A combined endothermic and exothermic hydrogen production reactor

A hydrogen production reactor, heat absorption and exothermic technology, applied in the field of hydrogen energy, can solve the problems of low reaction temperature of endothermic reaction, decrease of reaction conversion rate, failure to proceed normally, etc., achieve scale optimization, easy control, and solve the problem of uneven material distribution uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

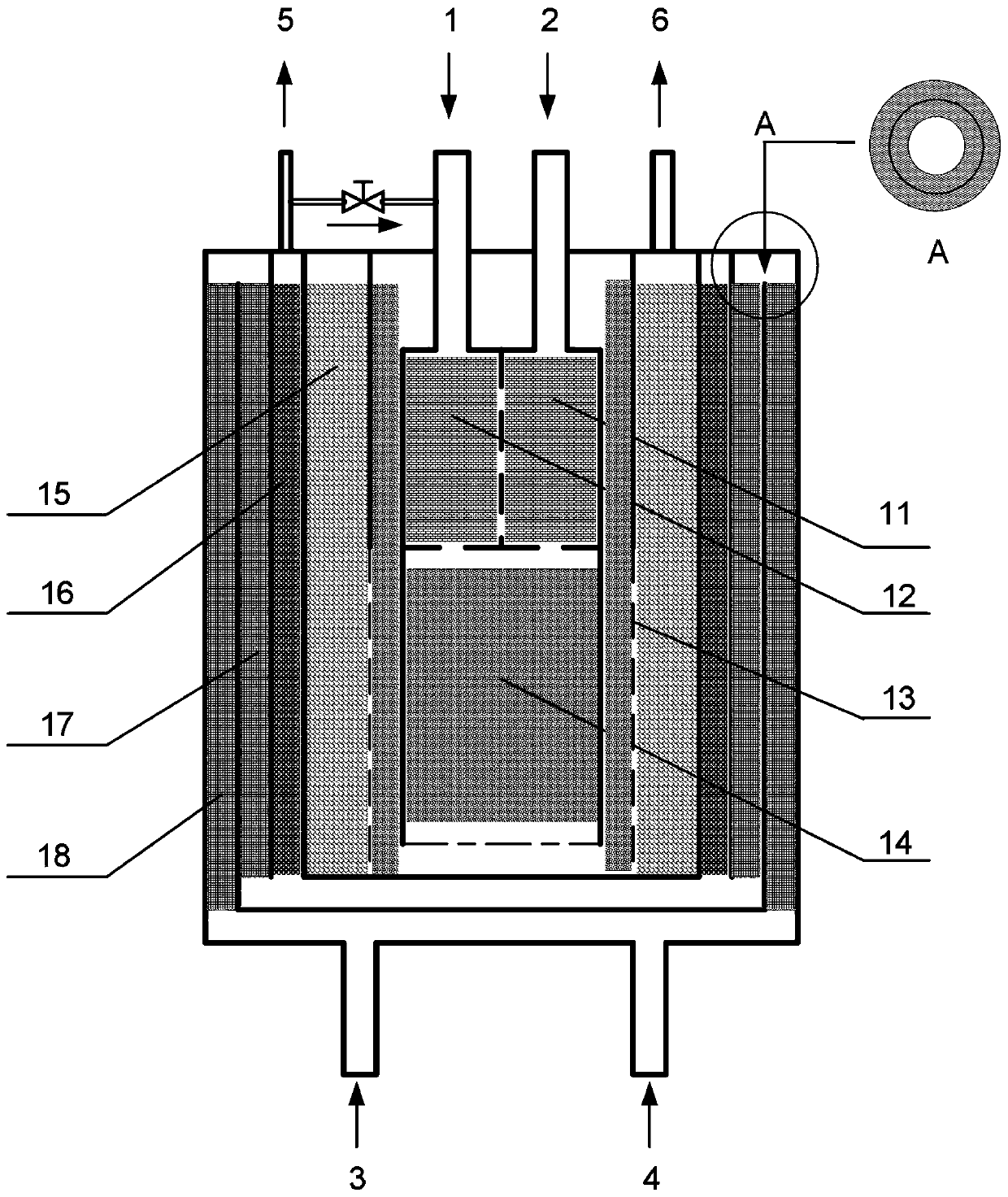

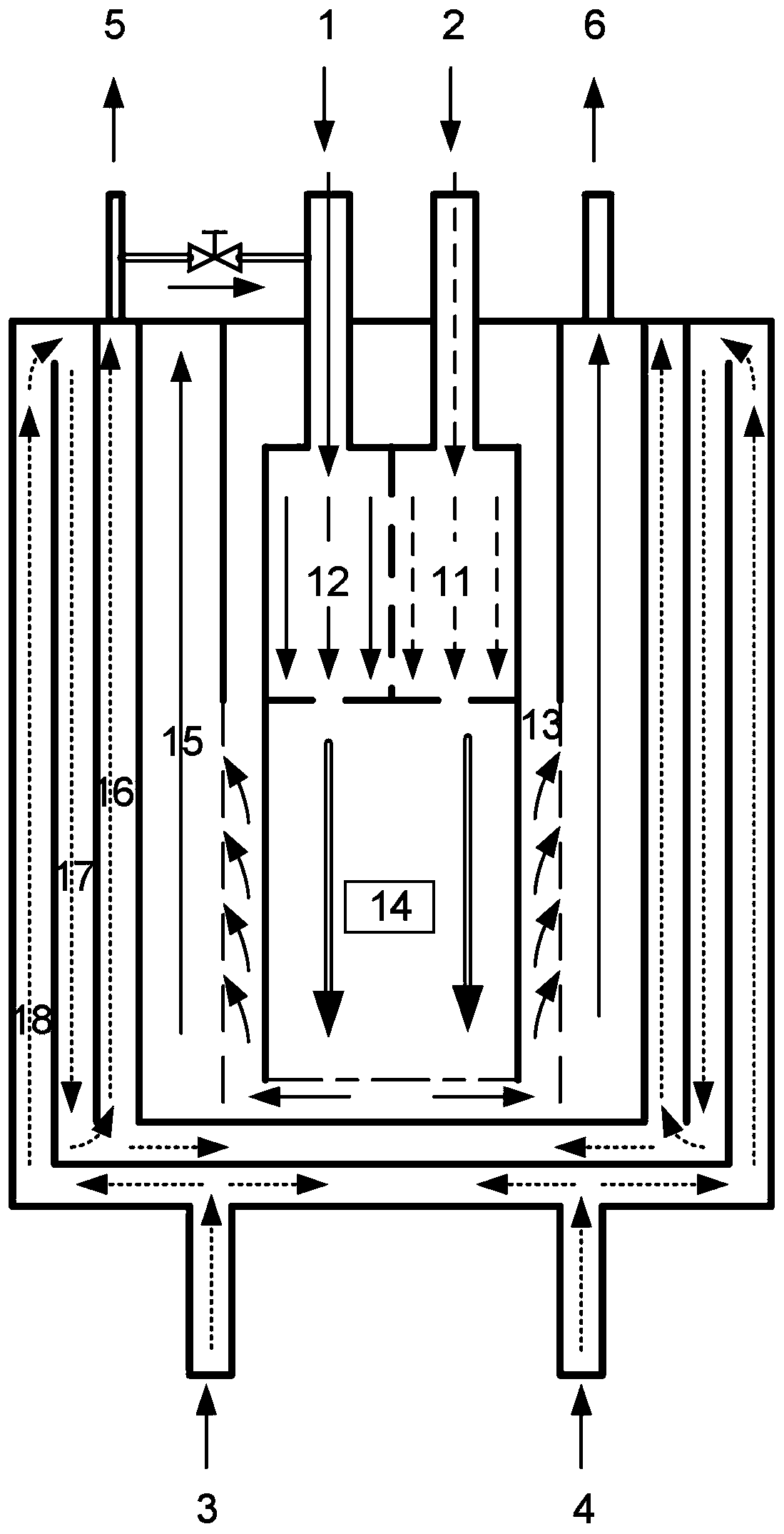

