Inner fin externally sintered porouslayer heat exchange tube

A technology of heat exchange tubes and porous layers, applied in the field of heat exchange tubes, can solve problems such as low production efficiency and poor bonding of porous layers, and achieve the effects of wide application, improved bonding strength and production efficiency, and high heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

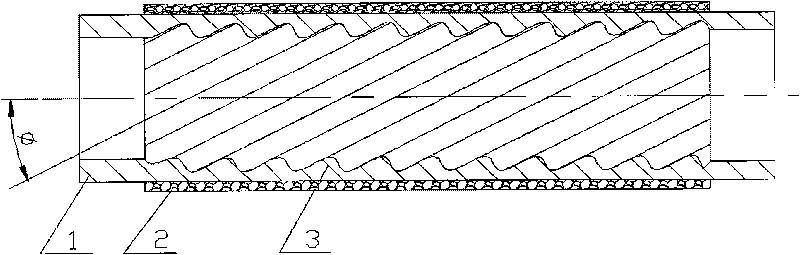

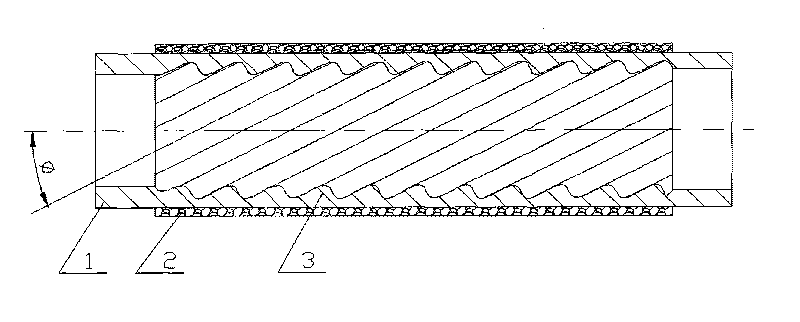

[0030] like figure 1 , 2 As shown, the inner fin outer sintered porous layer heat exchange tube, the heat exchange tube is processed by smooth carbon steel pipe 1, the specification of the carbon steel pipe is φ15×2×50mm, the processing method includes the following steps: smooth the metal The inner surface of the tube is machined into a spiral low-fin surface, and then the outer surface is sprayed with paint slurry, which is a mixture of metal brass powder and binder with a weight ratio of 10:2. The binder is polypropylene and acetone, and it is dried in the air. After drying, enter the high-temperature sintering furnace for sintering. The sintering temperature is 800°C. After cooling, it is released from the furnace to obtain a double-sided enhanced heat exchange tube with a regular spiral low-fin surface 3 on the inner surface and a metal porous surface layer 2 on the outer surface.

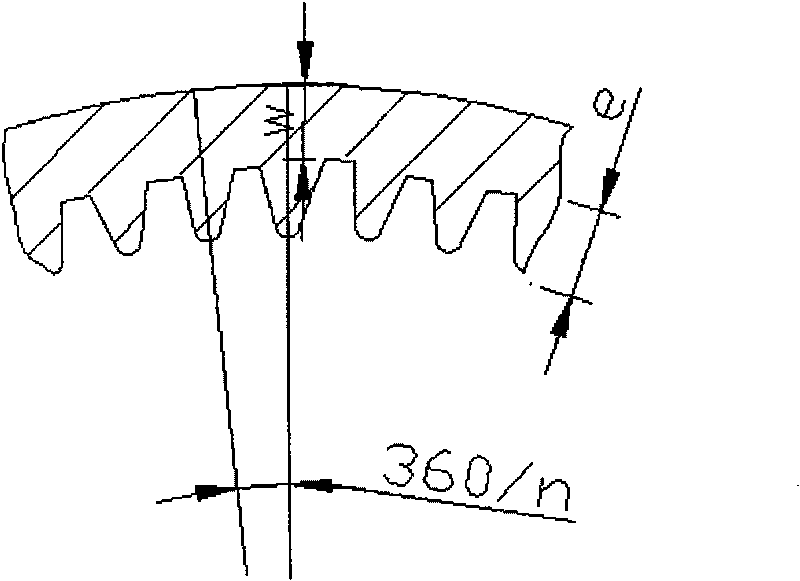

[0031] The bottom wall of the spiral low-finned surface is provided with 30 regular spira...

Embodiment 2

[0034] Inner fin outer sintered porous layer heat exchange tube processed on the basis of titanium tube with a specification of φ19×2×1500mm. The preparation method of the inner fin outer sintered porous layer heat exchange tube is to machine the inner surface of the metal smooth tube into Spiral low-fin surface, the specifications of the spiral low-fin surface layer are the number of helical teeth n=60, the helix angle φ=45°, the low wall thickness w=1.5mm, and the helix height e=0.5mm, and then spray the paint slurry on the outer surface, The slurry is a mixture of white copper powder and binder with a weight ratio of 10:5. The binder is polystyrene and xylene. After drying, it enters a high-temperature sintering furnace for sintering. Get the product right out of the oven. The metal porous surface layer has a thickness of 0.25 mm, an equivalent pore size of 40 μm, and a porosity of 65%. In a boiling heat transfer experiment using acetone as a medium, the boiling heat transf...

Embodiment 3

[0036] On the basis of copper light tube 1 with a specification of φ25×2.5×6000mm, the heat exchange tube with inner fins and outer sintered porous layer is processed. The two ends of the heat exchange tube are smooth circular section pipe joints, and the middle of the heat exchange tube is processed into A double-sided enhanced heat exchange section, the inner surface of the double-sided enhanced heat exchange section is a spiral low-fin surface layer 3 , and the outer surface is a metal porous surface layer 2 .

[0037] The preparation method of the heat exchange tube with a sintered porous layer outside the inner fin: machining the inner surface of the metal smooth tube into a spiral low-fin surface, the specification of the spiral low-fin surface layer 3 is that the number of spiral teeth is n=70, and the spiral angle φ=28 °, low wall thickness w=1.0mm, spiral height e=1.5mm, then spray paint slurry on the outer surface, the slurry is a mixture of metal copper powder and bi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com