Forced action mixer with adjustable stirring unit

A technology of forced mixers, applied in cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems of difficult asphalt concrete mixing requirements, cannot be easily replaced, cannot obtain mixing effect and mixing efficiency, and achieves convenient replacement and maintenance, the best stirring effect, the effect of high stirring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

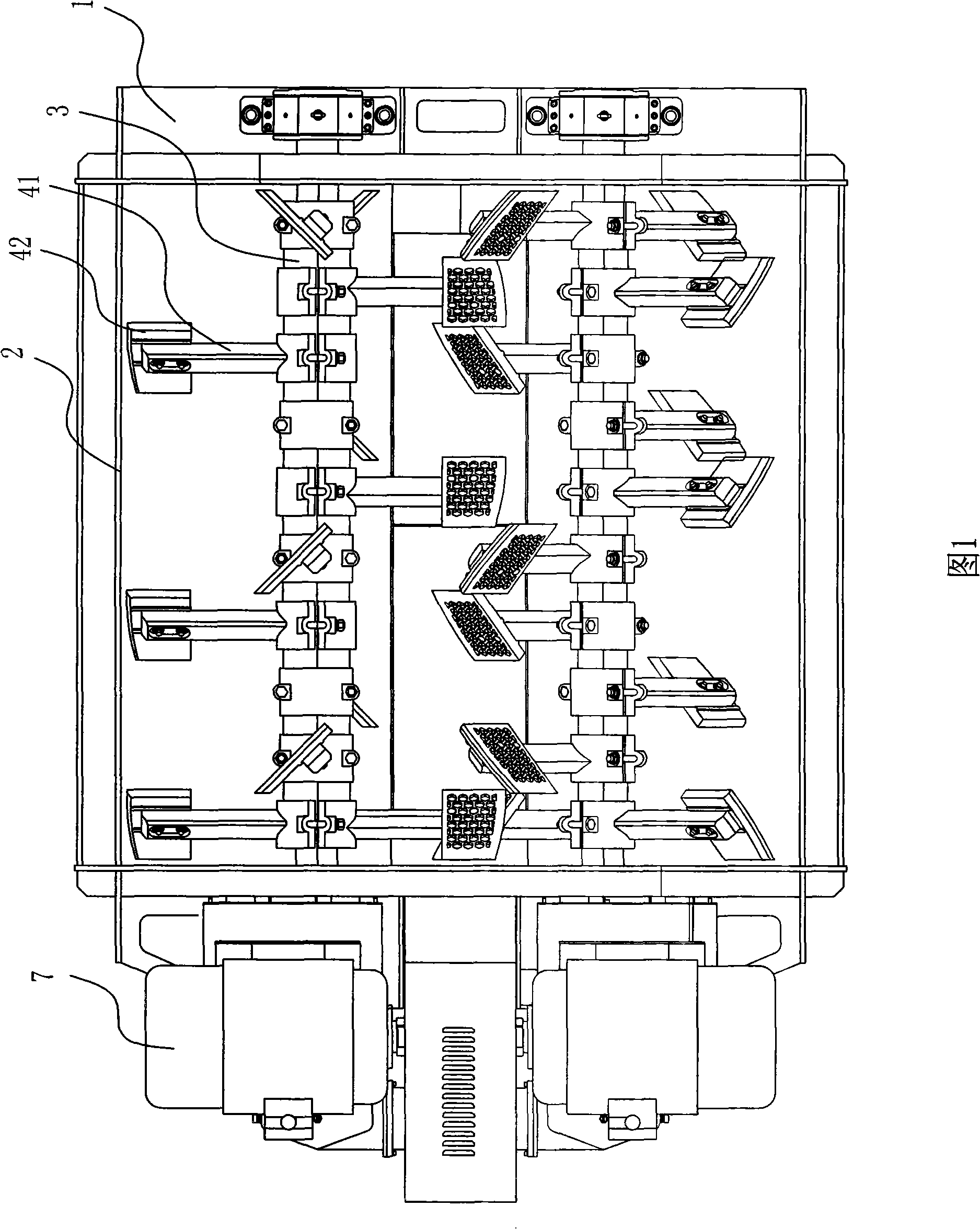

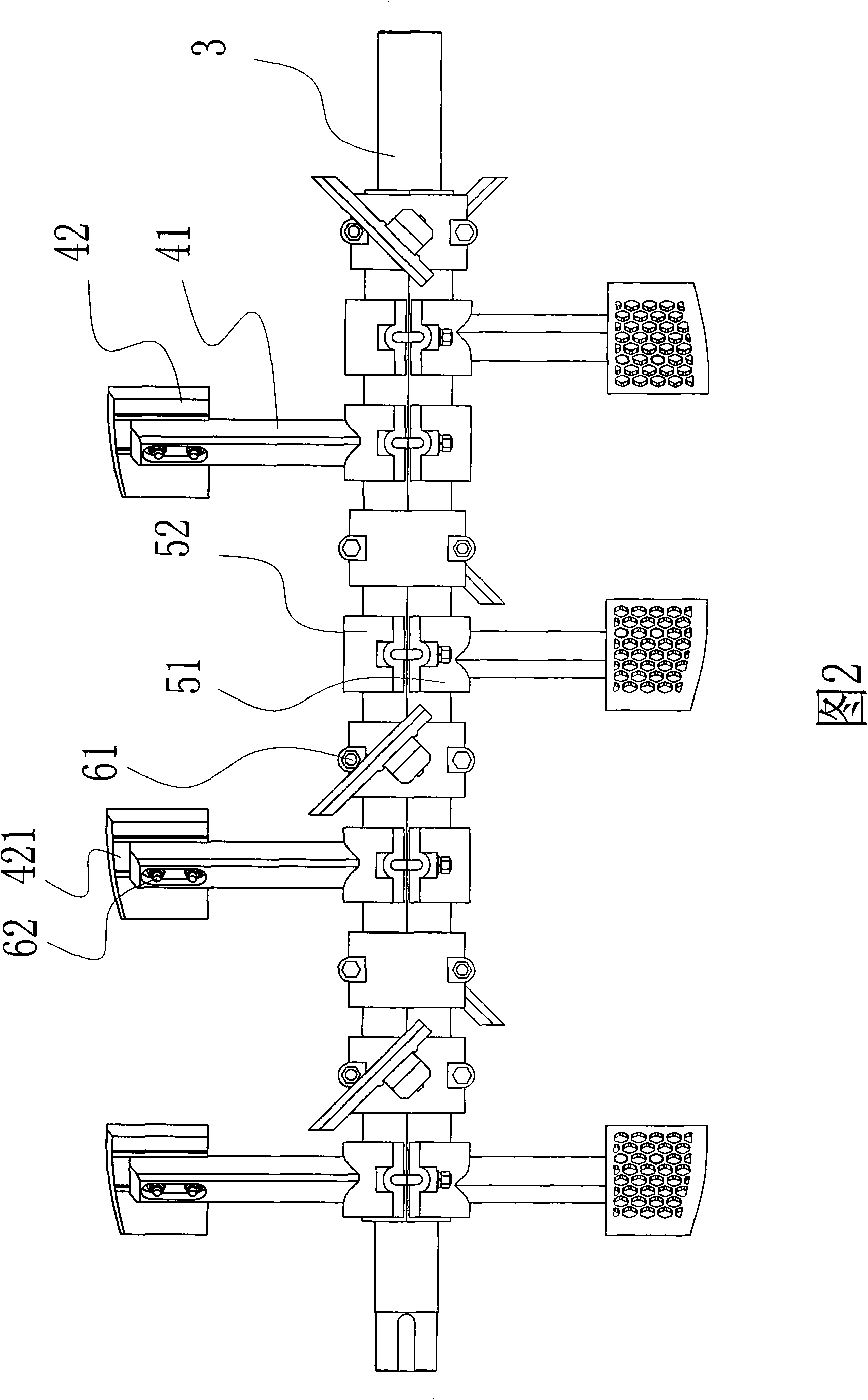

