Blade wheel structure of multiple wing type centrifugal blower fan

A centrifugal fan, multi-blade technology, used in mechanical equipment, non-variable-capacity pumps, machines/engines, etc., can solve the problem of uneven distribution of outlet speed along the axial direction, and achieve improved fan efficiency and uniform airflow speed distribution. , the effect of simple structure and shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

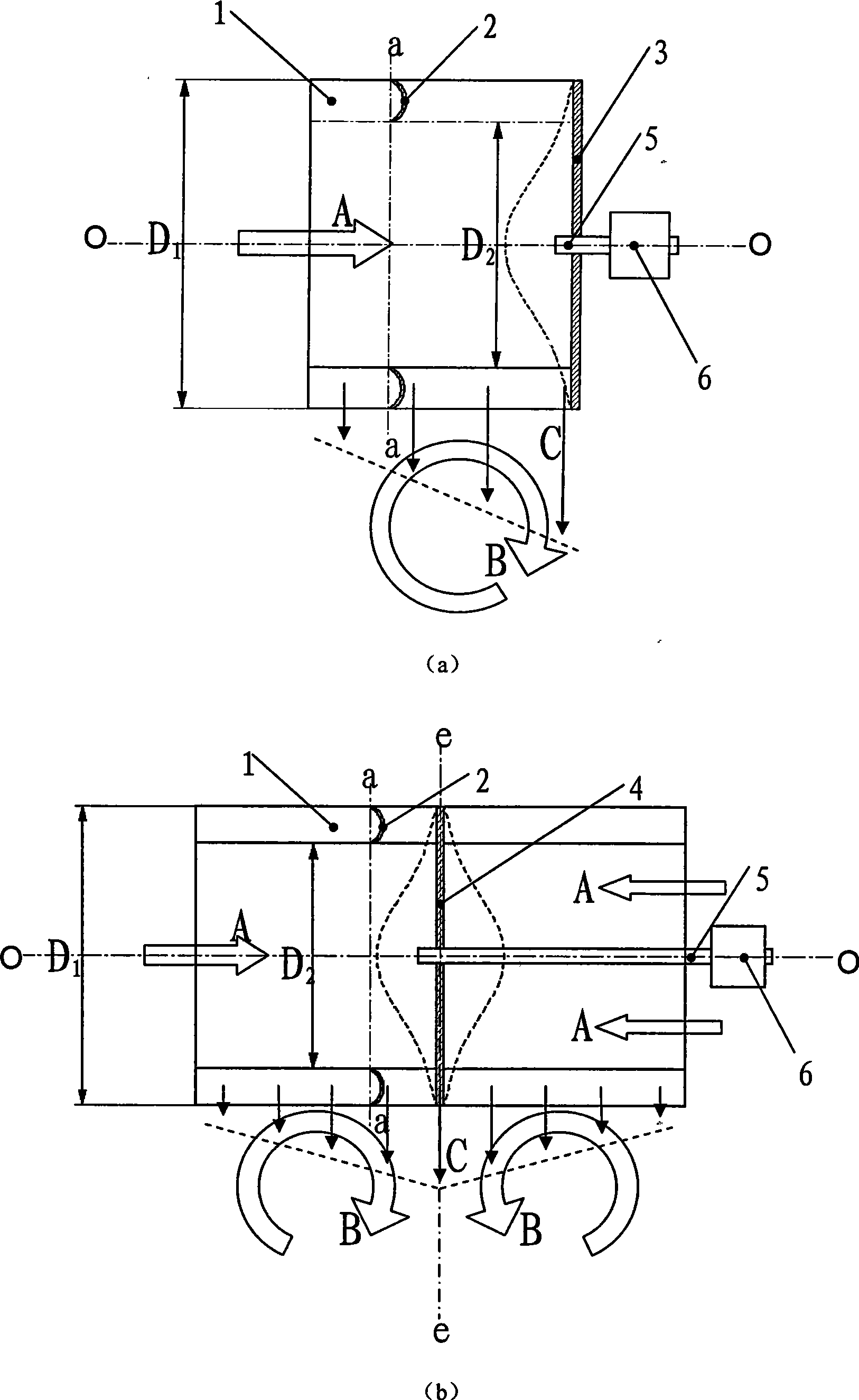

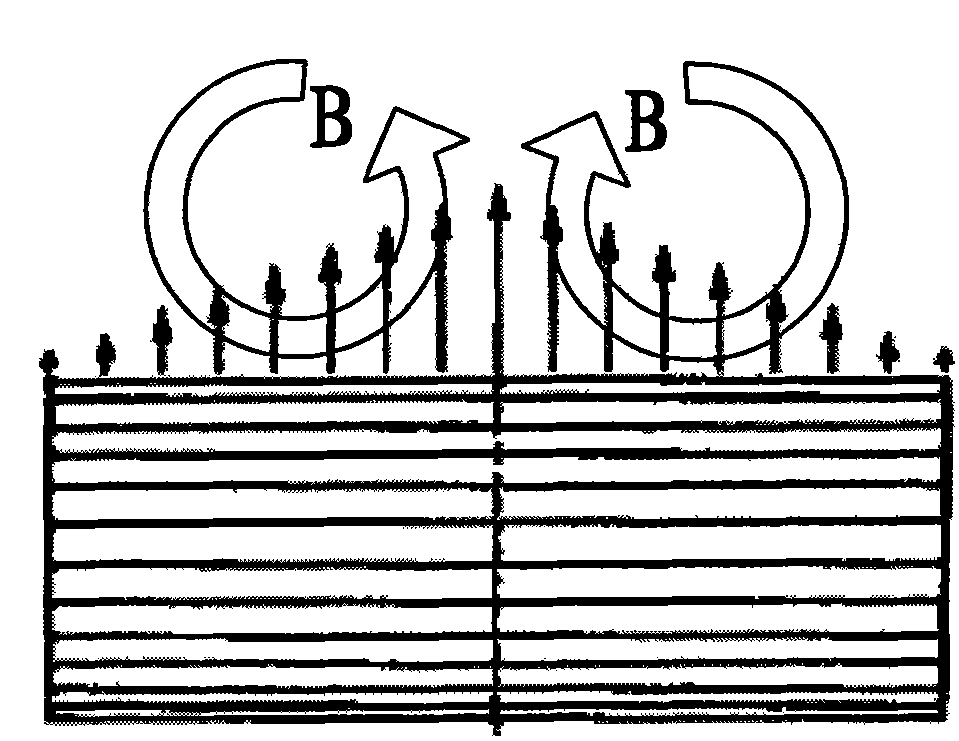

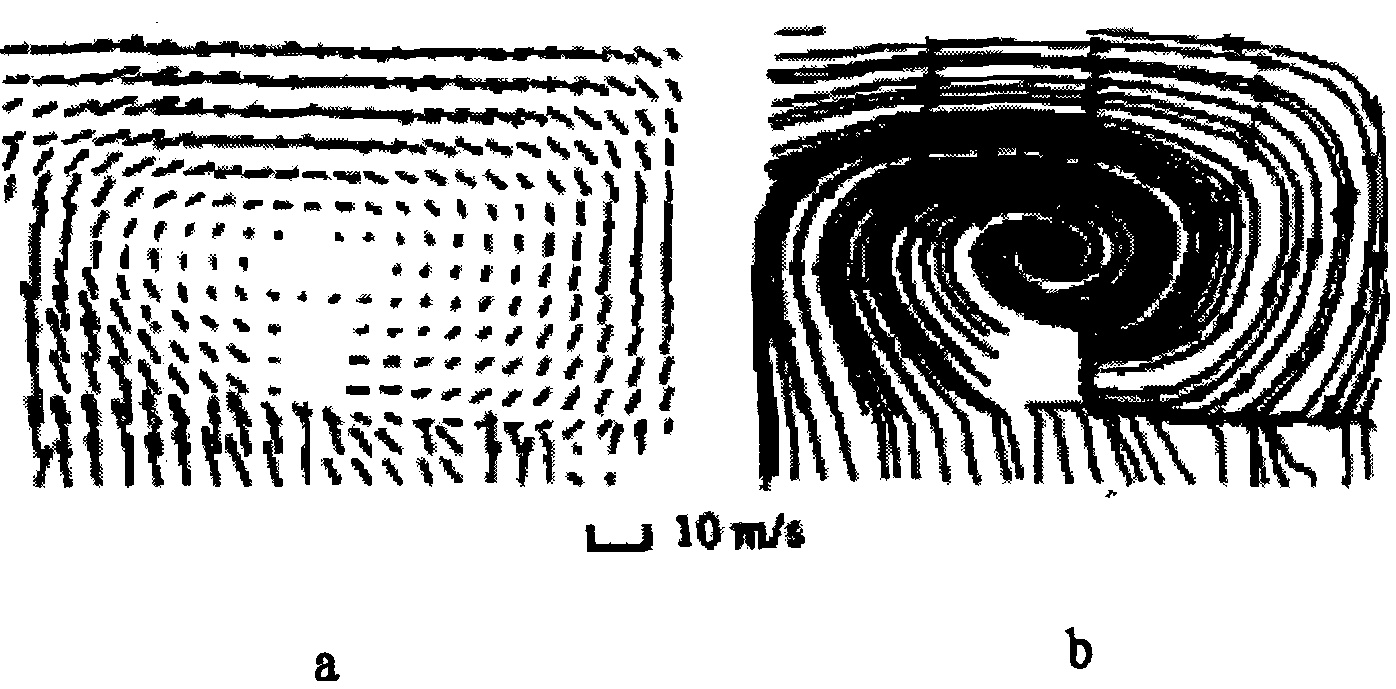

[0024] Such as Figure 4 As shown, the chord length of the impeller blade 1 changes from the cover side (the side of the impeller inlet airflow direction A) to the disk side (the side of the disk 3 or the middle disk 7), and the outer diameter of the impeller changes from D 1 reduce to D 3 , but the inner diameter of the impeller D 2 It remains the same from the lid side to the pan side. From the impeller cover side to the disk side, the chord length