Raw material quantitative mixing equipment for refractory brick production

A technology of mixing equipment and refractory bricks, applied in mixers, shaking/oscillating/vibrating mixers, dissolving and other directions, can solve the problems of inability to realize automatic quantitative feeding, uneven mixing of raw materials, etc., and achieve clever design and mixing. Good effect, improve accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

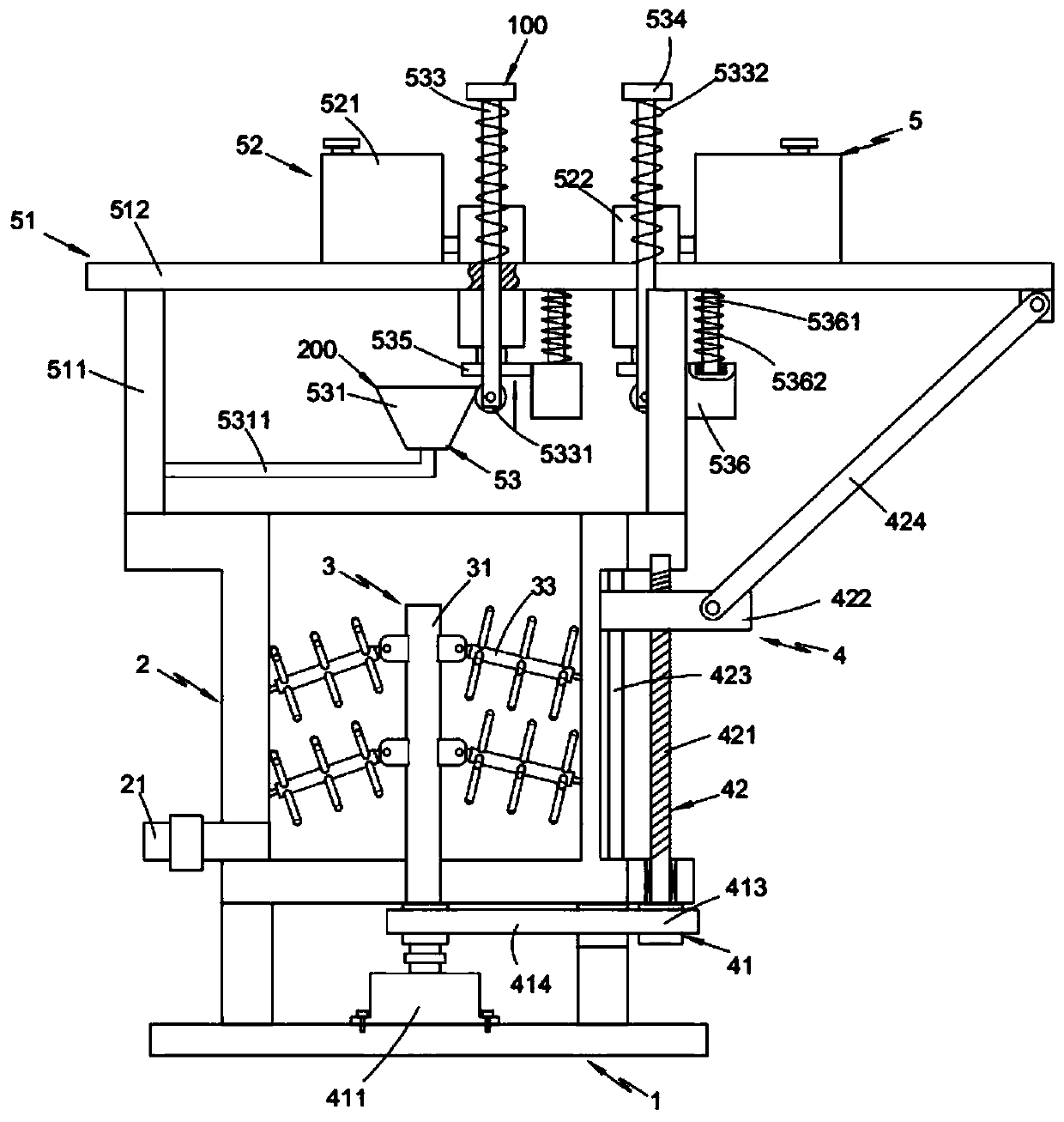

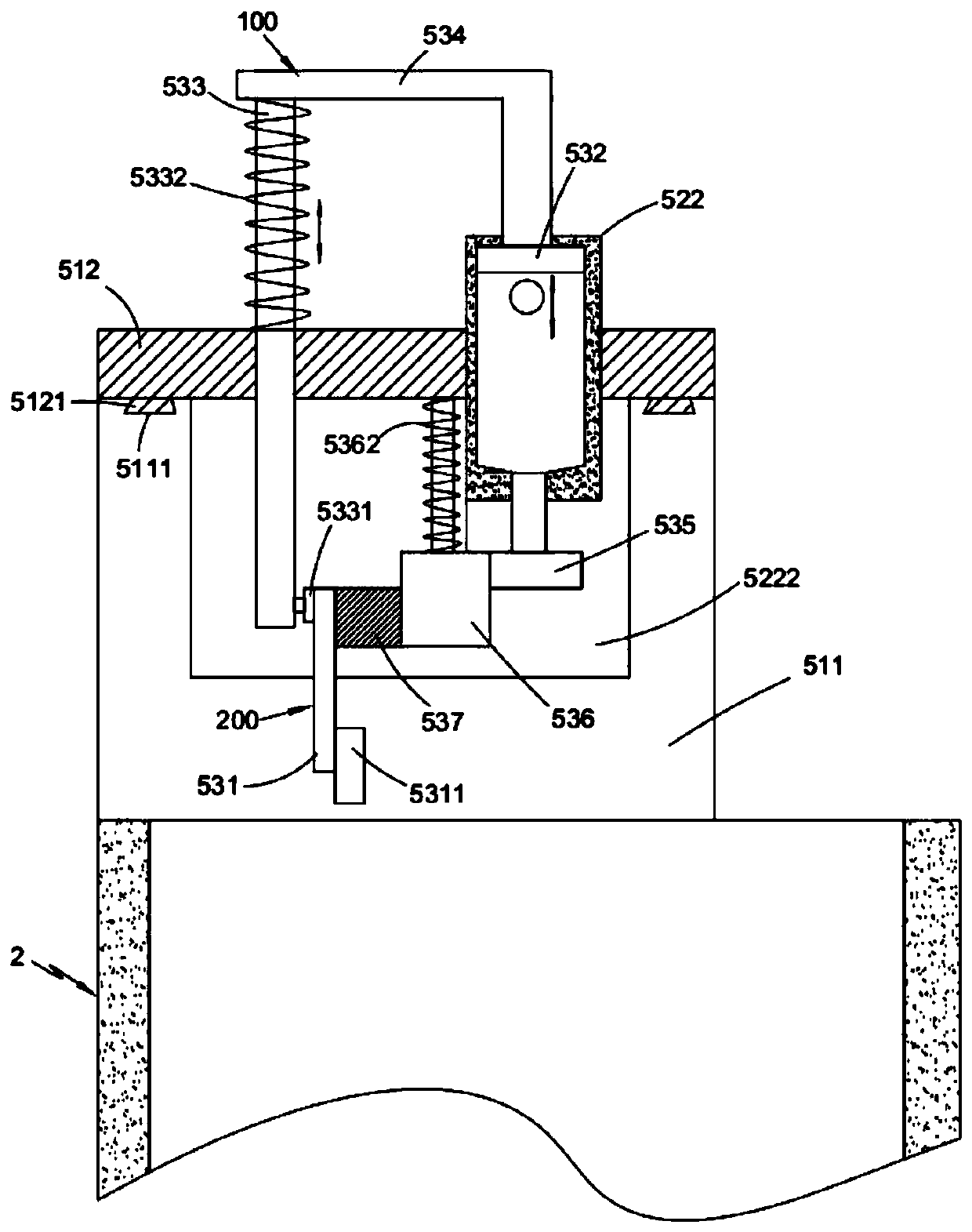

[0040] Such as figure 1 and figure 2 As shown, a quantitative mixing equipment for raw materials for refractory brick production includes a base 1 and a mixing tank 2, and the mixing tank 2 is provided with:

