Spray type filtering and stirring tank

The technology of a stirring tank and stirring shaft is applied in the field of spray-type filtering stirring tanks, which can solve the problems that the stirring tank does not have filtering characteristics and reflux characteristics, and achieve the effects of good filtering and stirring effect, enhanced stirring effect and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

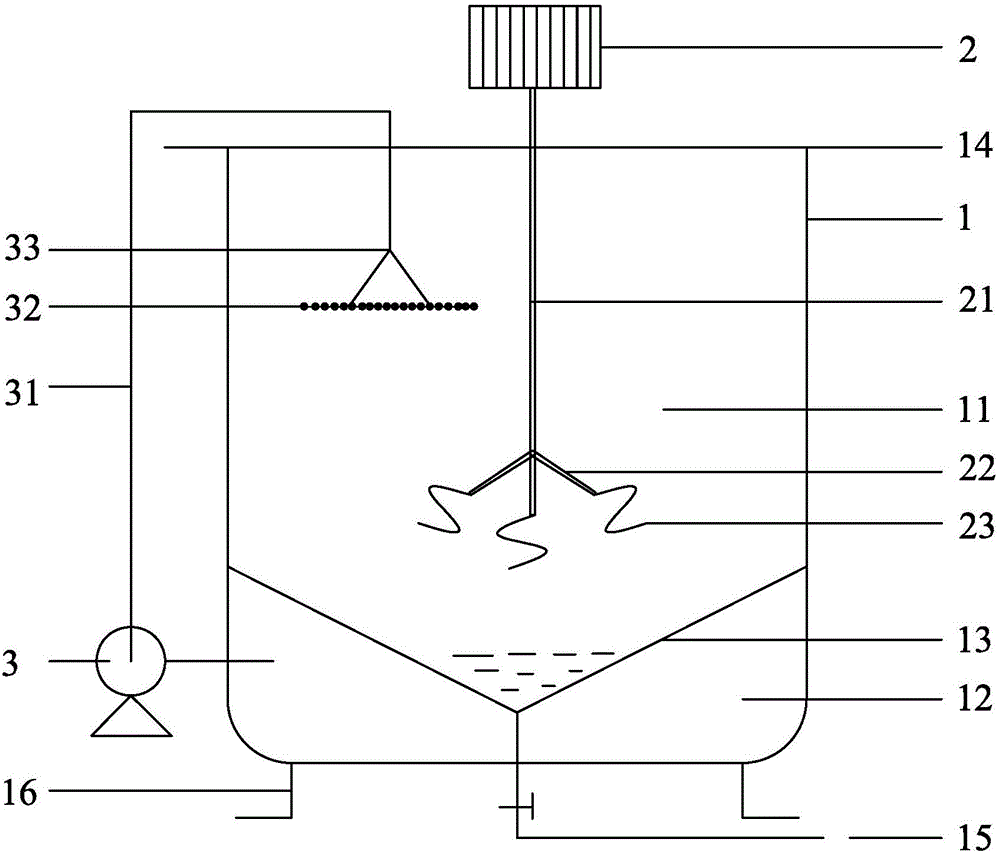

[0018] like figure 1 As shown, a spraying type filter stirring tank includes a tank body 1, a motor 2 arranged on the upper end of the tank body 1, and the lower end of the motor 2 is connected with a stirring shaft 21, and the lower end of the stirring shaft is provided with three angle-variable A stirring rod 22, at least two bases 16 are provided at the bottom of the tank body 1,

[0019] The inside of the tank body 1 is divided into a stirring area 11 and a filtering area 12 by a tapered filter screen 13 arranged at the lower end of the tank body 1, and the bottom of the filter screen 13 is communicated with a sewage pipe 15 with a valve;

[0020] The side wall of the filter area 12 of the tank body 1 is provided with an output pipeline connected with the pump 3, and the pump 3 returns the liquid extracted from the filter area 12 to the tank body through a return line 31 1, the liquid outlet end of the return pipeline 31 is provided with a shunt pipe through a connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com