Patents

Literature

39results about How to "With preheating function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

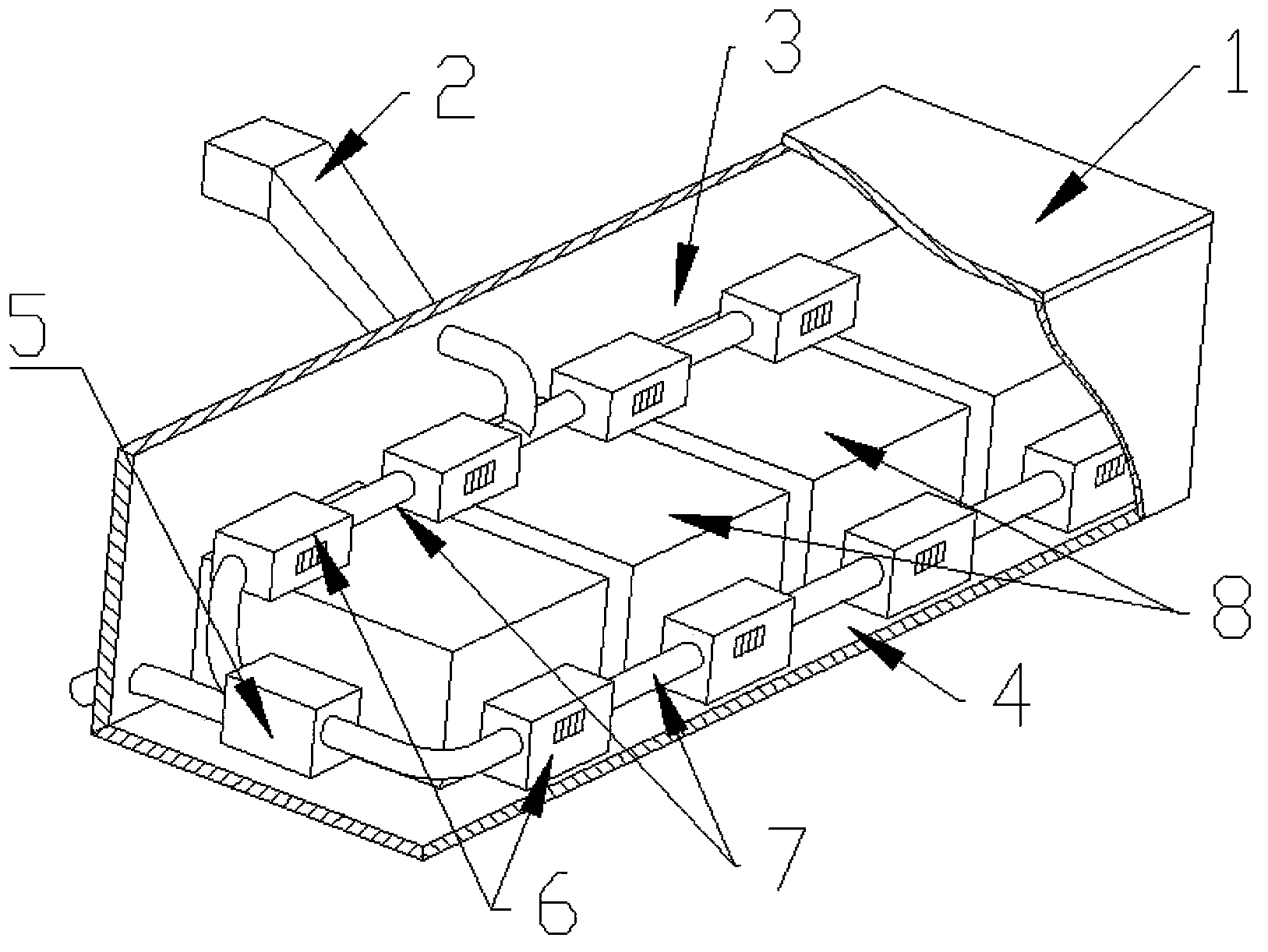

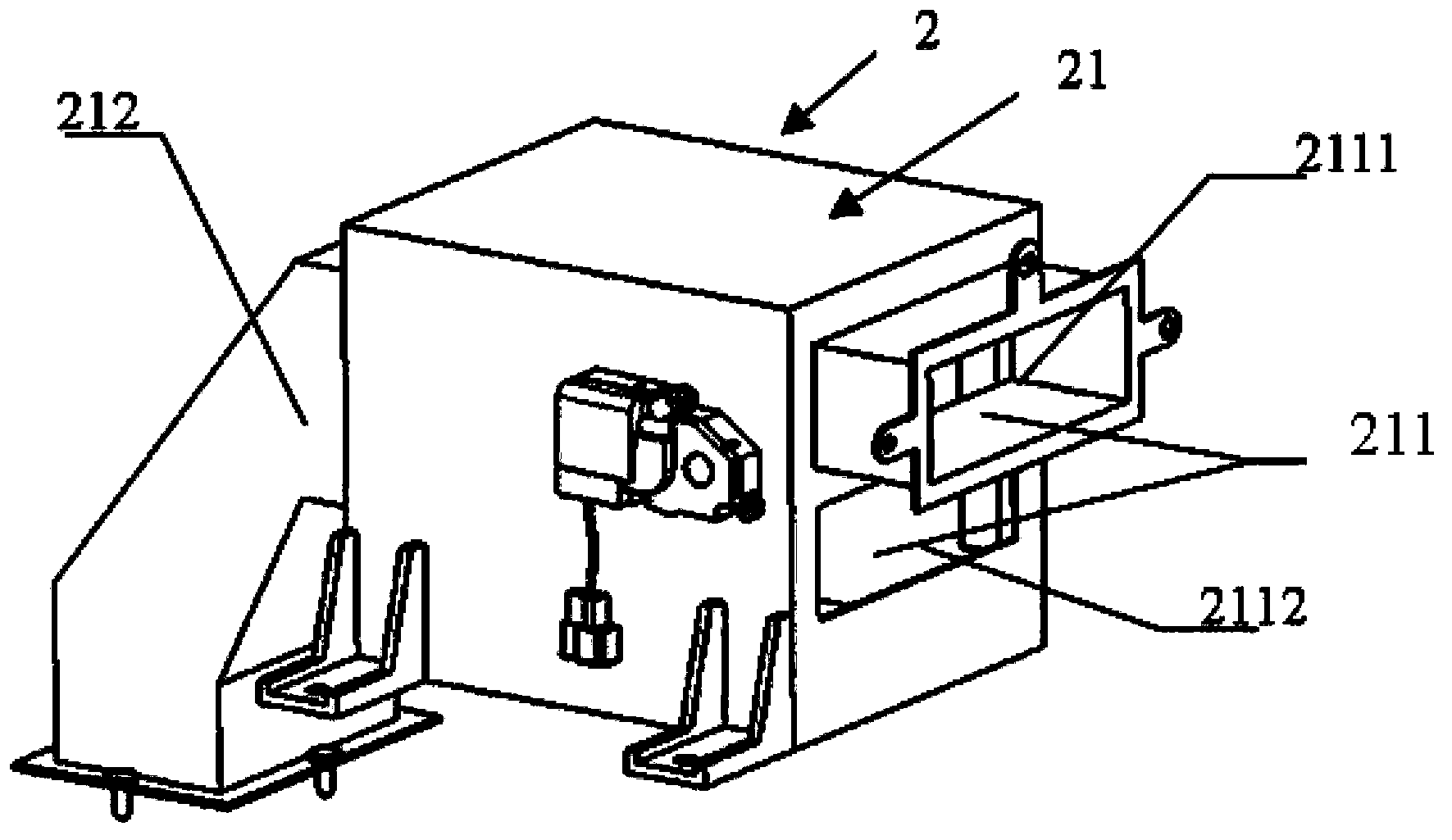

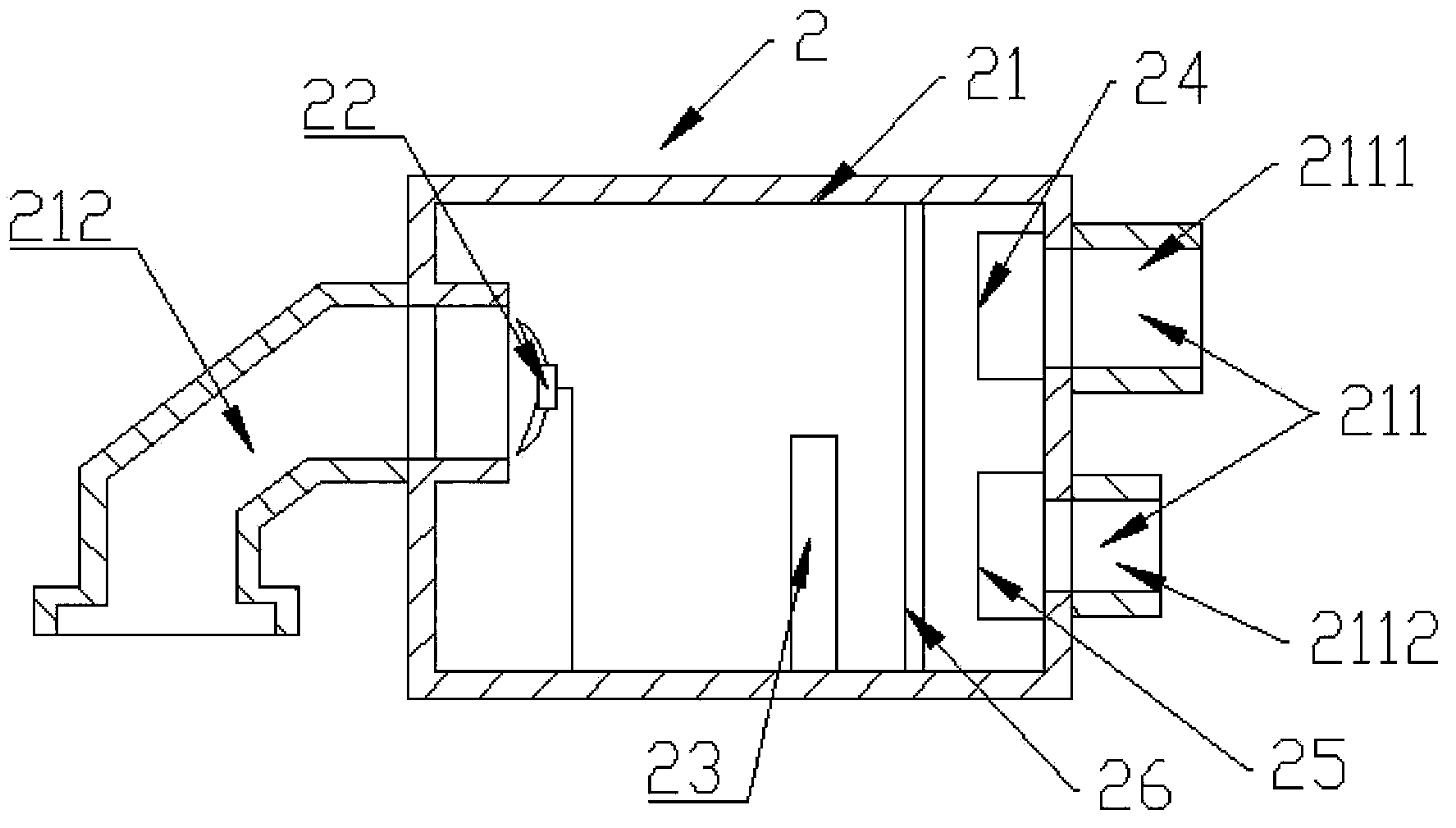

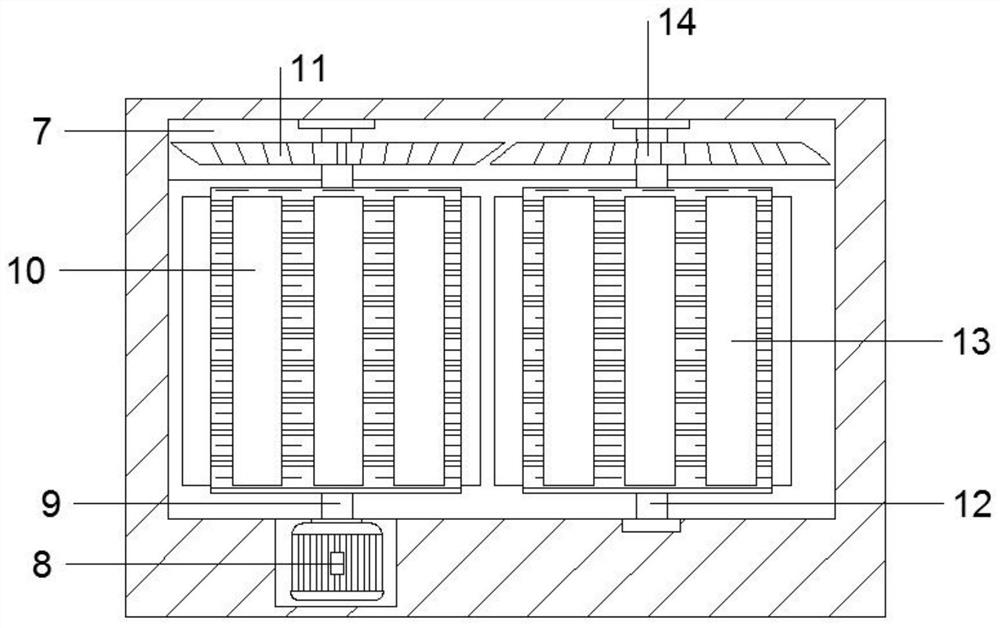

