Low-noise device for centrifugal compressor of turbocharger

A technology of centrifugal compressors and turbochargers, which is applied to the components of pumping devices for elastic fluids, machines/engines, mechanical equipment, etc., can solve the problems of low noise, high cost, and space requirements, and achieve improved Efficiency, ease of processing, and the effect of reducing the cost of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

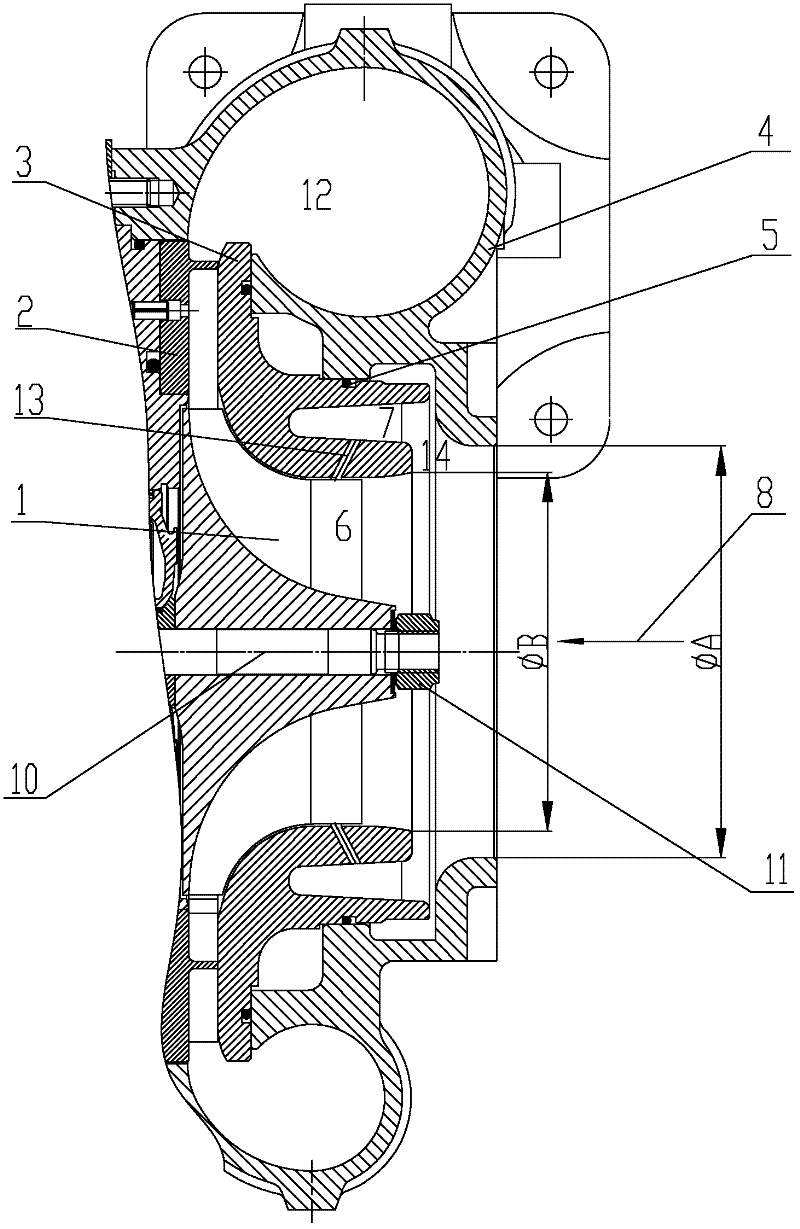

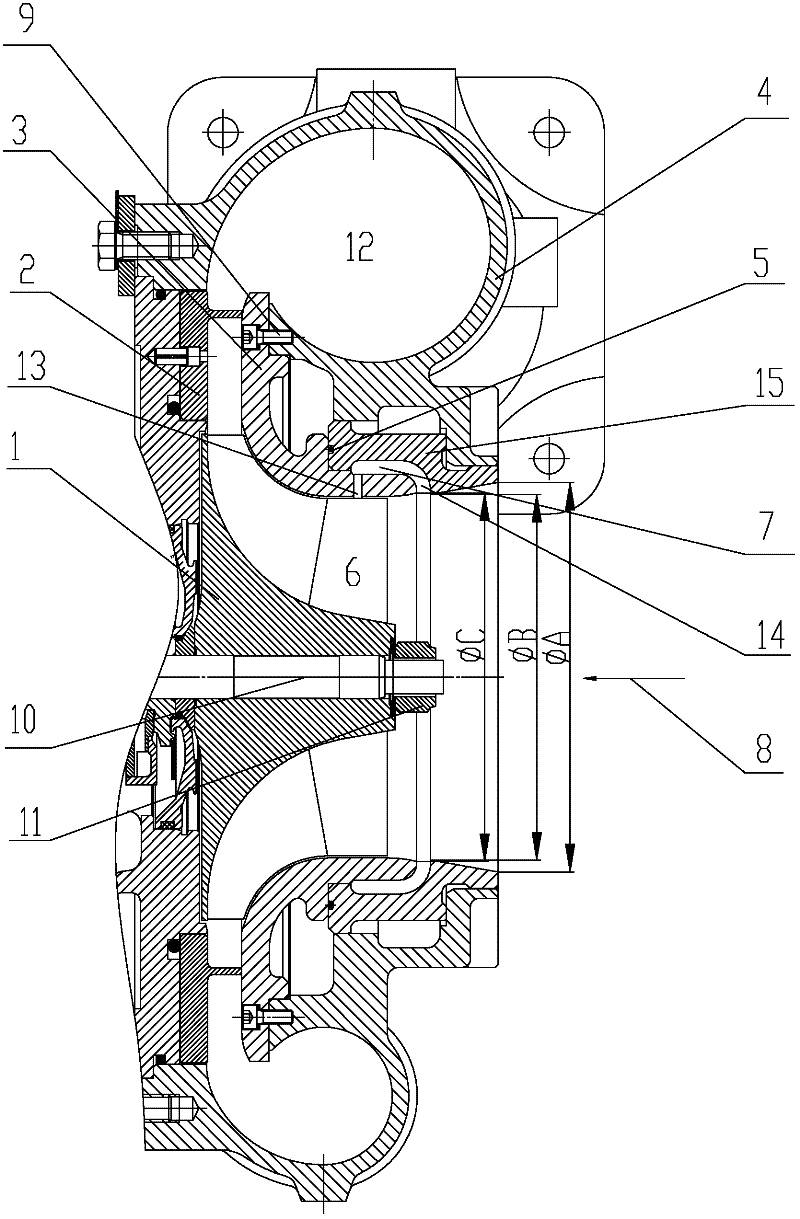

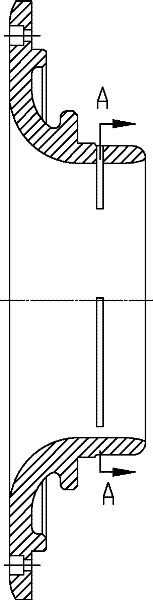

[0020] figure 1 It shows the sectional view of the structure of the turbo compressor compressor in the prior art along its axis; the compressor impeller 1 passes through one end of the shaft 10 and is fixed with a nut 11, and fresh air enters the impeller 1 channel 6 along the axial direction 8 for compression , and then diffuse in the diffuser 2, and finally enter the gas collection chamber 12 formed by the compressor casing 4. The intake shroud 3 is installed in the compressor housing 4 and arranged at the air inlet, forming part of the air channel 14 with the compressor housing, and slotting 13 at the radial position corresponding to the impeller 1, thereby forming Complete secondary air duct. Since the airflow velocity in front of the compressor impeller is as high as 100-150m / s, the inlet size φA of the compressor shell is much larger than the size φB of the airflow shroud 3, after the airflow violently impacts the shroud 3, impact noise is generated, and induced and Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com