Cogeneration device for light condensation of single-reflection compound parabolic condenser and application method

A compound paraboloid and combined heat and power technology, which is applied in the research field of comprehensive utilization of concentrated photovoltaic light and heat, can solve the problems of poor wind resistance, excessive materials, and insufficient rigidity, and achieve the effect of low cost and high concentration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

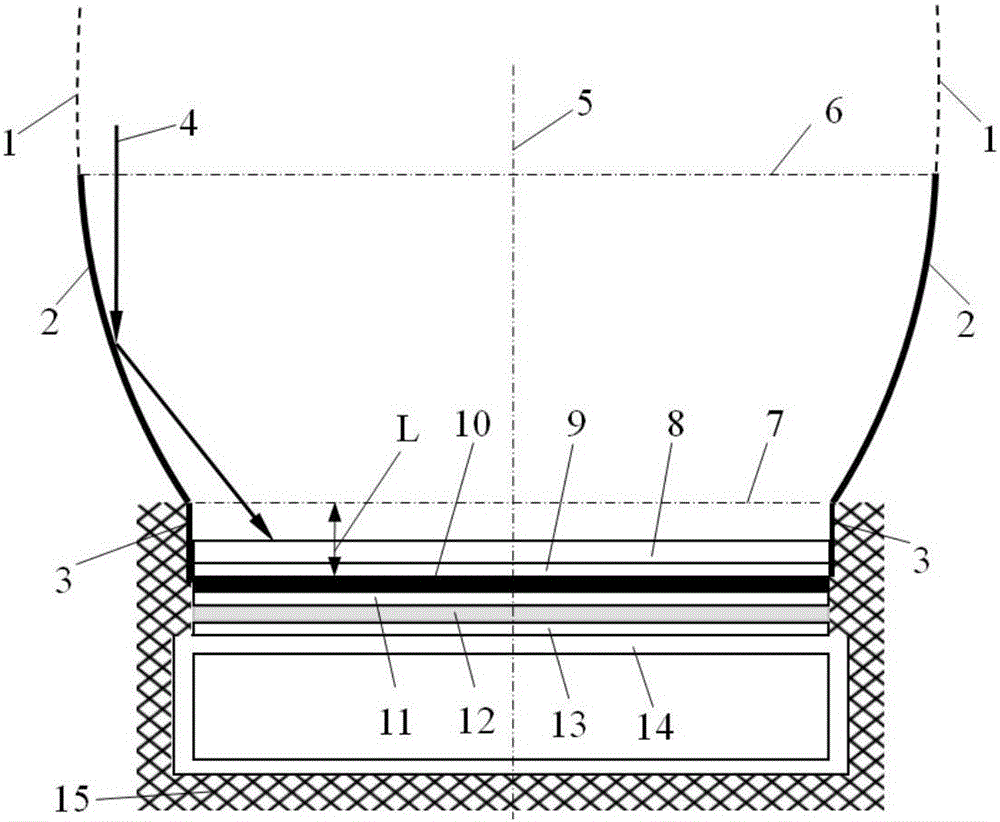

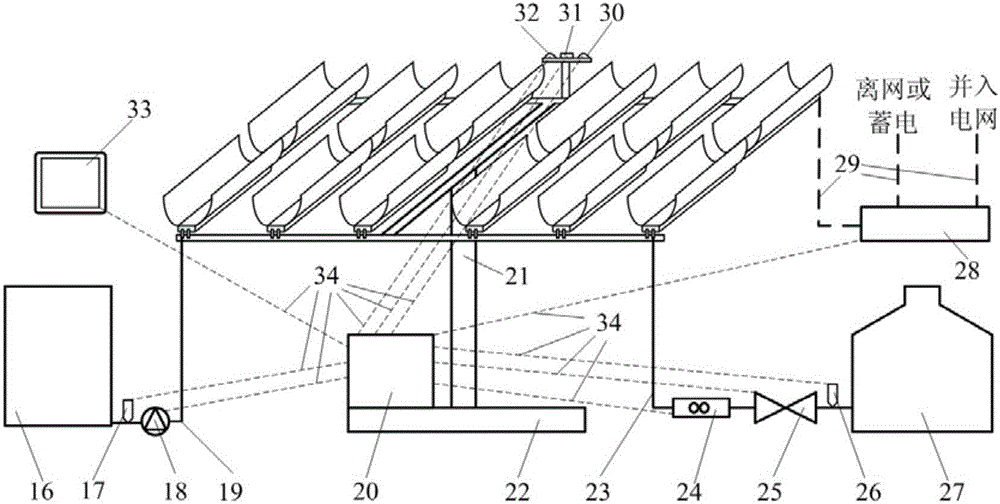

[0032]The present invention will be further described below in conjunction with the accompanying drawings. The nanofluid in the present invention is silicon dioxide nanofluid; the thermal insulation material in the present invention can be a material with thermal insulation function. The indoor monitoring module 33 is a computer.

[0033] refer to figure 1 and figure 2 , a single-reflection compound parabolic concentrator concentrating heat and power cogeneration device of the present invention includes a concentrating photovoltaic photothermal unit array, a tracking unit, an electric recovery unit, a heat recovery unit, and a control and monitoring unit, wherein, figure 2 The concentrated photovoltaic photothermal unit array shown is composed of 12 figure 1 The single concentrated photothermal units shown are arranged.

[0034] The concentrated photovoltaic photothermal unit array includes several concentrated photovoltaic photothermal units, the concentrated photovolta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com