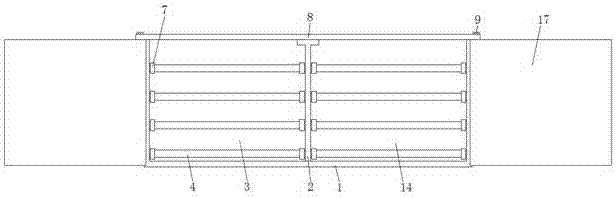

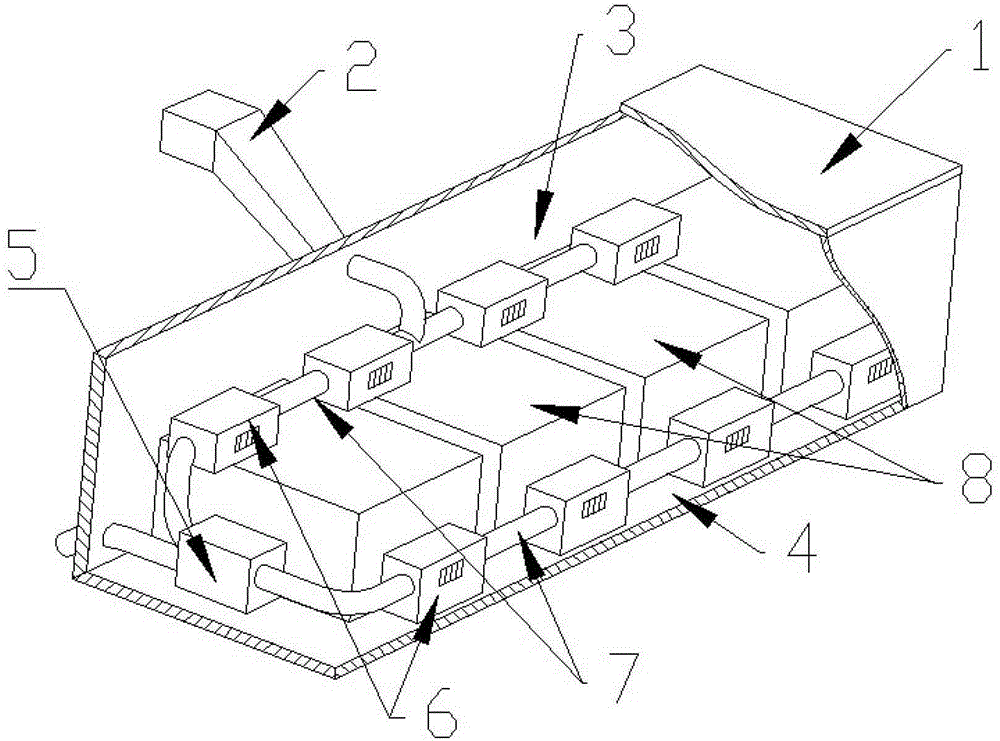

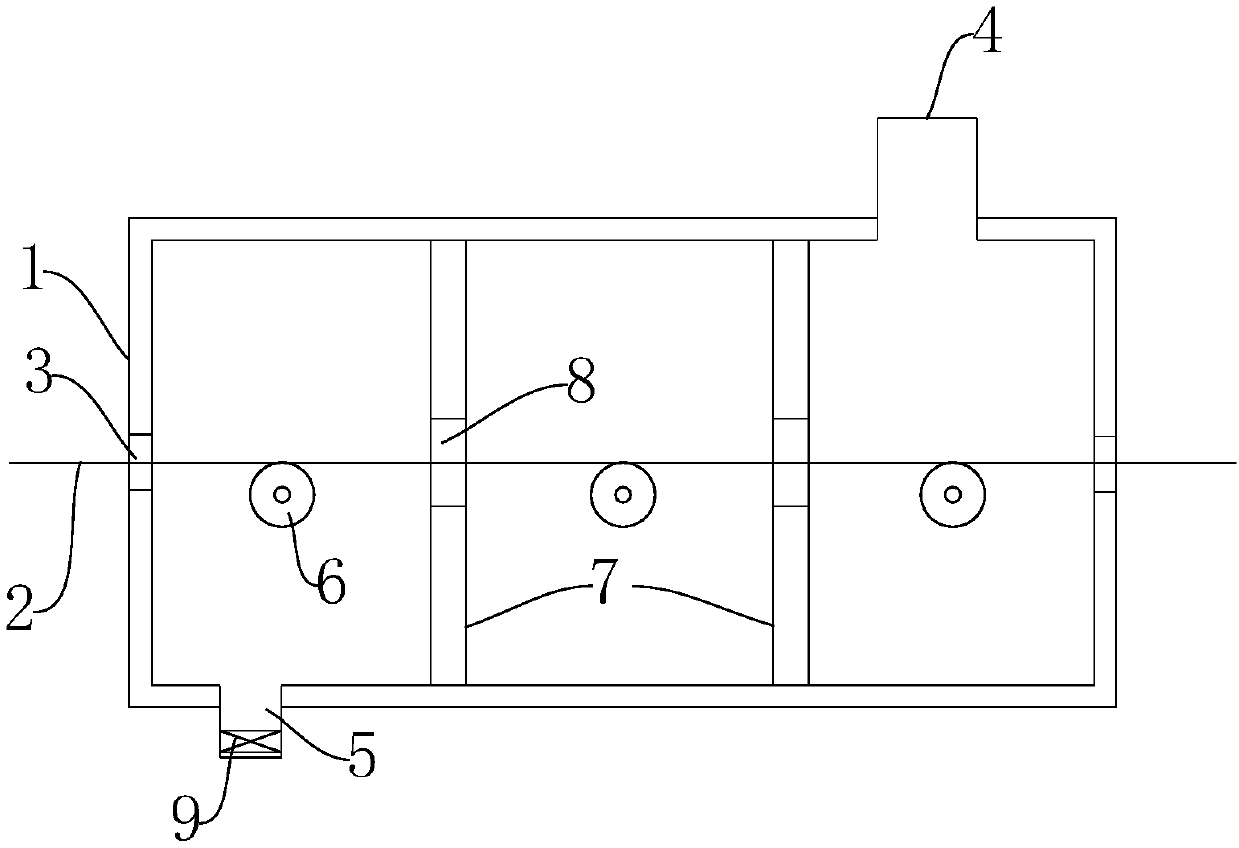

