Hydrocarbon refrigerant with intrinsic safety

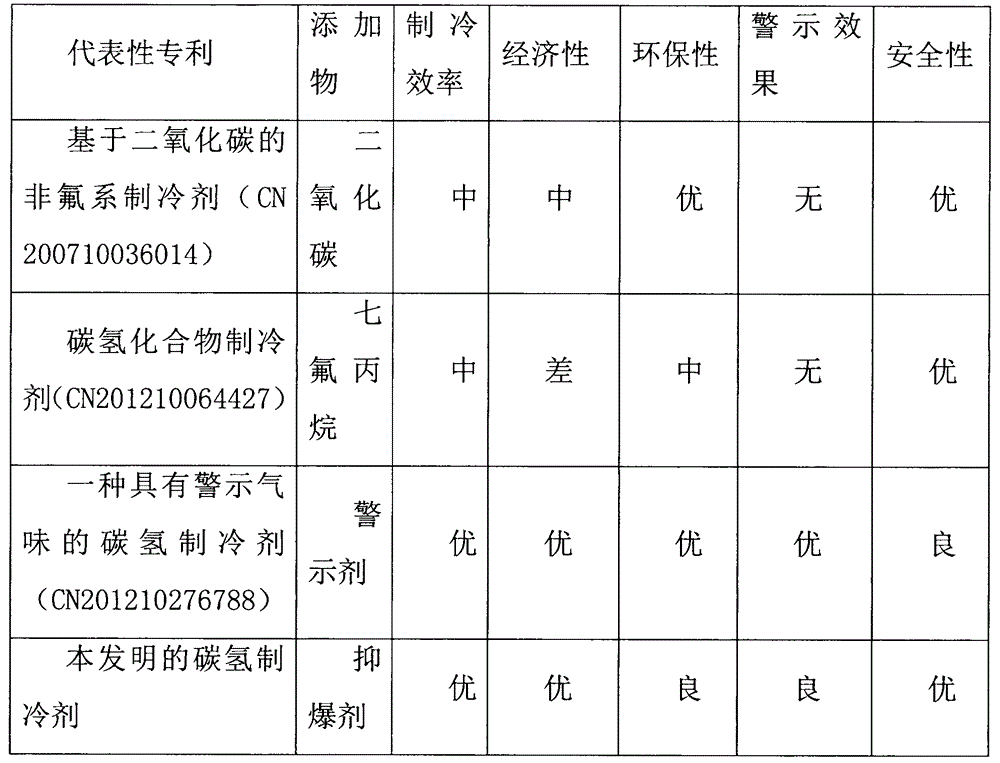

A technology of hydrocarbon refrigerants and refrigerants, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problem of hydrocarbon refrigeration systems being prone to explosion, destruction of the ozone layer or greenhouse effect, shortening the service life of compressors, etc. problem, to achieve the effect of eliminating the possibility of explosion, significant warning effect, and suppression of explosive reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: the present invention is mixed by low-carbon paraffin refrigerant and explosion suppressant, wherein, low-carbon paraffin refrigerant is propane, and anti-knock agent accounts for 1% (by the total mass of low-carbon paraffin refrigerant) , The explosion suppressant is tetraethyl lead. The evaluation of the warning odor and warning intensity of the finished product of the present invention is divided into 3 grades (weak), and the pressure value after ignition is 0.9MPa (refrigerant partially explodes).

Embodiment 2

[0026] Embodiment 2: The present invention is composed of a low-carbon paraffin refrigerant mixed with an explosion suppressant, wherein the low-carbon paraffin refrigerant is composed of a mixture of 63% propane and 37% isobutane. The antiknock agent accounts for 2% (according to the total mass of the low-carbon alkane refrigerant), and the antiknock agent (according to the mass ratio of the antiknock agent) is composed of 50% tetramethyl lead, 25% tetraethyl lead and 25% five Carbonyl iron mixed composition. The evaluation of the warning odor and warning intensity of the finished product of the present invention is divided into 5 grades (general), and the pressure value after ignition is 0.3MPa (refrigerant partial explosion).

Embodiment 3

[0027]Embodiment 3: The present invention is composed of a low-carbon paraffin refrigerant mixed with an explosion suppressant, wherein the low-carbon paraffin refrigerant is composed of a mixture of 100% propane and 0% isobutane. The antiknock agent accounts for 3% (according to the total mass of the low-carbon paraffin refrigerant), and the antiknock agent (according to the mass ratio of the antiknock agent) is tetramethyl lead. The evaluation of the warning smell and warning intensity of the finished product of the present invention is divided into 8 grades (very strong), and the pressure value after ignition is 0.1MPa (refrigerant does not explode).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com