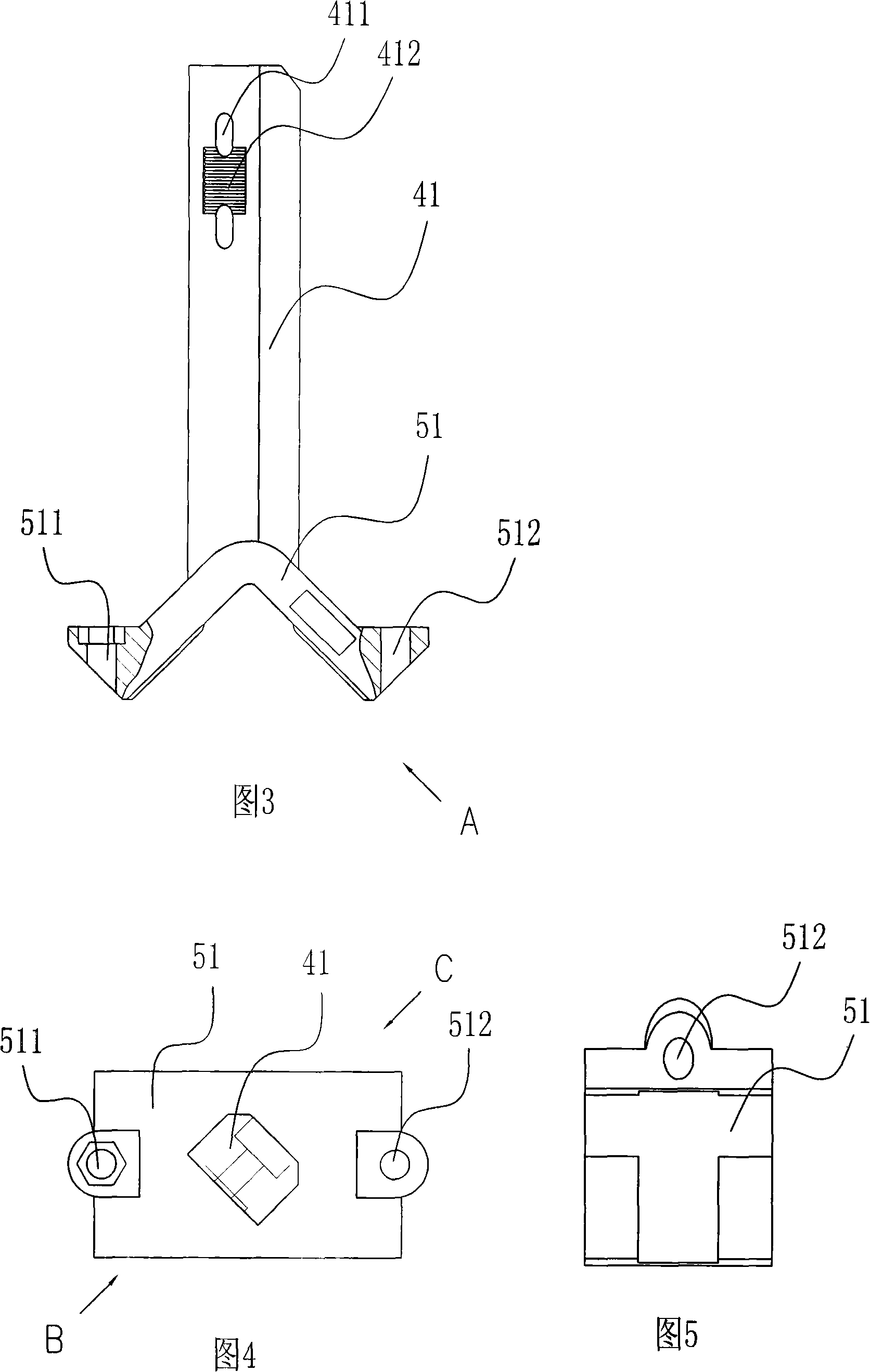

[0028] The invention provides a twin-shaft forced mixer with an adjustable mixing unit, which is especially suitable for efficiently producing high-quality and diverse asphalt concrete. Its structure is shown in Fig. 1 and Fig. 2, including: a horizontal mixing cylinder 2, which is horizontally fixedly supported on a frame 1. A chamber for accommodating the material to be stirred is formed inside the cylinder body 2, and the cylinder body 2 has a feeding mechanism and a discharging mechanism. Two stirring shafts 3 are rotatably supported on the mixing cylinder 2 in the axial direction. The rotation axes of the two stirring shafts 3 are located in the same plane and parallel to each other. The two stirring shafts 3 are driven by the driving device 7 to rotate synchronously in opposite directions. Each stirring shaft is provided with a plurality of stirring units which are spaced apart in the axial direction and deviate from a certain angle in the circumferential direction to fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com