Superheat section and condensing section-separately arranged evaporation type condensation heat exchanger and method thereof

An evaporative condensing and condensing section technology, used in evaporators/condensers, refrigerators, refrigeration components, etc., can solve the problems of increased volume, reduced cooling water temperature, increased floor space, etc., and improved heat exchange efficiency , the effect of reducing the heat exchange area and increasing the total heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

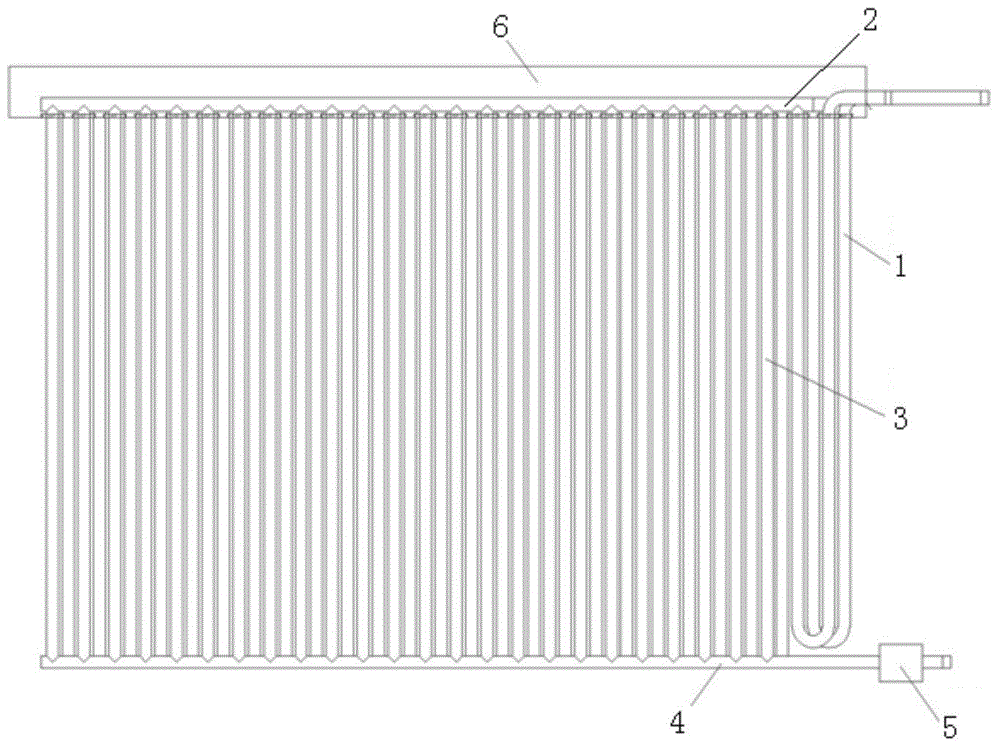

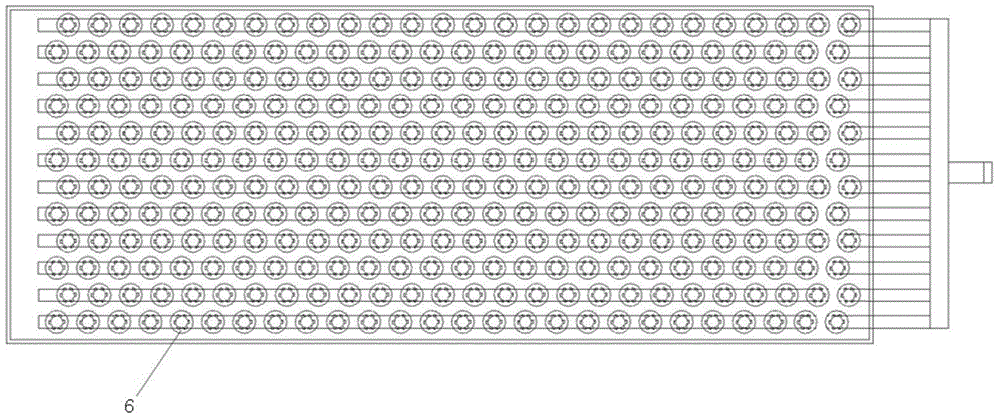

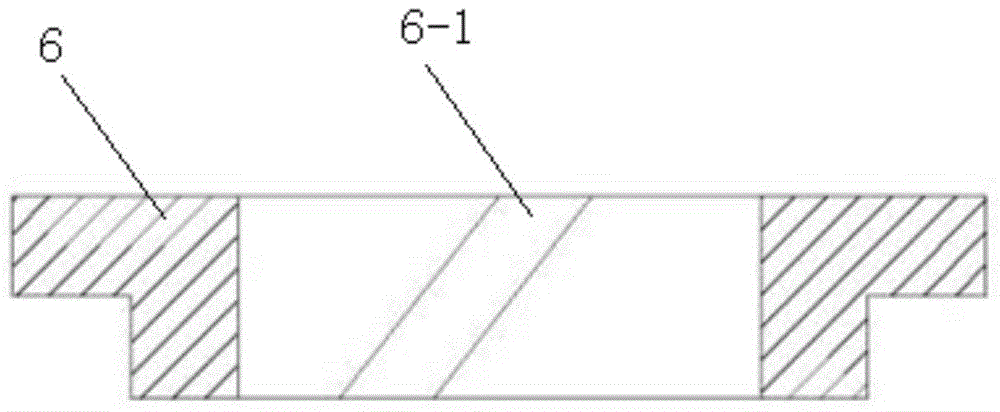

[0029] Such as Figures 1 to 4 shown. The evaporative condensation heat exchanger with separate superheating section and condensing section of the present invention includes a serpentine superheated steam cooling section 1, a horizontally arranged upper gas collecting pipe 2, a horizontally arranged lower liquid collecting pipe 4, and vertical falling film condensation heat exchange tubes 3;

[0030] There are multiple vertical falling film condensing heat exchange tubes 3, and they are distributed between the upper gas collector 2 and the lower liquid collector 4 at intervals;

[0031] The upper end of the vertical falling film condensing heat exchange tube 3 is connected to the upper air collector 2;

[0032] The lower end of the vertical falling film condensation heat exchange tube 3 is connected to the lower liquid collection pipe 4;

[0033] The port of the lower liquid collecting pipe 4 is provided with a liquid sealing device 5;

[0034] The serpentine superheated s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com