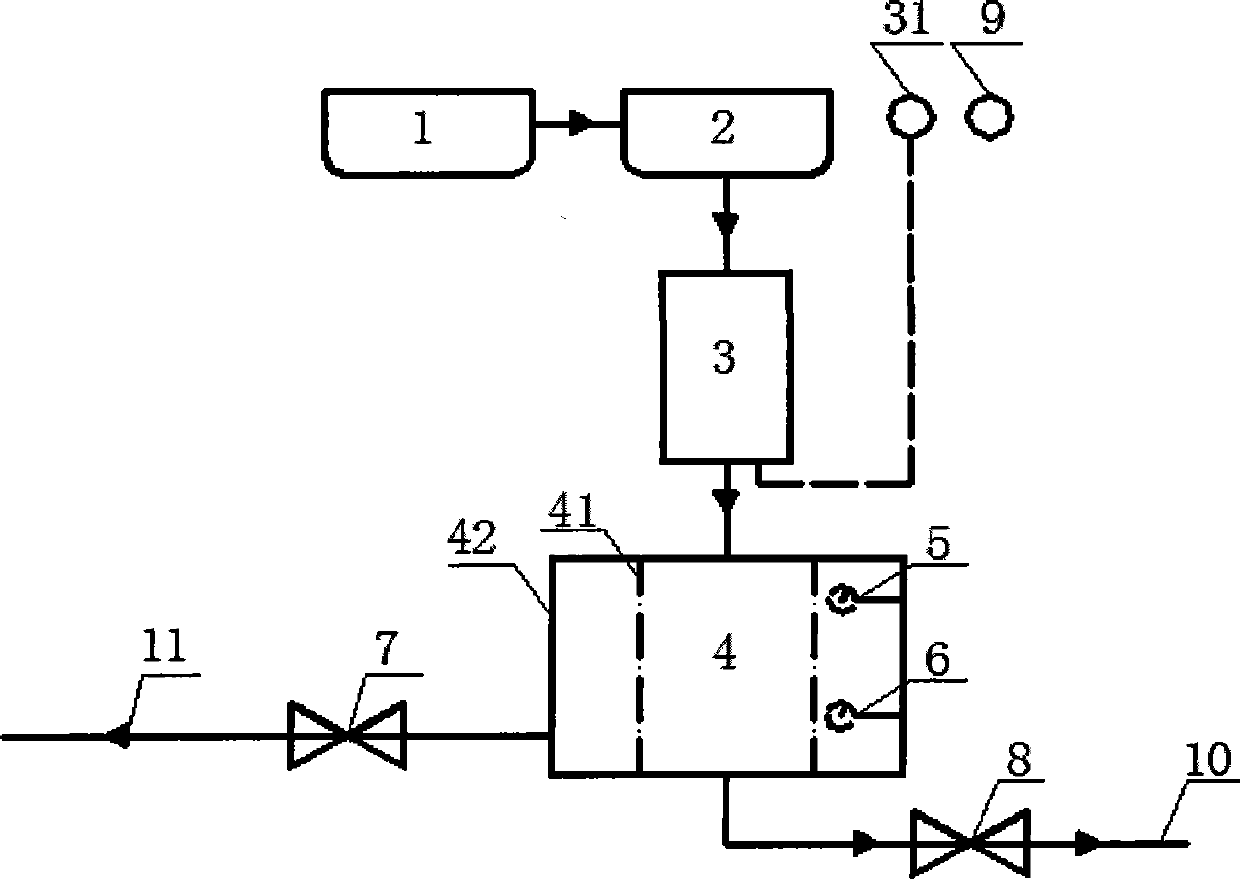

Methanol reforming hydrogen production system and process

PendingCN112209341ARaise the reaction temperatureImprove compactnessHydrogen separation using solid contactHydrogen/synthetic gas productionProcess engineeringHydrogen production

The present invention discloses a methanol reforming hydrogen production system, which comprises: a reforming reaction unit, which comprises a raw material tank for mixing desalted water and methanol,a reforming reactor communicated with the outlet of the raw material tank, a temperature adjusting unit arranged between the raw material tank and the reforming reactor, a hydrogen purification unitcomprising a palladium membrane purification device arranged at the downstream of the reforming reactor and used for purifying the hydrogen-rich gas after the reforming reaction, and a palladium membrane purification device provided with a purified hydrogen outlet and a residual gas outlet, and a combustion unit provided with a feeding port and a tail gas outlet, wherein the feeding port is connected with the residual gas outlet of the palladium membrane purification device, the tail gas outlet is communicated with the temperature adjusting unit, and the reaction temperature in the reforming reactor is controlled not to exceed the purification temperature interval of the palladium membrane purification device. According to the system, a methanol reforming hydrogen production process can also be provided. The system and process are compact in structure, simple in process, high in energy utilization rate and high in purity of purified hydrogen.

Owner:SHANGHAI MICROPOWERS

Ceramic diaphragm for lithium ion batteries and method for manufacturing ceramic diaphragm

InactiveCN109360921AGood surface treatmentImprove securityCell seperators/membranes/diaphragms/spacersPolyolefinAdhesive

The invention belongs to the technical field of processing of diaphragms for batteries, and discloses a ceramic diaphragm for lithium ion batteries and a method for manufacturing the ceramic diaphragm. The ceramic diaphragm for the lithium ion batteries comprises a polyolefin microporous film matrix. Ceramic slurry is coated on at least one surface of the polyolefin microporous film matrix and comprises inorganic ceramic particles and adhesive, the adhesive is polyvinylidene fluoride resin or polyacrylonitrile, and the ceramic particles are fixed to the surfaces or the insides of polyolefin microporous films. The method for preparing the ceramic diaphragm for the lithium ion batteries includes steps of coating the ceramic slurry on the surfaces of the polyolefin microporous film matrix; sequentially carrying out drying and ultraviolet irradiation. The ceramic diaphragm and the method have the advantages that the ceramic slurry is coated on the surfaces of the polyolefin microporous film matrix, accordingly, the ceramic diaphragm is in stable states with surface treatment convenience, the possibility of explosion due to short circuit of negative and positive electrodes of the batteries can be completely eradicated, and the use safety of the lithium ion batteries can be improved.

Owner:湖北江升新材料有限公司

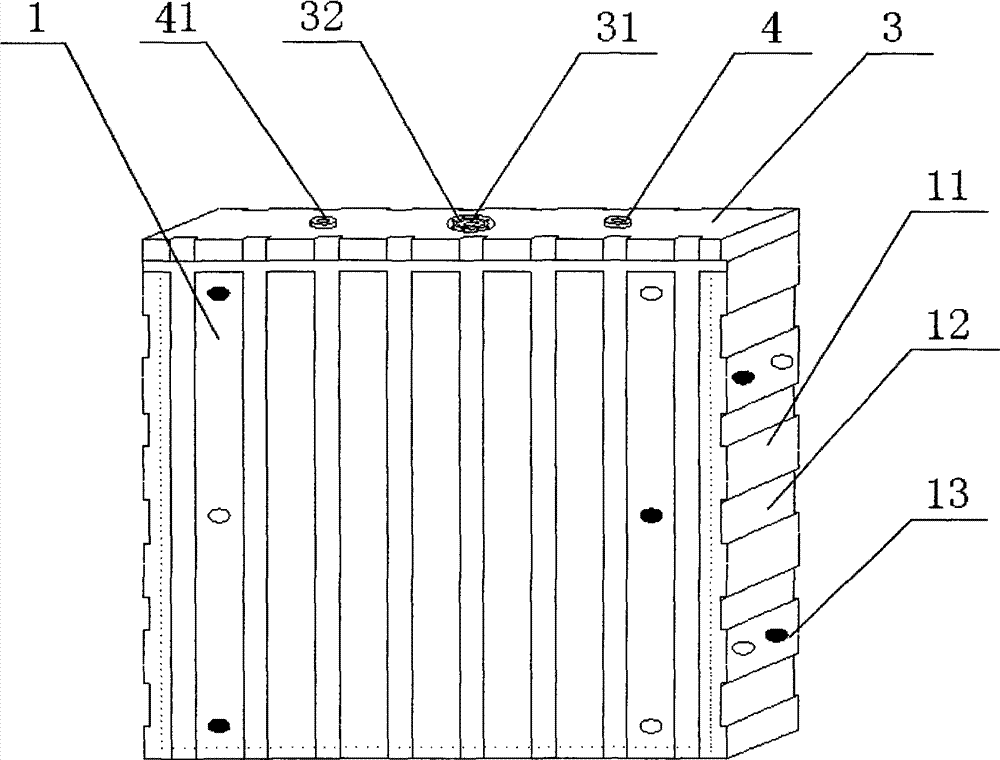

Power battery and manufacturing method thereof

InactiveCN102760909AEasy to useEasy maintenanceFinal product manufactureCell component detailsPower batteryEngineering

The invention discloses a power battery and a manufacturing method thereof. The method comprises the following process steps of: manufacturing a positive pole piece; manufacturing a negative pole piece; performing die cutting on the positive and negative pole pieces; laminating the positive and negative pole pieces to form an inner core; baking the inner core; assembling and welding; infusing liquid into the cell; ageing the cell; detecting the electrical property; and performing formation and grading capacity so as to finally obtain the power battery. The power battery is simple in process and convenient to manufacture, and by adoption of the laminating process, a 500Ah cell unit can be realized; and the power battery manufactured by the method has the advantages that use is safe, maintenance is easy, inner core capacity is large and the like.

