Spilling water filtration device

A filtering device and water overflow technology, applied in the field of washing machines, can solve the problems of lint easily flowing out of a water inlet, a reduced lint collection rate, and easy to hang clothes, etc., and achieve good market promotion prospects, simple structure, and low industrial manufacturing cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

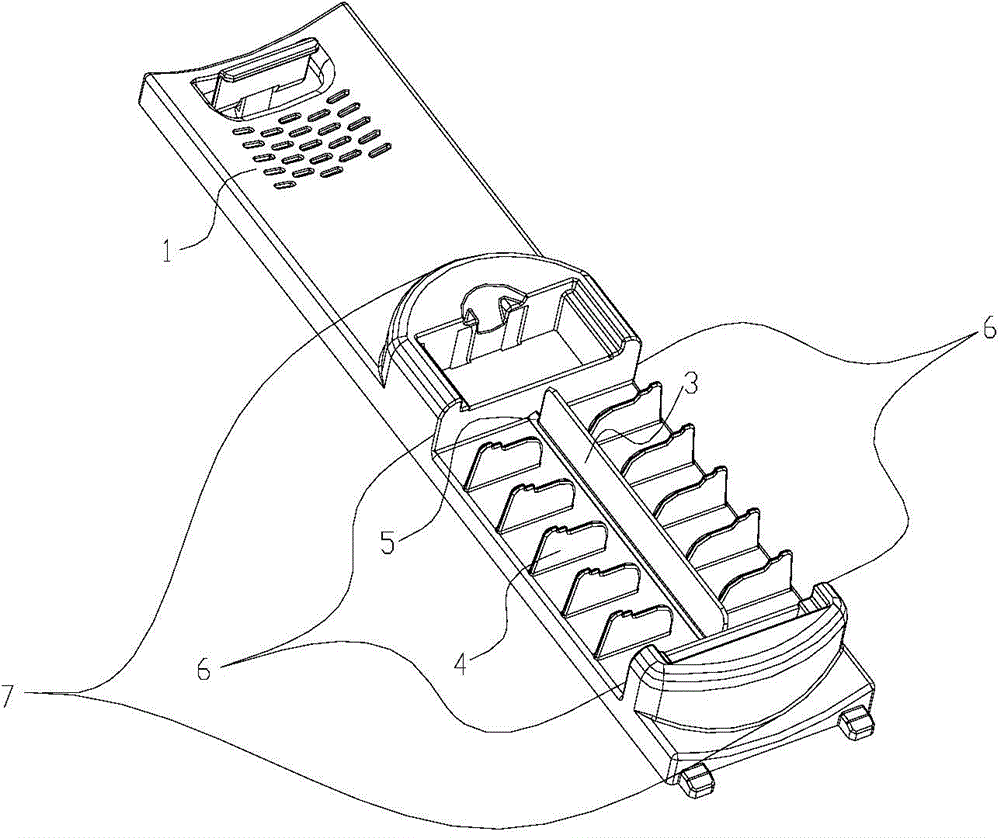

[0047] There is a certain distance between the lint filter 2 and the bottom wall of the filter part 7 , and the water inlet 6 is formed between the bottom wall of the filter part 7 and the supporting frames on both sides of the lint filter 2 .

[0048] In order to realize that there is a certain distance between the lint filter 2 and the bottom wall of the filter part 7, there are boss structures at both ends of the filter part 7, and the lint filter 2 is arranged on the convex structures at both ends. between the platform structures. The most common assembly method of the existing lint filter 2 is clamping, that is, an elastic tab 22 is provided at one end of the lint filter 2, and a claw 23 is provided at the other end, so that the structure of the existing lint filter 2 is not changed. and the connection method, the present invention sets an insertion part for inserting the claw 23 of the lint filter 2 on the lower end protrusion structure of the filter part 7, and sets an ...

