Mini-consumption electric controlling valve

A micro-motor and valve body technology, applied in the direction of sliding valves, valve details, valve devices, etc., can solve problems affecting gas-liquid flow, high power, and increased pressure loss, and achieve reduced impact force, simple structure, and stable precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

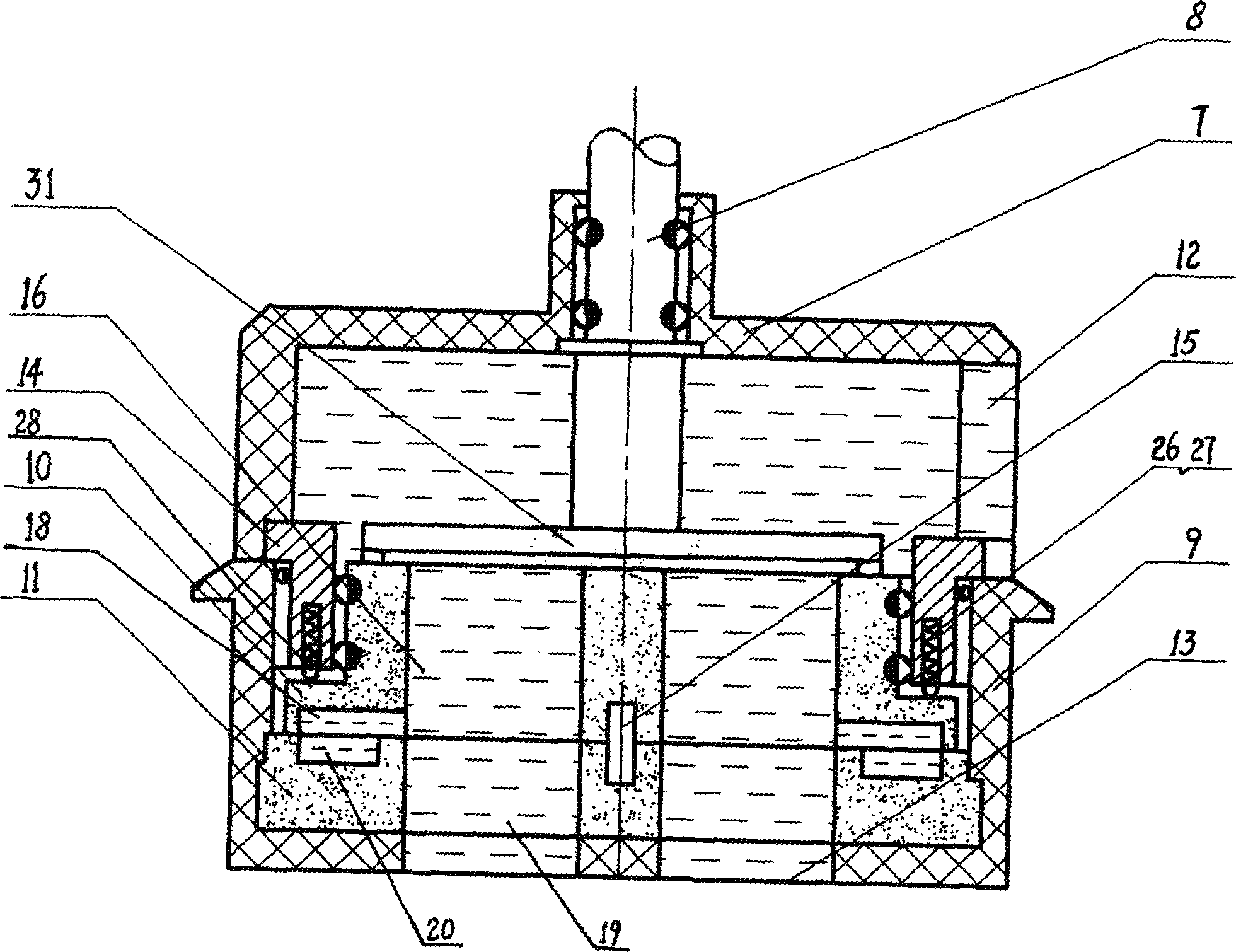

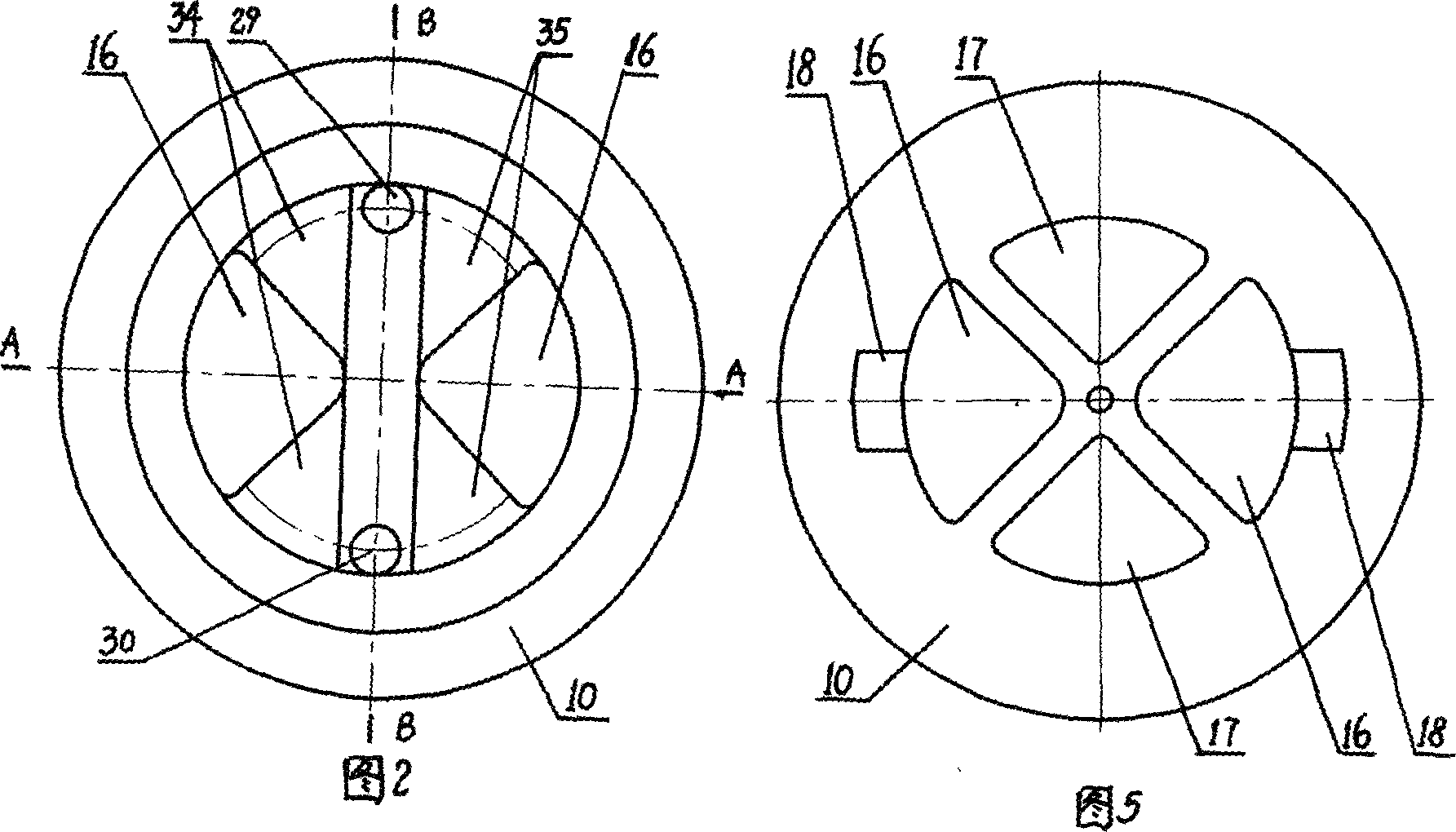

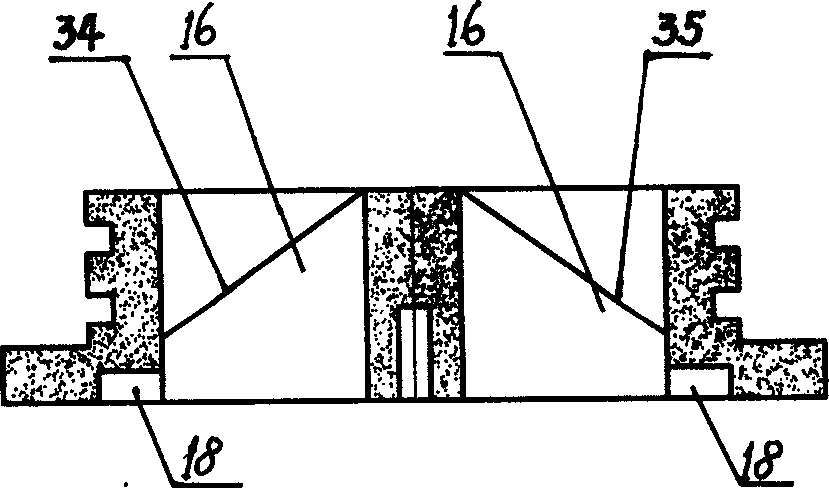

[0020] combined with figure 1 , 2, 3, 4, 5, 6, 7, 8, 9 describe an embodiment of the present invention.

[0021] An electric control valve with micro-power consumption, including a micro-motor (1), a valve body (2), a gear reduction mechanism (3), a photoelectric sensor device (4) and a positioning device (5), a micro-motor (1) and a gear The reduction mechanism (3) is arranged on the top of the valve body (2), the power input shaft of the gear reduction mechanism (3) is connected with the main shaft of the micro-motor (1), and the drive shaft (8) of the gear reduction mechanism (3) is provided with The positioning device (5), the photoelectric sensing device (4) is correspondingly arranged under the positioning device (5). The photoelectric sensing device (4) and the positioning device (5) are located in the valve body (2). The photoelectric sensing device (4) is composed of two slot-type photoelectric sensors (21) and a photoelectric sensor circuit board (22). Photoelectri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com