Pressing equipment adopted in method for making molded part and raw material mixture thereof

A mixture and molded product technology, applied in the field of molded product raw material mixture, can solve the problems of warping of molded products, long molding time, mold explosion, etc., to reduce the risk of delamination, prevent inconsistent specifications, and reduce cycle time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

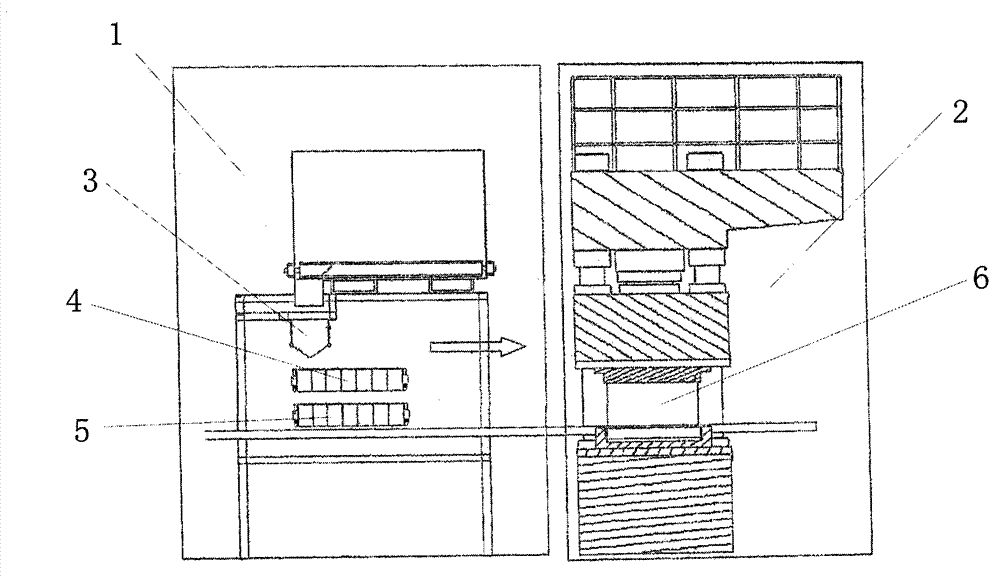

[0117] see figure 1 , a molded product pressing equipment, including a vibrating feeder 1 and a thermocompression molding machine 2, the vibrating feeder includes a material box for storing a moldable mixture, a weighing funnel 3 and a charging platform, the weighing The hopper is installed at the outlet of the hopper, the charging platform is arranged directly below the weighing hopper, the charging platform is provided with a movable transfer feeding tray 5, and the transferring feeding The tray has two stations, wherein the first station is located on the charging platform directly below the weighing funnel, and the second station is located at the feed port 6 of the thermocompression molding machine.

[0118] Preferably, a transfer feeding tray 4 is also provided between the charging platform and the weighing funnel, and the transfer feeding tray is located directly above the first station.

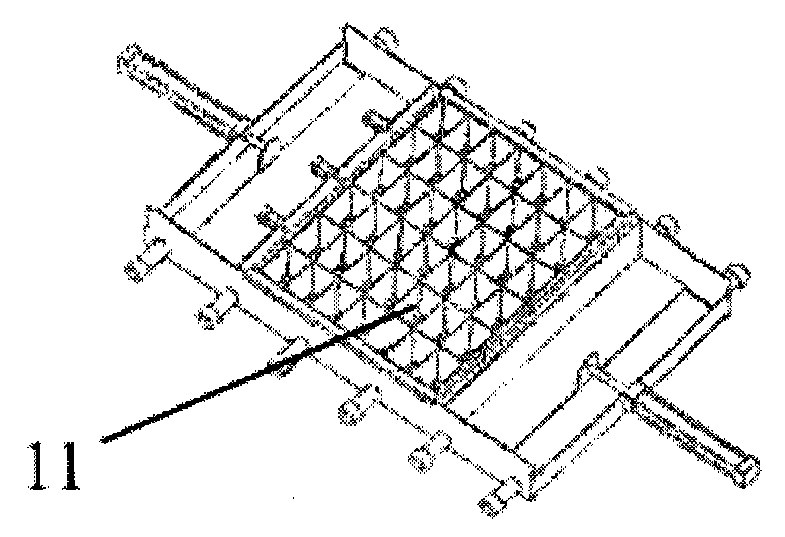

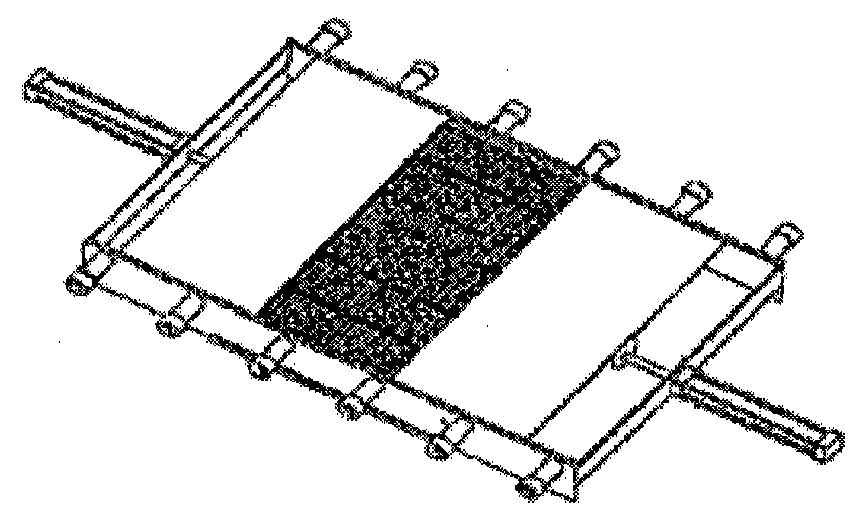

[0119] see figure 2 and image 3 , preferably, both the transfer feeding tray...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com