Paint slag drying and thermal oxidizing system

An oxidation system and paint slag technology, applied in drying, drying machines, drying solid materials, etc., can solve the problems of non-conforming to low-carbon environmental protection, low drying degree, easy agglomeration of paint slag, etc., to achieve easy maintenance The effect of maintenance, increasing the area, and less detection parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

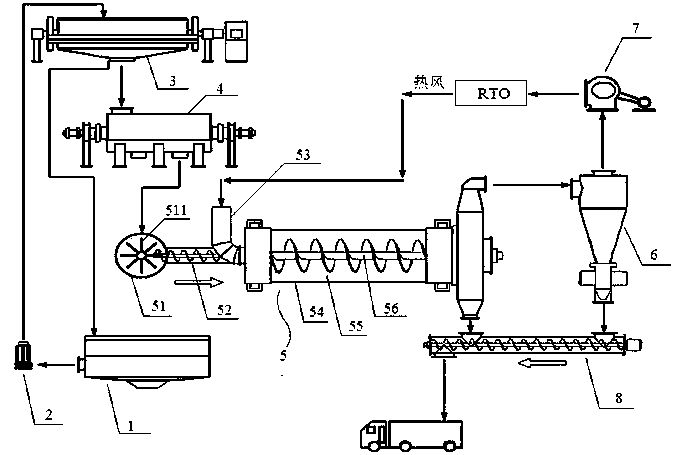

[0037] refer to figure 1 , this embodiment includes a paint residue pool 1, a paint residue pump, a paint residue filter press 3, a paint residue crushing mechanism 4, a drying oxidation mechanism 5, an exhaust gas dust removal mechanism 6 and a paint residue recovery mechanism 8; it also includes a heat storage type The oxidation furnace RTO, the gas outlet of the waste gas dedusting mechanism is connected to the air inlet of the regenerative oxidation furnace through the fan 7, and the gas outlet of the regenerative oxidation furnace is connected to the heat bypass interface 53 of the drying oxidation mechanism. The heat-containing exhaust gas treated in the system can be passed into the super dryer to realize recycling.

[0038] The water outlet of the paint residue filter press is connected to the paint residue pool. It can realize the recycling of water between the paint residue pool and the paint residue filter press. The mixing of water and sludge makes it easier for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com