Self-ventilation motor fan housing capable of enhancing capacities of heat dissipation and protection

A self-ventilating and windshield technology, which is applied in the direction of the casing/cover/support, electrical components, electromechanical devices, etc., can solve the problems of reduced reliability and poor protection ability of the air inlet and outlet of the self-ventilating motor, and achieve low-floor requirements , The structural design is reasonable and reliable, and the effect of sufficient heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

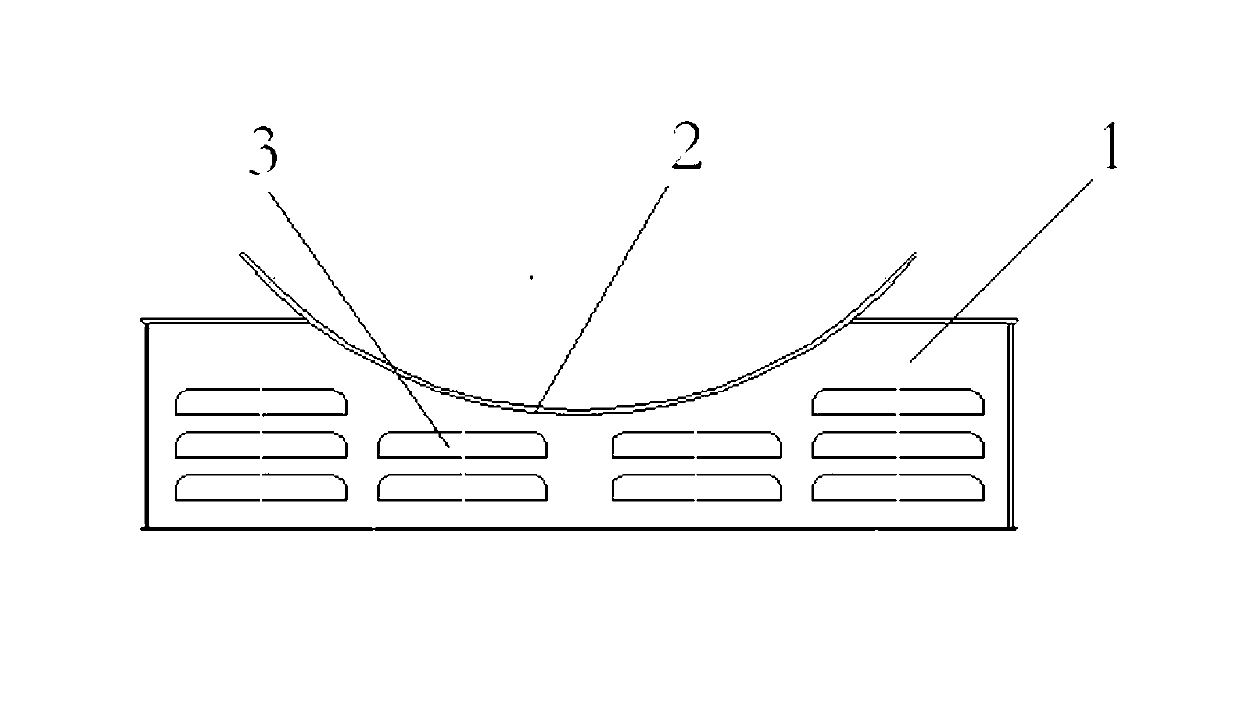

[0010] A self-ventilated motor wind hood with enhanced heat dissipation and protection capabilities includes a wind hood body arranged at the air inlet and outlet of the motor. The wind hood body includes a casing 1, and the upper end of the casing 1 is provided with an arc-shaped plate with a middle opening and mating connection with the motor casing 2. The front and rear sides of the housing 1 are provided with a number of louvered wind panels 3 with air openings below, and the bottom of the housing 1 is provided with water leakage holes.

[0011] In the specific implementation process, the shell 1 is made of steel plate welding or steel plate bending, and the size and shape of the wind cover body can be flexibly changed according to actual needs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com