Steam rotating heat conduction sludge drying device

A technology of sludge drying and steaming, which is applied in water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, special treatment targets, etc. Affect the drying rate and other issues, to achieve the effect of increasing the amount of dried mud, simple structure, and prolonging the reversal time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

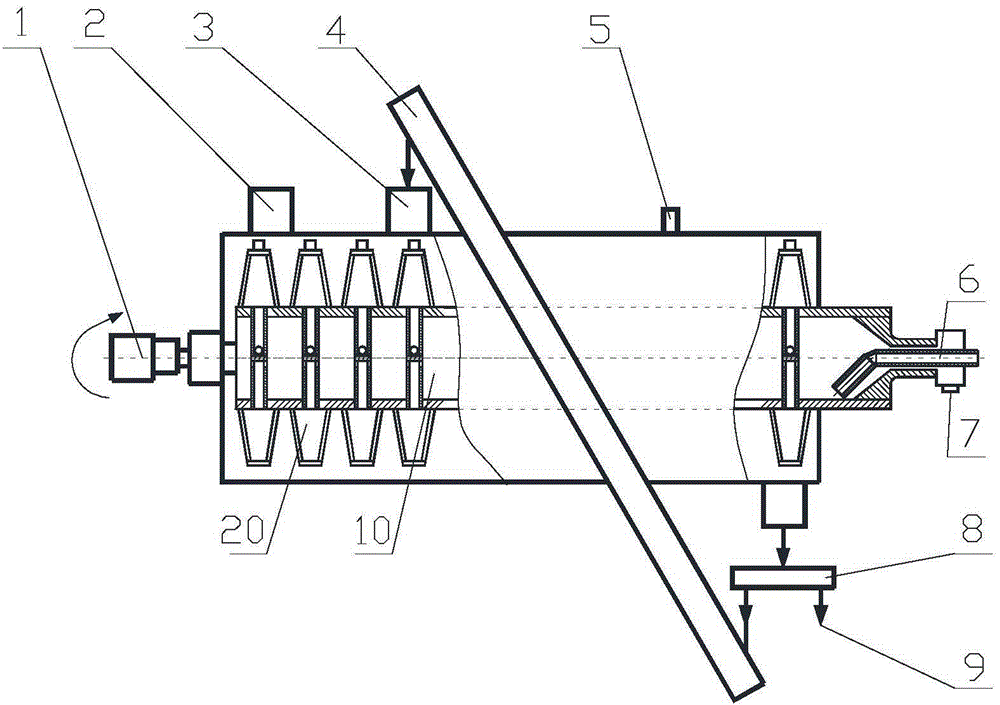

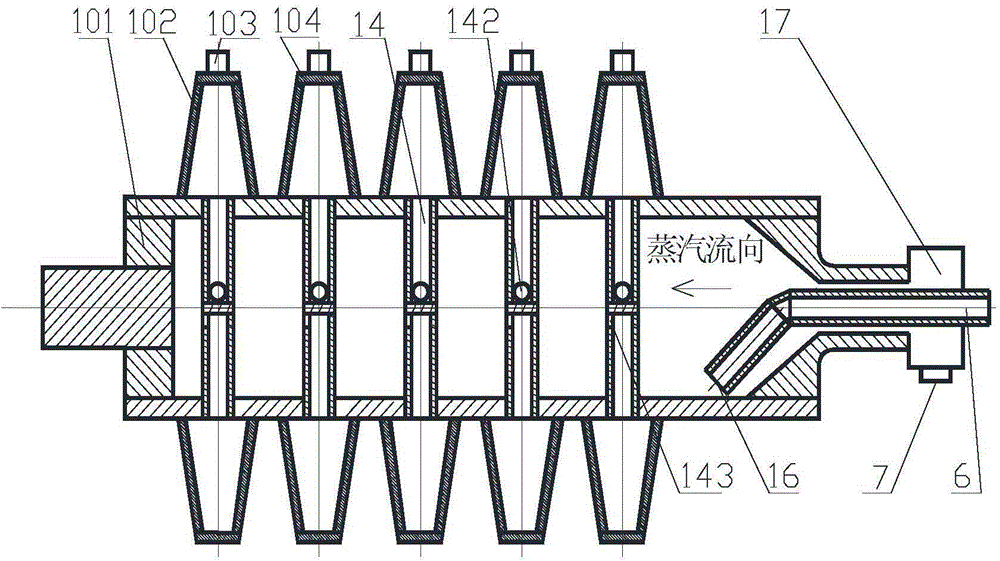

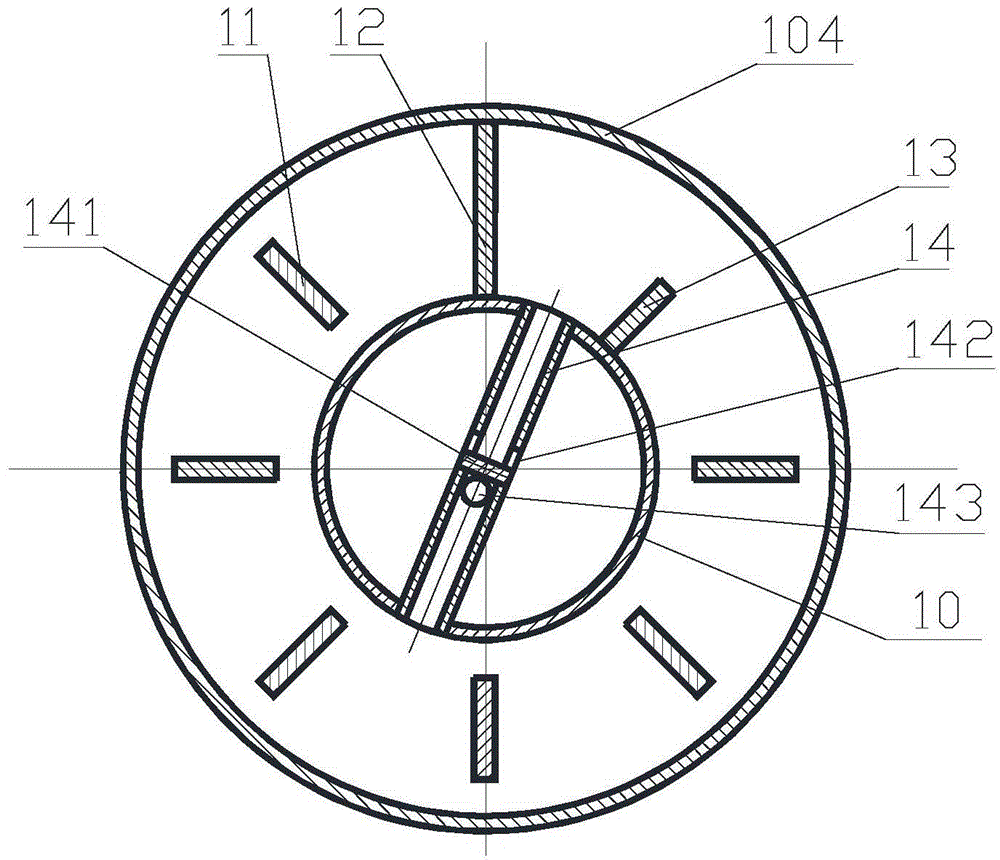

[0021] A steam-type sludge drying device is composed of a rotary heat conduction dryer, a dry sludge distributor 8, a dry sludge lifter 4, etc. The sludge inlet 2 is located above one end of the dryer, and the dry sludge distributor 8 is located at the other end of the dryer. On the side or bottom of one end, the upper outlet of the dry sludge lifter 4 is connected to the sludge return port 3. There are multiple inlets on the upper part of the dryer to adjust the position of the sludge return port. The sludge return port 3 is located on the sludge above the dryer. Viscous zone paddle. One end of the dry mud distributor 8 is provided with a dry mud outlet 9, and the other end is connected to the inlet of the dry mud lifter 4, and the amount of returned material is quantitatively adjusted by the time when the dry mud distributor 8 reverses. A plurality of blades 20 are arranged on the hollow shaft 10, and the blades are composed of two side plates 102 and a top plate 104. Each b...

Embodiment 2

[0024] A hollow shaft 10 for implementing the above-mentioned sludge drying device. The difference from Embodiment 1 is that each paddle 20 is provided with a steam inlet and drain pipe 14 and a paddle steam inlet pipe 15, and there is a certain distance between them. The angle is generally 90°, and they are arranged in front and back in the axial direction, and they are close to each other. The air inlet 143 of the paddle is parallel to the hollow shaft 10 and is set against the steam inlet direction. The outlet 142 of the blade is a total of 2 through holes Perpendicular to the hollow shaft 10, this structure is suitable for extra large paddles.

[0025] The working process of the device of the present invention is as follows:

[0026] The hollow shaft 10 of the dryer is driven by the motor reducer 1, and the wet sludge is sent into the dryer from the wet sludge inlet 2. The steam is sent into the hollow shaft through the steam inlet 7 of the rotary joint 17, and enters eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com