Hollow fibre heat-exchange device and method

A heat exchanger and fiber technology, applied in the field of hollow fiber heat exchangers, can solve the problems of low heat transfer coefficient and heat exchange efficiency, easy corrosion of metal heat exchangers, large inner and outer diameters and thicknesses, etc. Low cost and good salt tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

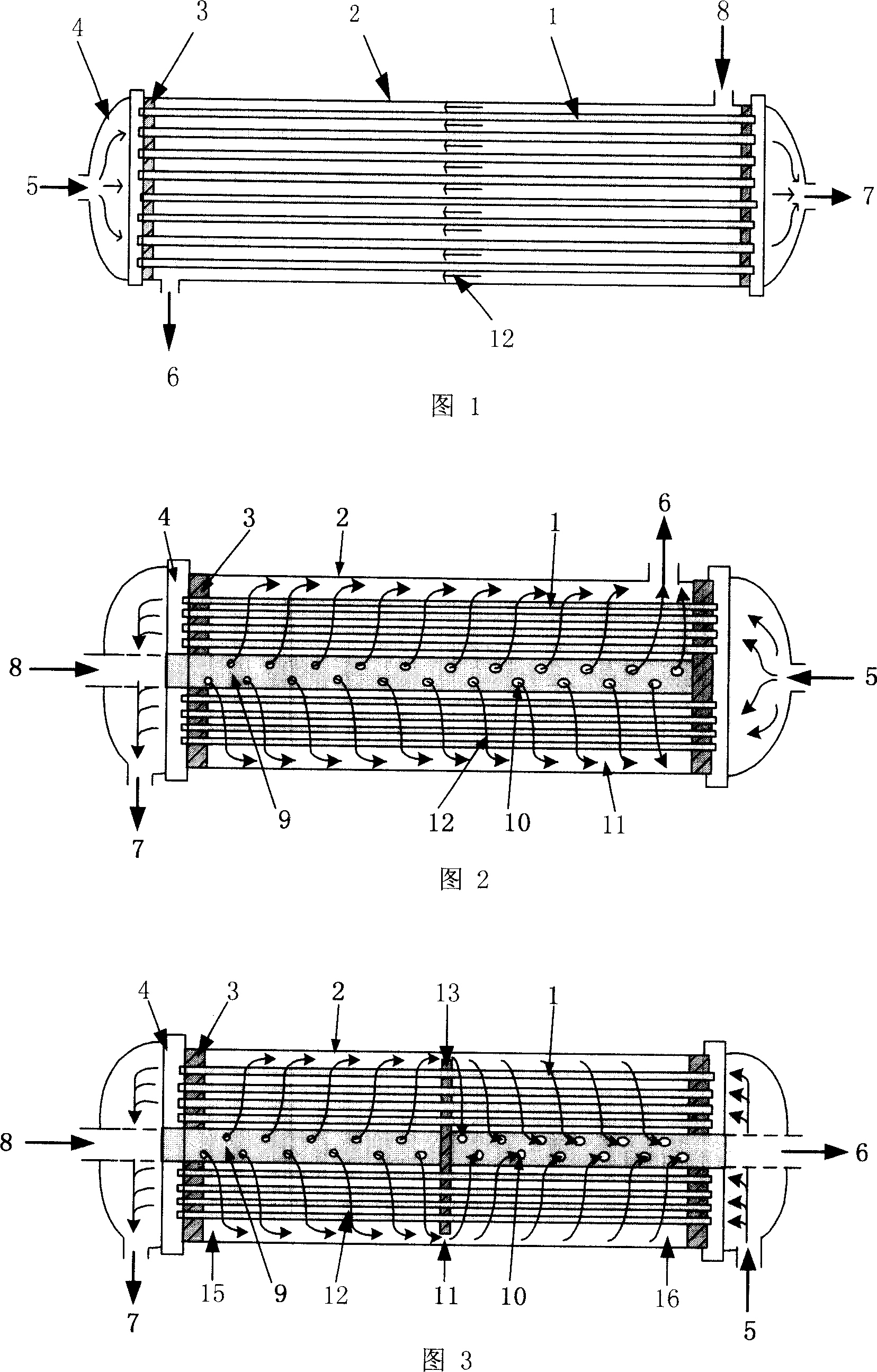

[0052] Hollow fiber: polyvinylidene fluoride, inner diameter 600 μm (micron), thickness 60 μm (micron), effective length 25 cm (centimeter).

[0053] Module: Parallel convection structure (as shown in Figure 1), 500 hollow fibers, filling density 0.43; module shell is made of polypropylene.

[0054] Operating condition 1: inside the hollow fiber: tap water, inlet temperature 25°C, linear flow velocity 4120cm / min; outside the hollow fiber: tap water, linear flow velocity 1860cm / min.

[0055] Results: When the inlet temperature of tap water outside the hollow fiber is 60°C, the total heat transfer coefficient is 1300watts / m 2 -K; when the inlet temperature is 90℃, the total heat transfer coefficient is 1452watts / m 2 -K

[0056] Operating condition 2: inside the hollow fiber: tap water, inlet temperature 24°C, linear flow velocity 4220cm / min; outside the hollow fiber: 3.5% NaCl brine, inlet temperature 90°C.

[0057] Results: When the linear flow rate of brine outside the holl...