Owner:李永康

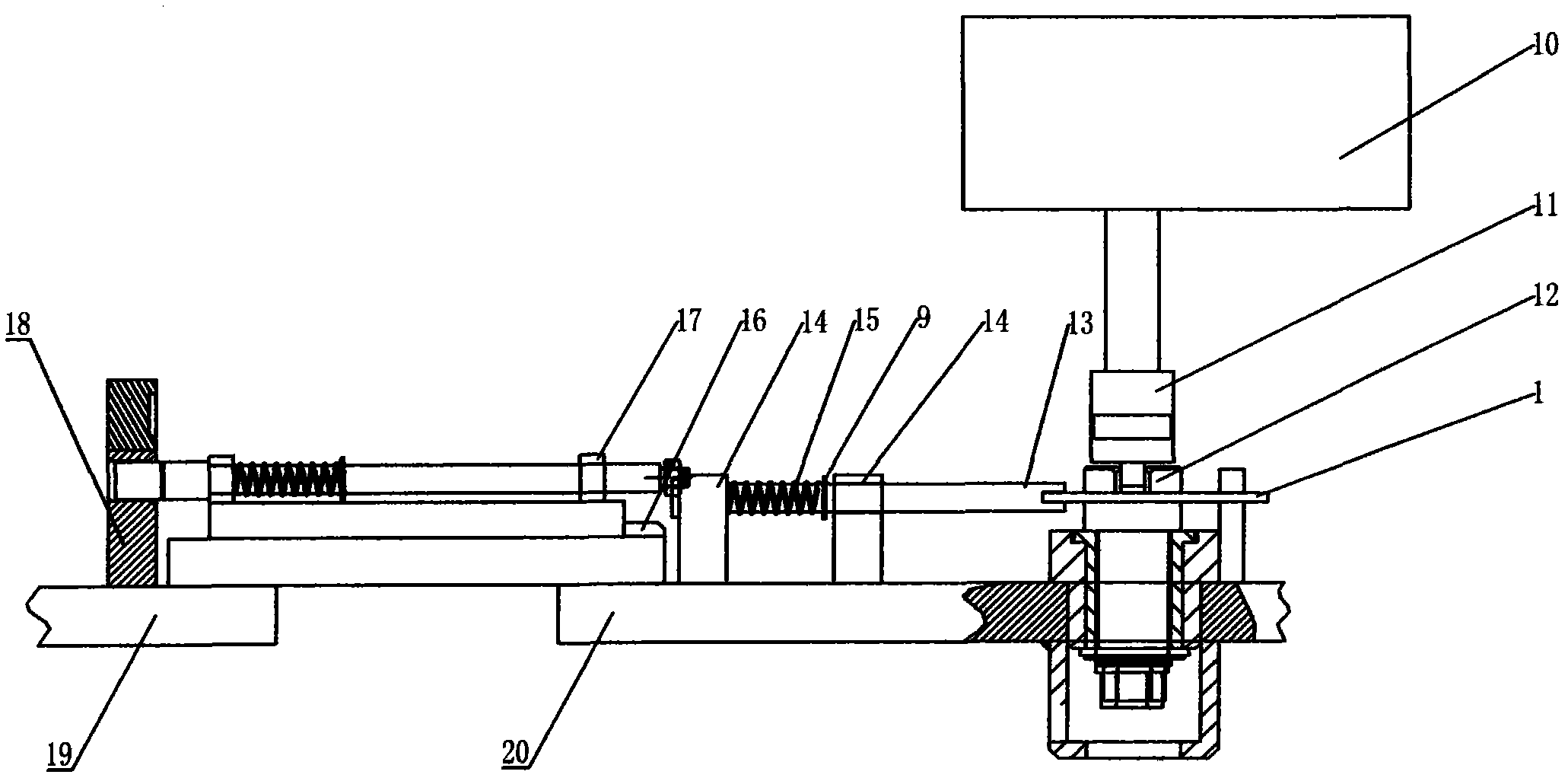

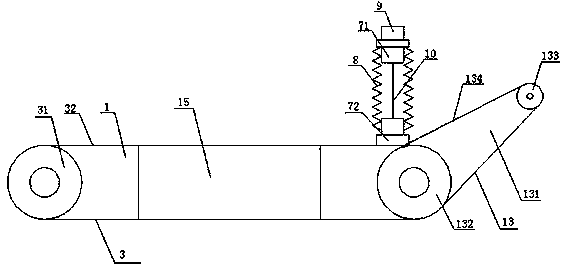

A tunnel poisonous gas detection device for mine engineering

ActiveCN107054486BSmooth trafficReduce the possibility of explosionMaterial heat developmentItem transportation vehiclesIntrinsic safetyToxic gas

The invention discloses a tunnel poisonous gas detecting device for mine engineering. The tunnel poisonous gas detecting device comprises a vehicle body; crawler-type travelling mechanisms are symmetrically mounted on the two sides of the vehicle body; mounting holes are formed in the two sides of the vehicle body correspondingly and communicate with an explosive-proof cavity of the vehicle body; a main drive shaft and the mounting holes are connected through shaft seats I fixedly mounted in the mounting holes; shaft sleeves are embedded in the shaft seats I; a gas detection sensor is further mounted at the front end of the vehicle body through a lifting column; the gas detection sensor is wirelessly connected with an intrinsically safe type wireless communication module mounted in the explosive-proof cavity through an intrinsically safe type communication system; and an upper lifting column body moves up and down under driving of a stranded wire I. According to the tunnel poisonous gas detecting device, the possibility that explosion is caused by the travelling mechanisms in travelling is effectively avoided, safety performance is improved, meanwhile, and the situation that the gas detection sensor can detect the state and concentration of poisonous gas of different heights is achieved, so that the gas detection sensor effectively avoids top obstacles, and smooth passing of the vehicle body is guaranteed.

Owner:内蒙古智盛达能源有限公司

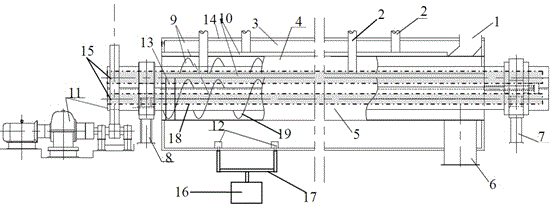

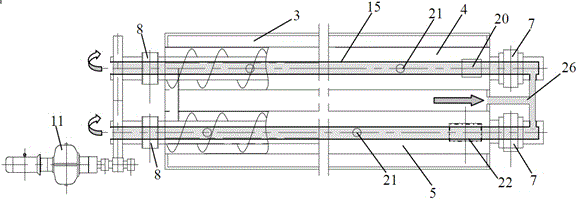

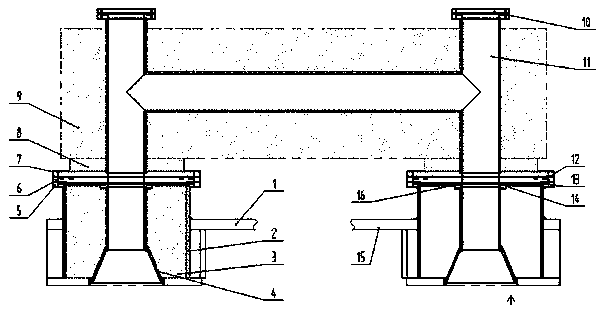

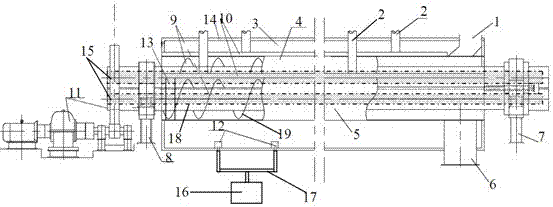

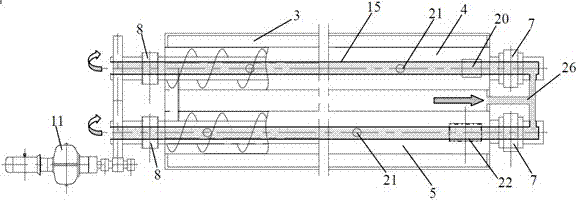

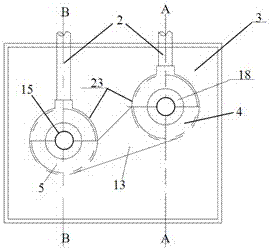

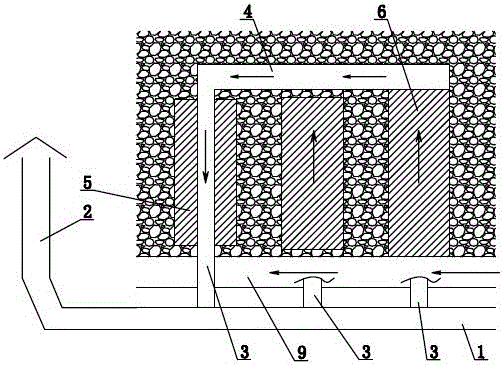

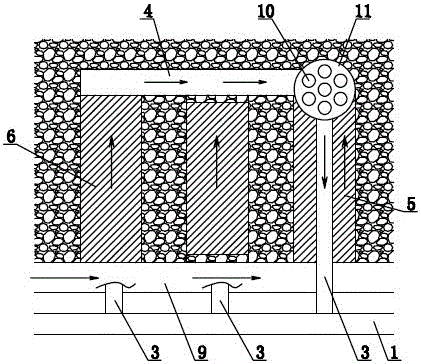

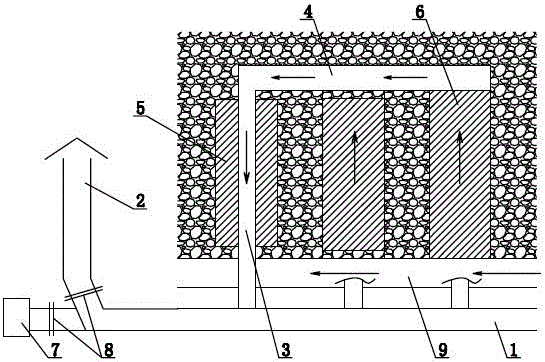

Screw-propelling external-heating type coal dry distillation device

ActiveCN105482841ABroad market prospectImprove retort efficiencyLiquid hydrocarbon mixture productionIndirect heating destructive distillationTarProcess engineering

The invention provides a screw-propelling external-heating type coal dry distillation device. The device comprises a heating chamber, dry distillation chambers, a spiral conveying device, a pyrolysis gas collection device, a bearing supporting base, a material feeding and discharging mechanism and a drive device, wherein the pyrolysis gas collection device is communicated with the dry distillation chambers , the heated part of each dry distillation chamber is located in the heating chamber, the dry distillation chambers are isolated from the heating chamber, the material feeding and discharging mechanism is connected with the dry distillation chambers, the spiral conveying device is arranged in the dry distillation chambers, the end of the spiral conveying device is supported by the bearing supporting base, the drive device is connected to the end of the spiral conveying device, a smoke exhaust channel is arranged in the spiral conveying device, and the heating chamber is communicated with the smoke exhaust channel. A spiral propelling mechanism is adopted for propelling of raw coal, multiple dry distillation chambers are connected in the same sealed heating chamber in parallel, combustion smoke is introduced into a raw material propelling device to realize recycling of heat energy, the raw coal propelling problem in dry distillation of coal is solved, the dry distillation heating efficiency is improved, and the device has the advantages that coal is uniformly heated in the dry distillation process, the heating efficiency is high, the yield of tar is high and the like.

Owner:王崇峰

Flow guide pipe sealing device in distillation process of titanium sponge production

The invention discloses a flow guide pipe sealing device in a distillation process of titanium sponge production. The sealing device comprises a cold-end large cover, a large cover heater flange, a transition flange, a passage assembly lower flange and a passage pipe upper flange, wherein the left end of the cold-end large cover is connected with a passage heater protection pipe, one side of the passage heater protection pipe is provided with a large cover heater, a conical pipe is arranged in the large cover heater, a heat preservation module is arranged above the conical pipe, a passage heater is arranged above the heat preservation module, a passage assembly is arranged above the passage heater, and a passage center pipe upper blind plate is fixed to the upper end of the passage assembly. According to the flow guide pipe sealing device in the distillation process of titanium sponge production, when a large-cover heater is maintained, cutting and welding operation is not needed, andthe large-cover heater can be maintained only by conveniently and rapidly loosening bolts.

Owner:朝阳金达钛业股份有限公司

Denitration agent used for SNCR flue gas denitration technology

InactiveCN107433123AEasy to prepareImprove denitrification efficiencyGas treatmentDispersed particle separationFlue gasNH3 compound

The invention relates to a denitration agent used for a SNCR flue gas denitration technology. The denitration agent comprises the following components: RO pure water, vehicle urea, liquefied ammonia or ammonia liquor, and a few of an additive. A preparation method comprises the following steps: employing RO pure water for hydrolyzing the vehicle urea, liquefied ammonia or ammonia liquor and the additive are placed in an above solution; wherein the concentration of the vehicle urea in the prepared denitration agent is 20-30%, and the ammonia concentration is 3-7%. The preparation method of the denitration agent is simple, the denitration agent can increase the denitration efficiency, ammonia escape and ammonia blast possibility can be prevented, the severe condition required by ammonia liquor storage and transport can be solved, the environment damage is reduced, and the problems of easy obstruction of the used urea and low denitration efficiency are solved.

