Building solid waste recycled concrete admixture treatment device

A recycled cement and processing device technology, which is applied in the direction of cement mixing device, clay preparation device, spring/shock absorber, etc., can solve the problem of overall convenience, efficiency and practicability, and reduce the preparation efficiency of recycled cement mixture. Increase the workload of staff and other issues to achieve the effects of overall stability and high practicability, overall efficiency and practicability, high efficiency and practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

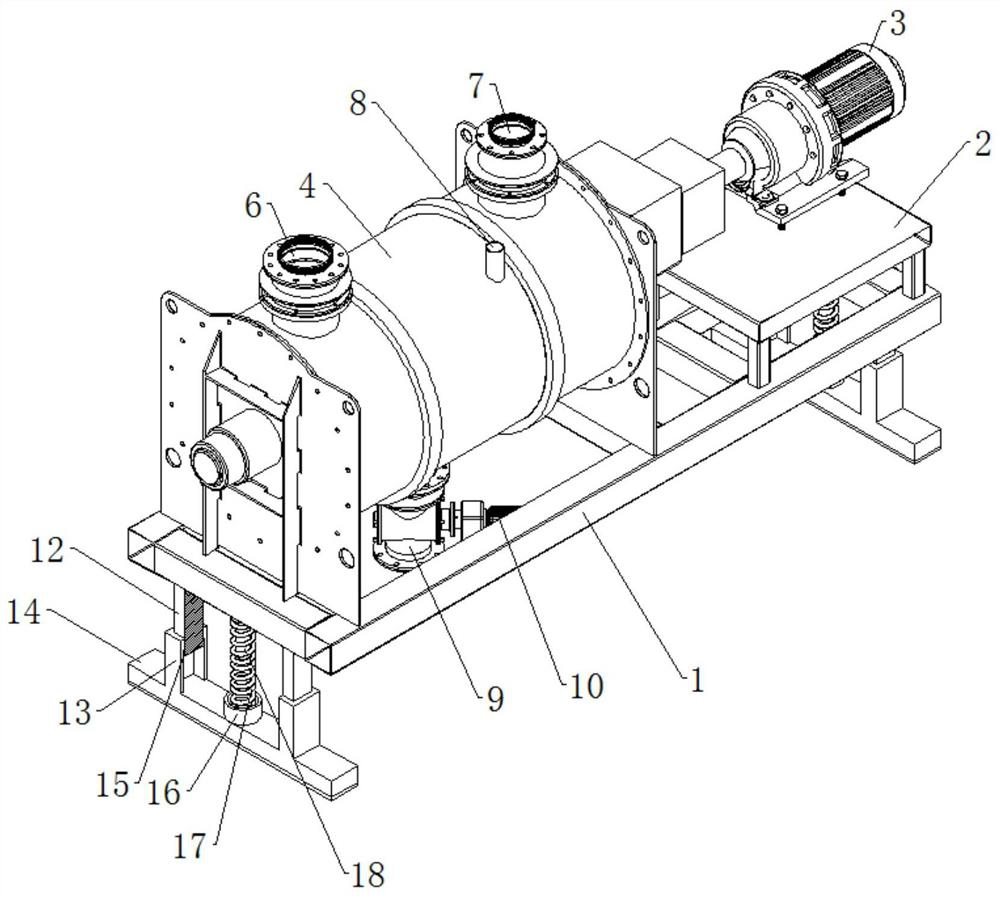

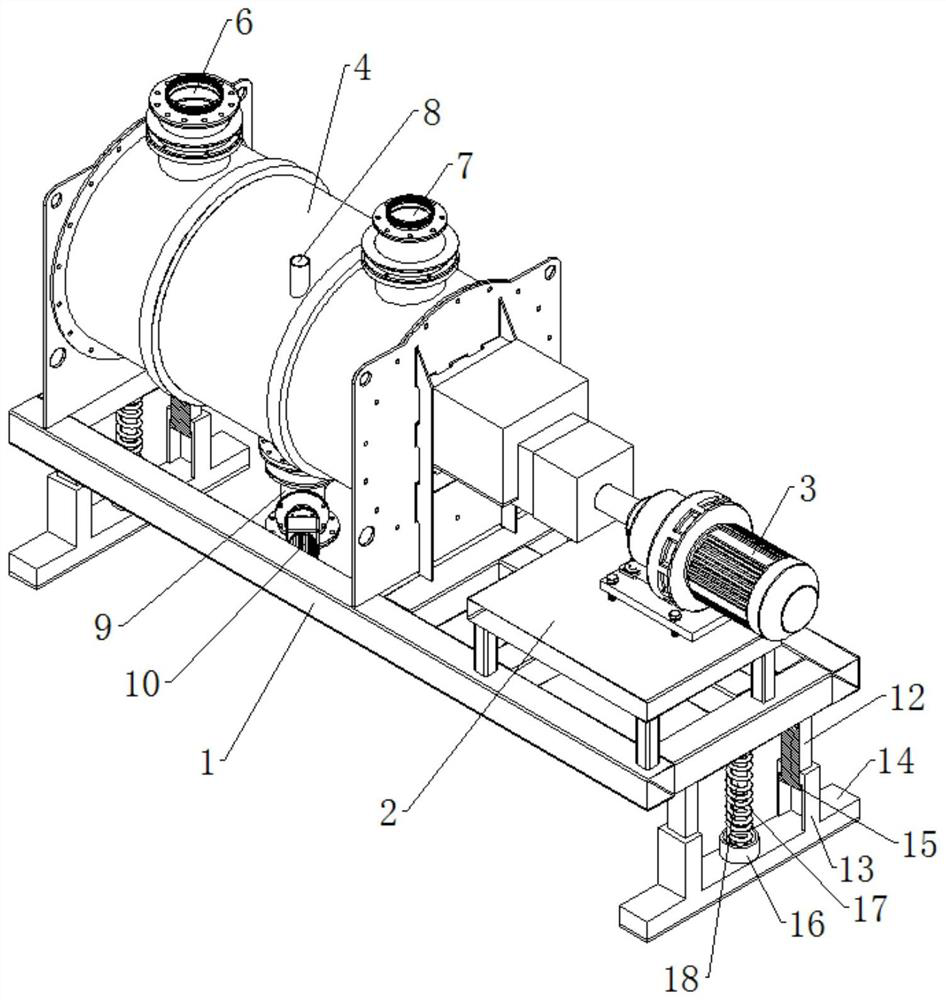

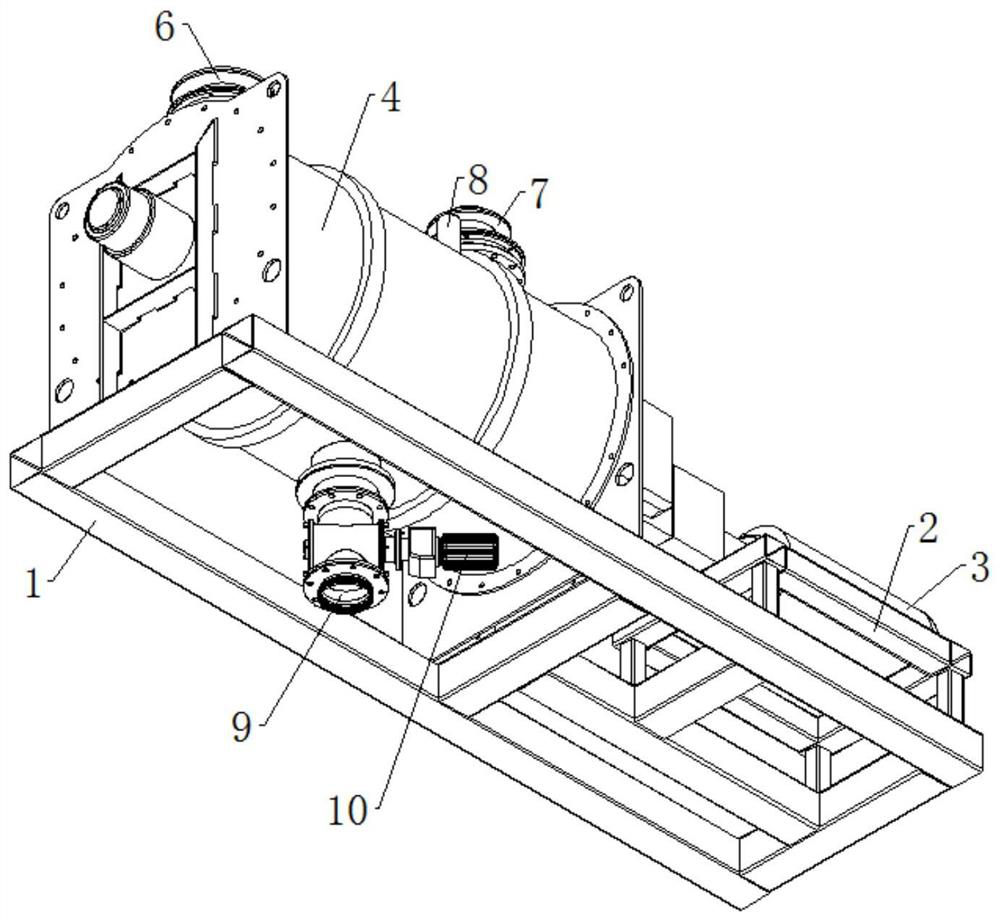

[0024] Examples, see Figure 1-5 , the present invention provides a technical solution: a construction solid waste regenerated cement mixed material treatment device, including a base 1, a mounting seat 2 is provided on the right side of the upper surface of the base 1, and a first drive motor is provided on the upper surface of the mounting seat 2 3. A mixing tank 4 is provided on the left side of the upper surface of the base 1. The driving end of the first drive motor 3 penetrates the right side wall of the mixing tank 4 and extends to the inside of the mixing tank 4. A first agitator 5 is provided. The mixing tank 4 The left side of the upper surface is correspondingly provided with the first addition port 6, and the right side of the upper surface of the mixing tank 4 is correspondingly provided with the second addition port 7, and the upper surface of the mixing tank 4 is located at the first addition port 6 and the second addition port 6. A water inlet 8 is provided bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com