Emulsified asphalt for ballastless track cement emulsified asphalt mortar and preparation method of emulsified asphalt

A technology of cement emulsified asphalt and emulsified asphalt, which is applied to building components, building insulation materials, buildings, etc., can solve the problem of emulsifier not contained, and achieve the effects of strong temperature adaptability, good compatibility, and good mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

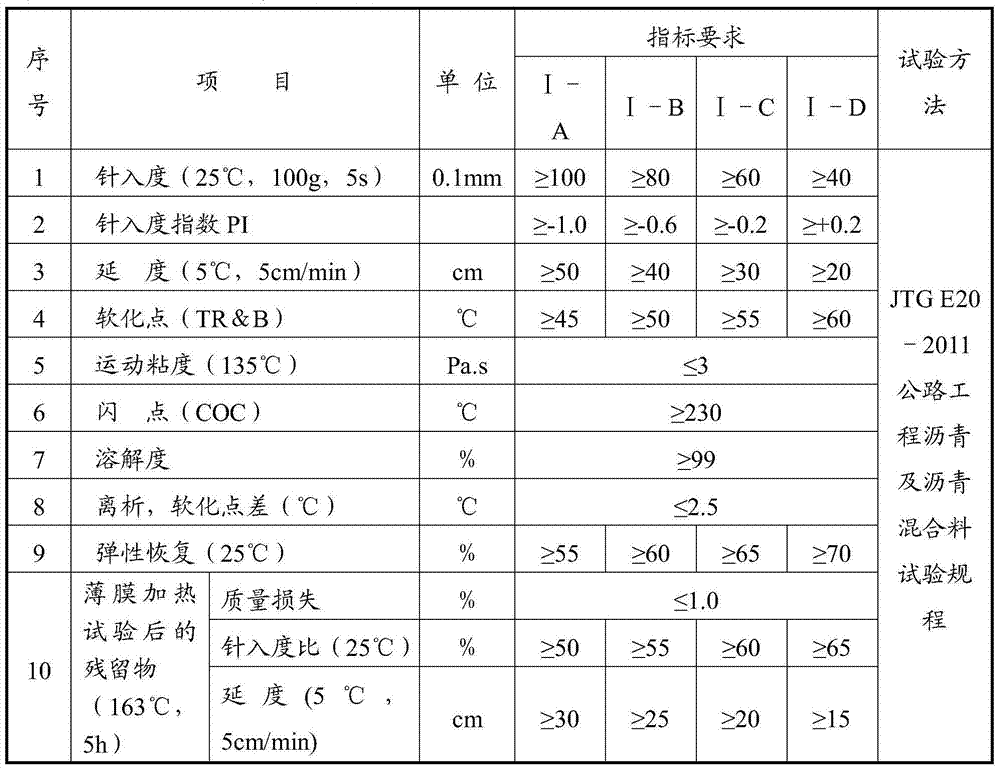

[0050] In this embodiment, the asphalt adopts No. 90 heavy traffic road petroleum asphalt, the cationic emulsifier is bis-octyl / decyl dimethyl ammonium chloride and aminated lignin, and the nonionic emulsifier is fatty acid polyoxyethylene ester, thickening The agent is cellulose ether and polyurethane, the mineral emulsifier is bentonite, the stabilizer is sodium chloride, the auxiliary agent is polycarboxylic acid, and the pH regulator is hydrochloric acid. The composition is shown in Table 5.

[0051] Preparation method of emulsified asphalt:

[0052] (1) Dehydrate No. 90 heavy-traffic road petroleum asphalt at 100°C, and then control the temperature of the asphalt at 120°C to 130°C;

[0053] (2) Add emulsifier, thickener, stabilizer and auxiliary agent to 60°C water in proportion, then adjust the pH value of the solution to 2.5-3.0 with hydrochloric acid, and control the solution temperature at 50°C-60°C;

[0054] (3) Pour the solution obtained in step (2) into a cleaned ...

Embodiment 2

[0058] In this embodiment, the asphalt is No. 110 heavy traffic road petroleum asphalt, the cationic emulsifier is octadecyltrimethylammonium chloride, octadecyldimethylpropionamide, and the nonionic emulsifier is polyoxyethylene ether , its polyoxyethylene polymerization degree is 40, zwitterionic emulsifier is lauryl imidazoline betaine, thickener is polyether, stabilizer is ammonium chloride, calcium chloride, additive is polycarboxylic acid, pH adjustment The agent is glacial acetic acid, and its composition is shown in Table 5.

[0059] Preparation method of emulsified asphalt:

[0060] (1) Dehydrate No. 110 heavy traffic road petroleum asphalt at 100°C, and then control the temperature of the asphalt at 120°C to 130°C;

[0061] (2) Add emulsifier, thickener, stabilizer and auxiliary agent to 60°C water in proportion, then adjust the pH value of the solution to 2.5-3.0 with hydrochloric acid, and control the solution temperature at 50°C-60°C;

[0062] (3) Pour the solut...

Embodiment 3

[0066] In this embodiment, the asphalt is modified asphalt with a SBS content of 2%, and the cationic emulsifier is cetyltrimethylammonium chloride, octadecyltrimethylammonium chloride and imidazoline, and the nonionic emulsifier It is polyoxyethylene ester, its polyoxyethylene polymerization degree is 30, the zwitterionic emulsifier is lauryl amidopropyl betaine, the thickener is polyurea, the stabilizer is calcium chloride, and the auxiliary agent is polycarboxylic acid , the pH regulator is hydrochloric acid, and its composition is as shown in Table 5.

[0067] Preparation method of emulsified asphalt:

[0068] (1) Dehydrate the SBS modified asphalt at 100°C, and then control the temperature of the asphalt at 150°C to 160°C;

[0069] (2) Add emulsifier, thickener, stabilizer and auxiliary agent to 70°C water in proportion, then adjust the pH value of the solution to 2.5-3.0 with hydrochloric acid, and control the solution temperature at 65°C-70°C;

[0070] (3) Pour the so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com