Owner:东莞市升佳净水材料有限公司

Environmental protection high-energy mixed light hydrocarbon industrial gas and producing method thereof

InactiveCN101144043AMeet the use requirementsLow evaporationGaseous fuelsHigh energyPotassium hydroxide

The present invention discloses an environmental friendly high energy mixed light hydrocarbon industrial gas, which is formed by mixing multi-purpose synergic agent and alkyl alkene according to 1 to 3 per mille of proportioning by weight. The alkyl alkene is formed by mixing light hydrocarbon gas and heavy hydrocarbon gas according to 1: (0 to 0.2) of proportioning by weight. The multi-purpose synergic agent is formed by preparing 120 # solvent oil, alcohol, methyl tert-butyl ether jiajishudingjimi, china wood oil, butyl-ferrocen ferrocene, sodium napthionate, cupric cyclo alkanes and potassium hydroxide according to a certain proportion. The present invention has the advantages that the energy consumption is low, the pollution is weak, the cost is low, the present invention is safe, the temperature of the flame is higher than the acetylene, the present invention can completely meet the requirement of the industry fuel gas, and can be suitable for operating in the severe cold area and on ships, and the fuel gas is saved by above 30 percent.

Owner:董必祥 +1

Production process and system of positive and negative electrode paste of lithium battery

ActiveCN103268931BQuality improvementImprove performanceElectrode manufacturing processesProduction rateMetallurgy

The invention discloses a production process and a production system of positive and negative electrode paste of a lithium battery. Positive and negative electrode materials are added to a first-order twin-screw extruder through a conveying device; then the materials are added to a second-order twin-screw extruder so as to be shorn and emulsified, and the consistency processing is performed; and finally, the materials are vacuum-degassed, cooled and shorn to obtain the positive and negative electrode paste. The dispersion degree of lithium ions in the paste is increased, the quality and performance of the battery in the subsequent production is effectively improved, the productivity is increased, and the cost input is reduced.

Owner:FOSHAN GOLD SILVER RIVER INTELLIGENT EQUIP CO LTD

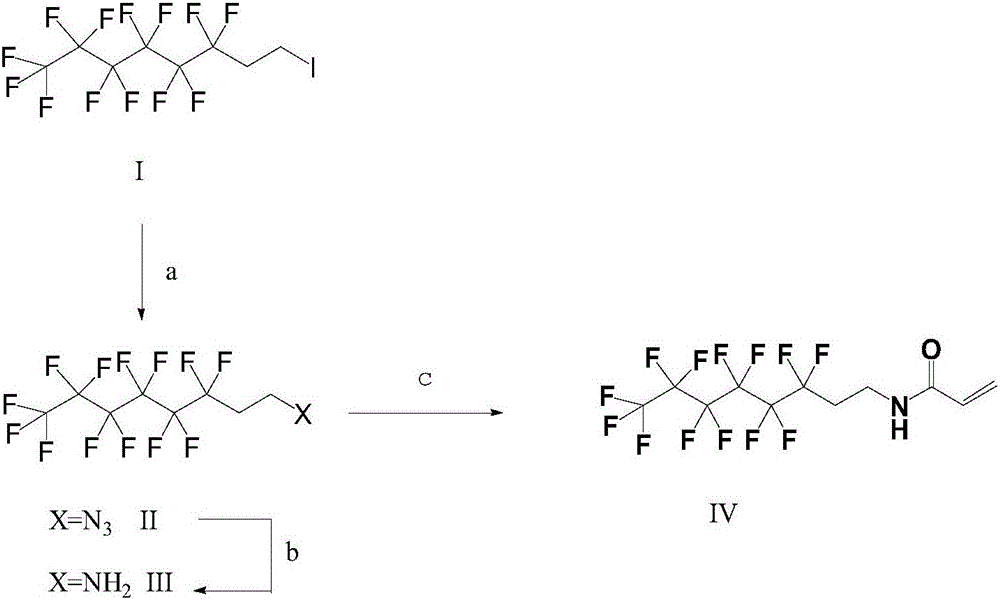

Synthetic method of N-(1H,1H,2H,2H-perfluorinated octyl) acrylamide

InactiveCN106278921AReduce usagePromote safe productionOrganic compound preparationCarboxylic acid amides preparationOrganic solventHydrogen

The invention discloses a synthetic method of N-(1H,1H,2H,2H-perfluorinated octyl) acrylamide. The method includes the steps that 1H,1H,2H,2H-perfluorinated hexyl ethyl iodide, sodium azide and organic solvent are mixed to react, water is added after the reaction is finished, the mixture is still standing and layered, and the organic layer is washed to obtain 1H,1H,2H,2H-perfluorinated octyl azide; under the action of Pd / C catalyst, hydrogen is used for hydrogenation reduction, and 1H,1H,2H,2H-perfluorinated octylamine is obtained through filtration and concentration; 1H,1H,2H,2H-perfluorinated octylamine, triethylamine and acryloyl chloride react in solvent at room temperature, after reaction is finished, the N-(1H,1H,2H,2H-perfluorinated octyl) acrylamide product is obtained through washing, concentration and reduced pressure distillation. The possibility of explosion in the production process is avoided, and the synthetic method has the advantages of being simple in process, safe in production, high in yield and easy to industrialize.

Owner:JUHUA GROUP TECH CENT

Fresh air system under dust environment

InactiveCN109794007AImprove air qualityReduce use costFire rescueRespiratory apparatusFresh airDust particles

The invention discloses a fresh air system under a dust environment. The fresh air system comprises a water tank assembly, an exhaust pipe, a filter net, an air filter, an exhaust pipe sealing sleeve,a diaphragm pump, a fresh air main pipe sealing sleeve, a fresh air main pipe, a fresh air branch pipe, a cut-off valve, a hose and a respirator. Air outside a dust workshop enters the diaphragm pumpthrough the air filter, air exhausted from the diaphragm pump enters the filter net through the exhaust pipe, bubbles crushed by the filter net enter clean water of a water tank body, the clean waterfully makes contact with the crushed bubbles to adsorb tiny dust particles in the air, the air is further purified and delivered to the respirator, the fresh air in the positive pressure state in therespirator is directly supplied to operators for breathing, thus the workers are prevented from inhaling dust, and the body health of the workers is effectively guaranteed.

Owner:HOHAI UNIV CHANGZHOU

Method for preparing 2, 4-dinitroaniline by using microreactor

PendingCN111635322AIncrease productivityReduce energy consumptionOrganic compound preparationChemical industryMicroreactorChlorobenzene

The invention relates to the technical field of preparation of 2, 4-dinitroaniline, in particular to a method for preparing 2, 4-dinitroaniline by using a microreactor. The method comprises the following steps: (1) preparing equipment, namely preparing a preheater, the microreactor and two chromatographic pumps; (2) connecting reaction equipment, respectively connecting two chromatographic pumps with the preheater and the micro-reactor, then connecting the preheater with the micro-reactor, and putting the preheater and the microreactor into a constant-temperature oil bath after the connectionis completed; (3) conveying a reaction material, namely conveying ammonia water to the preheater at a preset flow rate, conveying the molten 2, 4-dinitrochlorobenzene to the microreactor at a preset flow rate, and mixing and reacting with the ammonia water to obtain 2, 4-dinitroaniline; and (4) after the reaction of the material in the step (3) is completed, preparing the redundant ammonia gas into ammonia water again for reuse through an ammonia gas recovery device, and continuing to reuse the ammonia generated by the reaction of ammonium chloride generated by the reaction and potassium hydroxide. Tthe method has the characteristics of high production efficiency, low energy consumption, economy, environmental protection, safety and reliability.

