Method for preparing zeolite molecular sieve single finned tube for sintering shell type adsorbent bed

A technology of zeolite molecular sieve and sintered zeolite, which is applied in absorbent/adsorbent, chemical instruments and methods, refrigerators, etc., can solve the problems of large contact thermal resistance, etc., and achieves increasing filling amount, increasing heat exchange area, and enhancing uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1.1 Raw material ratio: use pure 13X type zeolite raw powder, add attapulgite with 8% mass of zeolite raw powder, kaolin with 2% mass of zeolite raw powder, and graphite powder with 4% mass of zeolite raw powder, stir evenly as adsorbent raw material. Then, add water glass with a modulus of 3.2 mixed with water as a binding agent, the mass ratio of water glass to water is 2:1, and the mass ratio of adsorbent raw material to binding agent is 3:2. Stir evenly to obtain a composite adsorbent.

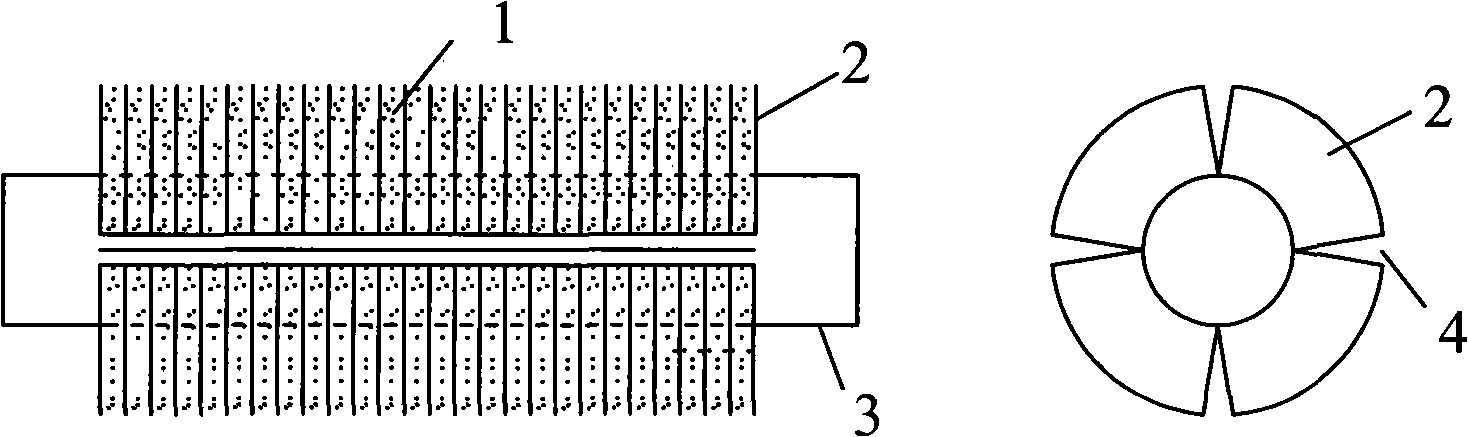

[0029] 1.2 Pre-treatment and pre-curing: open 4 V-shaped vertical grooves on the finned tube treated with an ultrasonic cleaner, pre-fill the V-shaped mold in the vertical grooves, and then fill the fins with the composite adsorbent prepared in 1.1, apply The annular mold is pressurized at 5-10 MPa, and the mold is removed.

[0030] 1.3 Baking and drying: Sinter the finned tube as a whole, heat it at 40°C, 70°C, and 100°C for 50 minutes, at 140°C and 180°C for 40 minutes each, and...

Embodiment 2

[0033] 2.1 Raw material ratio: use 13X type zeolite raw powder and granules to mix, the mass ratio of the two is 1:1, add attapulgite with 10% mass of zeolite raw powder, kaolin with 2% mass of zeolite raw powder, and zeolite raw powder 5% graphite powder, stirred evenly as the raw material of the adsorbent. Then, add water glass with a modulus of 3.2 mixed with water as a binding agent, the mass ratio of water glass to water is 2:1, and the mass ratio of adsorbent raw material to binding agent is 3:2. Stir evenly to obtain a composite adsorbent.

[0034] 2.2 Pre-treatment and pre-curing: open 4 rectangular longitudinal slots on the finned tube treated with an ultrasonic cleaner, pre-fill a rectangular mold in the longitudinal slot, then fill the fins with the composite adsorbent prepared in 2.1, and apply a ring mold Pressurize at 5-10MPa, and remove the mold.

[0035] 2.3 Baking and drying: Sinter the finned tube as a whole, heat it at 50°C and 90°C for 50 minutes, heat at...

Embodiment 3

[0038] 3.1 Raw material ratio: use pure 13X zeolite particles as the raw material of the adsorbent, add water glass with a modulus of 3.2 mixed with water as the binder, the mass ratio of water glass and water is 2:1, the raw material of the adsorbent and the binder The mass ratio is 3:1. Stir evenly to obtain a composite adsorbent.

[0039]3.2 Pre-treatment and pre-curing: open 3 V-shaped longitudinal grooves on the finned tube treated with an ultrasonic cleaner, pre-fill the V-shaped mold in the longitudinal grooves, and then fill the fins with the composite adsorbent prepared in 3.1, apply The annular mold is pressurized at 5-10MPa, and the mold is removed.

[0040] 3.3 Baking and drying: Sinter the finned tube as a whole, heat it at 40°C and 90°C for 50 minutes, heat it at 140°C and 180°C for 30 minutes each, and keep it warm at 200°C After 1.5 hours, air-cool to obtain a sintered zeolite molecular sieve finned single tube.

[0041] Compared with the bulk zeolite partic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com