Embodiment 1

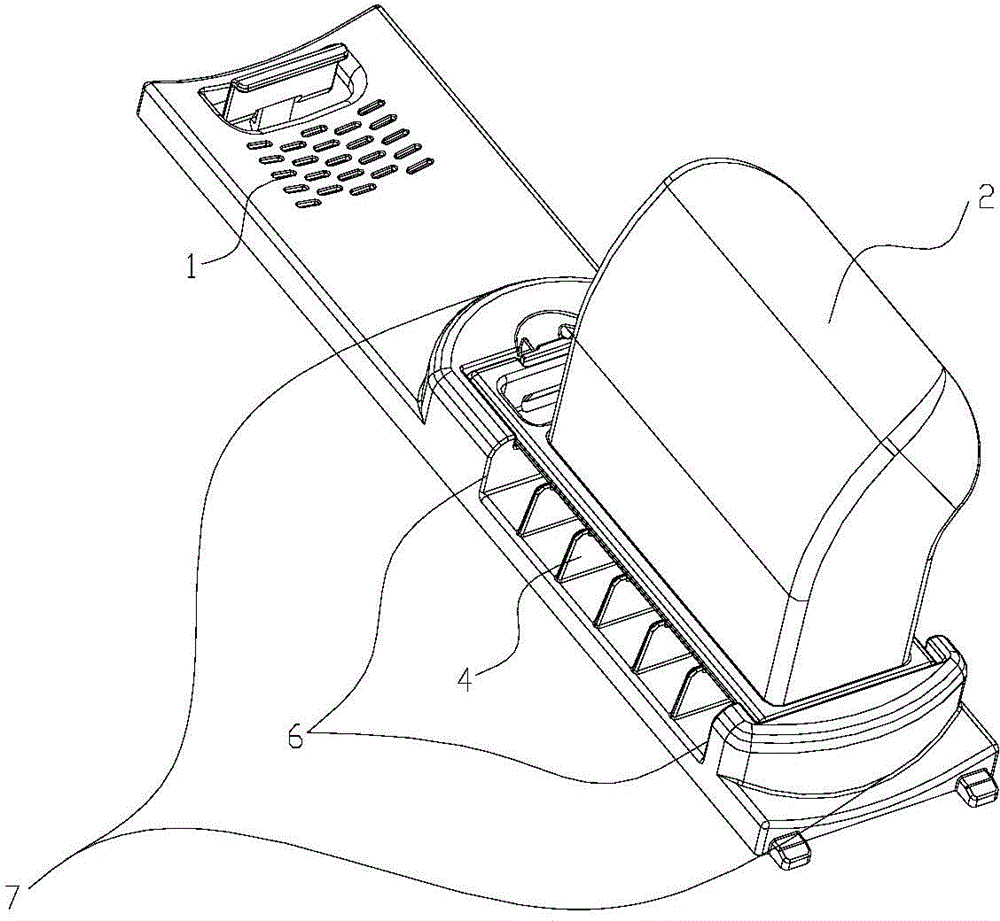

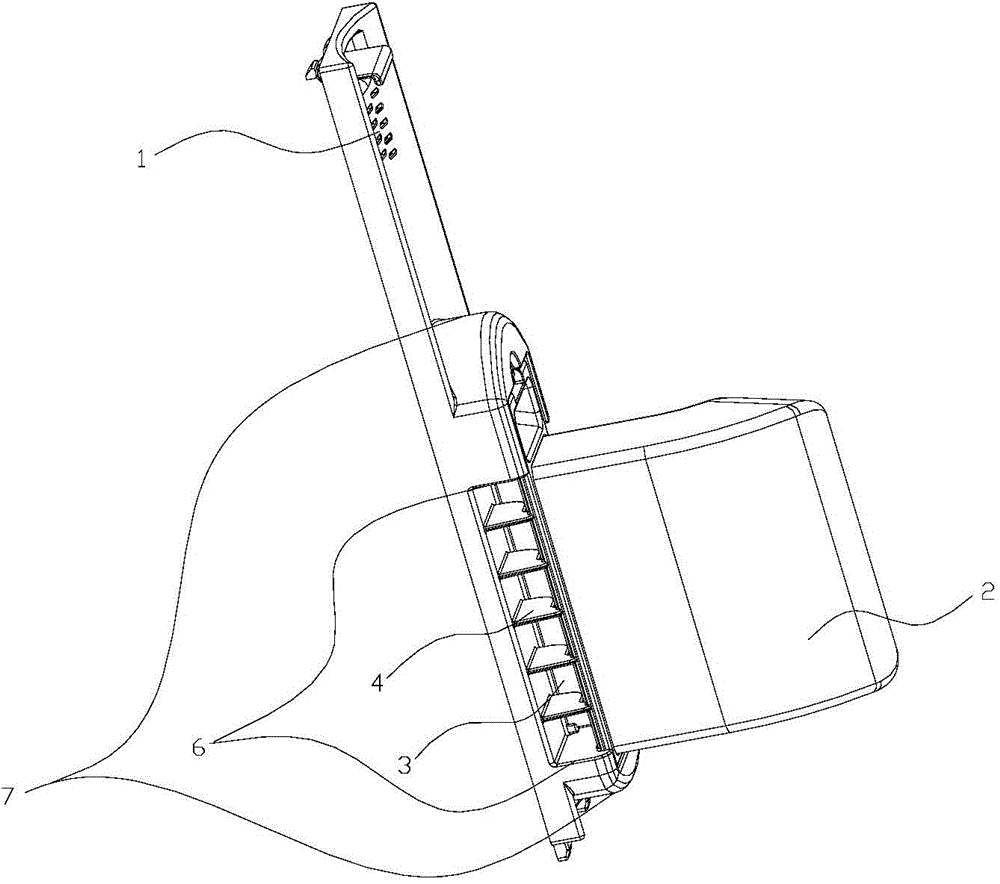

[0059] Such as Figure 1-5 Shown, is the overflow filter device of the present invention, comprises overflow part 1 and filter part 7, and the bottom wall upper part of overflow filter device is overflow part 1, and overflow part 1 is provided with some overflow holes, and overflow hole is used for in the washing machine. When the washing water is higher than the limited water level, the excess washing water is discharged. The lower part of the bottom wall of the overflow filter device is a filter part 7, and the two ends of the filter part 7 have boss structures respectively, and the lint filter 2 is arranged between the boss structures at both ends. The most common way of assembling the lint filter 2 and the filter part 7 is clamping, that is, an elastic tab 22 is provided at one end of the lint filter 2, and a claw 23 is provided at the other end. An insertion portion for inserting the claw 23 of the lint filter 2 is provided on the top, and a mounting portion for snapping...

Embodiment 2

[0069] Compared with Embodiment 1, the only difference is that the filter part is not provided with guide ribs 4, and the free end of the water guide baffle 3 is provided with a rotating shaft, which is inserted into the raised structures at both ends of the filter part, and the filter part Corresponding limit grooves are set on the two ends of the raised structure, and the rotation axis of the free end of the water guide baffle 3 moves along the track of the limit groove to realize the swing at a fixed angle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com