Humidification agitator

A technology for mixers and mixing drums, which is applied to mixer accessories, mixers with rotating agitation devices, mixers, etc., can solve problems such as difficulties in production and maintenance, broken blades, and scaling of blades, and is beneficial to mixing efficiency and effect, the effect of uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

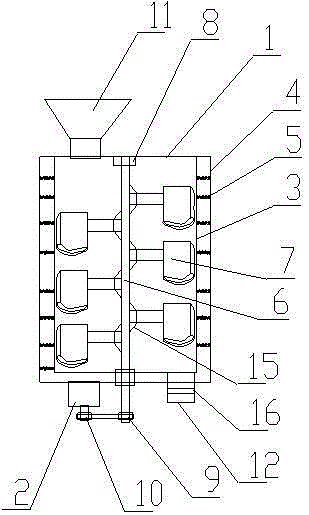

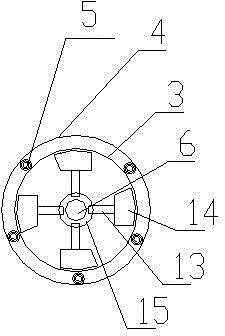

[0017] to combine figure 1 A humidifying mixer shown includes a vertically arranged cylindrical mixing drum 1 and a drive motor 2. The mixing drum 1 includes an inner drum 3 and an outer drum 4. The inner drum 3 is sleeved in the outer drum 4 and arranged concentrically. A spring 5 is arranged between the cylinder 3 and the outer cylinder 4. The inner cylinder 4 is an elastic rubber cylinder. The center of the inner cylinder 4 is vertically provided with a stirring shaft 6. The stirring shaft 6 is provided with a stirring blade 7. Both ends are fixed on the mixing drum through bearings 8, the lower end of the stirring shaft 3 runs through the mixing drum 1, a driven pulley 9 is arranged on the stirring shaft 6 outside the mixing drum 1, the driving motor 2 is arranged under the mixing drum 1, and the driving motor 2 The rotating shaft is provided with the driving pulley 10 that cooperates with the driven pulley 9, a belt is provided between the driven pulley 9 and the driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com