Glass fiber fabric compounding machine with pre-heating function

A technology of glass fiber cloth and composite machine, applied in the field of machinery, to achieve the effects of wide application range, improved quality, and guaranteed bonding firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

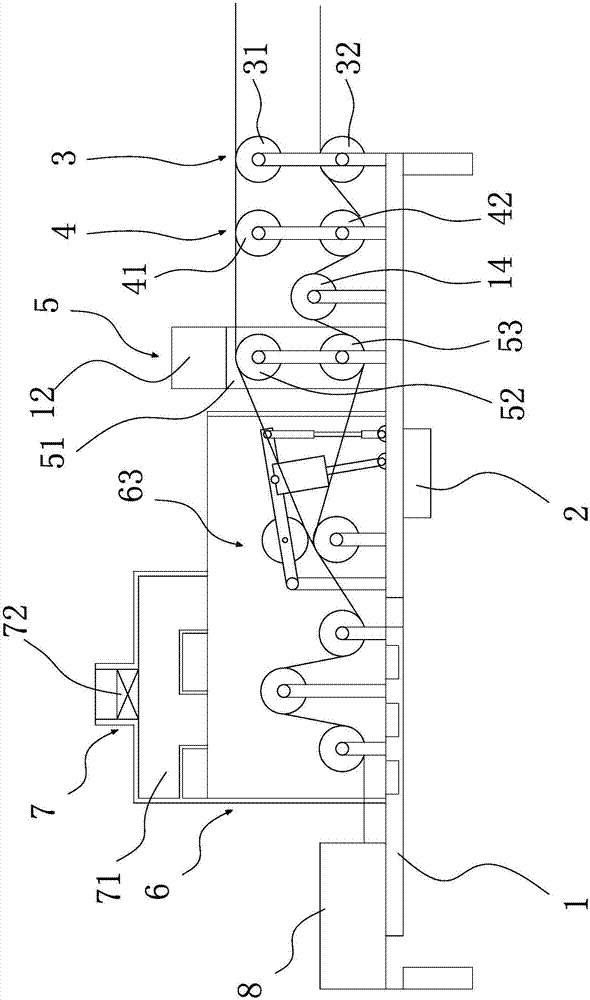

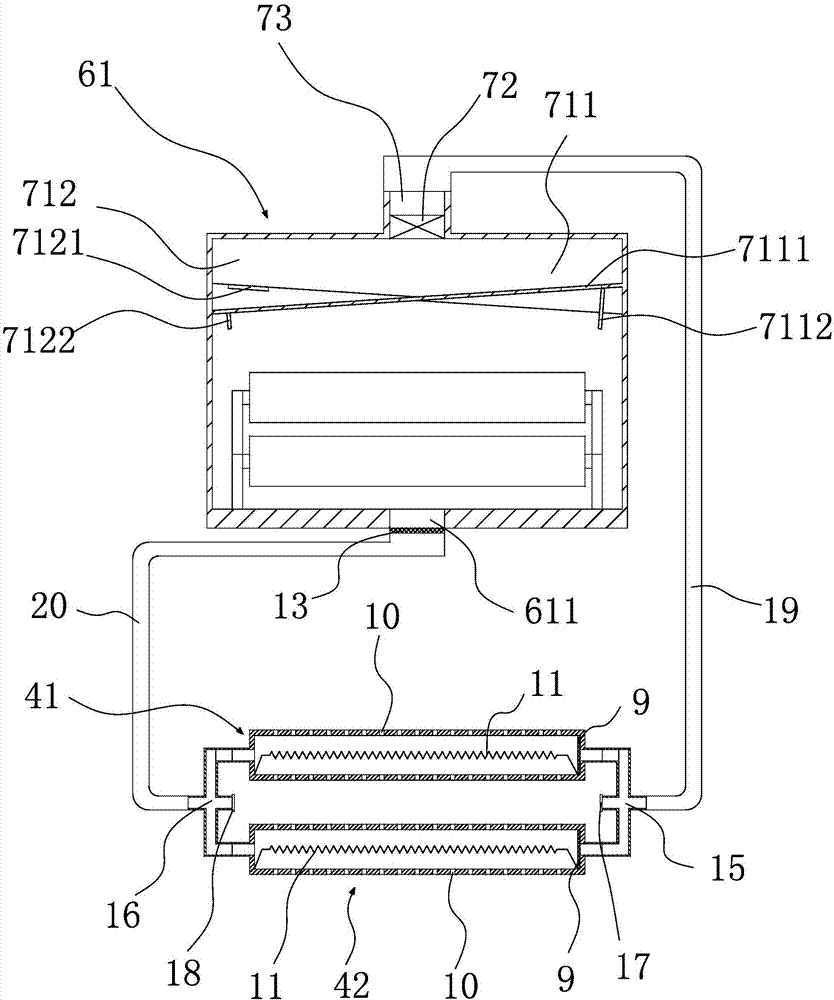

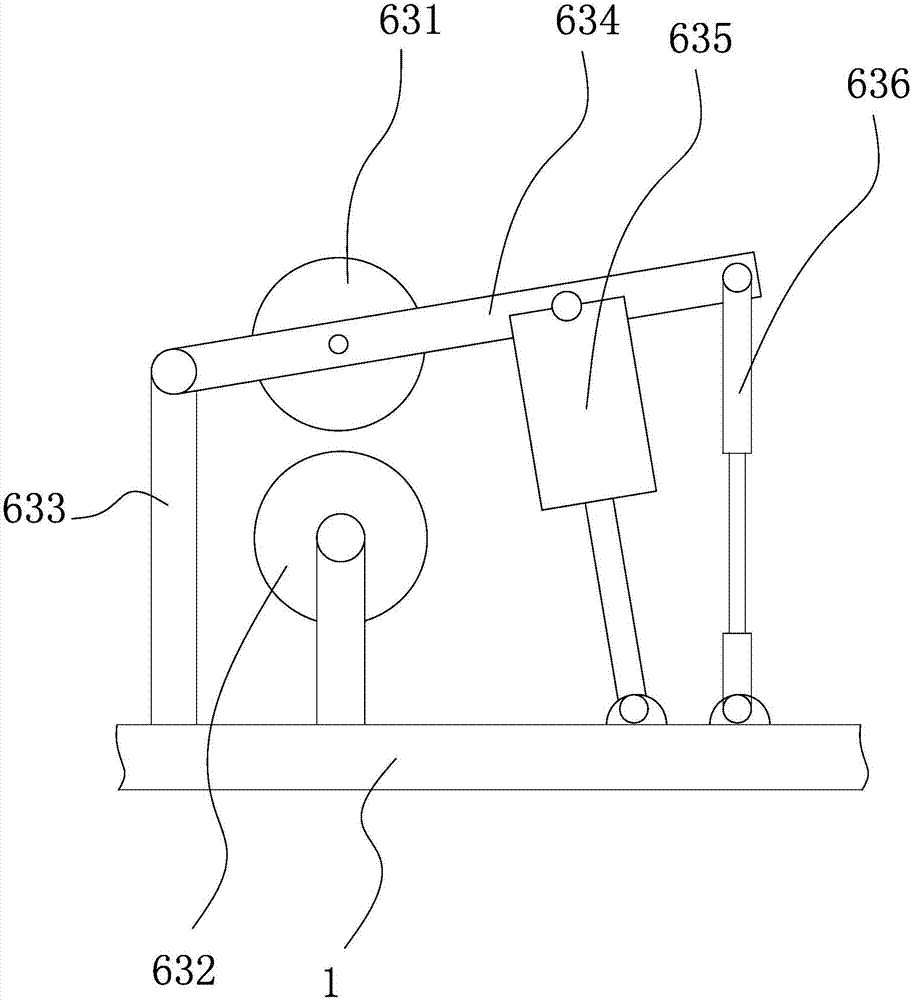

[0024] refer to figure 1, the present embodiment is a glass fiber cloth composite machine with a preheating function, comprising a frame 1 arranged horizontally and horizontally, the bottom surface of the frame 1 is provided with a controller 2, and the top surface of the frame 1 is along the direction of the glass fiber cloth. In the conveying direction, a feeding device 3 , a preheating device 4 , a gluing device 5 , a composite drying device 6 , a cooling device 7 and a winding frame 8 are arranged in sequence. The feeding device 3 includes a first feeding roller 31 and a second feeding roller 32 that are independent of each other. The glue applying device 5 includes a glue box 51 and a glue box 12 positioned at the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com