Owner:杭州迈科瑞科技有限公司

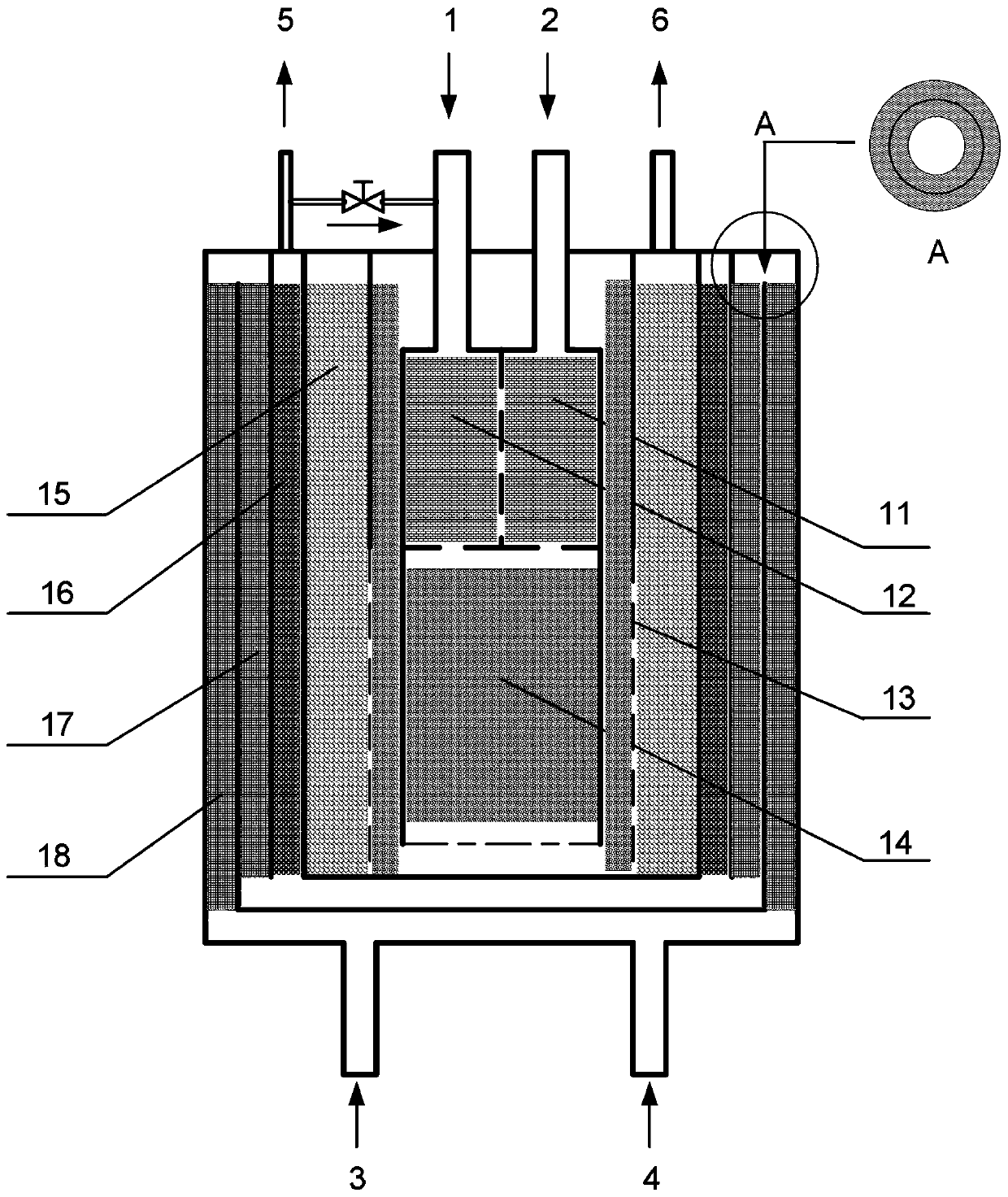

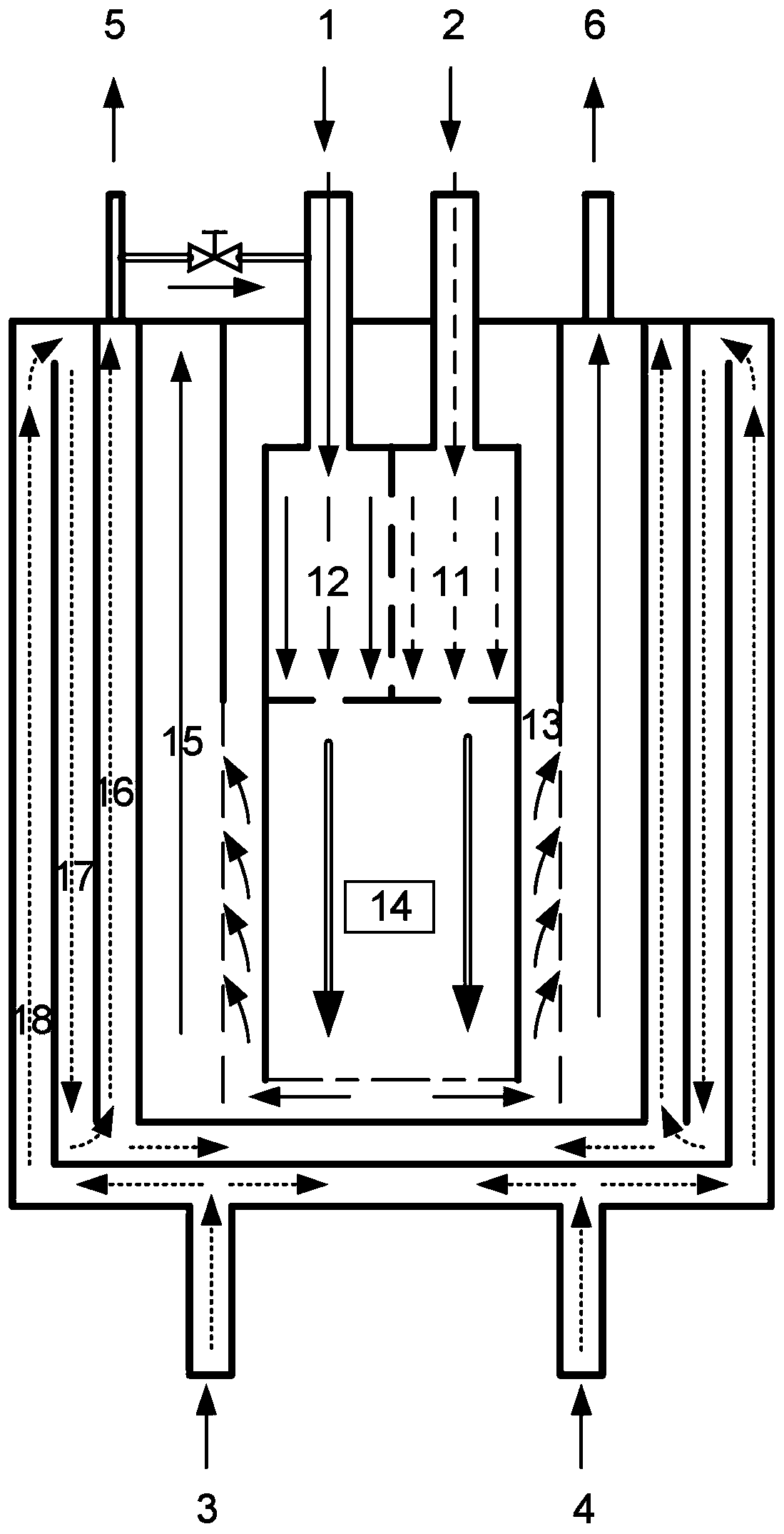

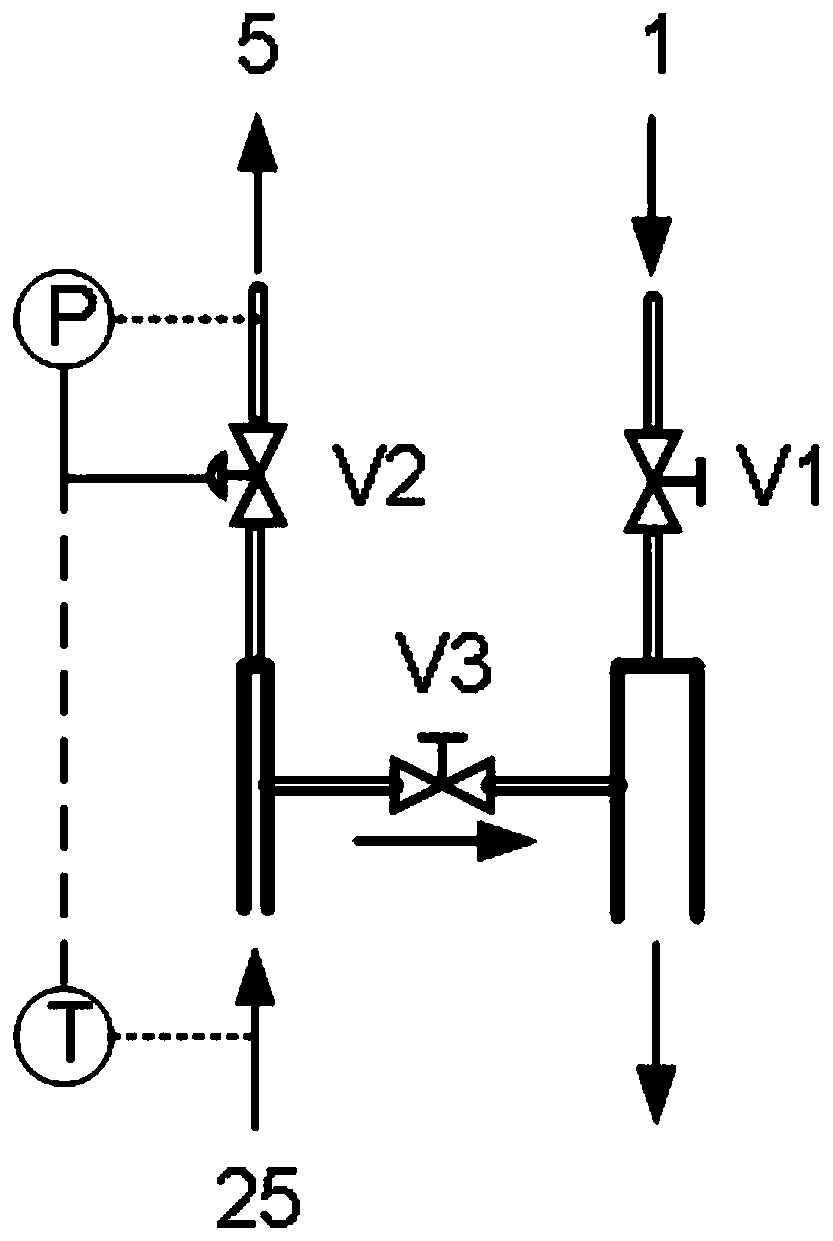

A combined endothermic and exothermic hydrogen production reactor

ActiveCN108557761BImprove heat transfer efficiencyImprove hydrogen production efficiencyHydrogenHydrogen/synthetic gas productionCombustionReaction temperature

The invention relates to a heat absorption and heat release coupled hydrogen production reactor. The reactor is of a concentric circle type multilayered cylindrical structure and comprises a low-temperature reaction raw material cavity, a high-temperature reaction raw material cavity, a hydrogen production reaction cavity, a combustion reaction cavity, a combustion distribution cavity, a combustion mixing cavity and a buffering cavity in sequence from an outer layer to an inner layer. According to the reactor provided by the invention, high heat transferring efficiency of the reactor and uniform distribution of reaction temperature are ensured by sufficiently utilizing effective matching of an airflow distribution design and different reactions, and reasonable distribution of heat of a system and stable operation of the system are effectively realized. The buffering cavity, the distribution cavity, the mixing cavity and the distribution cavity of raw materials are designed, so that theproblem that the materials in a small-size reaction space are uniformly distributed is solved. A valve group is designed so that the energy efficiency of the hydrogen production reactor is improved.To sum up, the hydrogen production reactor provided by the invention has the appearance characteristics of compactness and small size, has the advantages of high combustion efficiency and heat transferring efficiency, and capability of reducing heat transferring resistance in a heat absorption process and a heat release process, and has a good application prospect.

Owner:江苏尚亿氢能源科技有限公司

A kind of spiral propelling material external heating coal dry distillation device

ActiveCN105482841BSlow advance and even heatingSolve problems that limit pyrolysis yieldIndirect heating destructive distillationLiquid hydrocarbon mixture productionCombustionProcess engineering

The invention provides a screw-propelling external-heating type coal dry distillation device. The device comprises a heating chamber, dry distillation chambers, a spiral conveying device, a pyrolysis gas collection device, a bearing supporting base, a material feeding and discharging mechanism and a drive device, wherein the pyrolysis gas collection device is communicated with the dry distillation chambers , the heated part of each dry distillation chamber is located in the heating chamber, the dry distillation chambers are isolated from the heating chamber, the material feeding and discharging mechanism is connected with the dry distillation chambers, the spiral conveying device is arranged in the dry distillation chambers, the end of the spiral conveying device is supported by the bearing supporting base, the drive device is connected to the end of the spiral conveying device, a smoke exhaust channel is arranged in the spiral conveying device, and the heating chamber is communicated with the smoke exhaust channel. A spiral propelling mechanism is adopted for propelling of raw coal, multiple dry distillation chambers are connected in the same sealed heating chamber in parallel, combustion smoke is introduced into a raw material propelling device to realize recycling of heat energy, the raw coal propelling problem in dry distillation of coal is solved, the dry distillation heating efficiency is improved, and the device has the advantages that coal is uniformly heated in the dry distillation process, the heating efficiency is high, the yield of tar is high and the like.