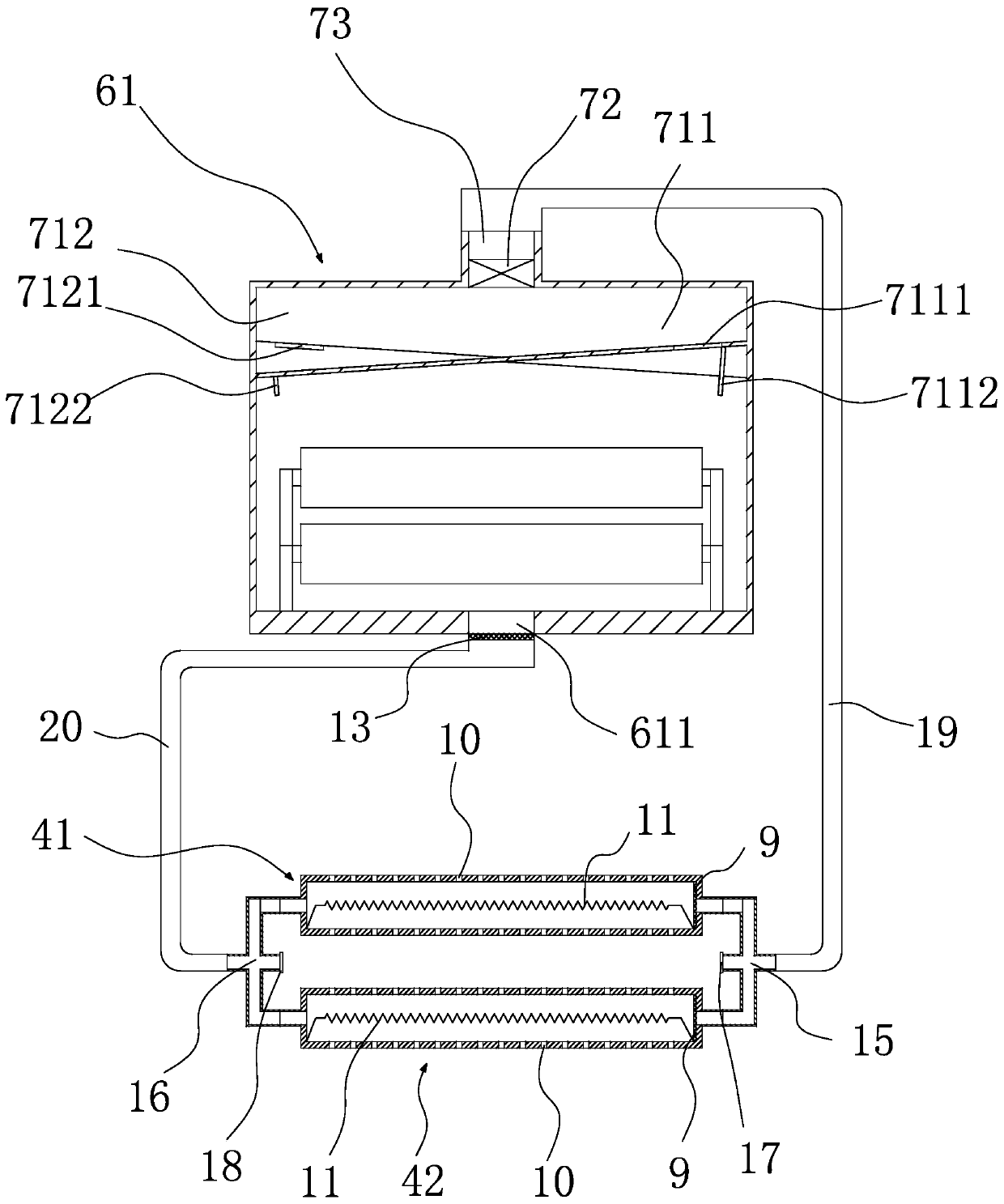

Air-cooled power battery heat management device for electric vehicle and control system

