Combustion system applied in direct injection diesel

A combustion system and diesel engine technology, which is applied to combustion engines, mechanical equipment, machines/engines, etc., can solve problems such as too thick mixture, many particles, and large inhomogeneity of mixture, so as to achieve full utilization of air and reduce harmful Emissions, Ease of Product Application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

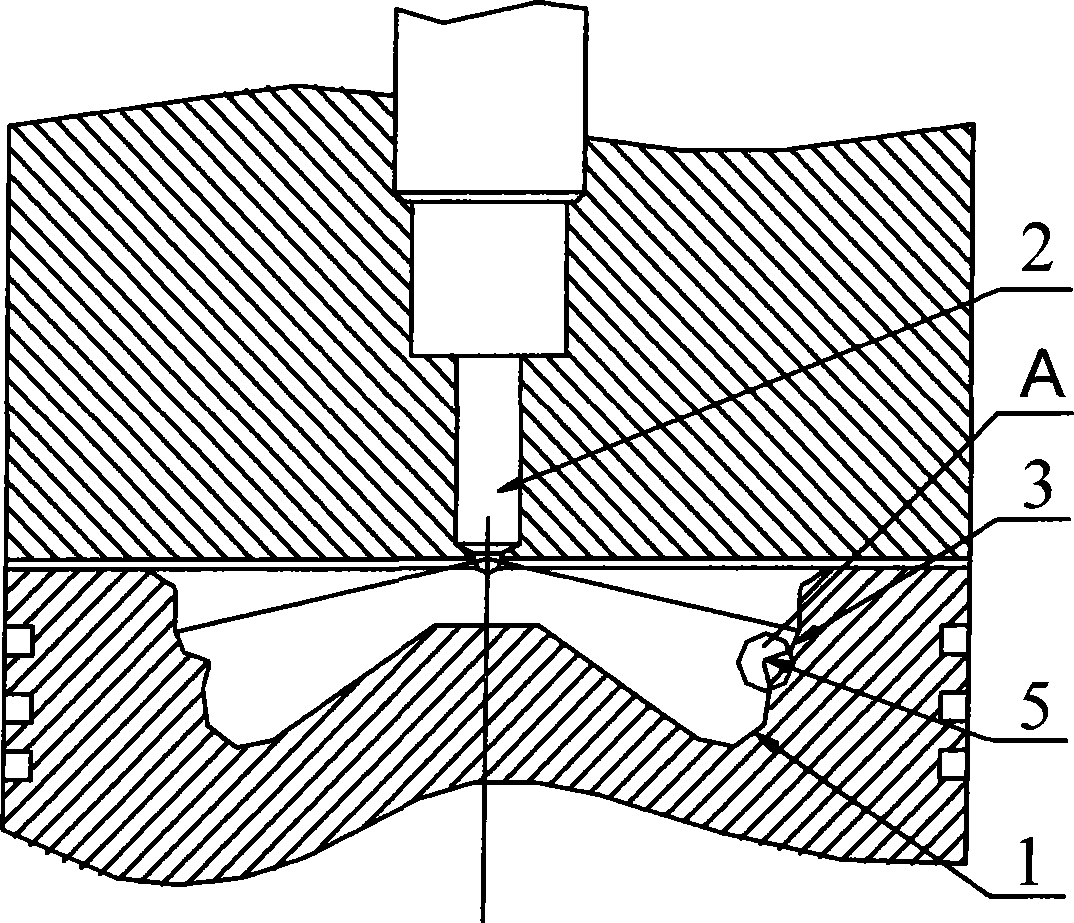

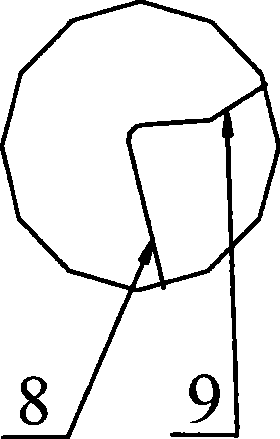

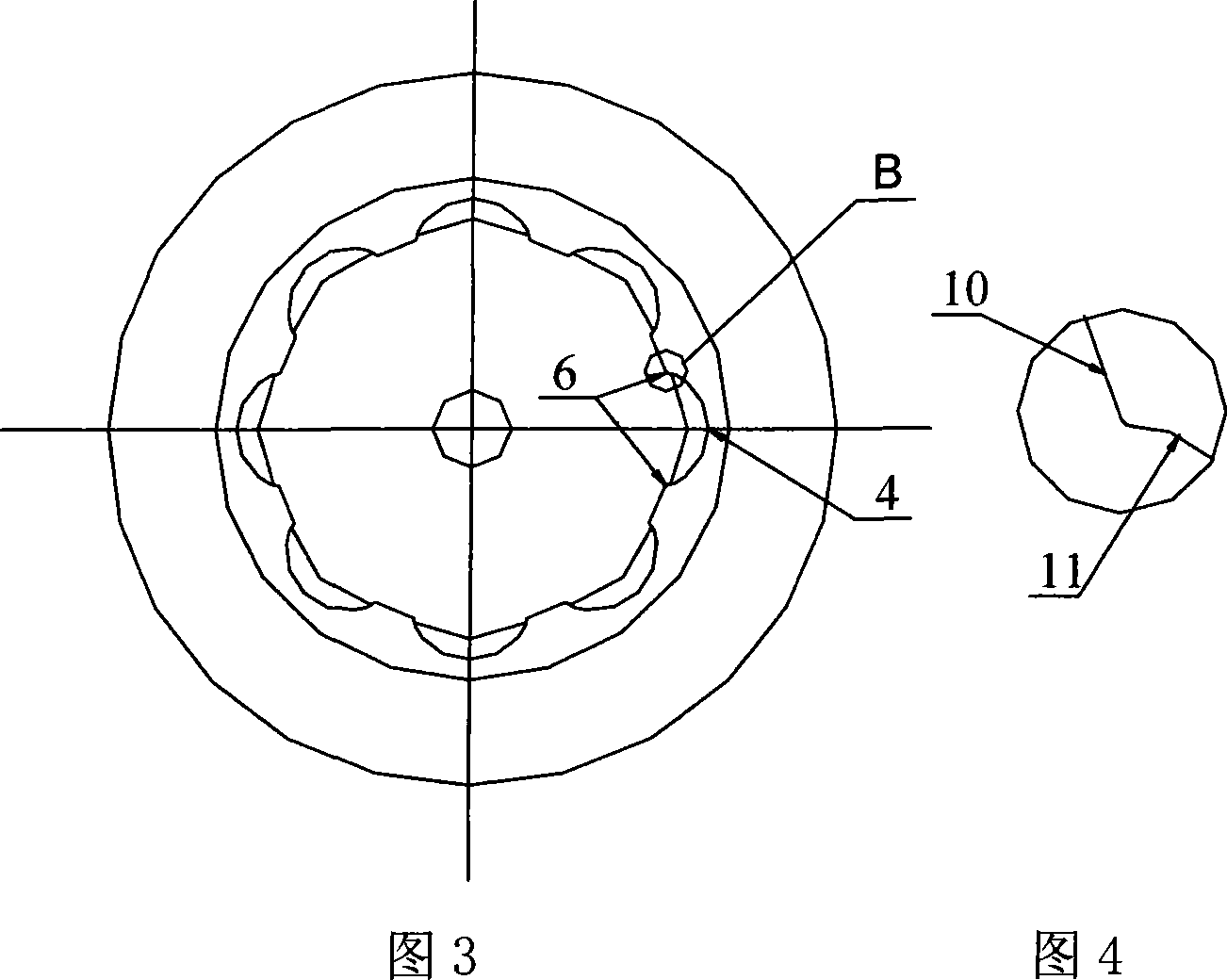

[0013] A combustion system applied to a direct-injection diesel engine of the present invention comprises an ω-shaped combustion chamber 1 and a fuel injector 2 for injecting high-pressure fuel into the combustion chamber. The direction is evenly provided with a number of arc-shaped pits equal to the number of oil jets of the injector and corresponding to the injection direction. The lower edge of each arc-shaped pit and the inner wall of the combustion chamber are formed by a small round transition. The first sudden change structure 5 is connected, and the intersection of the two side edges of each arc-shaped pit with the inner wall surface of the combustion chamber is connected through a small round transition to form a second sudden change structure 6 . The greater the sudden change formed at the junction of the lower edge and both side ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com