Efficient textile dye mixing device for textile machinery

A technology for textile dyes and mixing devices, which is applied in mixers, mixers with rotating agitating devices, transportation and packaging, etc. It can solve the problems of ordinary and obsolete mixing methods, insufficient mixing range, and low mixing effect, and reach the mixing range Wide, stable stirring process, high degree of freedom effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

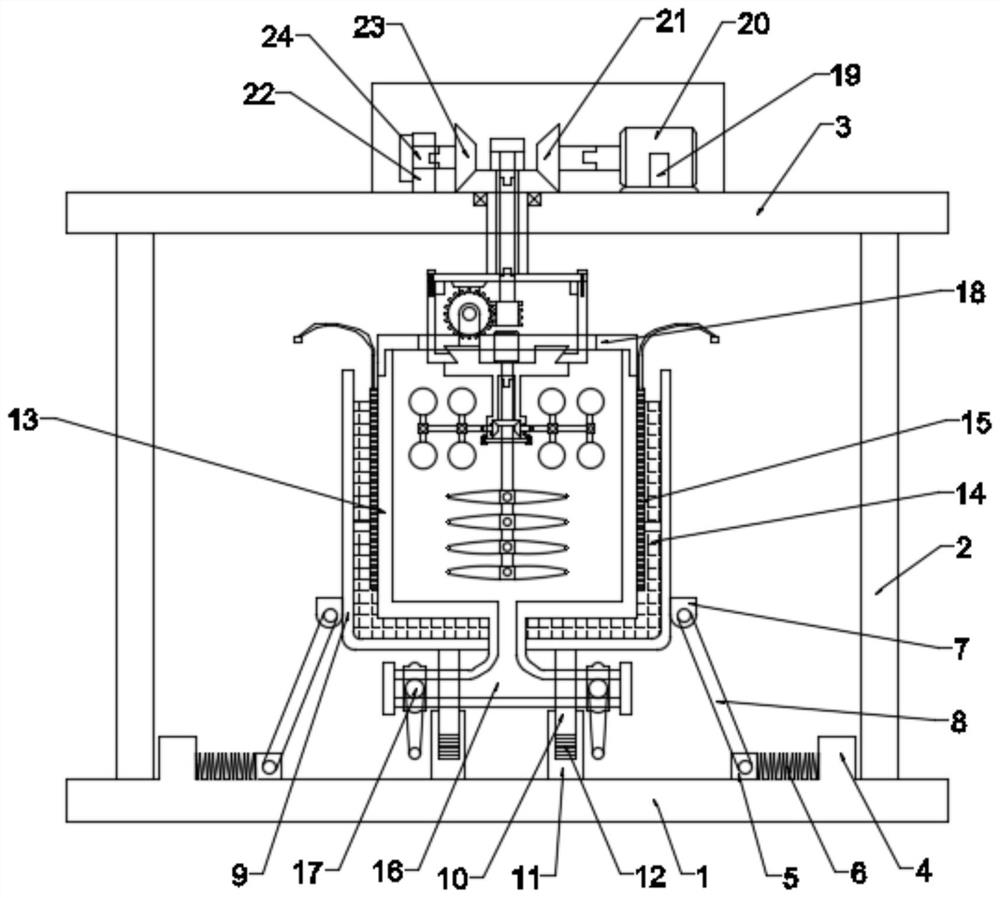

[0021] see figure 1 and Figure 4 , in an embodiment of the present invention, a high-efficiency mixing device for textile dyes for textile machinery, comprising a first base 1, a support column 2 is arranged above the first base 1, and the connection between the support column 2 and the first base 1 Fixedly connected between, above the support column 2 is provided with a second base 3, fixedly connected between the second base 3 and the support column 2; above the first base 1 is provided with a shock-absorbing bearing device, so The shock-absorbing and bearing device includes a first box body 9, a second box body 13 is provided inside the first box body 9, and a feed port 1301 is provided on the front side of the second box body 13, and the second box body 13 is provided with a material inlet 1301. A heating wire 15 is provided on the outer wall of the body 13, a shock absorbing pad 14 is provided between the second box body 13 and the first box body 9; a first box cover 18...