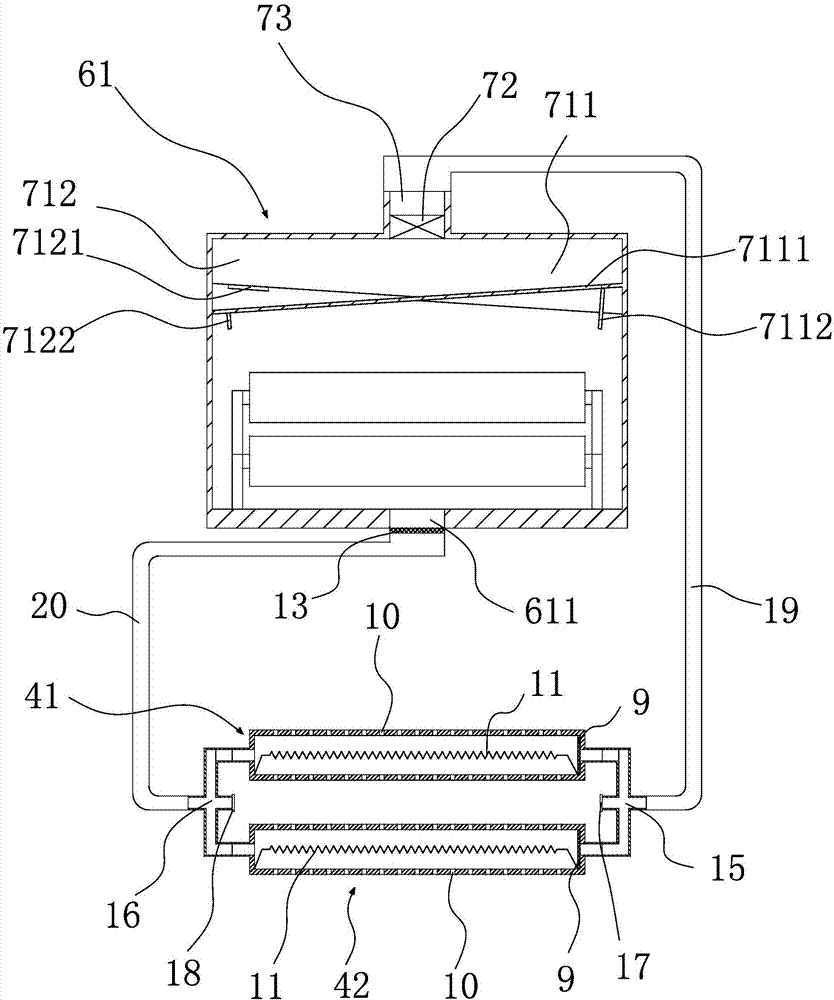

The invention relates to the field of electric automobiles and discloses an air-cooled power battery heat management device for an electric vehicle. The air-cooled power battery heat management device comprises a battery box for mounting a power battery, an air outlet ventilating group and a cycle ventilating group which are formed by connecting multiple ventilating boxes through pipelines, and an air inlet assembly and a cycle assembly, wherein the air outlet ventilating group is arranged in the battery box and is connected with the power battery in parallel; the cycle ventilating group is arranged at a position, which is far away from the air outlet ventilating group, in the battery box; the air inlet assembly absorbs air outside the battery box and blows air into the battery box through the air outlet ventilating group; the cycle assembly absorbs the air in the battery box through the cycle ventilating group, and the air is discharged out of the battery box. The air quantity and air speed of the air flowing in the battery box are uniform, and the problem of non-uniform cooling existing in a forced convection cooling mode in the prior art is solved. Furthermore, a heater is arranged in the cycle assembly, so that the power battery is preheated. The invention also provides a special control system. According to the control system, the power battery can be maintained to operate under optimal operating temperature conditions.

