Power battery and manufacturing method thereof

A power battery and manufacturing method technology, which is applied in the direction of electrolyte battery manufacturing, secondary batteries, battery pack components, etc., can solve problems such as hidden dangers of explosion, large changes in battery parameters, hidden dangers of battery safety, etc., to ensure safety, The inner core capacity is large and the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

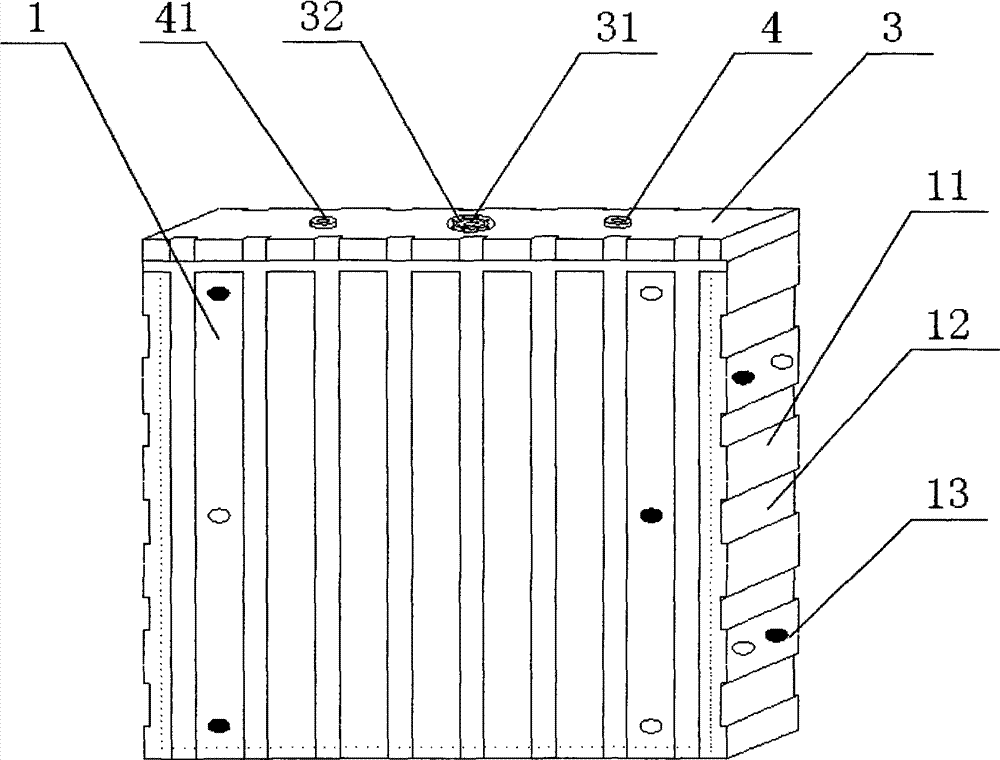

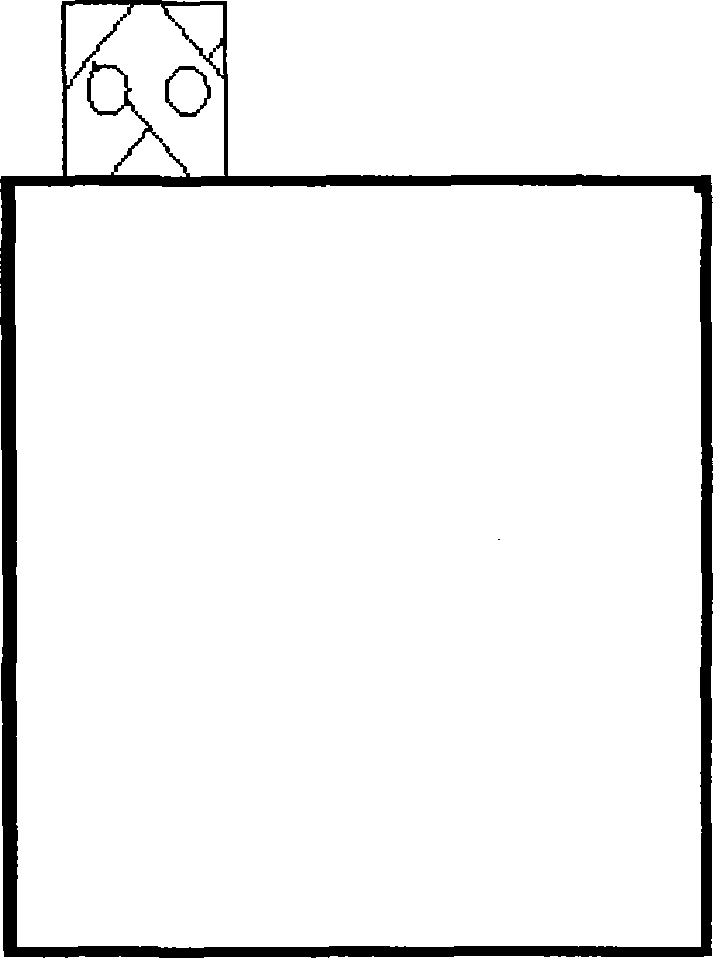

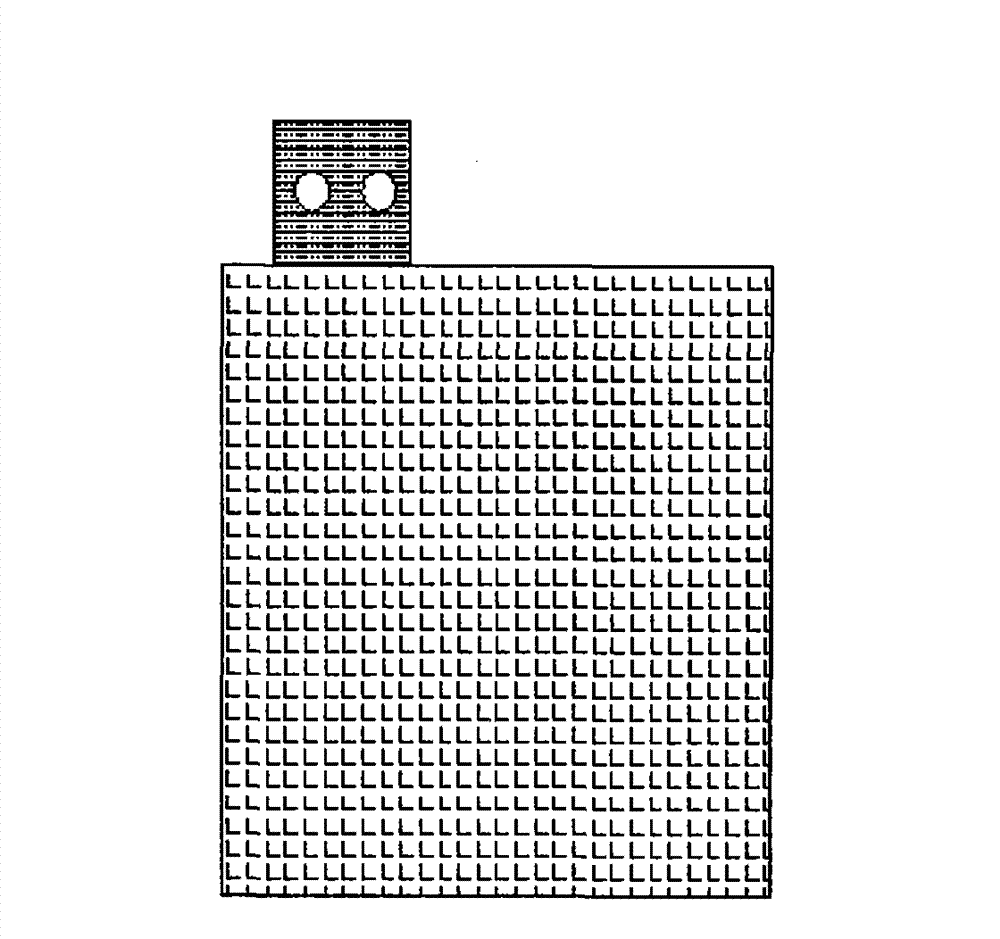

[0029] Please refer to the attached figure 1 to attach image 3 As shown, the present invention is a method for manufacturing a power battery, which includes the following process steps:

[0030] 1), LiFePO4 (lithium iron phosphate), super-p conductive agent, ks-6 conductive agent, CNT (carbon nanotube), PVDF (polyvinylidene fluoride) according to the weight ratio of 91:3:0.5:1.5:4 Mix, or LiFePO4 (lithium iron phosphate), super-p conductive agent, ks-6 conductive agent, CNT, LA132 (aqueous binder for lithium-ion batteries) in a weight ratio of 91:3:0.5:1.5:4 Mixing, using a planetary mixer to stir evenly, and coating on the aluminum foil to form a positive pole piece; wherein, the thickness of the aluminum foil is 16um, the coating surface density is 290g / m2, and the compacted density is 2.28g / cm3;

[0031] 2) Mix graphite, super-p conductive agent, PTFE (polytetrafluoroethylene), and CMC (adhesive) in a weight ratio of 92.5:2:1:4.5, and coat it on the copper foil to form ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com