Multi-chip parallel series UVLED array support

An array type, multi-chip technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of insignificant temperature rise of LEDs, uniformity of light emission, deterioration of consistency, and decrease in brightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

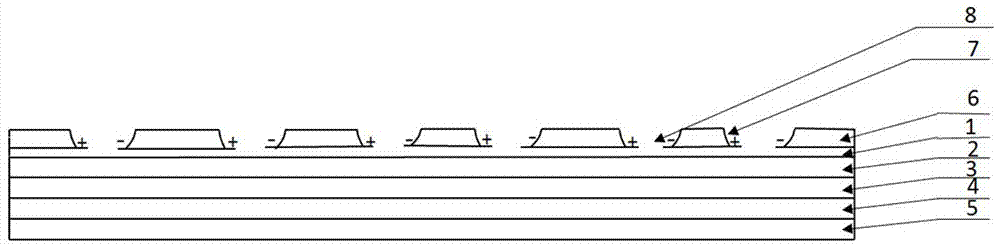

[0019] A multi-chip parallel-series UVLED array support, the support has a stacked structure, including sequentially stacked heat dissipation layer 5, first insulating layer 4, circuit layer 3, second insulating layer 2 and single-sided mirror emission layer 1 , The reflective cups 7 are evenly distributed on the single-sided specular emission layer 1, and the chip pads are arranged in the intervals of the reflective cups.

[0020] The material of the single-sided specular emission layer 1 is light aluminum and ALC aluminum, and the material of the support substrate is light aluminum and ALC aluminum base. For light aluminum, it has light, soft and good electrical conductivity, heat conduction, and high reflection performance. In addition , also has strong corrosion resistance and certain insulation, and the ALC aluminum base has the advantages of comprehensive insulation, which can solve the heat conduction problem of LED chips. The aluminum material model in this example is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com