Method for manufacturing diamond-type metal nanometer particle array structure

A metal nanoparticle and array structure technology, applied in nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve problems such as low efficiency, limited area of graphics produced by electron beam or ion beam lithography, and inability to realize batch production, etc., to achieve Large area and high, high-sensitivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

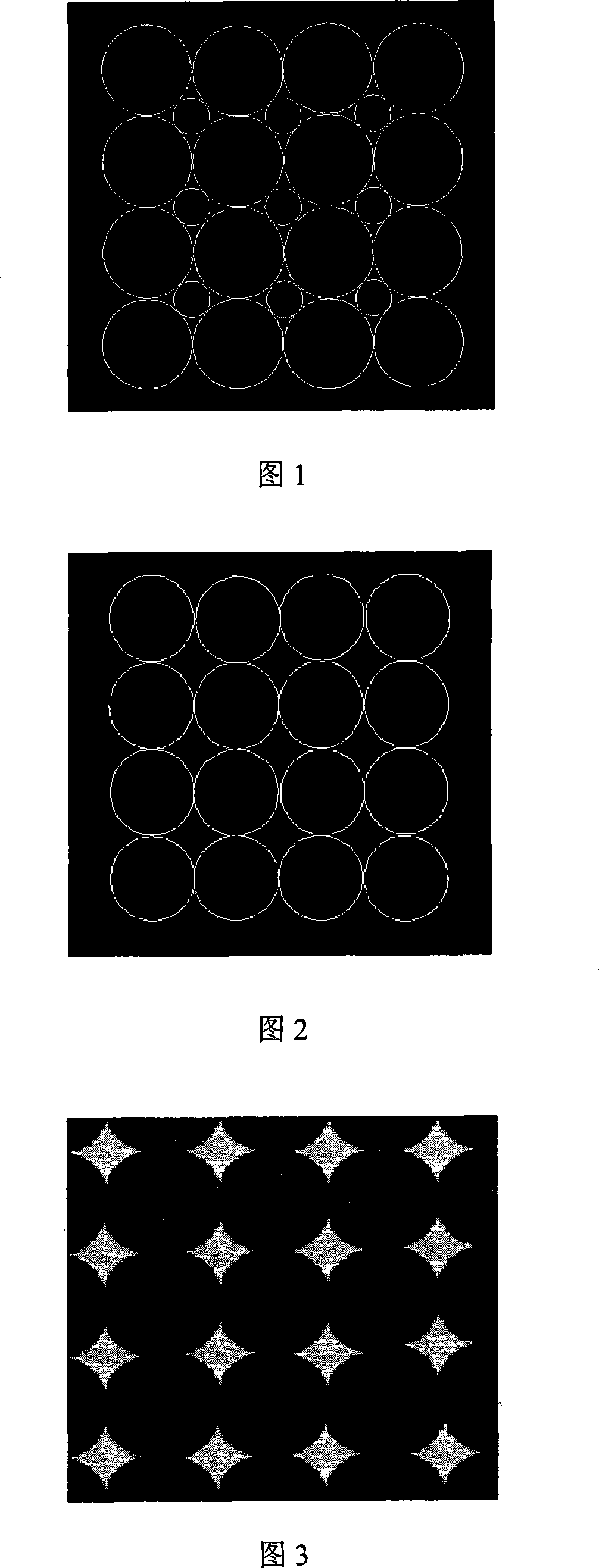

[0023] Embodiment 1 is an array-type rhombic metal nano-array structure with a characteristic size of less than 170 nanometers fabricated by the method of the present invention.

[0024] (1) First select a finely polished silicate glass sheet with a size of φ25mm×2mm as the substrate, and use a vacuum coating machine to deposit a layer of 5nm chromium film on the surface of the glass sheet;

[0025] (2) 1ml of monodisperse polystyrene nanosphere hydrosol with a diameter of 500nm and a concentration of 2% and 0.2ml of monodisperse polystyrene nanosphere hydrosol with a diameter of 200nm and a concentration of 1% are mixed with ultrasonic waves for subsequent use;

[0026] (3) Put the chrome-plated glass substrate into 98% concentrated sulfuric acid and hydrogen peroxide H 2 SO 4 : 30%H 2 o 2 Heat it to 80℃~120℃ for 30~60 minutes in the washing solution prepared by 3~4:1 to remove impurities, then rinse repeatedly, and then put in the solution NH3:H composed of ammonia water,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com