Owner:王崇峰

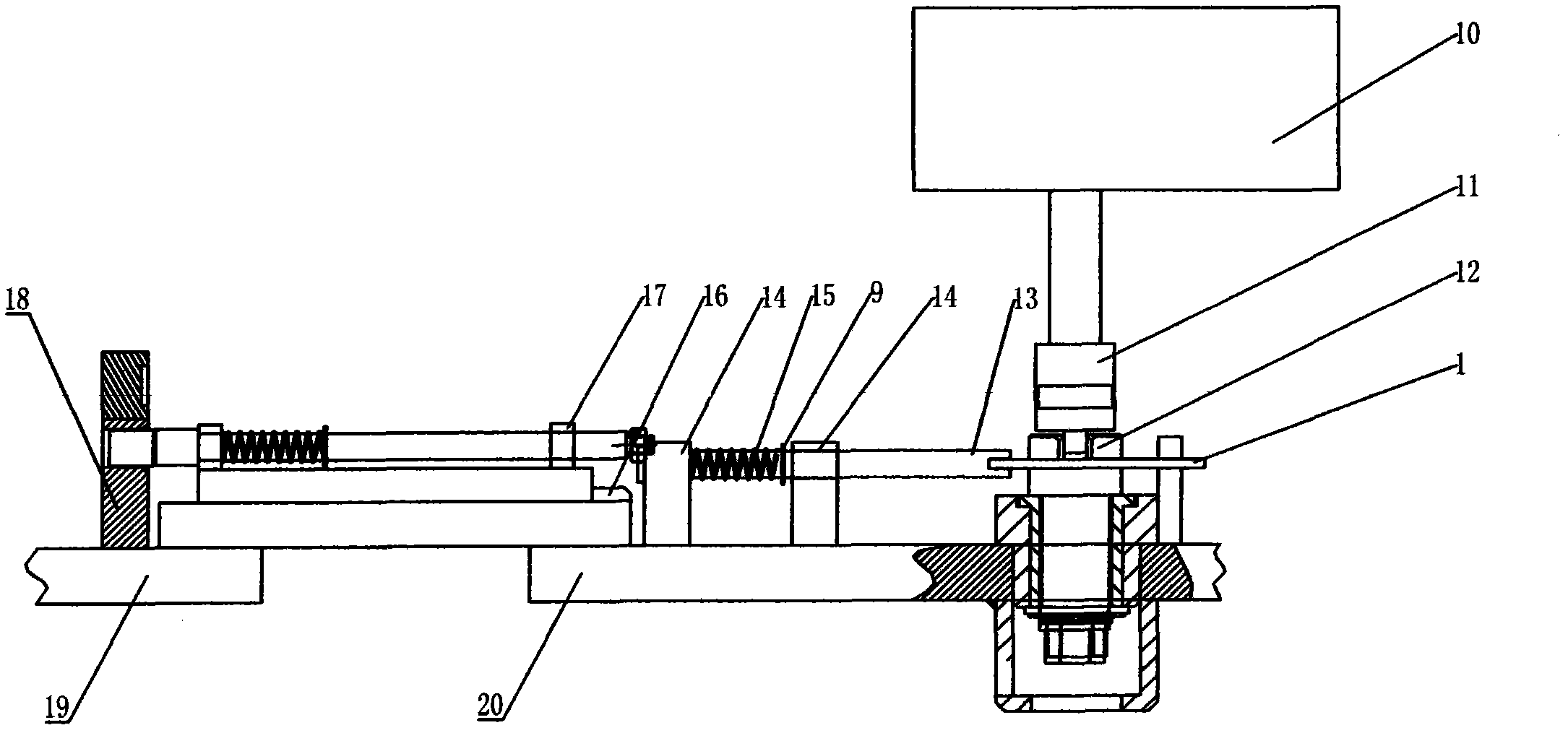

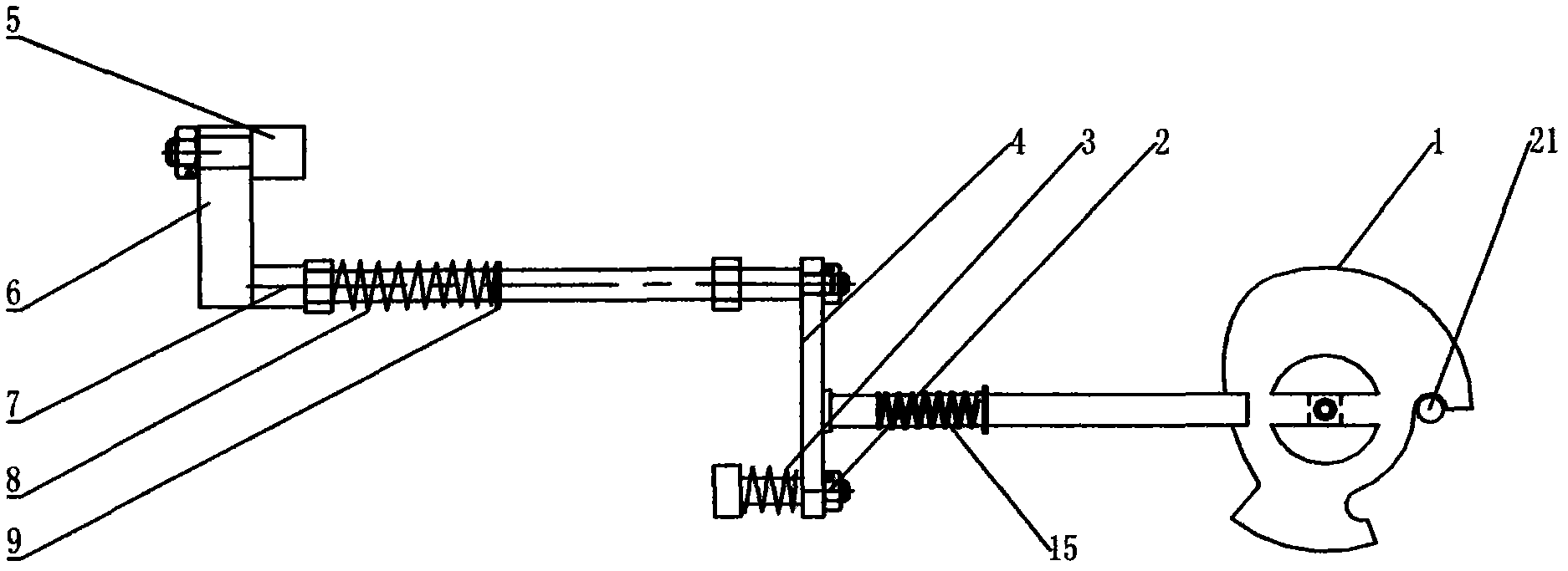

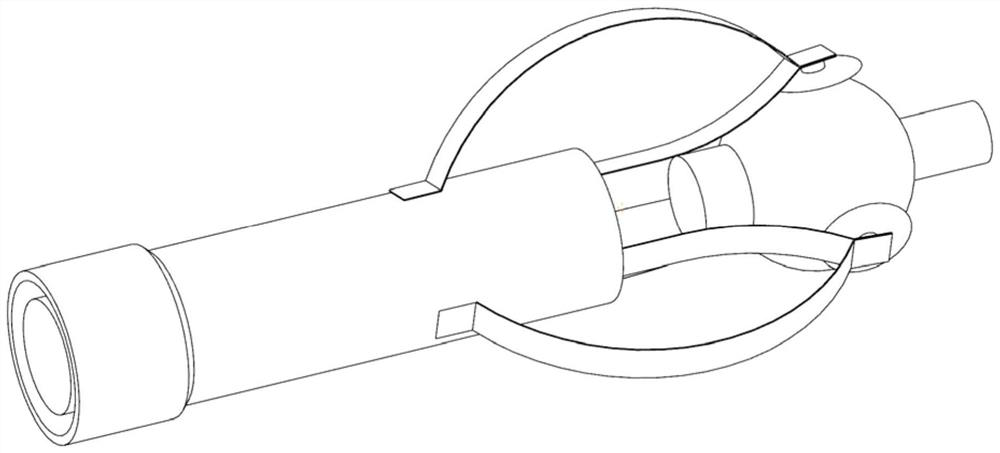

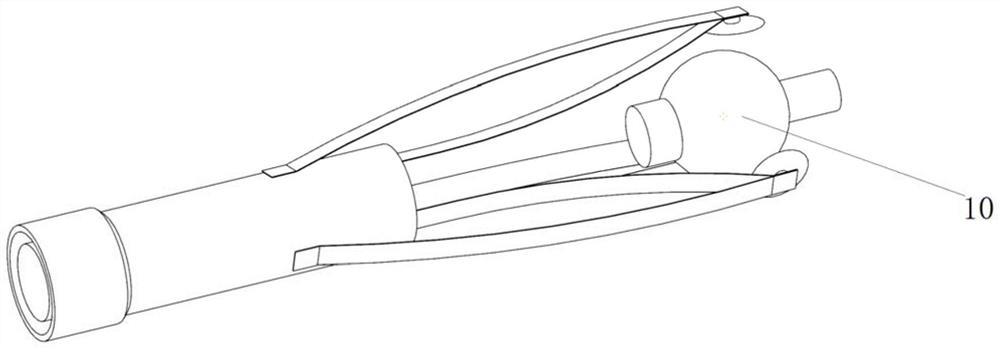

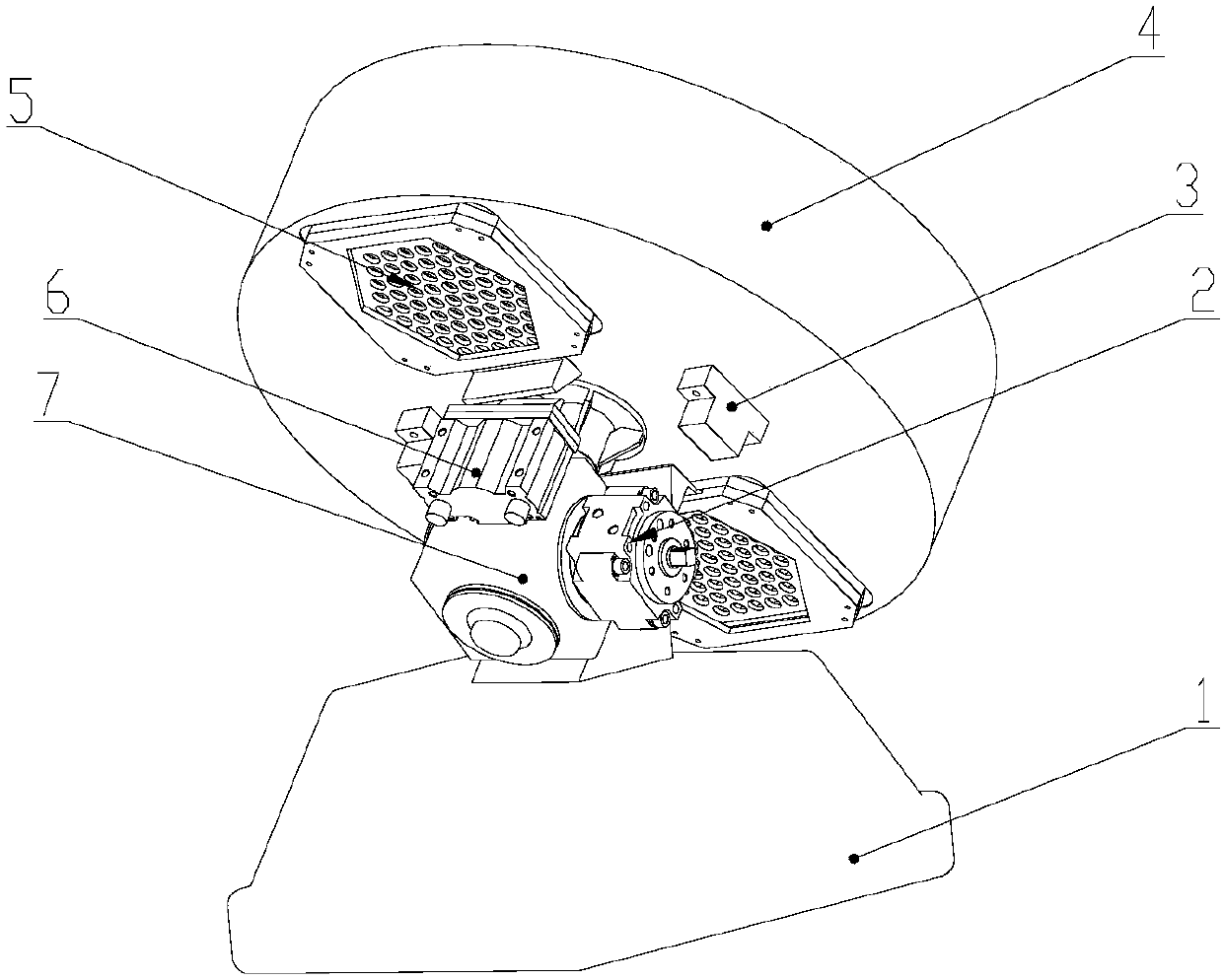

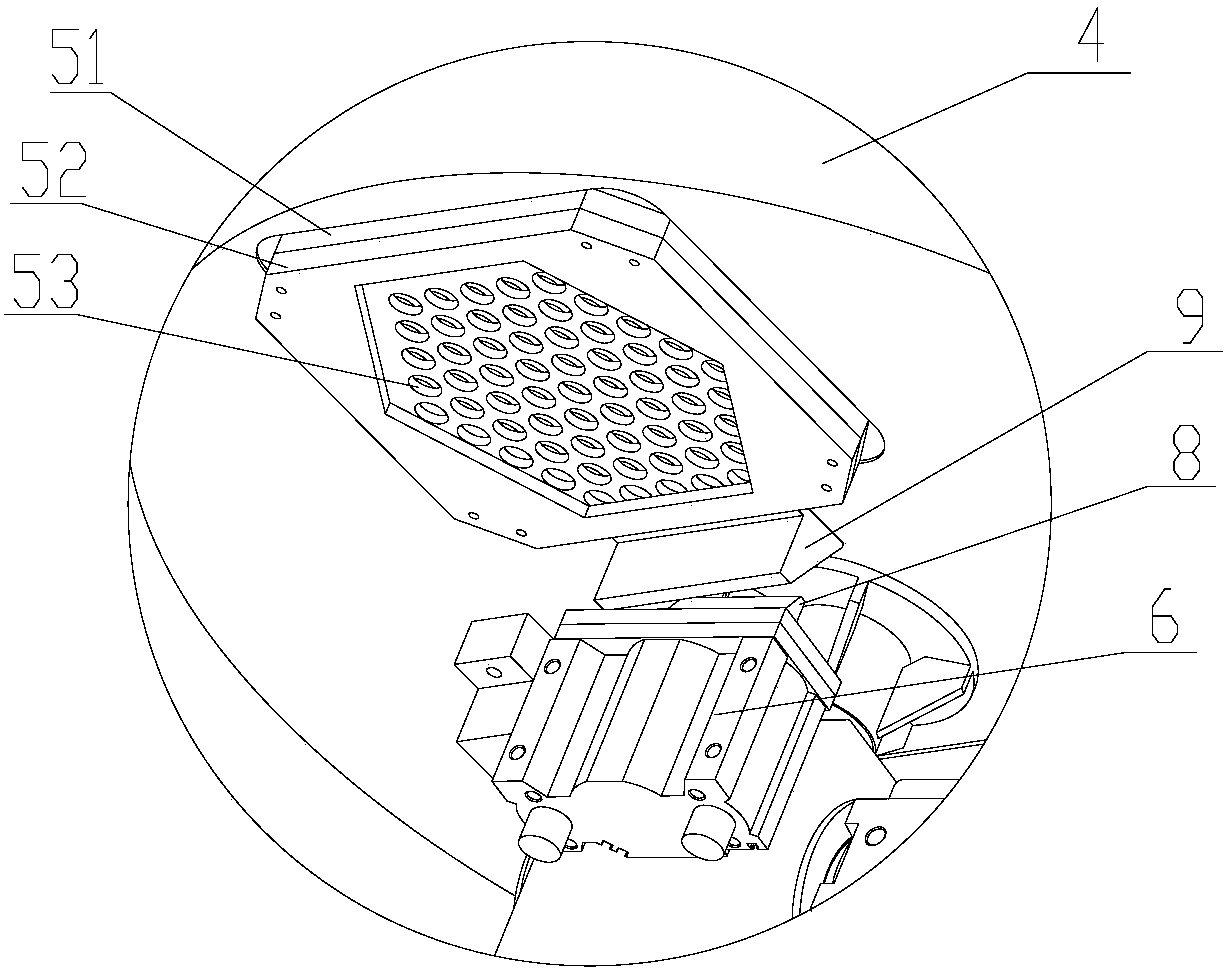

Flexible manipulator for grenade grabbing

InactiveCN113146673AInhibit sheddingReduce the possibility of explosionGripping headsLinear motionEngineering

The invention discloses a flexible manipulator for grenade grabbing. The flexible manipulator comprises a power mechanism, a shell, a guide block, discs, reeds and elastic pieces; the power mechanism is mounted in the shell, one end of each reed is driven by the power mechanism and does linear motion in the shell under the action of the guide block, the other end of each reed stretches out of the shell and is fixedly connected with the corresponding elastic piece and the corresponding disc to form one mechanical arm clamping jaw, and the at least three mechanical arm clamping jaws are evenly distributed on the outer circumference of the shell; one end of each elastic piece is fixedly connected with the corresponding reed, and the other end is fixed to the outer circumference of the shell; the rigidity of the reeds is higher than that of the elastic pieces, when the length of the extending parts of the reeds is greater than the length of the elastic pieces from the end surface to the tail end of the shell, the reeds are opened outwards under the limiting action of the