Novel electric stirring machine

An electric mixer, a new type of technology, applied in the direction of mixer accessories, mixers with rotating stirring devices, mixers, etc., can solve the problems of uneven additive addition effect, unsatisfactory mixing effect of additives and raw materials, etc., to achieve mixing effect Ideal, evenly added effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

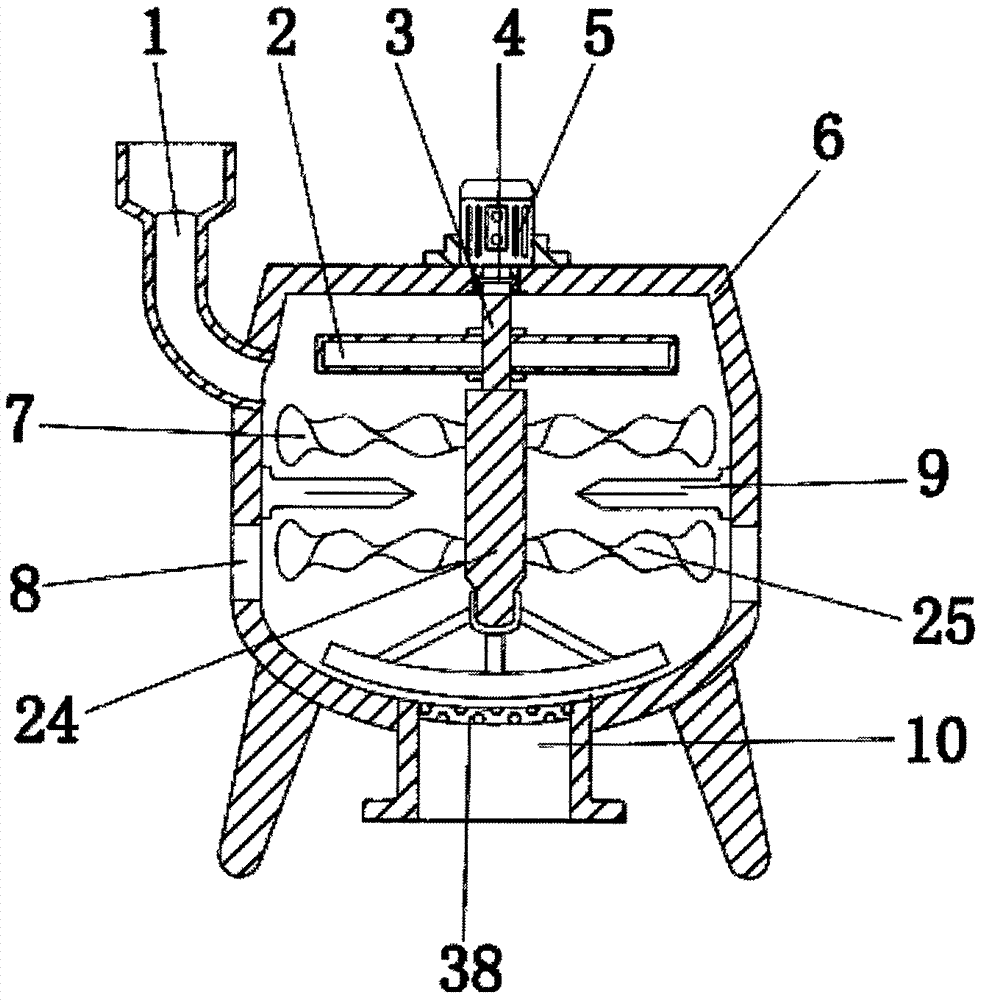

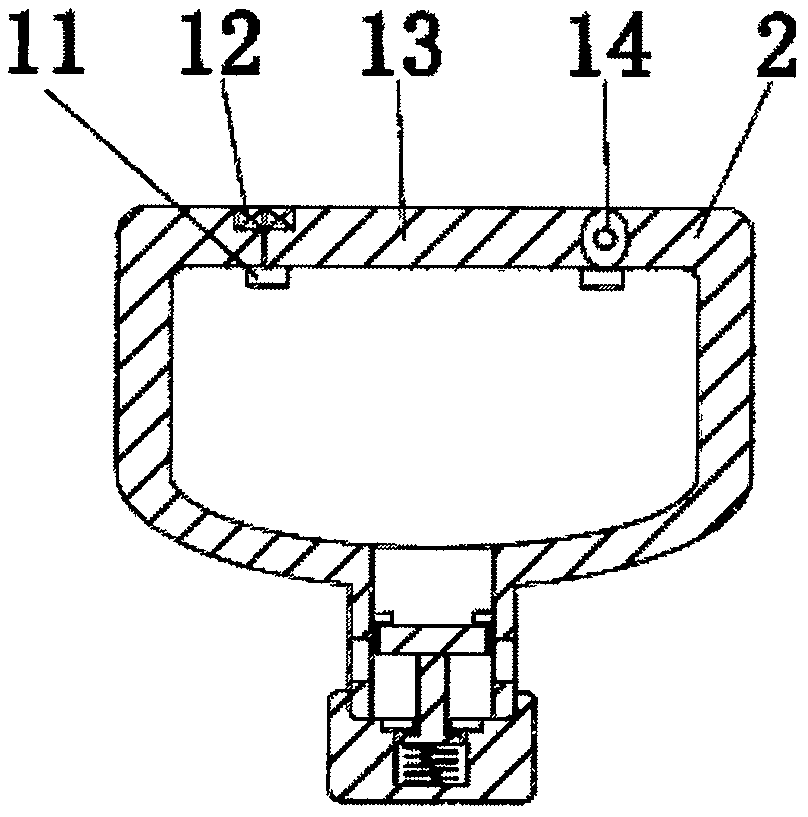

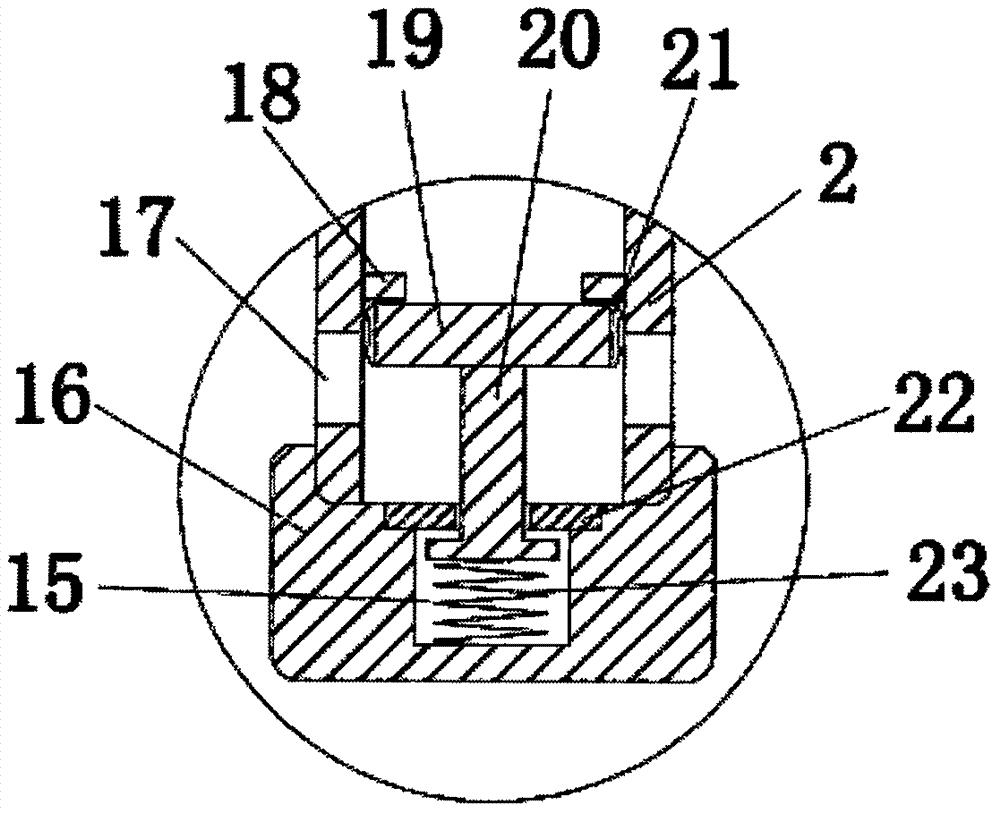

[0016] Example 1: Please refer to Figure 1-5 , the present invention provides a technical solution: a new type electric mixer, including a casing 6, the left top and bottom center of the casing 6 are respectively provided with a hopper 1 and a discharge hopper 10, the top center of the casing 6 A servo motor 5 is installed, the model of the servo motor 5 is MR-J2S-10A, and it is connected with an external power supply, the external power supply is 380V AC, the servo motor 5 works when the external power supply of the servo motor 5 is connected, and the external power supply of the servo motor 5 is disconnected. The power supply servo motor 5 stops working, the inner top of the casing 6 is provided with a rotating rod 3, the rotating rod 3 is connected with the servo motor 5 through a coupling 4, the bottom end of the rotating rod 3 is equipped with a stirring roller 24, and the outer side of the stirring roller 24 The first stirring blade 7 and the second stirring blade 25 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com