Inner spiral outer crossed tunnel double-side reinforced boiling heat transfer pipe

A technology of enhanced boiling and heat transfer tubes, applied in the field of enhanced heat transfer tubes, can solve the problems of inability to enhance the heat transfer coefficient, achieve long-lasting good convective heat transfer performance in the tube, prolong the induction period, and prevent fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The implementation of the invention will be further described below in conjunction with the drawings and examples, but the implementation and protection of the invention are not limited thereto. Processes that are not specifically described in detail below can be performed by those skilled in the art with reference to the prior art.

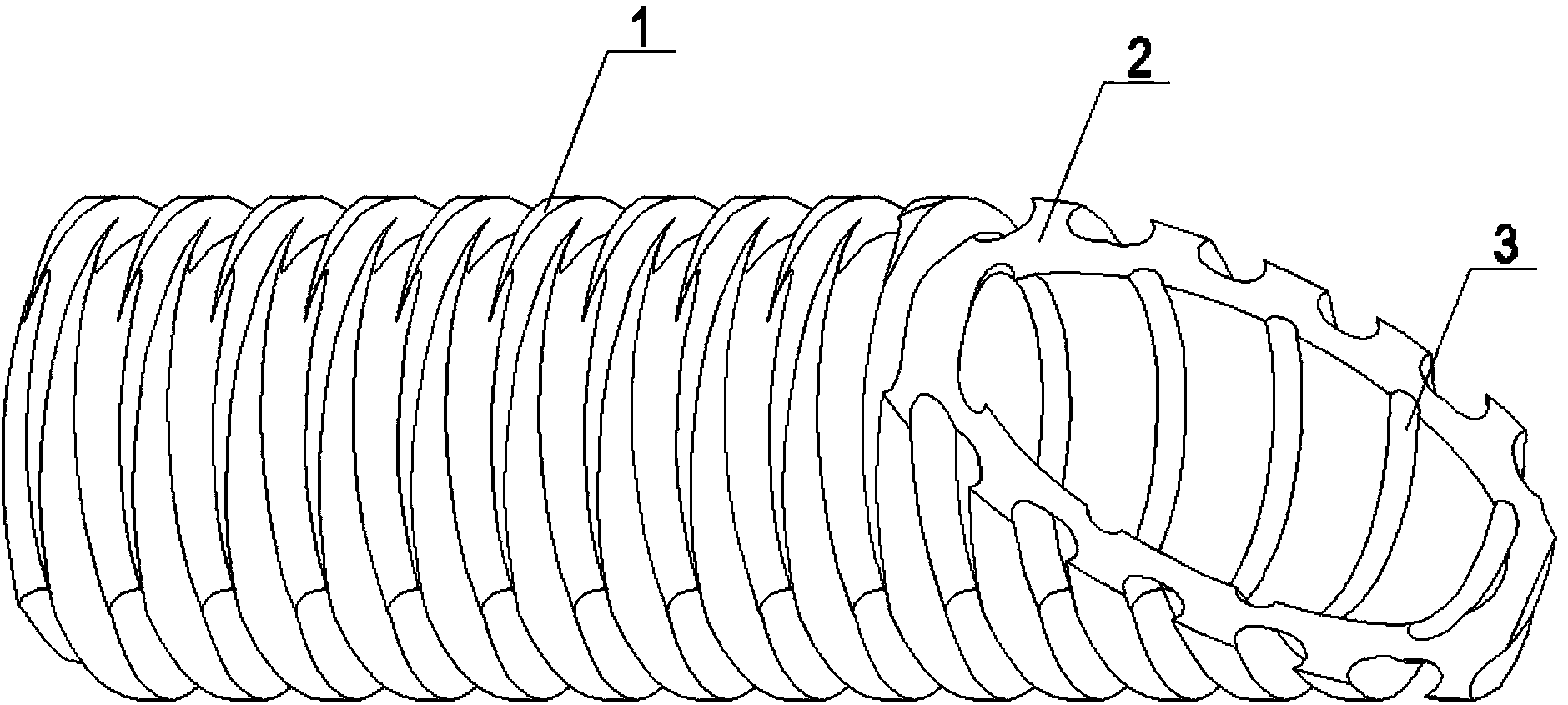

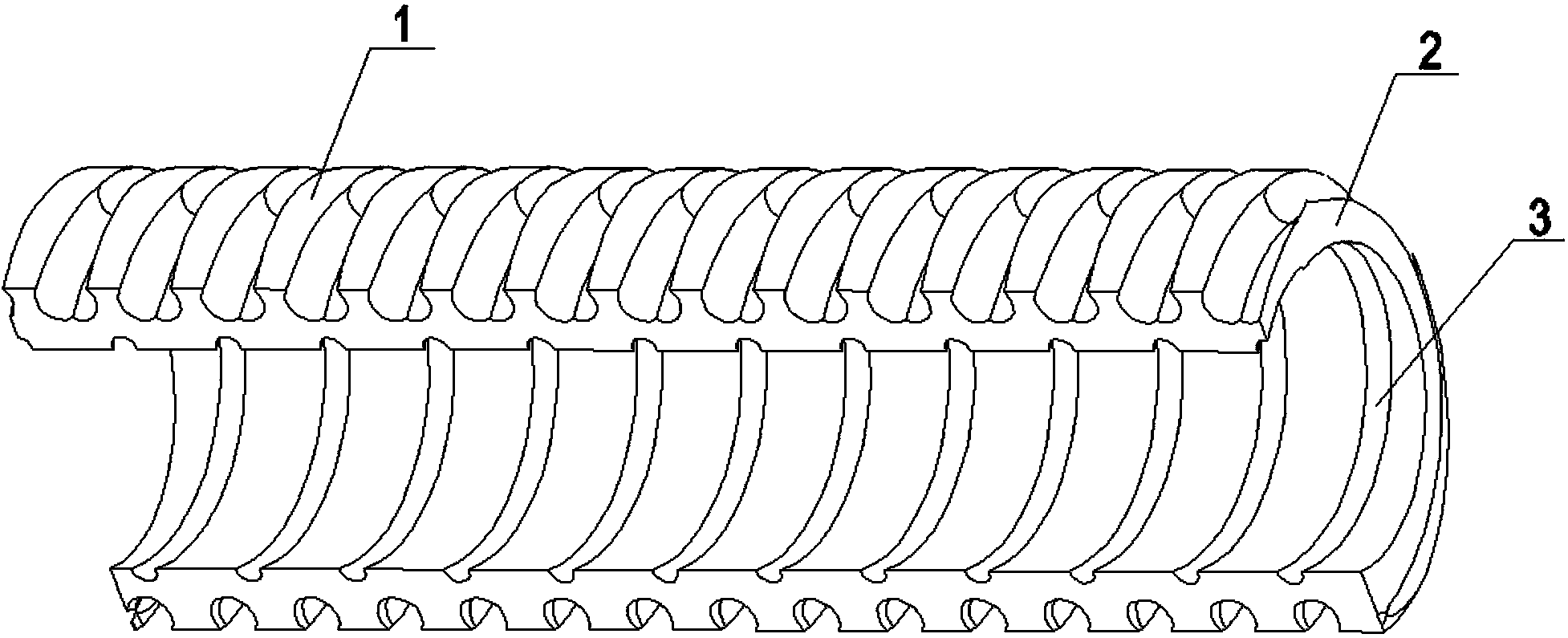

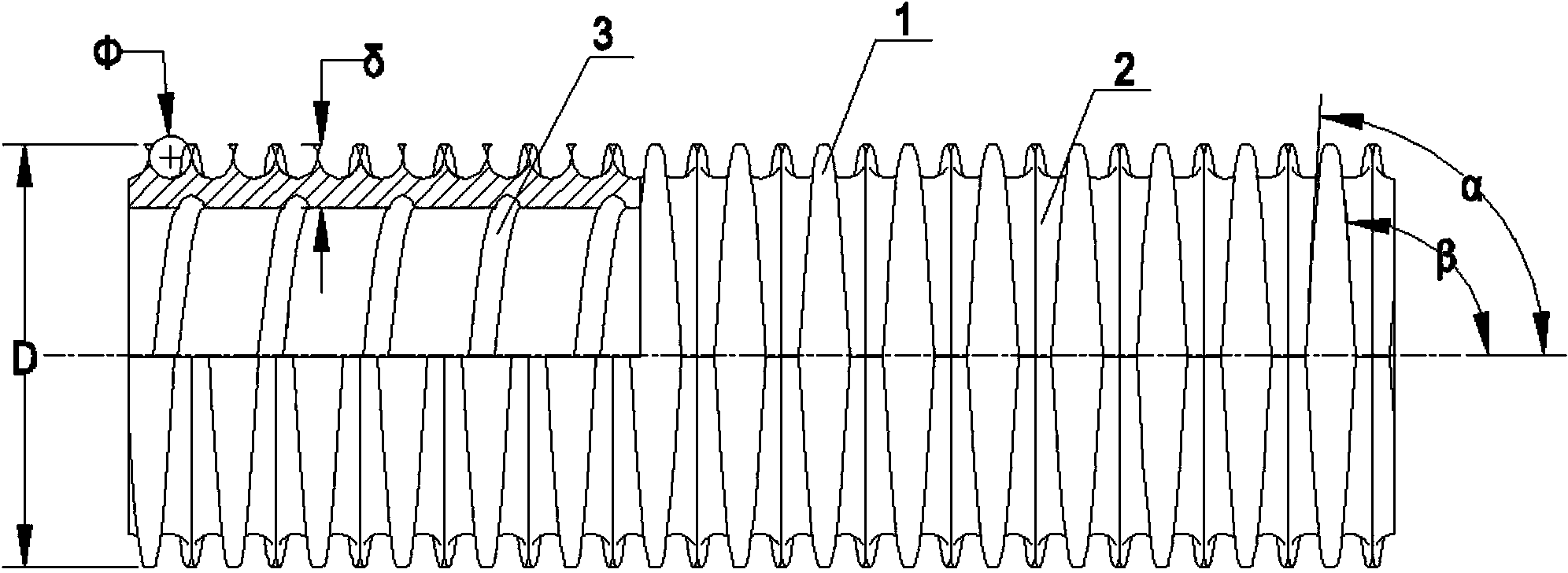

[0049] Such as figure 1 3D structural diagram of the heat transfer tube implemented, figure 2 As shown in the local three-dimensional structure diagram, a double-sided enhanced boiling heat transfer tube with an inner spiral and an outer cross tunnel includes a heat transfer tube base 2, fins 1 distributed in a spiral shape along the outer surface of the base, and half ribs distributed along the inner surface of the base. Internal helical groove 3 of circular cross-section. Wherein, the outer fins 1 of the tube are naturally formed by crossing the helical grooves with a left-handed arcuate section and the helical grooves with a right-ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com