Method for separating and recycling acrolein in 1,3-propylene glycol preparation process

A technology of acrolein and hydroxypropionaldehyde, applied in the chemical industry, can solve the problems affecting the selectivity and service life of hydrogenation catalysts, and achieve the effects of uniform material distribution and heat transfer, high reaction efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

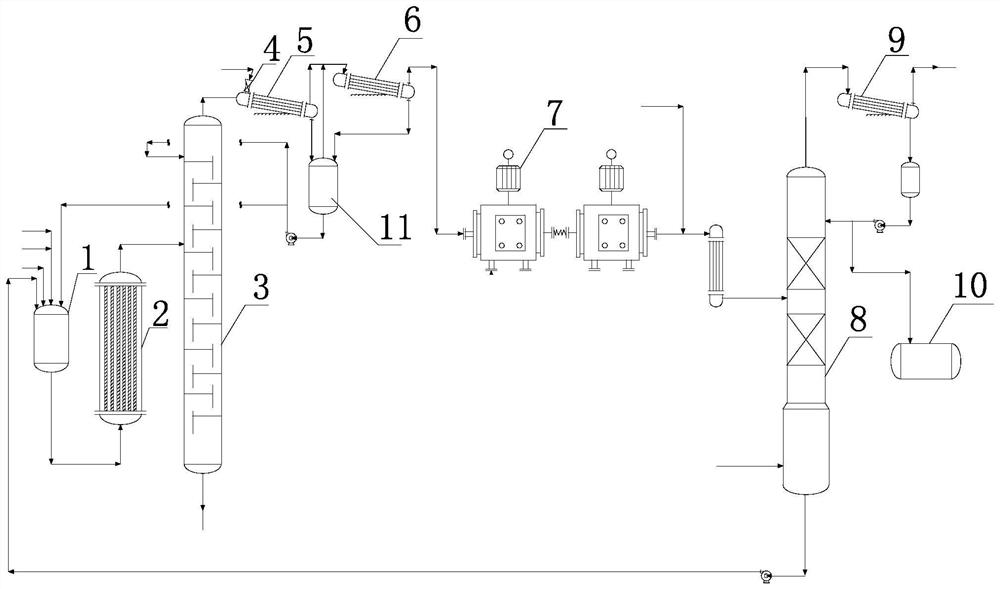

[0107] use figure 1 The process shown: in the seasoning tank, add 0.1wt% polymerization inhibitor hydroquinone to the 15wt% acrolein solution to obtain the raw material solution for the hydration reaction; pass the raw material solution into the hydration reactor for 45~ Hydration reaction at 55°C; the reaction product containing acrolein, water, 3-hydroxypropionaldehyde and acetaldehyde is discharged from the upper end of the hydration reactor, and enters the acrolein rectification tower to separate acrolein from 3-hydroxypropionaldehyde, and acrolein The pressure at the top of the rectification tower is 18~20kPa(A), the temperature at the top of the tower is 55~60°C, and the temperature at the bottom of the tower is 63~70°C; the separated 3-hydroxypropanal solution (the content of acrolein is 37ppm) The bottom of the distillation column is discharged into the subsequent hydrogenation reaction unit; the separated steam is discharged from the top of the tower, mixed with a po...

Embodiment 2

[0129] and figure 1 The process shown is the same: acrolein raw material, water and 0.1% polymerization inhibitor solution are mixed in the blending tank to form a 15% acrolein solution, pumped into the lower end of the hydration reactor, discharged from the upper end after reaction, and discharged from the tower The middle and upper part enters the acrolein rectification tower. Control the pressure at the top of the tower to 18~20kPa(A), the temperature at the top of the tower to 55~60°C, and the temperature at the bottom of the tower to 63~70°C. The output from the tower kettle is 3-hydroxypropanal solution, in which the content of acrolein is 37ppm. 77% of the top steam is condensed, part of it is refluxed into the tower, part of it is pumped into the mixing tank for batching, and 23% of the gas is directly fed from the middle of the acrolein recovery tower through a vacuum pump, and the content of acetaldehyde is 5%. The (mass) flow rate is 240kg / h, the number of theore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com