Owner:陈言平

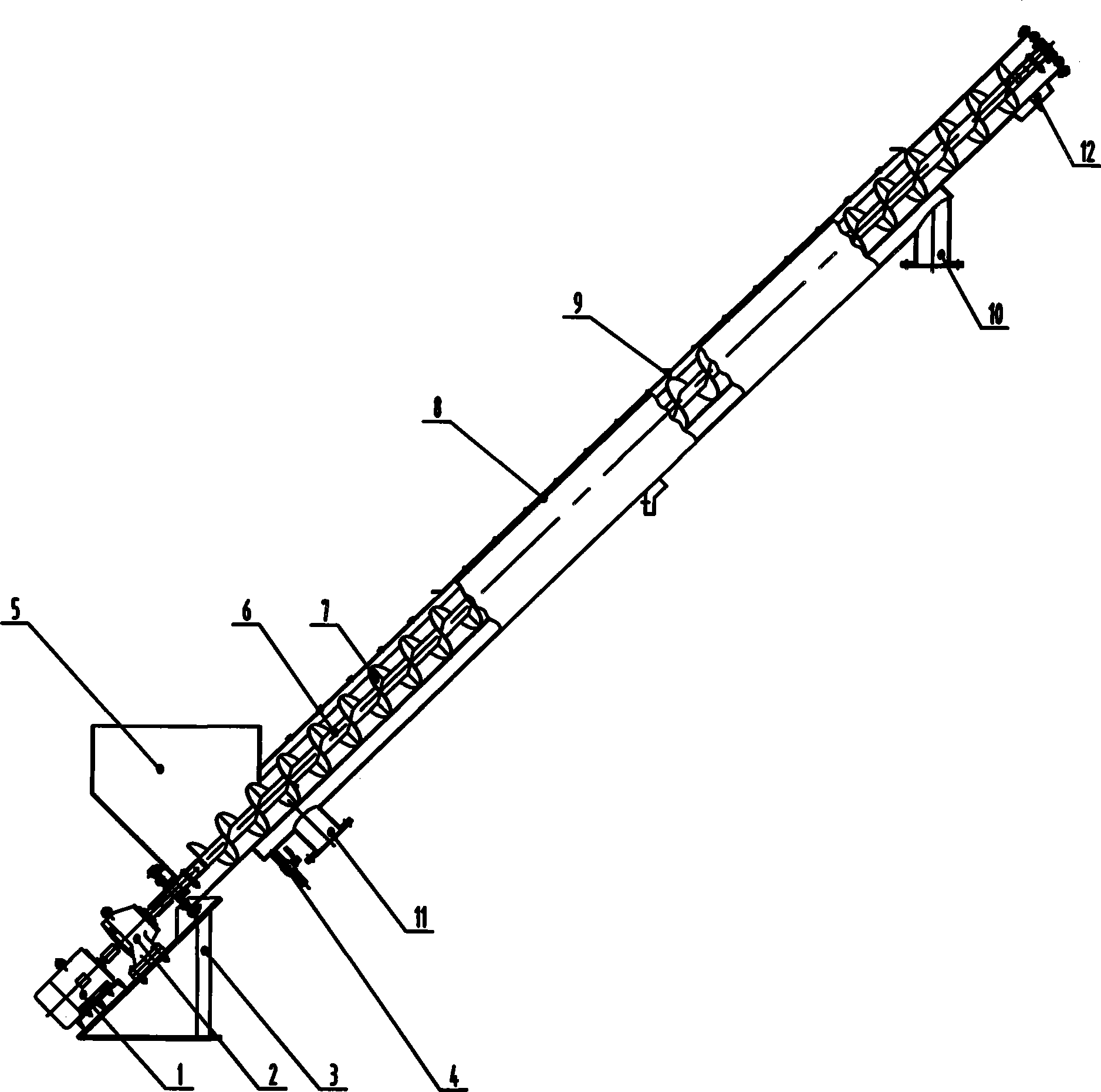

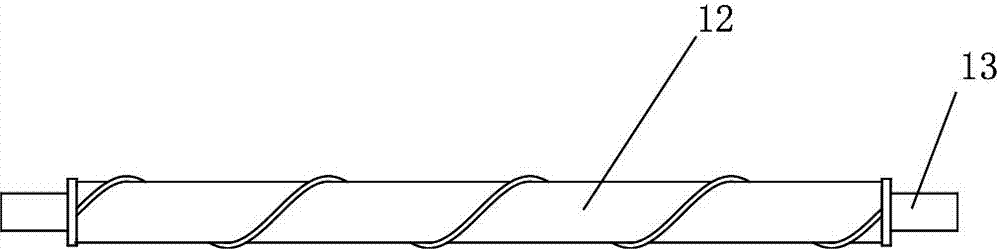

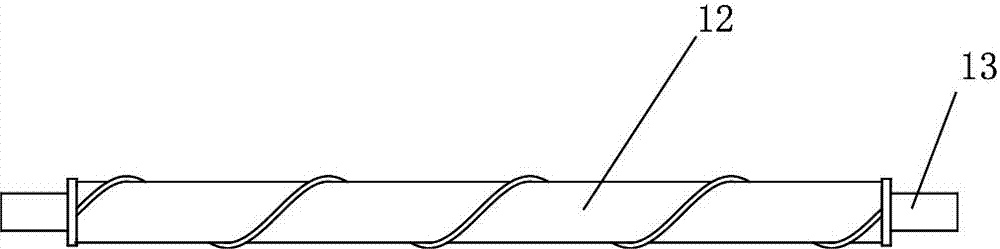

Helical feeder

Owner:SHENGLI OIL FIELD SHENGLI POWER MACHINERY GRP

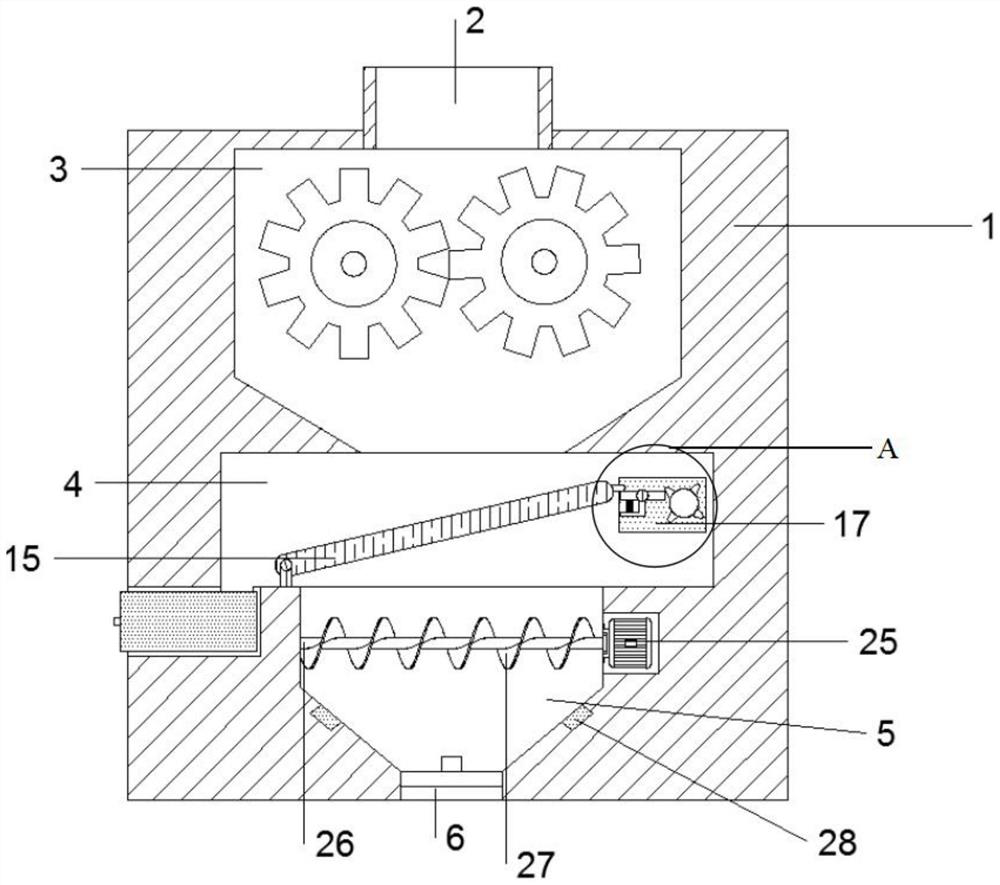

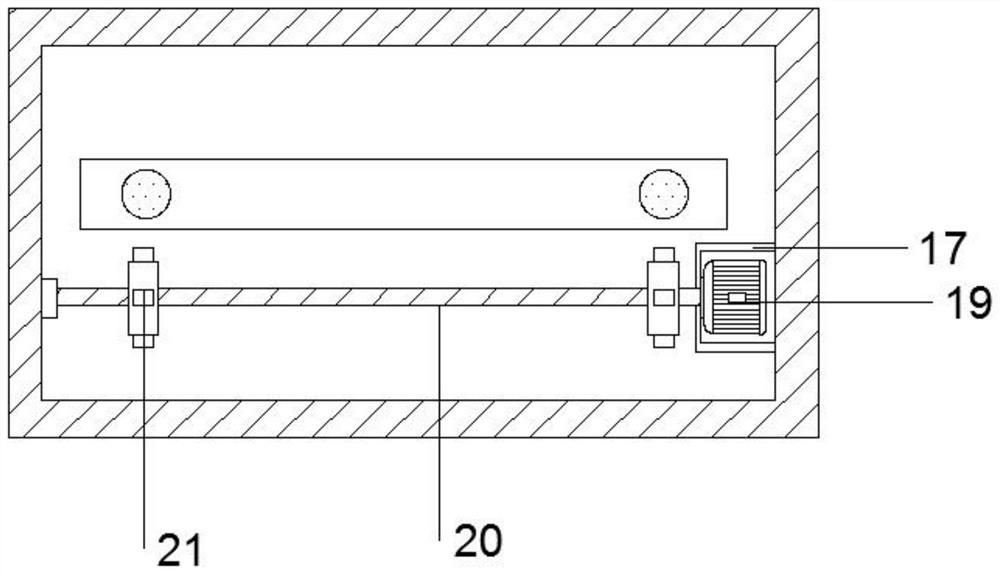

Rare earth waste roasting uniform feeding device

InactiveCN112414147AAvoid uneven heatingReduce manufacturing costSievingScreeningElectric machineProcess engineering

The invention provides a rare earth waste roasting uniform feeding device. The device comprises a feeding box, a feeding port is formed in the top of the feeding box, a smashing cavity is formed in the bottom of the feeding port, a filtering cavity is formed in the bottom of the smashing cavity, a stirring cavity is formed in the bottom of the filtering cavity, a discharging port is formed in thebottom of the stirring cavity, an adjusting table is clamped in the discharging port, a motor groove is formed in one side of the smashing cavity, and a mounting groove is formed in the other side ofthe smashing cavity. Rare earth waste can be smashed through the smashing cavity, when the smashed rare earth waste enters the filtering cavity, a screening net can be driven by a rotating motor to vibrate, accordingly, the rare earth waste is screened, and the screened rare earth waste enters the stirring cavity to be stirred and heated, so that the rare earth waste can be preheated, the workingefficiency of waste roasting is improved, when the rare earth waste passes through the discharging port, the adjusting table can adjust the discharging speed of the rare earth waste, and therefore thesituation that the rare earth waste is accumulated is prevented.