elastic pieces; when the length of the extending parts of the reeds is smaller than the length of the elastic pieces from the end surface to the tail end of the shell, the elastic pieces are bent inwards under the pulling force of the reeds, and meanwhile, the deformation directions of the reeds are opposite to those of the elastic pieces through the elastic force generated by deformation of the reeds to clamp a grenade. According to the flexible manipulator, the safety and reliability of clamping the grenade can be improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

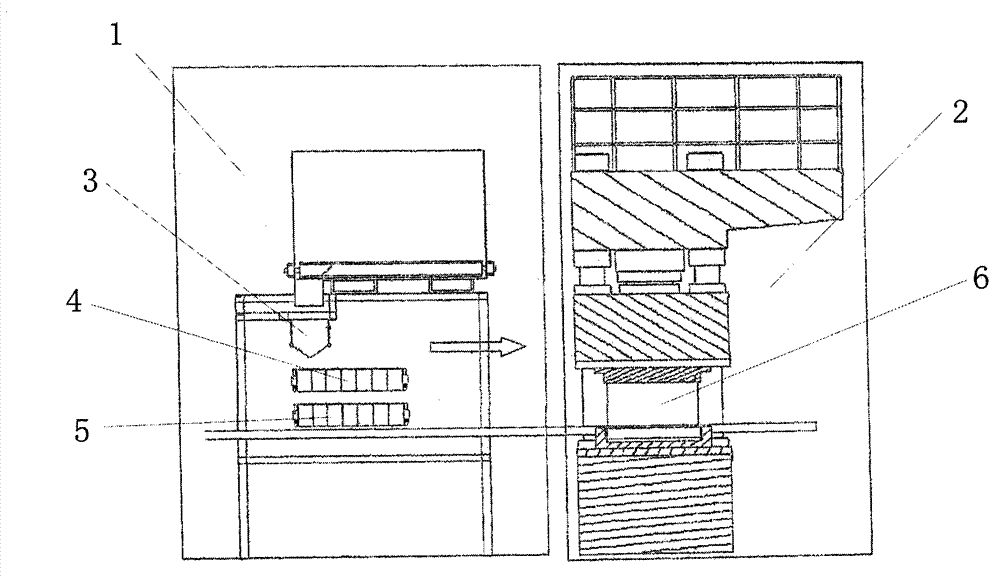

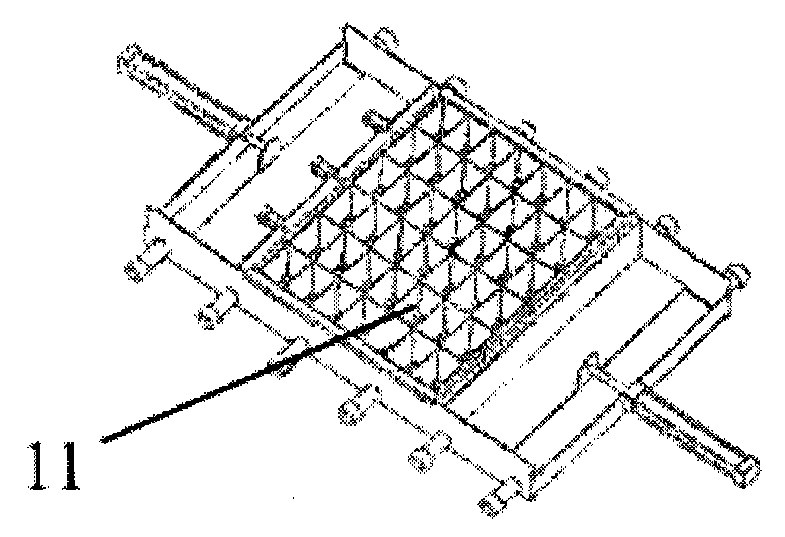

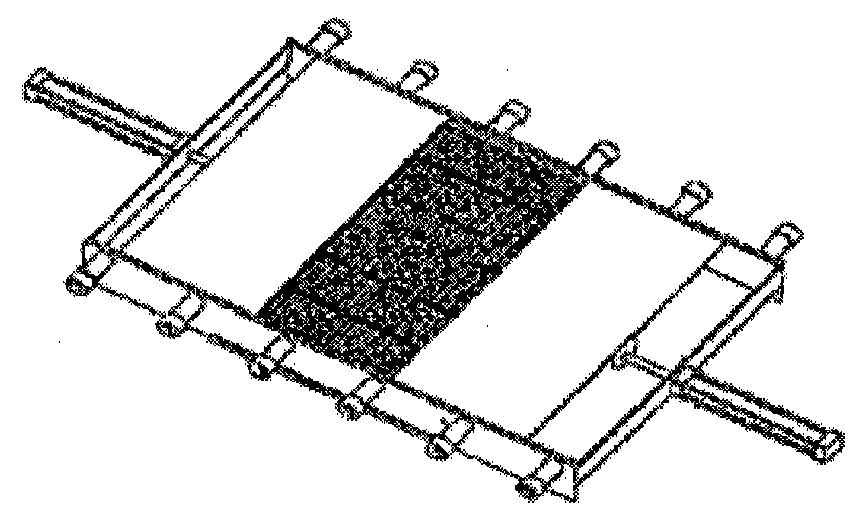

Pressing equipment adopted in method for making molded part and raw material mixture thereof

The invention relates to pressing equipment adopted in a method for making a molded part and a raw material mixture thereof. A moldable mixture does not contain formaldehyde, a hardening agent, an impact-resistant modifier or a co-solvent, and has the characteristics of low water content and the like; the molded part produced through the method for making the molded part has high stretching viscosity and uniform density, and thermal treatment and fumigation are not required; through adoption of the molded part pressing equipment, automatic implementation of the method is realized, and labor force is reduced; and the pressing equipment has the characteristics of high speed and the like.

