Coaxial heat exchanger

A heat exchanger, coaxial technology, applied in the direction of heat exchanger conduit, heat exchanger type, indirect heat exchanger, etc., can solve the problems of large heat exchange metal consumption, high manufacturing cost, high manufacturing cost, and achieve enhanced Heat exchange performance, easy operation and installation, and the effect of reducing metal consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] based on the following Figure 1 to Figure 15 , specify a preferred implementation example of the present invention:

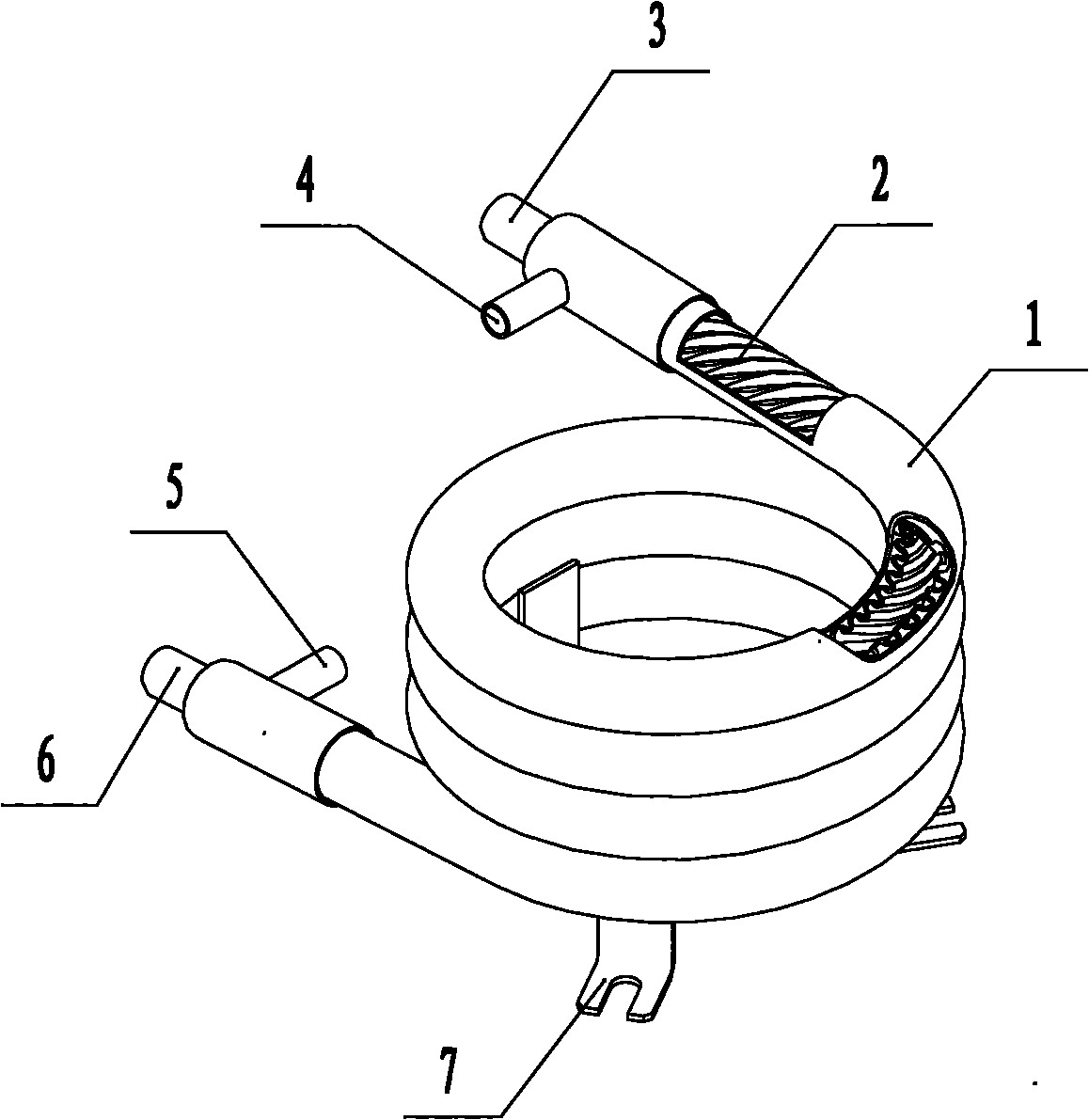

[0033] Such as figure 1 Shown is a coaxial heat exchanger, which contains:

[0034] An outer tube 1; mouthpieces 4 and 5 are provided at both ends of the outer pipe 1, the mouthpiece 4 is the second fluid inlet, and the mouthpiece 5 is the second fluid outlet;

[0035] An inner tube 2 sleeved inside the outer tube 1, the inner tube 2 is arranged coaxially with the outer tube 1;

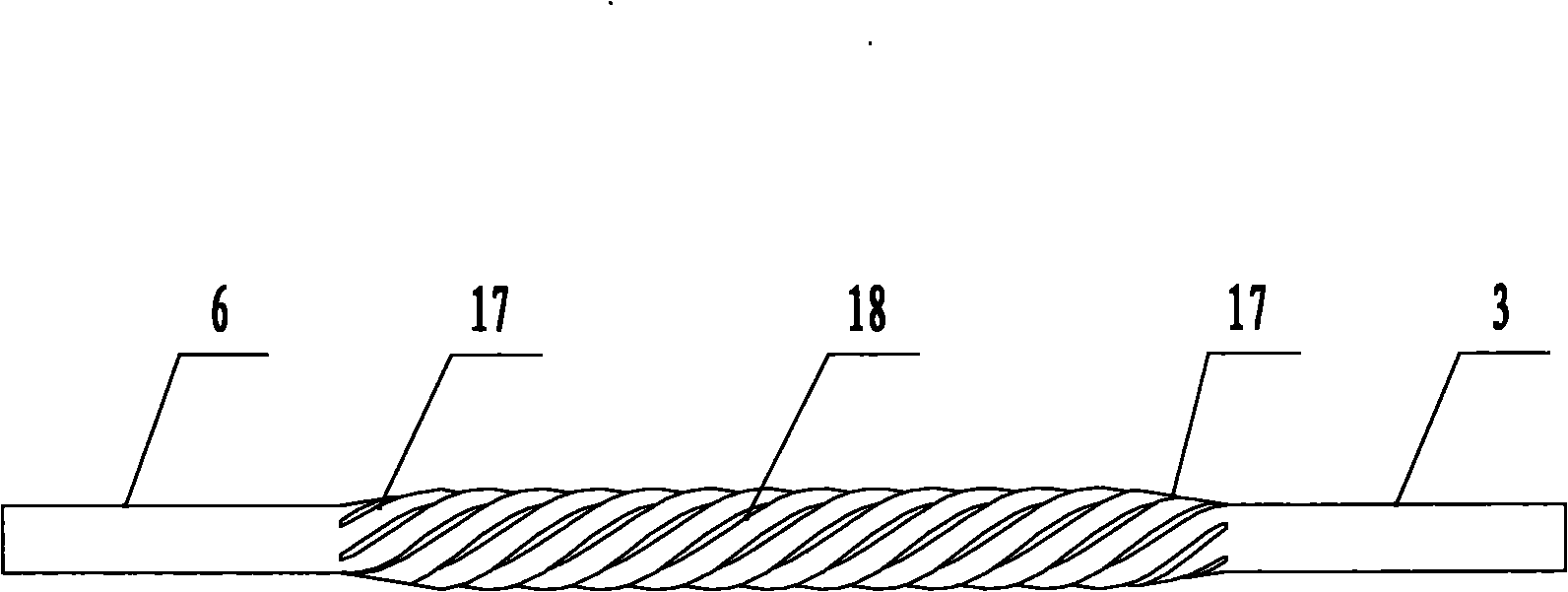

[0036] Such as figure 2 As shown, the inner tube 2 includes a main body section 18, a transition section 17 located at both ends of the main section 18, and also includes necking pipe sections 3 and 6 respectively connected to the transition section 17. The outer diameter of the main body section 18 is smaller than that of the outer tube 1, the main body section 18 is closely matched with the outer pipe 1, and the fit gap is 0.1-1 mm, the necked pipe section 3 is the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com