Coal mine underground natural ventilation system and method

A natural ventilation and coal mine technology, which is applied in mine/tunnel ventilation, mining equipment, earthwork drilling, etc., can solve the problems of huge waste of equipment and energy, poor fluidity of dirty gas, loss of life and property, etc., to achieve energy saving, The effect of small exhaust air volume and high ventilation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

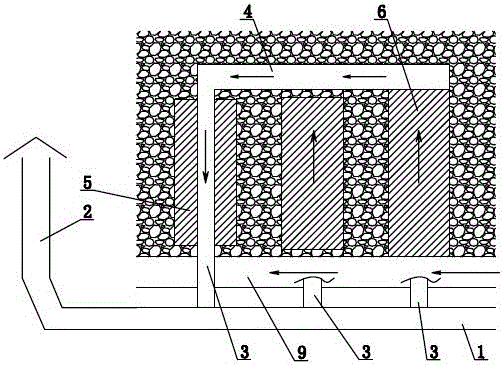

[0036] like figure 1 Shown, this coal mine underground natural ventilation method comprises the following steps:

[0037] 1) The return air duct 3 is airtightly connected with the main return air tunnel 1 or the main return air duct of the coal mine, and the suction port of the return air duct 3 extends into the mining area 6 synchronously with the coal mining excavation action. Under the action of the difference in temperature, the fresh air enters the roadway of the mining area 6 from the main roadway 9, and the gas generated during the excavation process is led out by the return air duct 3 and sent to the main circuit of the coal mine before being diffused under the action of the temperature difference and pressure difference. The wind tunnel 1 or the main return air duct is finally discharged by the discharge chimney 2;

[0038] 2) After the mining in the first mining area is completed, both ends of the first goaf 5 are closed, and at the same time, the suction port of th...

Embodiment 2

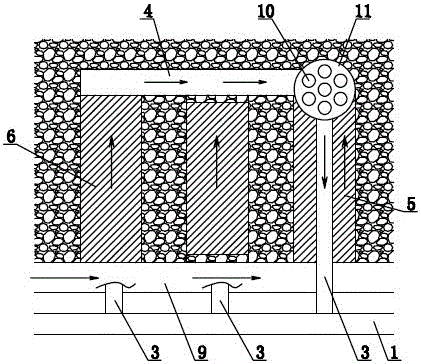

[0041] like figure 2 Shown, this coal mine underground natural ventilation method comprises the following steps:

[0042] 1) The return air duct 3 is airtightly connected with the main return air tunnel 1 or main return air duct of the coal mine. Under the effect of temperature difference, fresh air enters the roadway of the mining area 6 from the hole, and the gas generated during the excavation process is led out by the return air duct 3 under the action of the pressure difference and temperature difference and sent to the main return air roadway 1 or the main air return roadway of the coal mine. The return air duct is finally discharged by the discharge chimney 2;

[0043] 2) After the excavation of the first mining area is completed, a plurality of boreholes 10 connecting the mining area with the outside world are drilled on the top rock mass at the innermost end of the mining area. Collapsing and blocking, then build a large chimney 11 at the top of the combined boreho...

Embodiment 3

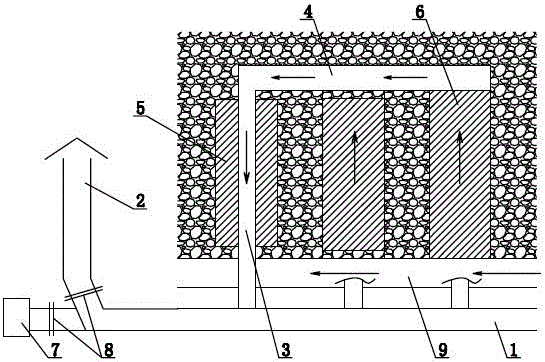

[0046] like image 3 As shown, the induced draft fan 7 connected with the main air return roadway 1 or the main air return duct is installed at the bottom of the discharge chimney 2, so that fresh gas will be introduced into the main roadway 9 and each mining area 6 in calm wind or light wind weather. The blower fan 7 and the discharge chimney 2 cannot be opened at the same time, and the pipe in front of the induced draft fan 7 and the pipe leading to the discharge chimney 2 are provided with a valve 8 or a damper to switch the flow direction of the dirty air. Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com