Embodiment 2

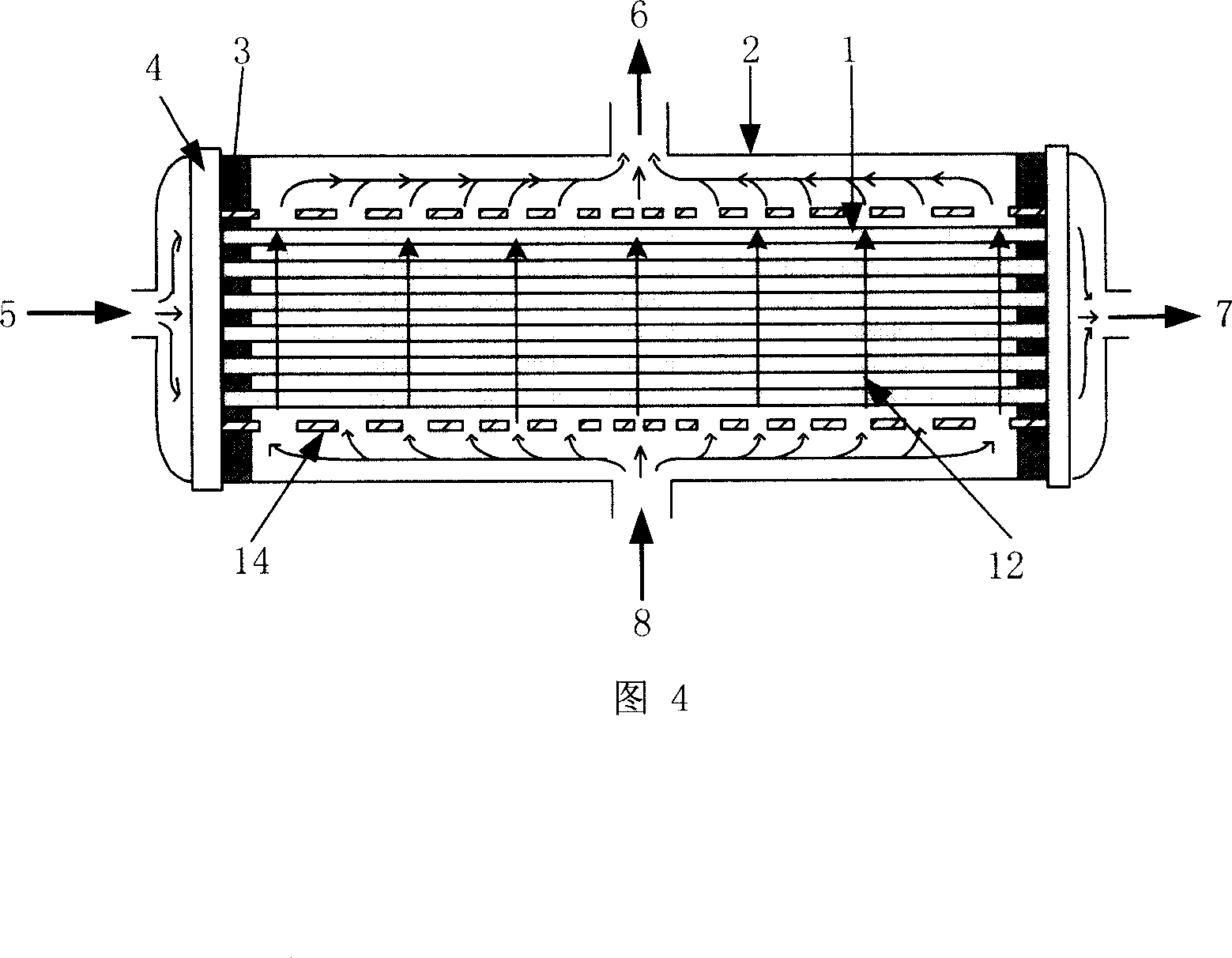

[0061] Hollow fiber: poly-4-methyl-1-pentene, inner diameter 425 μm (micrometer), thickness 50 μm (micrometer), effective length 20 cm (centimeter).

[0062] Components: cross-flow structure (as shown in Figure 2), 800 hollow fibers, filling density 0.36; hollow porous tube and component shell are made of polytetrafluoroethylene.

[0063] Operating condition 1: inside the hollow fiber: tap water, inlet temperature 33°C, linear flow rate 3520cm / min; outside the hollow fiber: 3% NaCl brine, inlet temperature 90°C.

[0064] Results: When the gap flow velocity of brine outside the hollow fiber is 120cm / min, the total heat transfer coefficient is 1250watts / m 2 -K; When the interstitial velocity of brine is 230cm / min, the total heat transfer coefficient is 1736watts / m 2 -K.

[0065]Operating condition 2: Inside the hollow fiber: water vapor, inlet temperature 115°C, 1 atm, linear flow rate 60cm / min (converted to the linear flow rate of water); outside the hollow fiber: 3% NaCl bri...

Embodiment 3

[0070] Hollow fiber: polypropylene, inner diameter 500μm (micrometer), thickness 70μm (micrometer), effective length 30cm (centimeter).

[0071] Components: cross-flow structure (as shown in Figure 3), 3000 hollow fibers, packing density 0.55; the hollow porous tube and component shell are made of polypropylene.

[0072] Operating conditions: inside the hollow fiber: seawater, inlet temperature 25°C, linear velocity 4440cm / min; outside the hollow fiber: seawater, inlet temperature 80°C.

[0073] Results: When the interstitial velocity of seawater outside the hollow fiber is 150cm / min, the total heat transfer coefficient is 1450watts / m 2 -K; when the interstitial velocity of seawater is 250cm / min, the total heat transfer coefficient is 1767watts / m 2 -K.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com