Owner:王德善

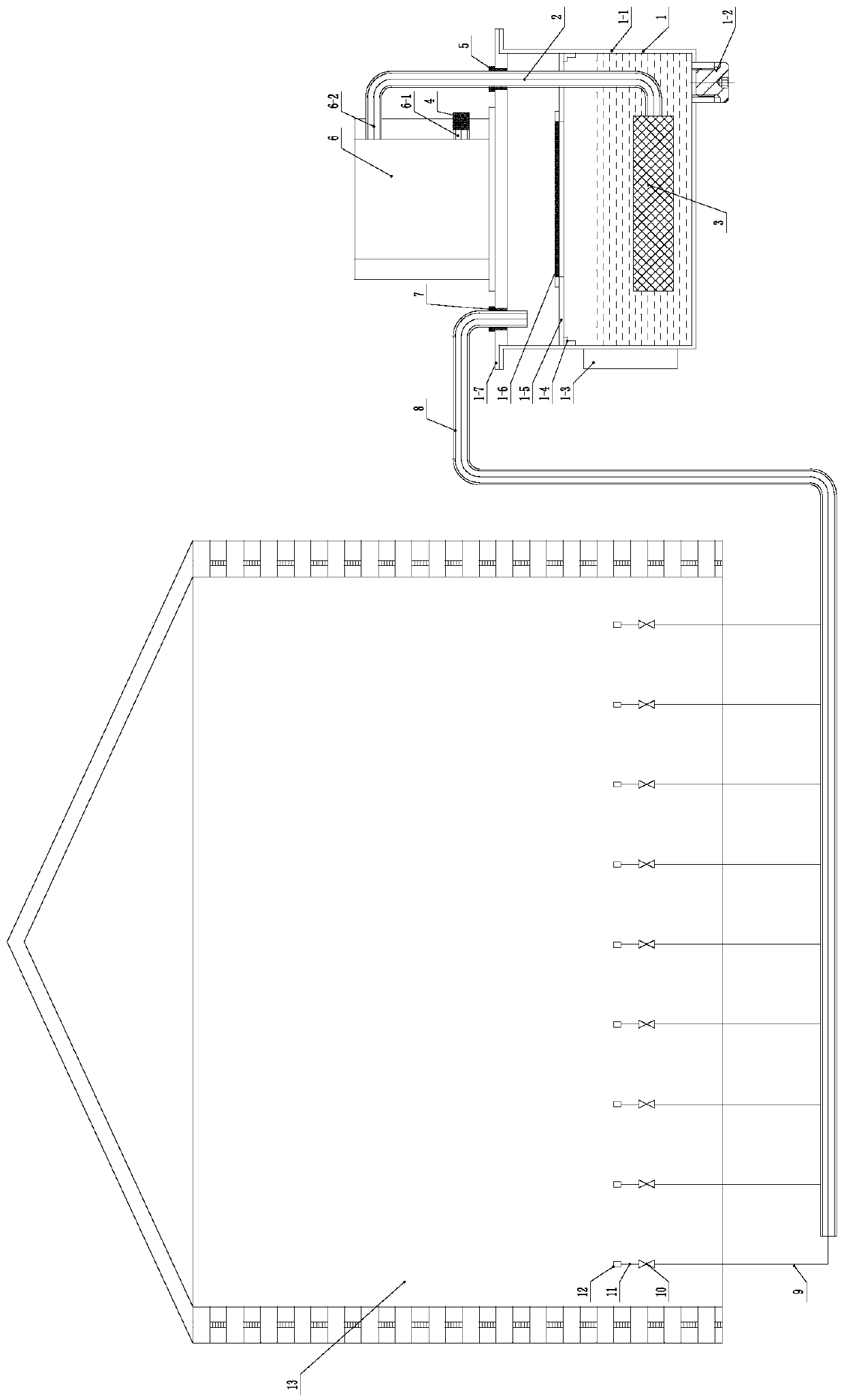

Coal mine underground natural ventilation system and method

ActiveCN104533500BReduce the possibility of explosionSolve the backlogTunnel/mines ventillationNatural ventilationGas explosion

The invention relates to a natural ventilation system for a coal mine underground and a natural ventilation method for the coal mine underground. The natural ventilation system comprises a main air return roadway, a main return air duct, an exhausting chimney, and a return air duct, wherein the return air duct is synchronously extended into a mining area along mining and tunneling actions, gas generated in a tunneling process is extracted and conveyed into the main coal mine air return roadway or the main return air duct through the suction inlet of the return air duct before being diffused, and finally discharged through the exhausting chimney; a return air connection roadway or a return air connection pipeline is arranged on the innermost end of the mining area and the return air pipeline in a first mining area is connected with other subsequent mining areas, or the first mining area is connected with the other subsequent mining areas. According to the system and the method, the problem of gas accumulation in the mining area and the mining empty area is completely solved, so that gas in each place of the mining areas can enter into the main return air roadway or the main return air duct in the first time and cannot be retained in the production area and accumulated in the mining empty area, gas explosion is completely eradicated, the energy is saved and the hole is in a constant temperature status such as warmer winter and cooler summer.

Owner:耿秀

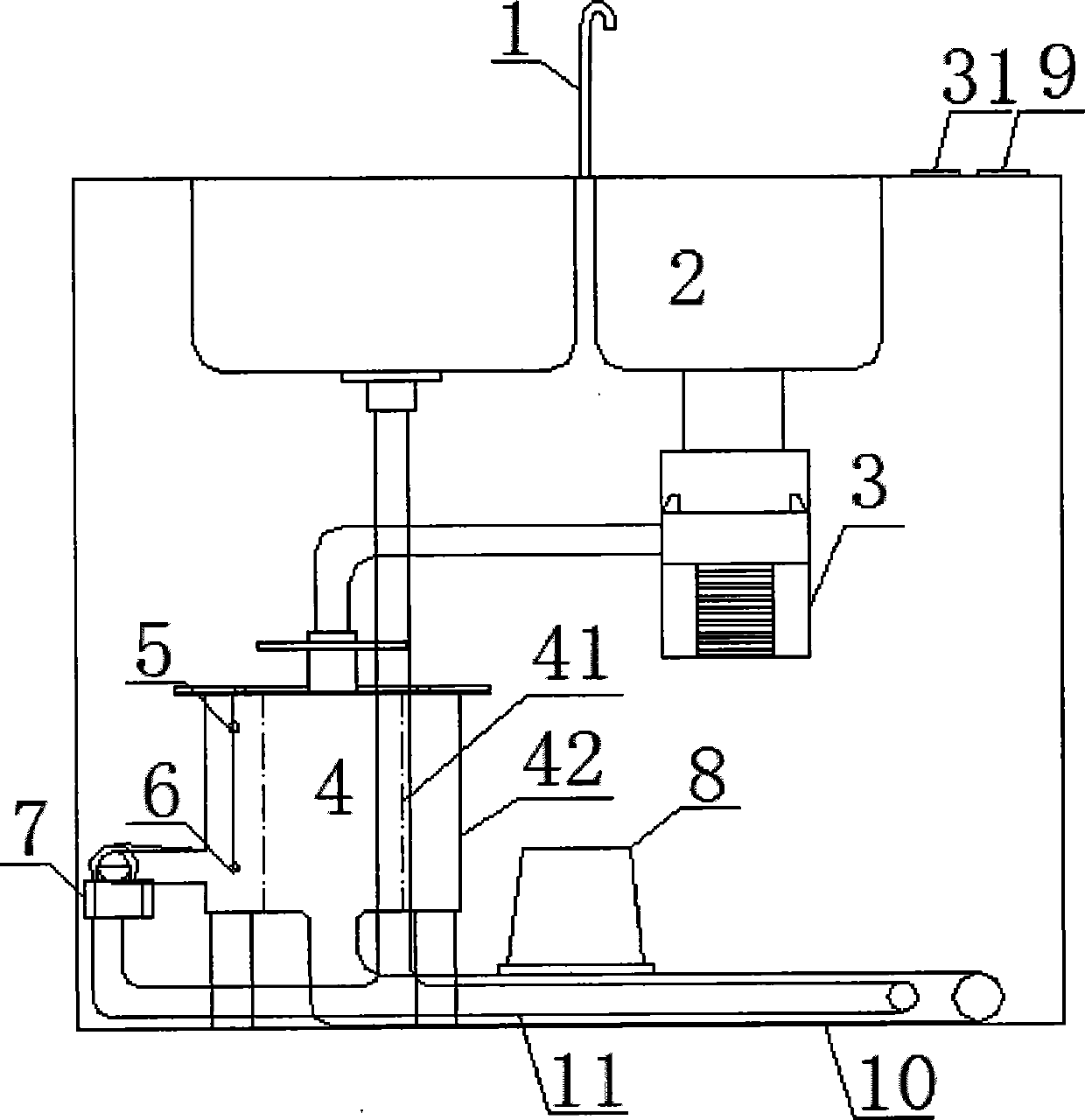

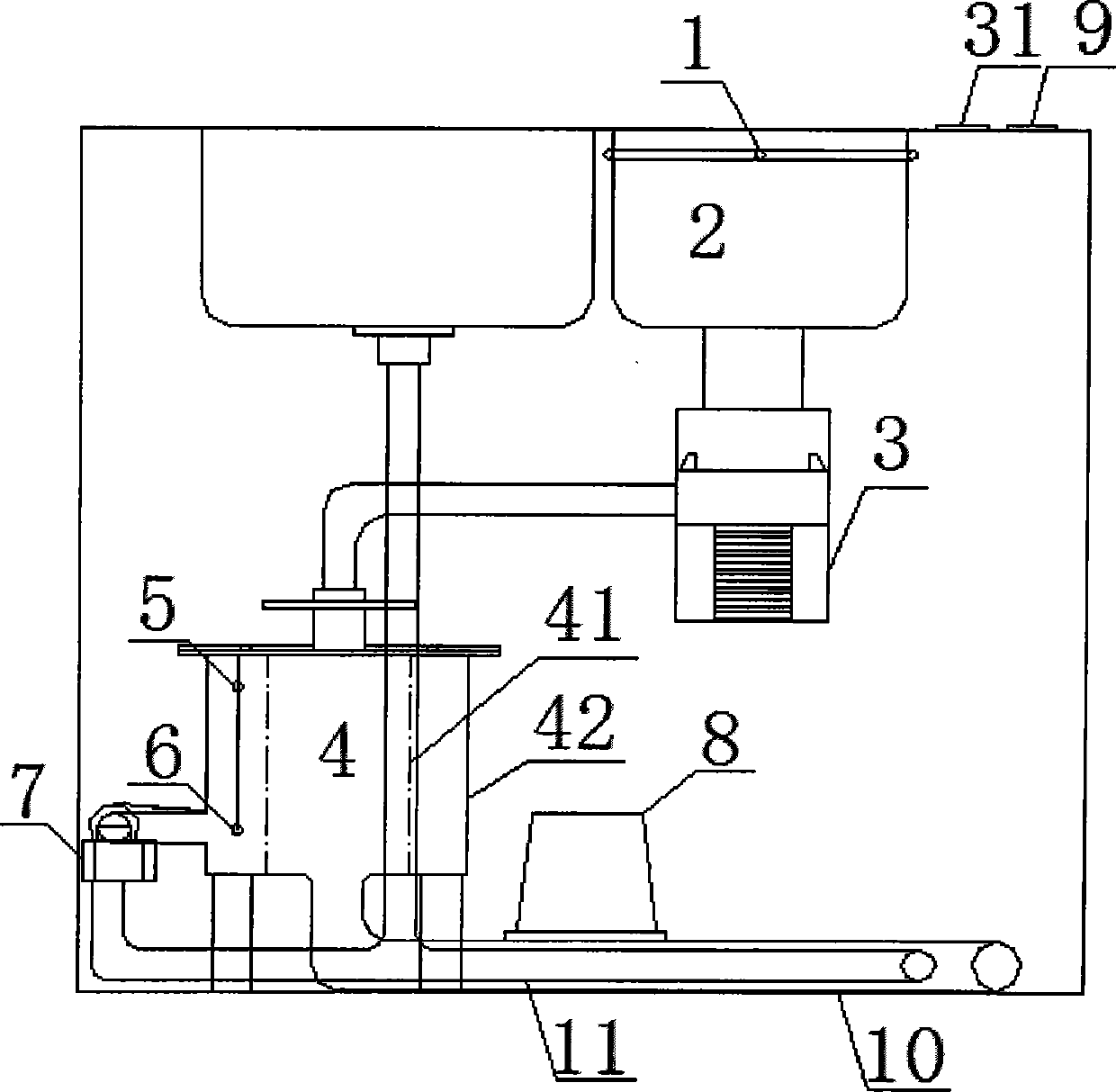

Classified collection system for kitchen garbage sewage

InactiveCN103866821AReduce secondary pollutionRaise the level of taxonomy collectionDomestic plumbingLiquid separationLitterCollection system

