Vertical type mixing and heating device capable of mixing stirred materials

A technology of mixing, stirring and heating device, which is used in roads, road repair, roads, etc., can solve the problems of uneven heating, low utilization rate of heat energy, poor quality of discharge, etc. High rate and good stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

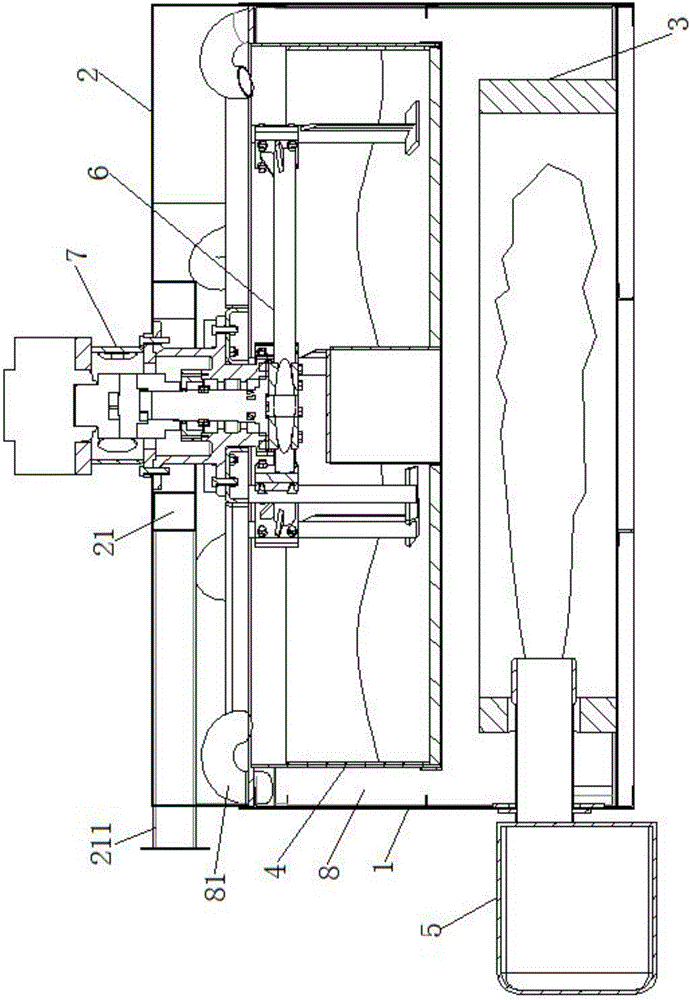

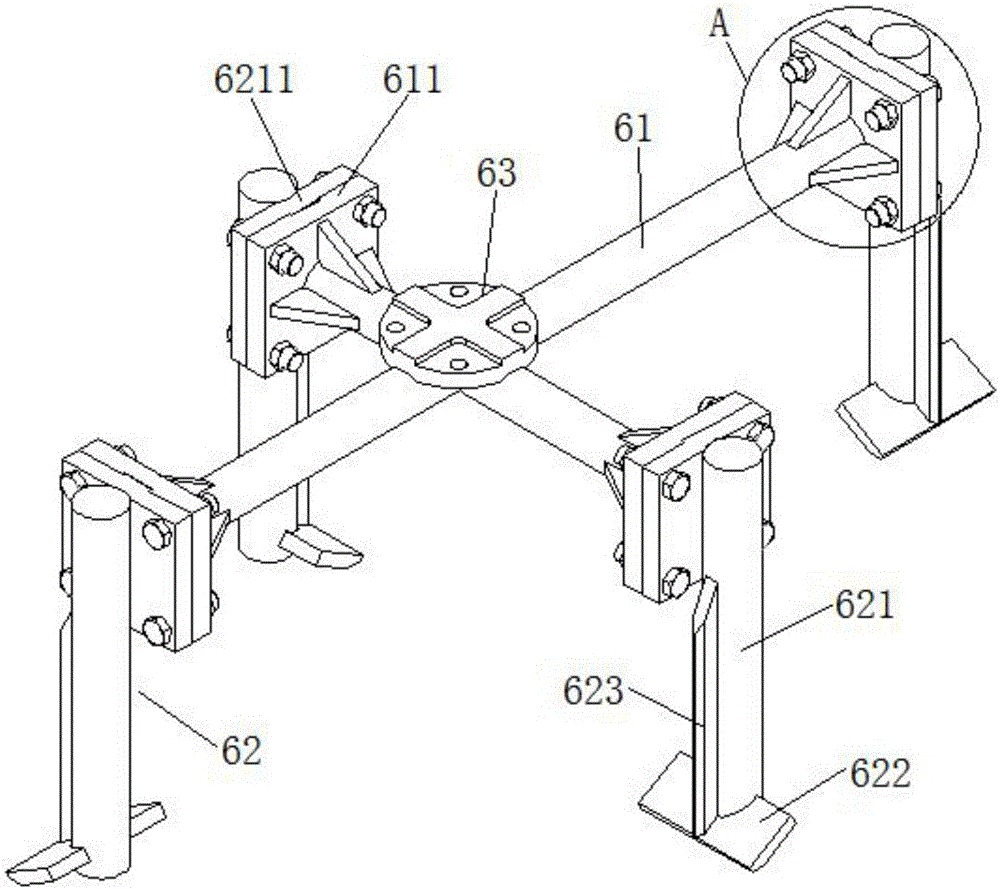

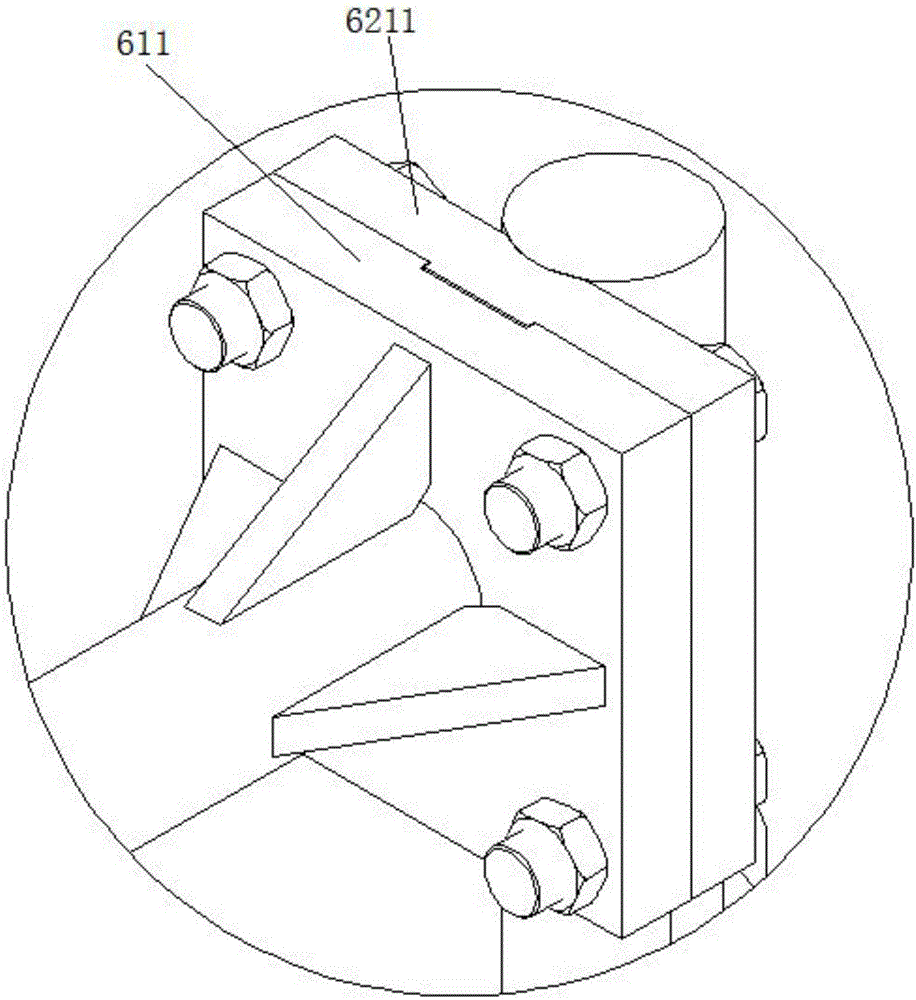

[0030] Example: such as figure 1 As shown, the vertical mixing and heating device for mixing and stirring materials in this embodiment includes a box body 1, an upper cover 2, a furnace 3, a stirring tank 4, a burner 5, a stirring and cutting assembly 6 and a power drive device 7. The above box The upper end of the body 1 is open, the above-mentioned upper cover 2 is detachably installed on the opening end of the above-mentioned box body 1, the above-mentioned furnace 3 is installed on the inner bottom wall of the above-mentioned box body 1, and the above-mentioned stirring tank 4 is fixed on the inner wall of the above-mentioned box body 1 through a bracket, And located above the furnace 3, the burner 5 is installed outside the box 1, and its nozzle head passes through the box wall of the box 1 and the side wall of the furnace 3 into the furnace 3, and the stirring and cutting assembly 6 is set In the above-mentioned stirring tank 4, the above-mentioned power drive device 7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com