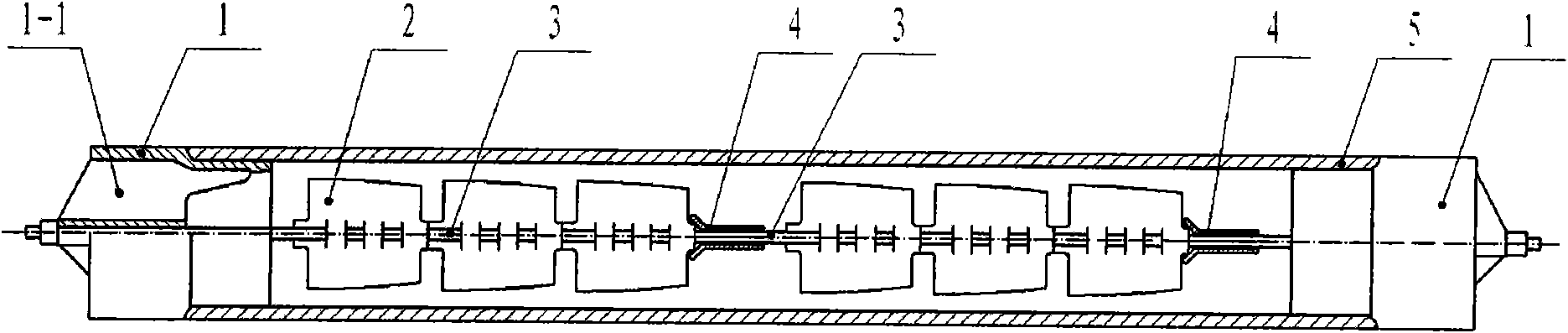

Rotating piece type automatic-cleaning and heat-transfer enhancing device

An enhanced heat transfer and self-cleaning technology, applied in the direction of cleaning heat transfer devices, rotating equipment cleaning, heat transfer modification, etc., can solve the problems of large wear of rotors and shafts, reduced service life, inconvenient processing and molding, etc., to reduce friction , improve the service life, easy to replace the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

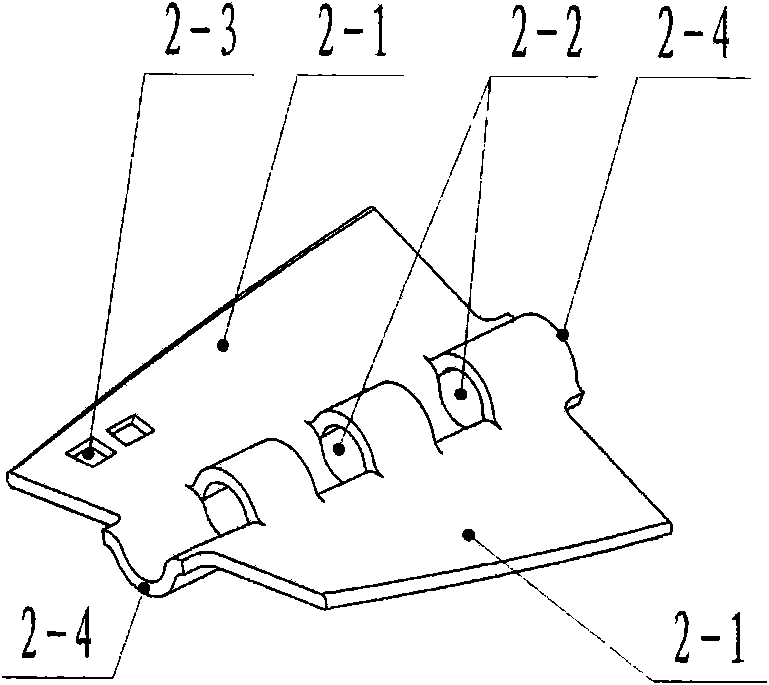

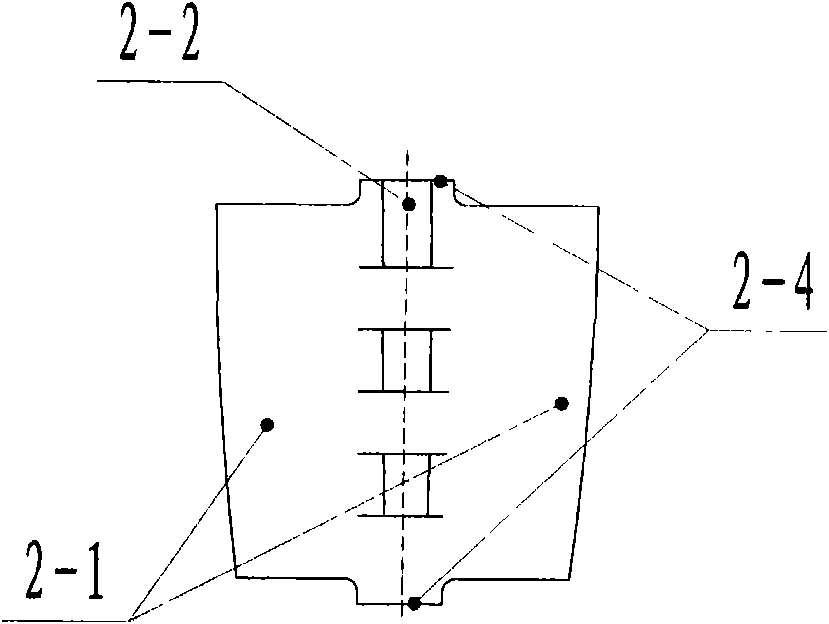

[0020] Embodiment: The main parameters of the rotary plate self-cleaning enhanced heat transfer device are: the length of the heat transfer tube 5 is 2000mm, its inner diameter is Φ23mm, the outer diameter of the rotary plate 2 is Φ19mm, the rotary plate is made of nickel metal material, and the helix angle of the blade is 72° , Rotor length 20mm. The experimental test shows that the rotation resistance of the rotor is about half of the rotation resistance of the existing rotor under the same operating conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com