of the blade decreases gradually, and the working ability of the blade decreases, thereby reducing the airflow outlet velocity at the impeller disk side, so that the distribution of the airflow velocity C at the impeller outlet along the axial direction tends to be uniform. The straight line a-a where the airfoil chord line is located is perpendicular to the impeller rotation axis O-O.

Embodiment 2

[0026] Such as Figure 5 As shown, similar to Embodiment 1, the impeller blades 1 become chord-length from the cover side to the disc side, but the impeller outer diameter D 1 It remains the same from the cover side to the disc side, and the inner diameter of the impeller changes from the cover side to the disc side by D 2 increase to D 4 . From the impeller cover side to the disk side, the chord length of the blade gradually decreases, and the working ability of the blade decreases, thereby reducing the airflow outlet velocity on the disk side, and making the airflow velocity distribution of the impeller outlet along the axial direction tend to be uniform. The straight line a-a where the airfoil chord line is located is perpendicular to the impeller rotation axis O-O.

Embodiment 3

[0028] Such as Figure 6 As shown, similar to Embodiment 1, the chord length of the impeller blade 1 changes from the cover side to the disk side, and the inner diameter of the impeller changes from D to the disk side. 2 increase to D 4 , the outer diameter of the impeller from the cover side to the disc side by D 1 reduce to D 3 . From the impeller cover side to the disc side, the chord length of the blade decreases gradually, and the working ability of the blade decreases. Therefore, the velocity at the outlet of the airflow at the side of the impeller disk is reduced, and the velocity distribution of the airflow at the outlet of the impeller tends to be uniform along the axial direction. The straight line a-a where the airfoil chord line is located is perpendicular to the impeller rotation axis O-O.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com