Metal base diamond grinding wheel and preparing method thereof

A diamond and fund technology is applied in the field of metal-based diamond grinding wheels and their preparation, which can solve the problems that diamond particles cannot be uniformly dispersed, segregation is easy to occur in the mixing process, and the grinding performance of metal-based diamond grinding wheels is affected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

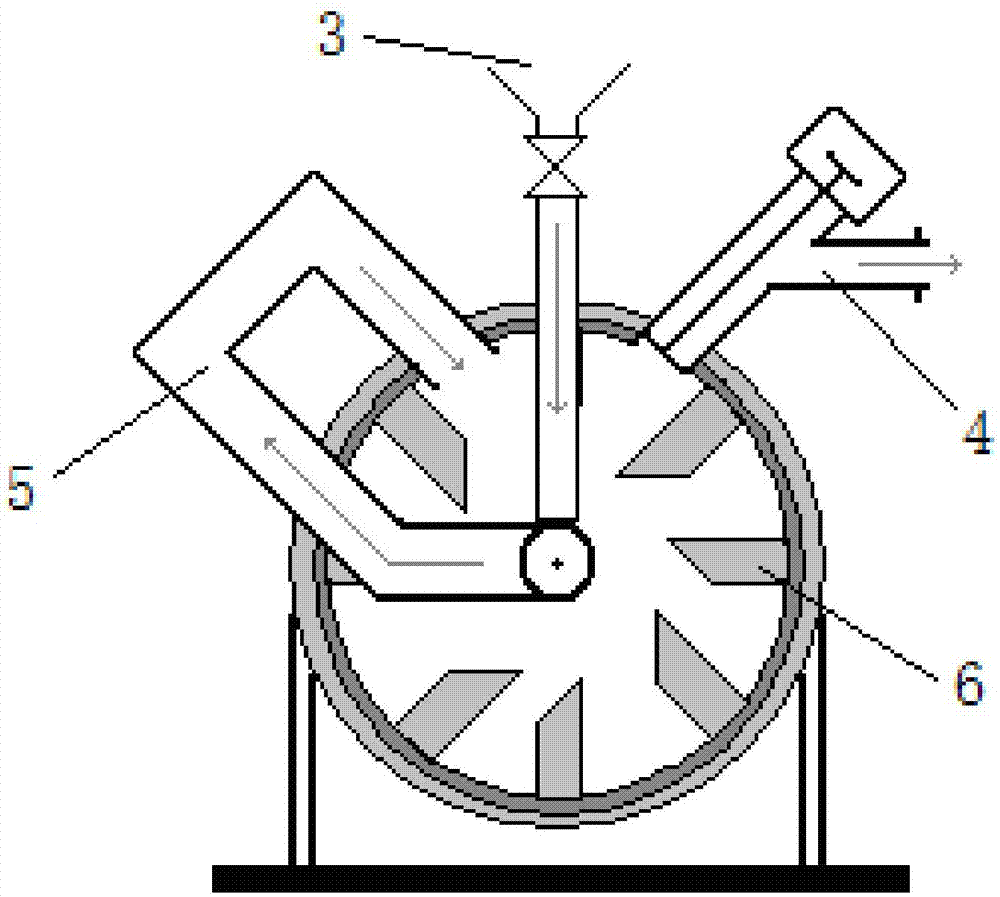

[0021] The invention provides a kind of preparation method of metal-based diamond grinding wheel, wherein, described preparation method comprises:

[0022] 1) Premixing of raw materials: mixing diamond-like materials and metal materials to obtain premixed materials;

[0023] 2) Abrasive coating: the premix prepared in step 1) is subjected to micro-nano particle shaping and coating to obtain composite particles;

[0024] 3) Forming and sintering: the composite particles prepared in step 2) are pressed and then sintered to obtain a metal-based diamond grinding wheel.