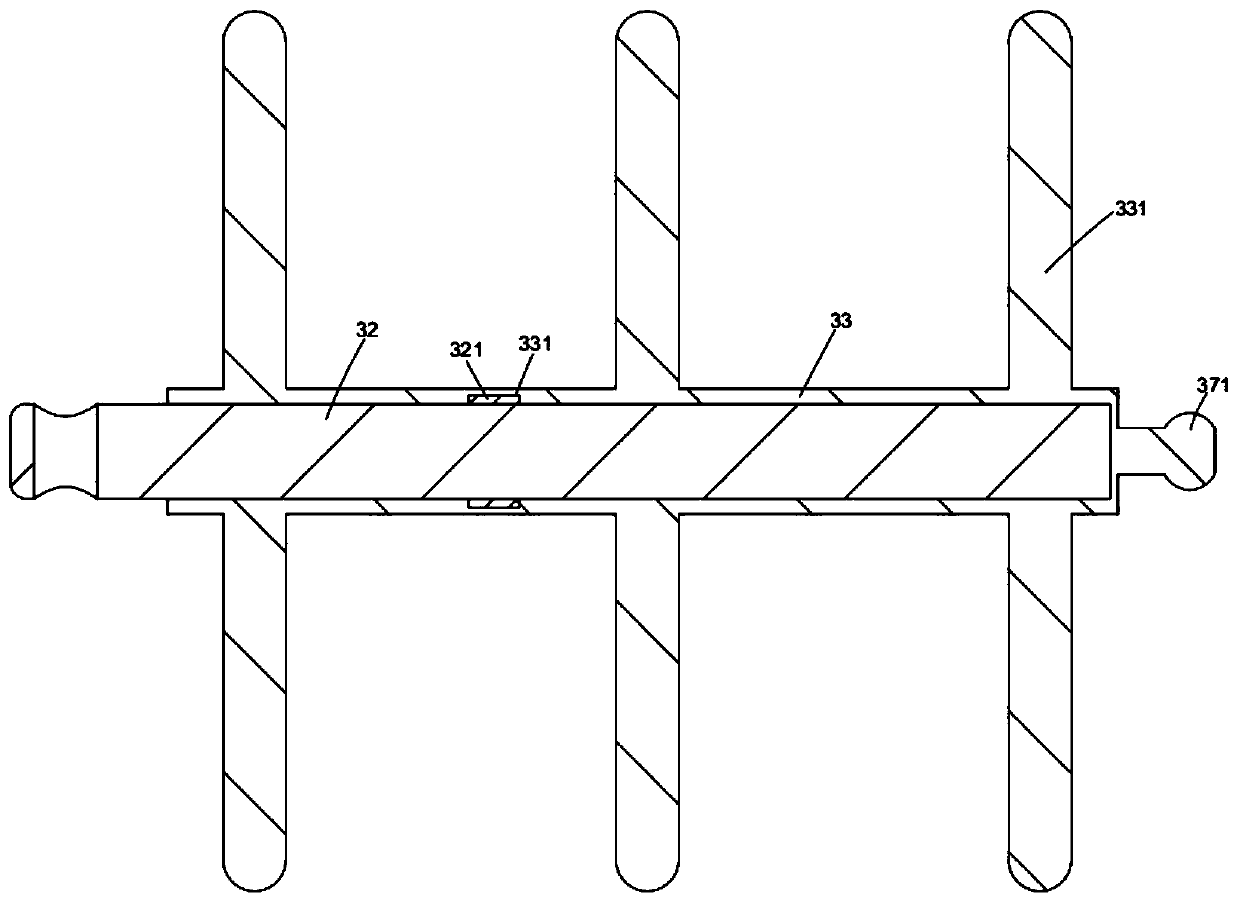

[0041]A stirring assembly 3, the stirring assembly 3 includes a rotating shaft 31, a stirring rod 33 and a guide groove 34, the rotating shaft 31 is installed inside the mixing tank 2, the stirring rod 33 is arranged in a circle along the length direction of the rotating shaft 31, The guide groove 34 is arranged on the inner wall of the mixing tank 2 in a wave shape, and the stirring rod 33 revolves around the rotating shaft 31 along the path of the guide groove 34, and realizes rotation through the switching assembly 30;

[0042] The power assembly 4, the power assembly 4 includes a transmission member 41 and a drive member 42, the transmission member 41 drives the drive member 42 to move, the transmission member 41 is connected to the stirring assembly 3, and the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com