The present invention relates to a classified collection system for kitchen garbage sewage, the classified collection system comprises a water supply device, a sewage putting-in device, a crushing machine, a separator, a high-level floating ball, a low-level floating ball, an electromagnetic water valve, a vacuum valve and a selection switch, the electromagnetic valve is connected with a gravity drainage pipe network, and the vacuum valve is connected with a vacuum drainage network. The classified collection system not only solves the problem of classified collection of domestic garbage, but also reduces kitchen garbage production amount, realizes the classified collection of kitchen light sewage and heavy sewage, and is convenient for subsequent processing.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

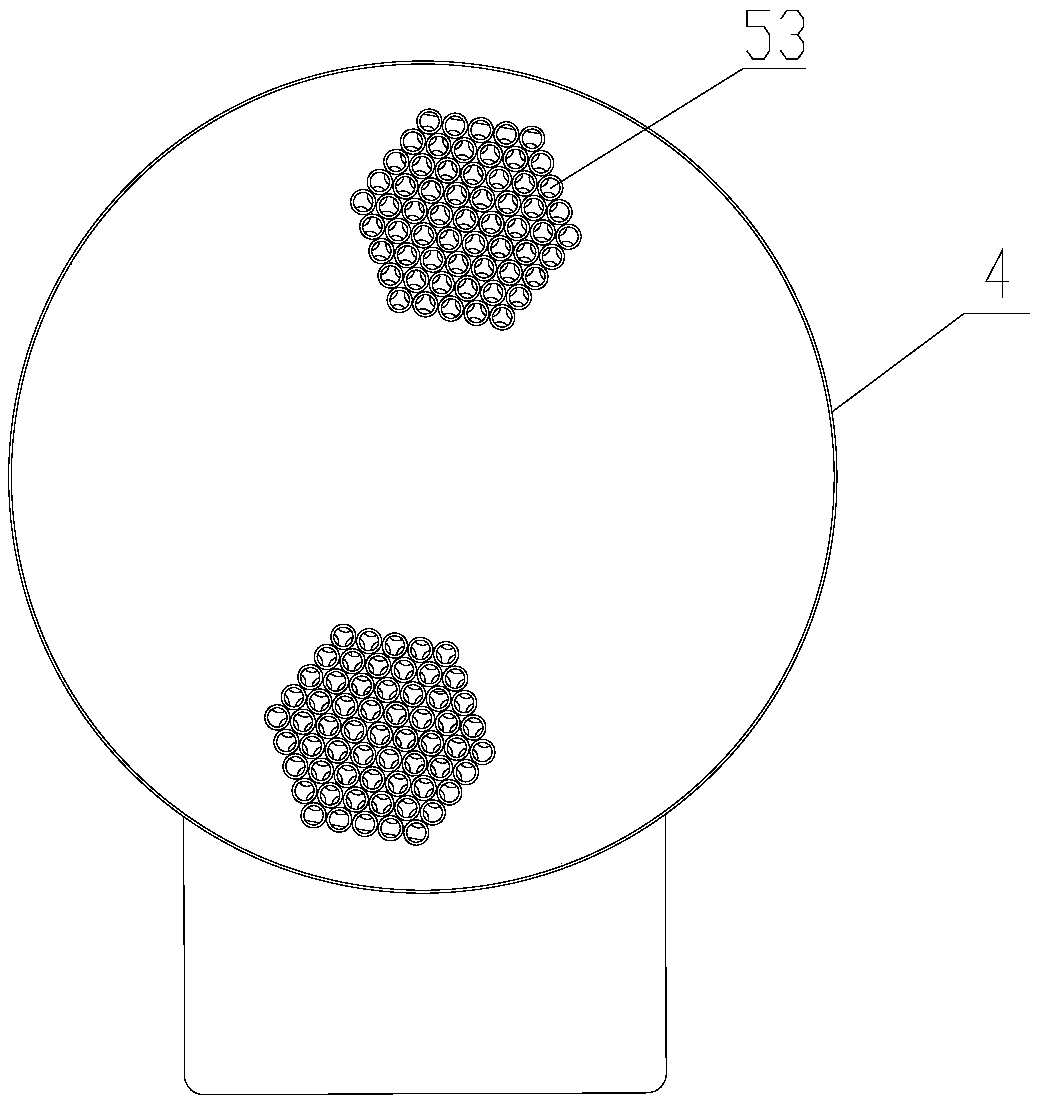

Device for quantitatively filling fireworks inner cylinder drugs

The invention relates to the technical field of production of binding fireworks inner cylinder drug filling, in particular to a device for quantitatively filling fireworks inner cylinder drugs. The device includes an inclined bracket, a rotary driving mechanism, a rotating cylinder block, a vibrator, falling composition plate and a falling driving air cylinder, wherein the rotary driving mechanismis arranged on the inclined bracket and connected with the rotating cylinder block, two discharging ports are symmetrically formed in the bottom of the rotating cylinder block, baffle discharging devices are arranged at the discharging ports correspondingly, the baffle discharging devices are used for controlling discharging of the discharging ports, and the vibrator is arranged on the rotating cylinder block. According to the device for quantitatively filling the fireworks inner cylinder drugs, mechanized filling of the inner cylinder drugs is realized, the consistency and security of filling are ensured, meanwhile, damage to people and the uncertainty of manual filling in the production process are avoided, and then the device can be put into the automatic production line, so that unmanned operation is completed.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

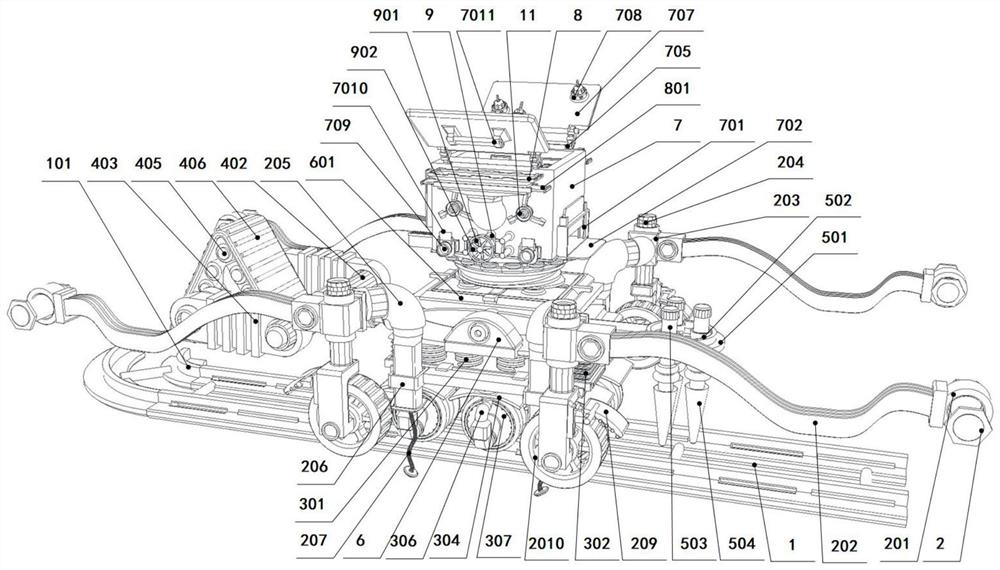

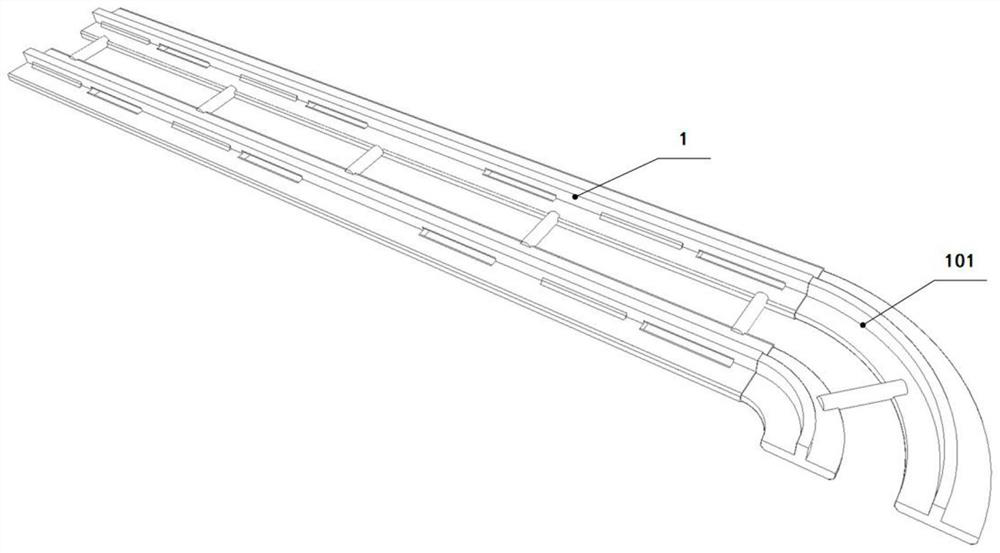

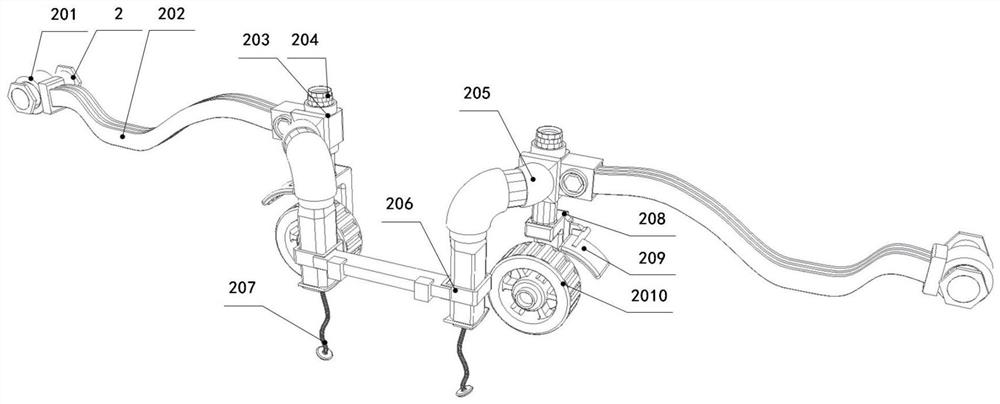

An explosion-proof transport vehicle

ActiveCN111908051BImprovement of self-management abilityPlay the role of heat insulation and coolingFire rescueMechanical conveyorsWater storageThermodynamics

The invention discloses an explosion-proof transport vehicle, which includes straight rails, curved rails, an independent moving system, a rail moving system, a spanning system, a fixing system, a base system, and a loading system; The tool can not only carry out high-speed transfer operations along the established path, but also carry out free-moving transportation operations in complex terrains; through the installation of metal conduits in the independent moving system, even if the carrier encounters strong external factors such as lightning strikes in the work site At the same time, by storing water in the box of the loading system and setting a flip door above the box, it can play a role in heat insulation and cooling, so that the vehicle will not have accidents due to a sharp rise in temperature after a long period of exposure Accident; by setting the wave plate and the baffle rod in the loading system, the slippage of coal particles is limited to the greatest extent, the filling rate between coal materials can be improved, and the possibility of friction sparks caused by materials can also be reduced.

Owner:山东中煤工矿物资集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com