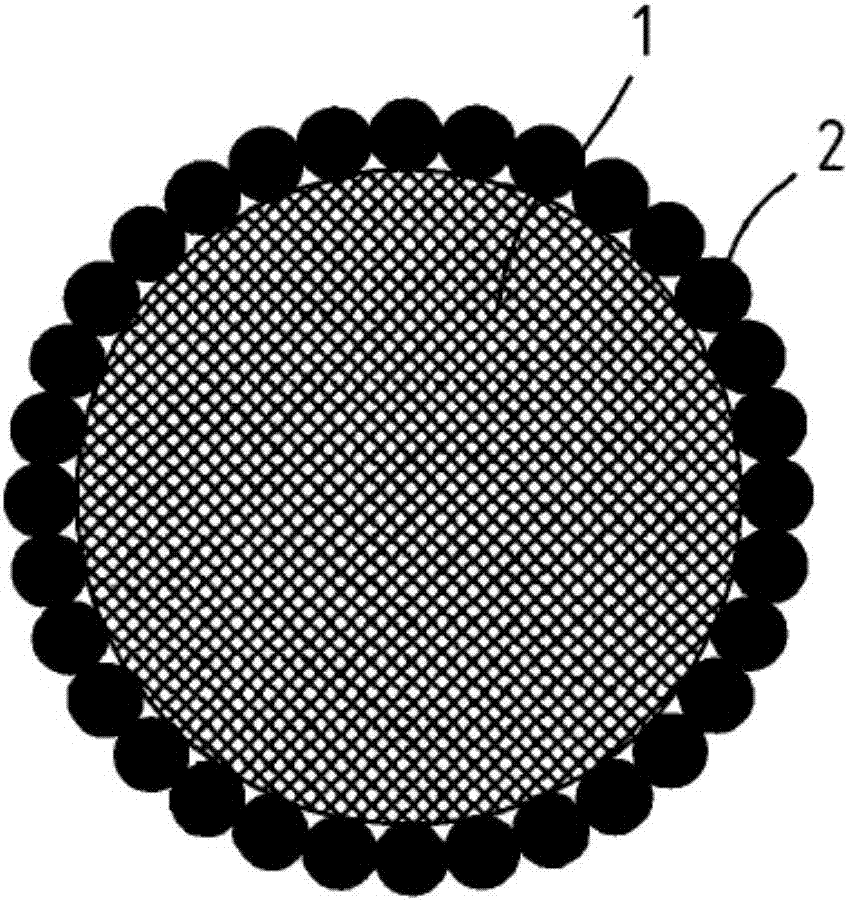

[0025] The above-mentioned design mixes the diamond-like material and the metal material and performs micro-nano particle shaping and coating operation, and then performs pressing and sintering, so that the diamond-like material can be evenly dispersed inside the prepared metal-based diamond grinding wheel, thereby improving the production efficiency. The grinding efficiency and service life of the metal-based di...

Embodiment 1

[0041] First, 300g of 2000-mesh diamond powder, 60g of dispersant, 1800g of 400-mesh copper powder and 300g of 400-mesh tin powder were premixed with a high-speed mixer for 5 minutes at 1480r / min to obtain a premix; then 2000g of the premix was put into the micro In the nanoparticle shaping and coating equipment, process (ie, react) at a speed of 3000r / min for 10 minutes, and discharge for 3 minutes to obtain composite particles. Finally, the composite particles were shaped and sintered to obtain a metal-based diamond grinding wheel A1 with evenly dispersed diamond-like particles.

Embodiment 2

[0043]First, 300g of 2000-mesh nickel-plated diamond powder, 60g of dispersant, 1800g of 400-mesh copper powder and 300g of 400-mesh zinc powder were premixed with a high-speed mixer for 5 minutes at 1480r / min to obtain a premix; then 2000g of the premix was put into In the micro-nano particle shaping and coating equipment, the composite particles were obtained by processing at a speed of 3000r / min for 10 minutes and discharging for 3 minutes. Finally, the composite particles were molded and sintered to obtain a metal-based diamond grinding wheel A2 with evenly dispersed diamond-like particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com