A flat plate heat pipe with arrayed microchannels

A flat-plate heat pipe and flat-plate heat pipe technology, applied in the direction of indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of low efficiency of local heat dispersion and transfer, high local temperature of heat pipes, and easy drying of working medium, etc., and achieve efficiency improvement , enhance the radial thermal conductivity, reduce the effect of thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

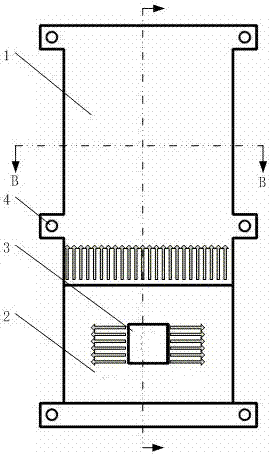

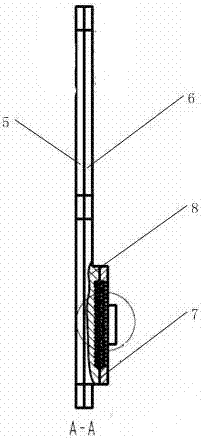

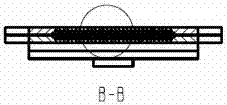

[0025] The invention is formed by superimposing two flat heat pipes, arranged vertically and horizontally. The vertical micro-channel flat heat pipe is used as a long-distance heat transfer, transferring heat from the evaporation end to the condensation end; a micro-channel flat heat pipe is arranged horizontally on the back of the heat-conducting micro-channel flat heat pipe, and the heat conduction direction of the heat pipe is horizontal transfer, and the high heat flow The density heat source is attached to the center of the heat pipe, which can quickly transfer heat along the horizontal direction and play the function of horizontal heat uniformity. Through the micro-channel flat heat pipe with thermal uniformity function, the heat pipe can be applied to the situation with higher heat flux density.

[0026] The above two microchannel flat heat pipes are composed of two upper and lower flat plates with microchannels. Microchannel arrays with a certain geometric shape are o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com