Embodiment 2

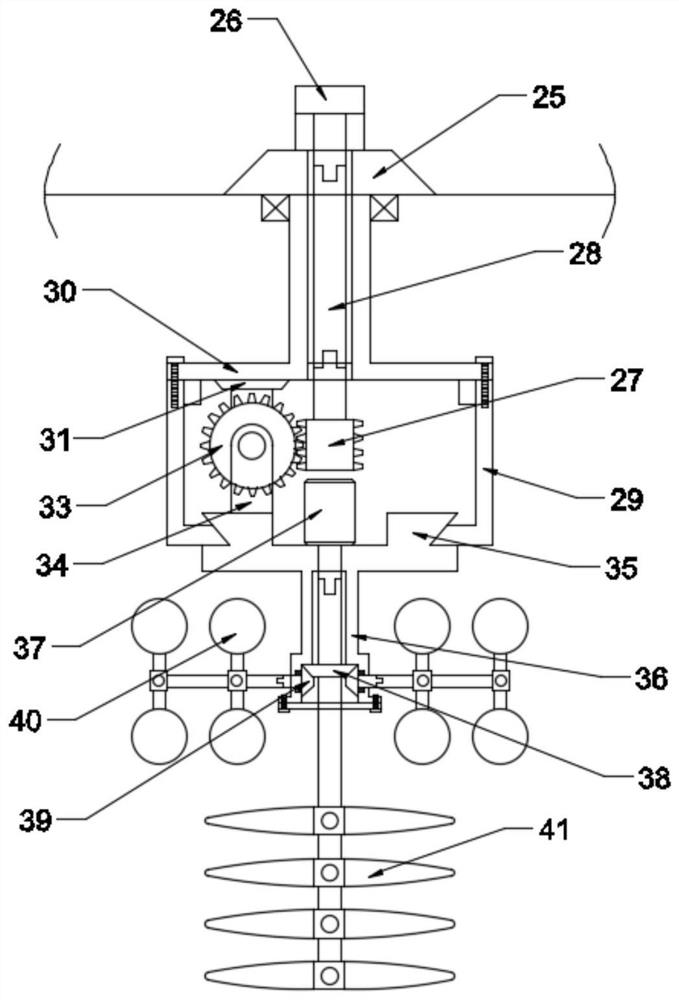

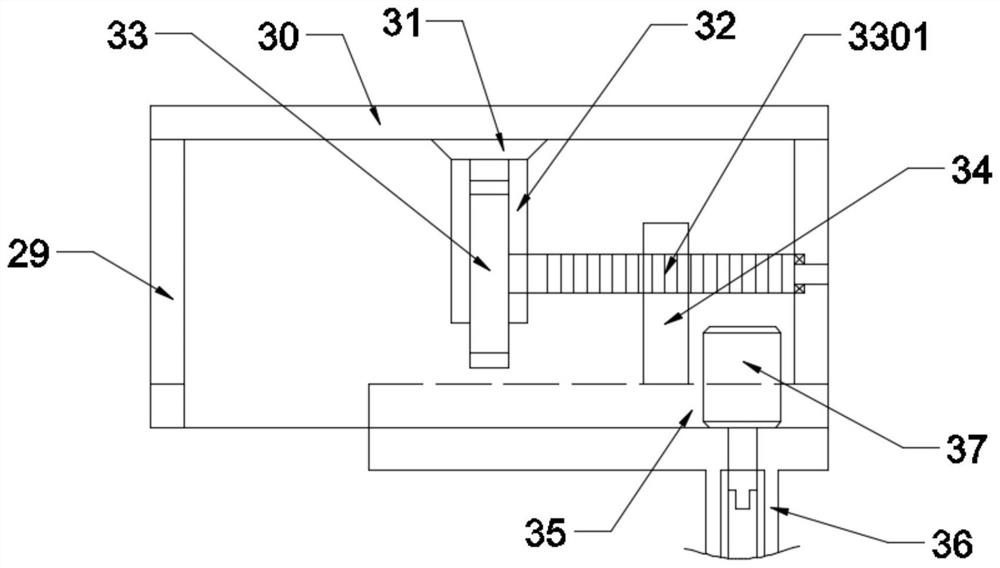

[0026] see Figure 1-3 , the difference from Embodiment 1 is that in the embodiment of the present invention, the power device includes a first motor frame 19, and the first motor frame 19 is fixedly connected to the second base 3, and the first A first motor 20 is arranged above the motor frame 19, which is detachably connected between the first motor 20 and the first motor frame 19, and a first gear 21 is detachably connected to the output shaft of the first motor 20; A limit seat 22 is arranged above the second base 3, and the limit seat 22 is fixedly connected with the second base 3, and a second gear 23 is rotatably connected inside the limit seat 22. The gear 23 is detachably connected to the limit seat 22 through an end buckle 24; a third gear 25 is arranged below the first gear 21 and the first gear 21, and the third gear 25 is connected to the first gear 21. The gears 21 are meshed, and the third gear 25 is meshed with the second gear 23;

[0027] Further, the stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com