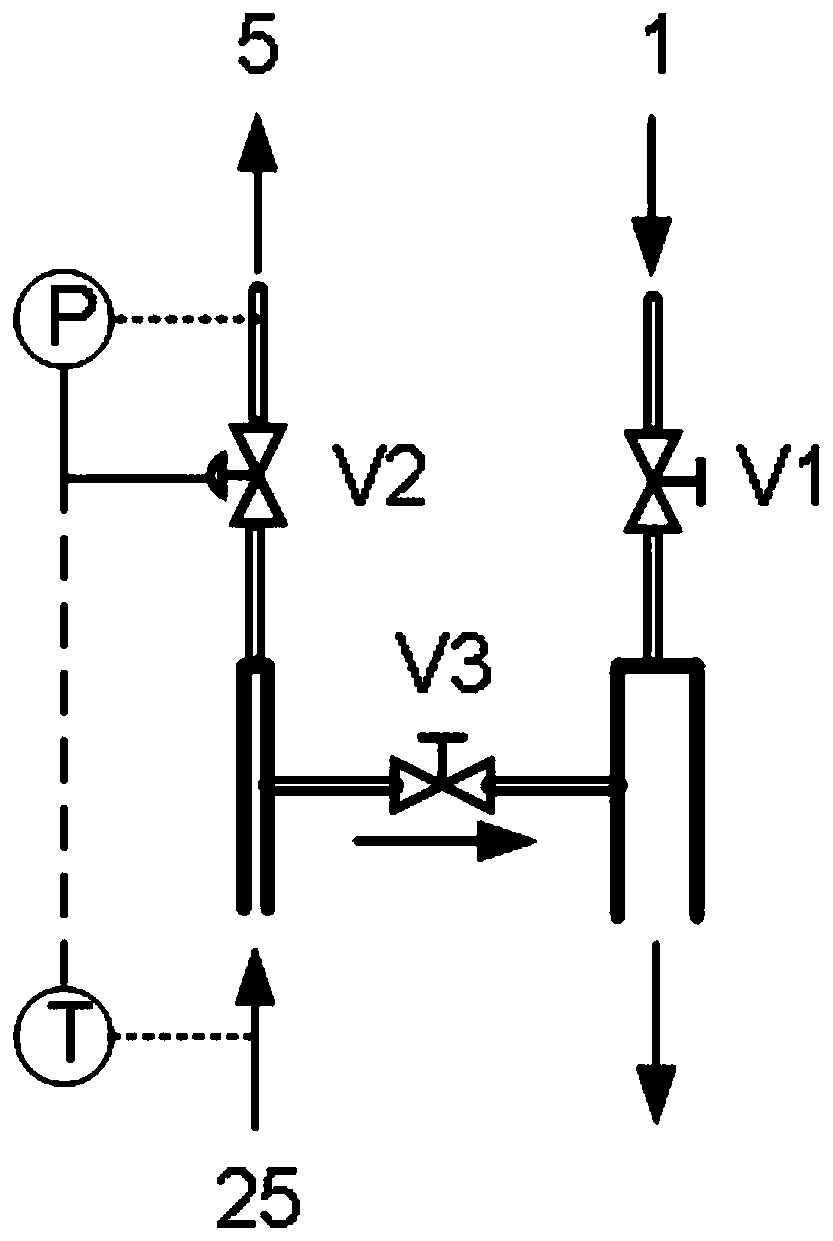

[0028] Such as figure 1 As shown, a schematic diagram of an axial cross-section of a hydrogen production reactor coupled with heat absorption and release, the reactor is a concentric multi-layer cylindrical structure, and from the outer layer to the inner layer are successively low-temperature reaction raw material chambers 18 and high-temperature reaction raw material chambers 17, the hydrogen production reaction chamber 16, the combustion reaction chamber 15, the combustion distribution chamber 13, the combustion mixing chamber 14 and the buffer chamber above the combustion mixing chamber 14. The hydrogen production reactor has 4 material inlets and 2 material outlets. The material inlets are: combustion raw material inlet 1, air inlet 2, hydrogen production raw material inlet 3 and water inlet 4; material outlets are: product gas outlet 5 and combustion tail gas exit6. An air inlet 2 is provided above the air buffer chamber 11, a combustion raw material inlet 1 is provided...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com