Stirrer combining revolution and rotation

A technology of a mixer and a stirring motor, which is applied to cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems of poor mixing effect, single mixing structure, and narrow mixing range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

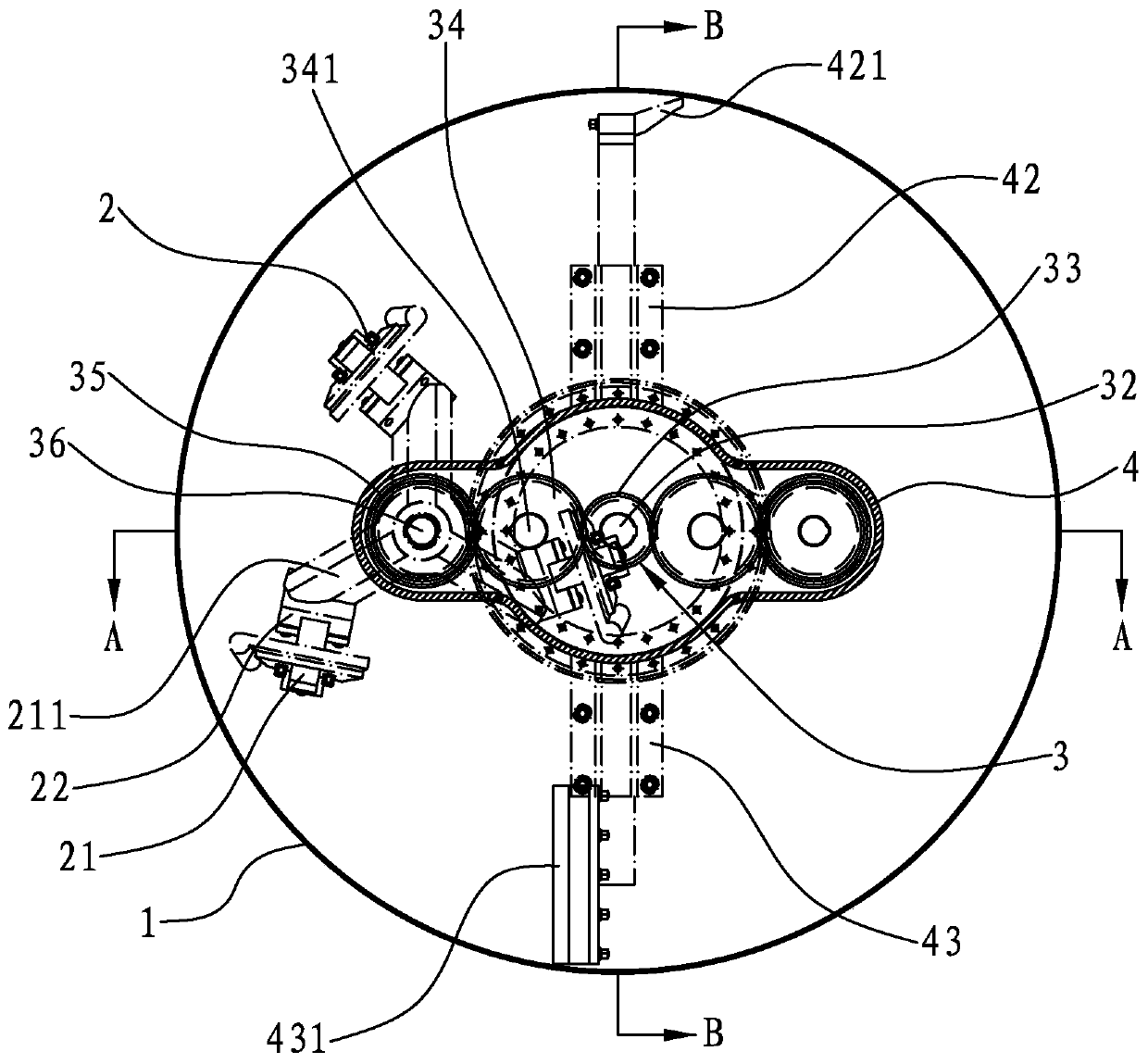

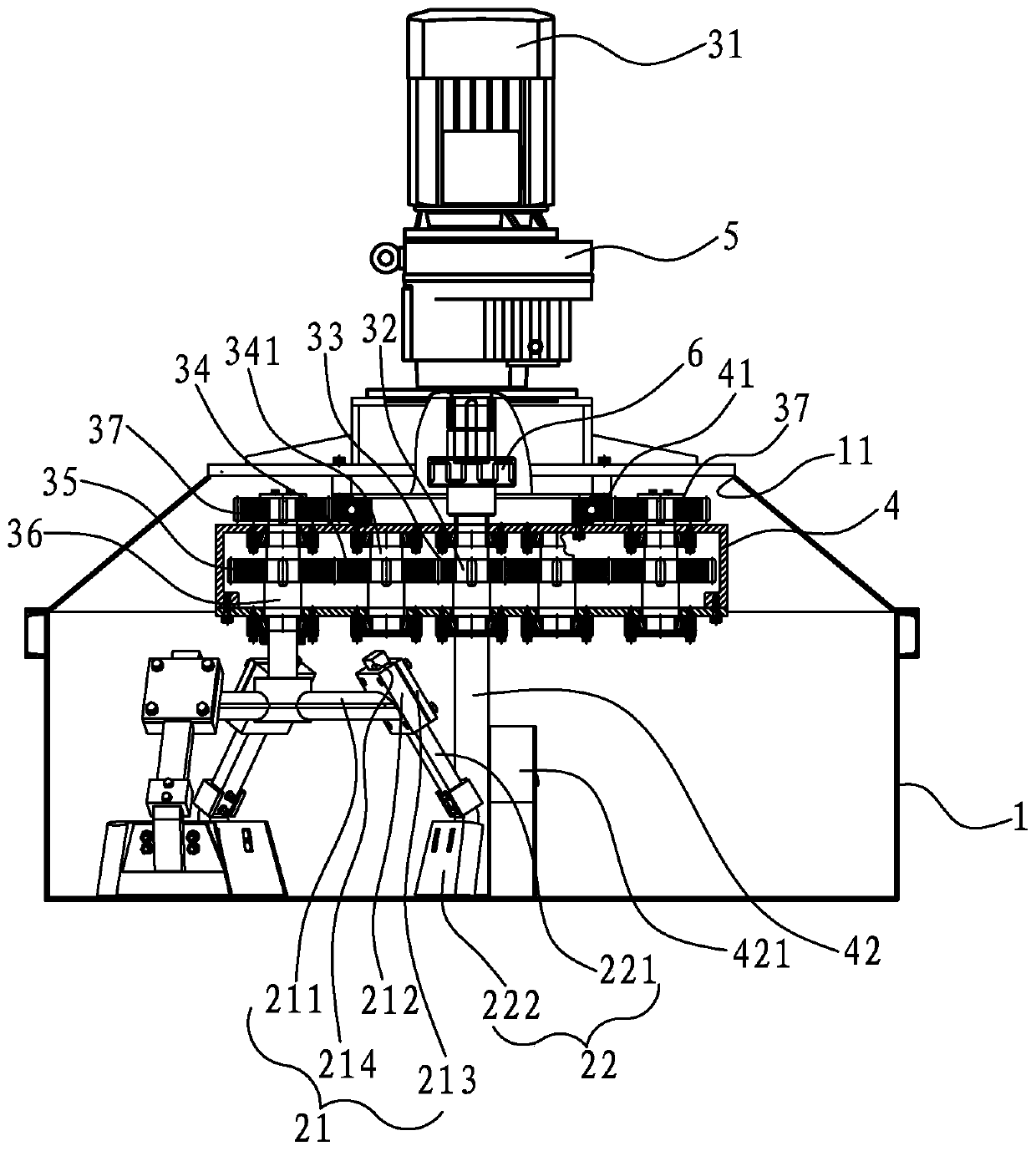

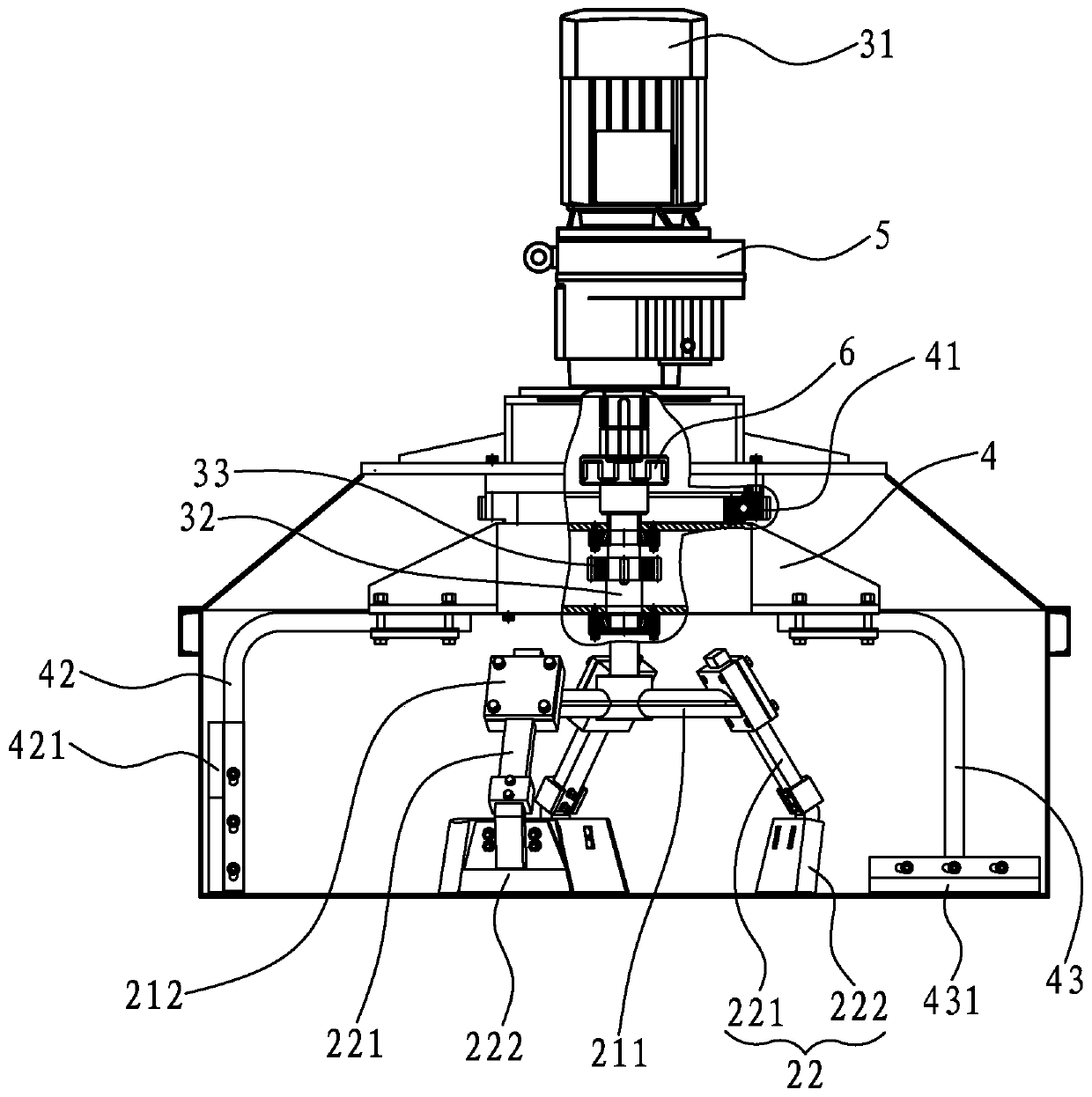

[0039] see Figure 1 to Figure 4 , the present invention discloses a mixer with revolution and rotation, which includes a mixing tank body 1, a mixing arm assembly 2 and a stirring power mechanism 3, the mixing tank body 1 has an upper opening 11, and the stirring power mechanism 3 is movably arranged at the upper opening 11, and the stirring arm assembly 2 is set under the stirring power mechanism 3 and extends into the mixing barrel body 1; the stirring power mechanism 3 has a stirring motor 31, a power spindle 32, and a driving gear 33 , transition gear 34, rotation gear 35, stirring main shaft 36 and revolving gear 37; the output shaft of described stirring motor 31 is connected with power main shaft 32 upper ends, and described driving gear 33 is assembled on the power main shaft 32, and described transiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com