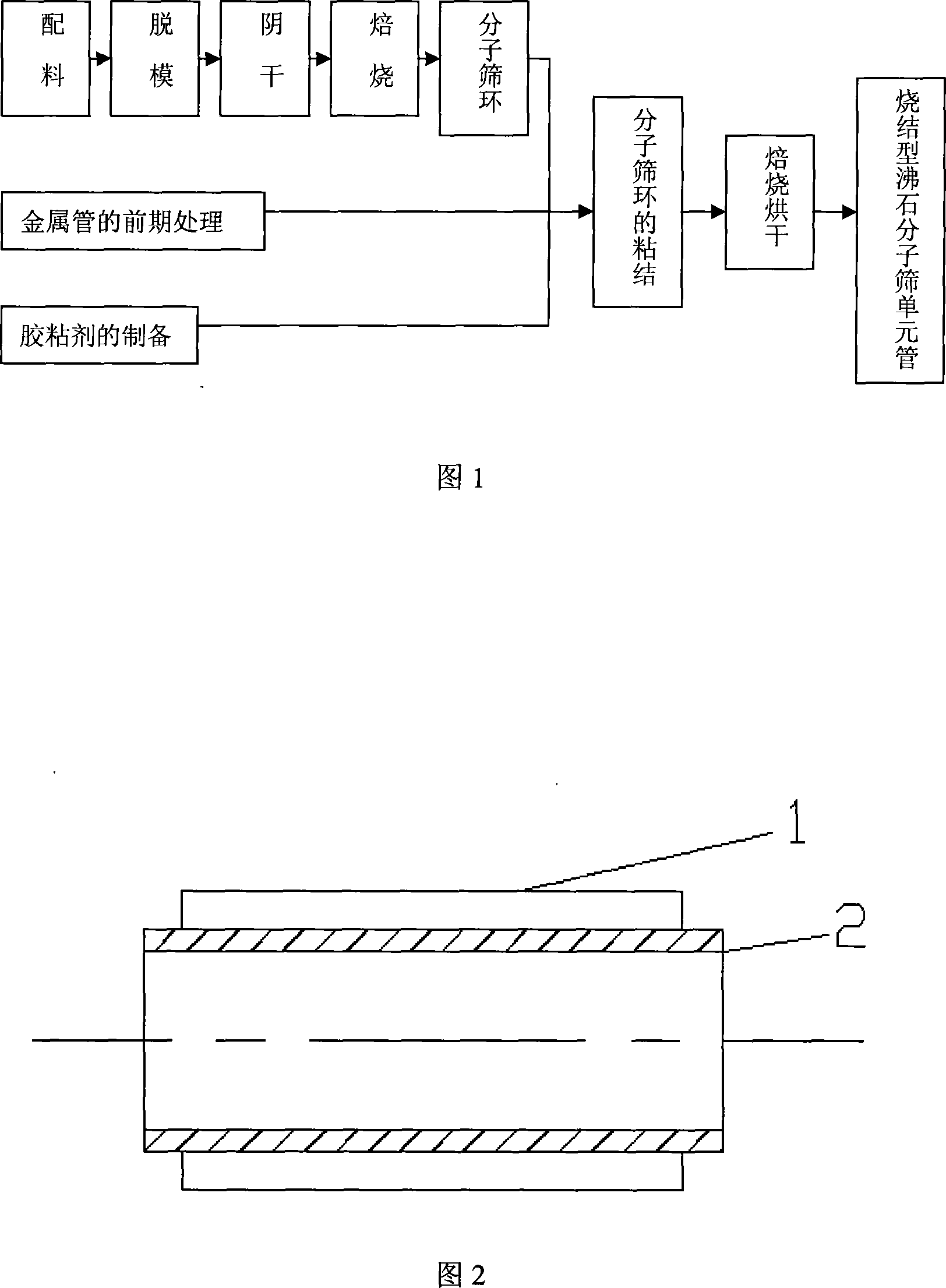

Sintering type zeolite molecular sieve adsorption refrigeration unit tube preparation process

A technology of zeolite molecular sieve and adsorption refrigeration, which is applied in the direction of molecular sieves and alkali exchange compounds, refrigerators, refrigeration components, etc., can solve the problems of large contact thermal resistance, low thermal conductivity, and low refrigeration coefficient COP, and achieve thermal conductivity. The effect of reducing the resistance and improving the heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Sintering molding of zeolite molecular sieve:

[0027] Ingredients - Weigh 40g of zeolite molecular sieve raw powder, mix with 20g of molecular sieve binder, stir it evenly with a glass rod, then add 55ml of deionized water, stir evenly to make it moist and slightly sticky.

[0028] Demoulding—take an appropriate amount of the mixture and add it to the pre-made mold, extrude and demould to obtain a molecular sieve ring with a length of 35 mm and a thickness of 3.5 mm.

[0029] Dry in the shade - put the molecular sieve ring in a cool place for a period of time, after its shape is stable, it can be sent to the furnace for roasting.

[0030] Roasting—put the molecular sieve ring into the furnace for roasting, the heating rate is 80°C / h, and the maximum sintering temperature is 600°C. When the temperature rises to the maximum sintering temperature, keep it warm for 2 hours, and finally air-cool to obtain the formed molecular sieve ring. Weighs 9.69g.

[0031] ② Sintering...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com