Sealed mixing tank wall washing device

A flushing device and mixing tank technology, which is applied in the direction of dissolution, mixers, chemical instruments and methods, etc., can solve the problems of bonded solid materials and the area directly under the mixing blades, etc., so as to achieve ideal mixing effect and improve the mixing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

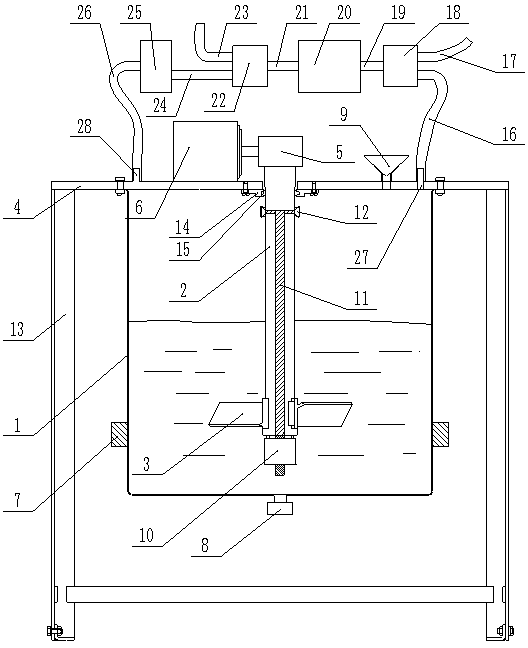

[0039] Below in conjunction with accompanying drawing, the present invention is further described in detail:

[0040] Referring to the accompanying drawings, a sealed mixing tank wall flushing device includes a mixing system, a nozzle system and a ventilation system, the mixing system is connected to the nozzle system, and the mixing system is connected to the ventilation system;

[0041] The mixing system includes a mixing tank 1, a tank cover 4, a rotating shaft 2 and blades 3. The mixing tank 1 and the tank cover 4 are fixedly connected by bolts. At the lower end of the rotating shaft 2, the bung 4 is provided with a feed inlet, the feed inlet is plugged with a rubber stopper 9, and the bung 2 is also provided with an end cap air inlet 28 and an end cover air outlet 27; There is a discharge port; the discharge port is welded at the center of the bottom of the mixing tank, and the discharge port is connected to the discharge nut 8.

[0042] The top of the rotating shaft 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com