Owner:萍乡鑫森新材料有限责任公司

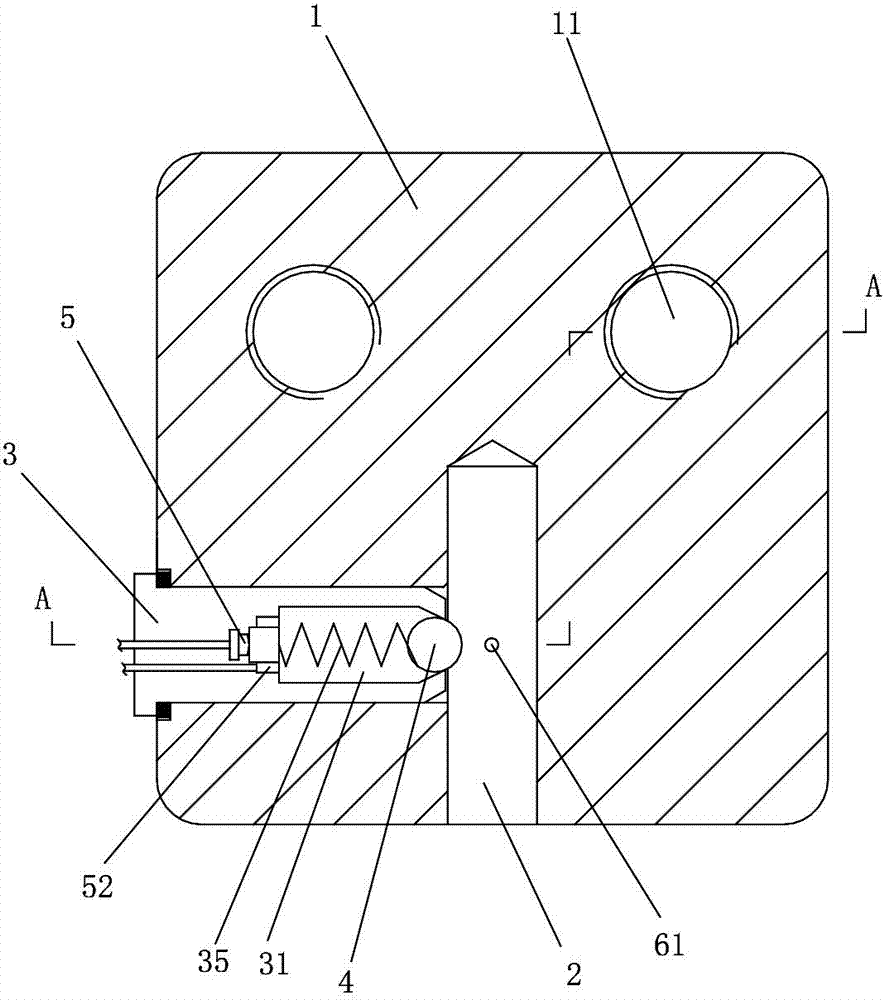

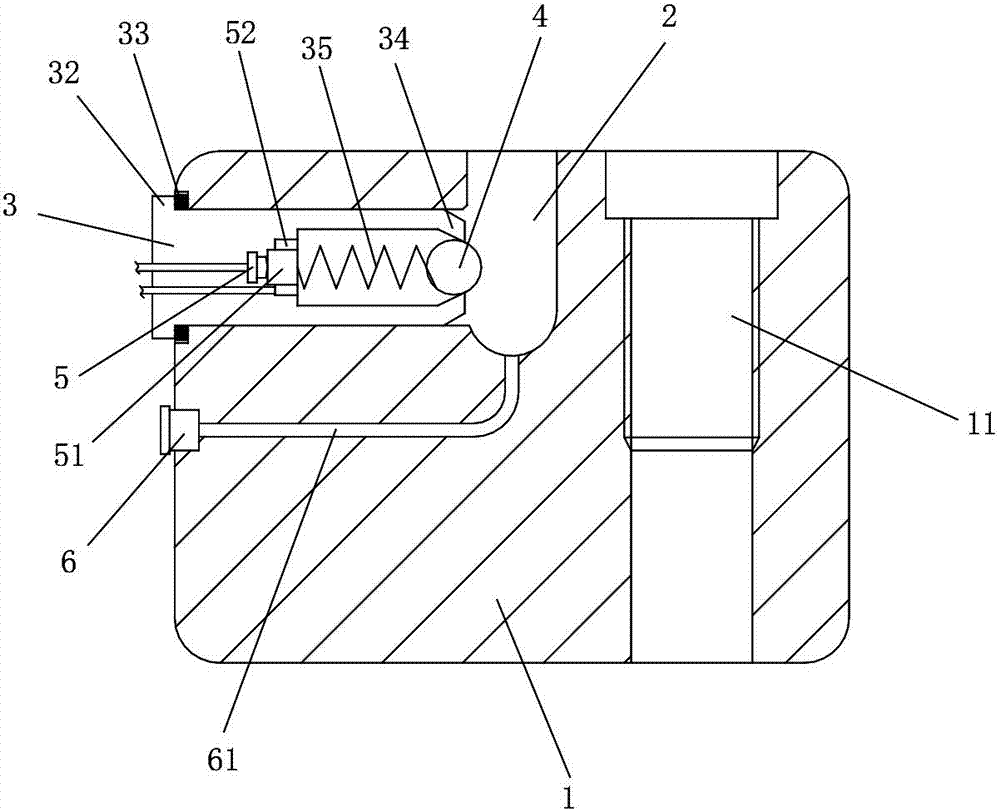

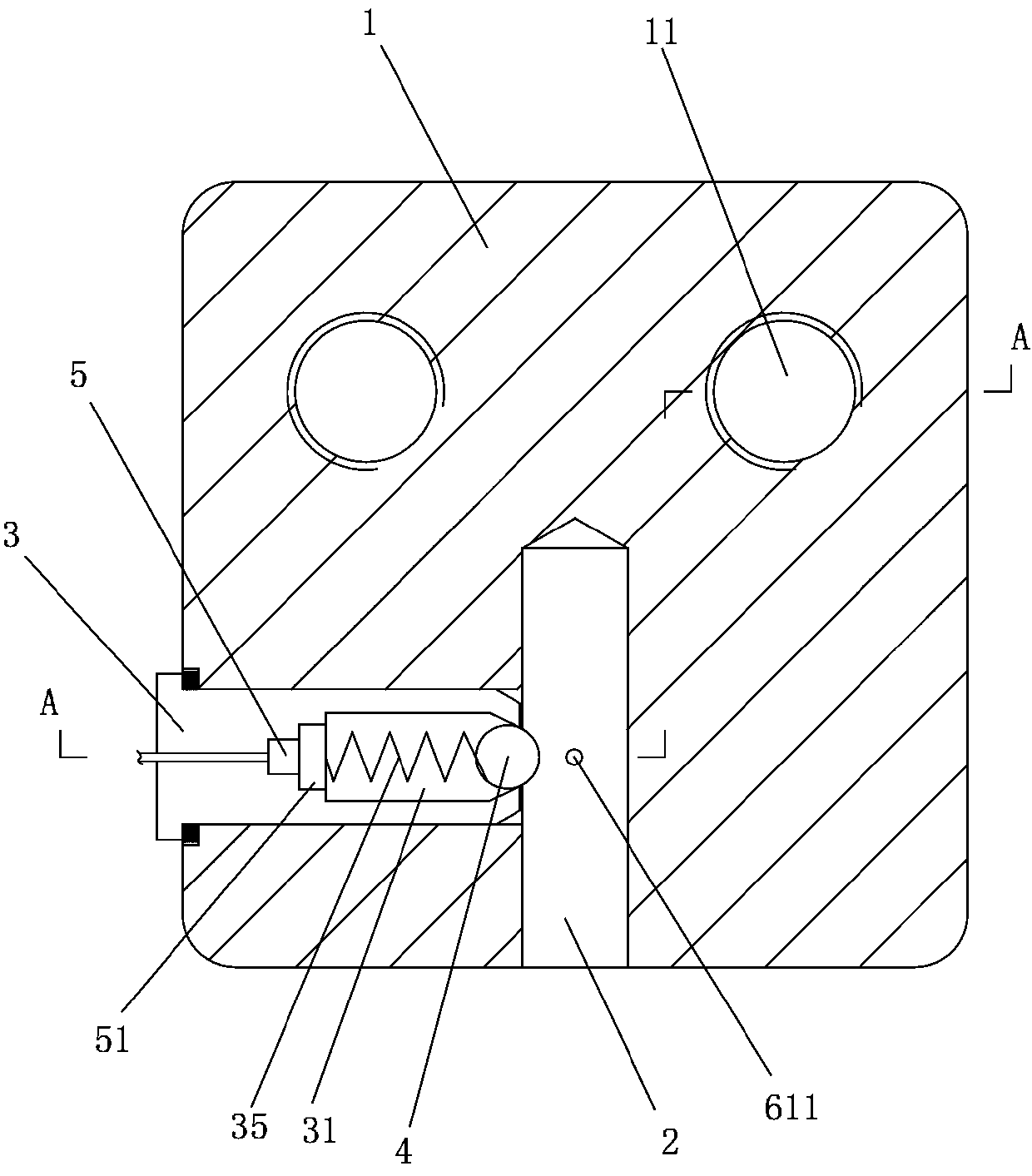

Injection mold with insert positioning function

The invention discloses an injection mold with the insert positioning function. The injection mold comprises an insert mounting part; the insert mounting part is provided with threaded holes and is arranged on a mold body in a threaded connection mode; an insert mounting groove is formed in the insert mounting part; an insert positioning part is arranged at the side edge of the insert mounting groove; a storage cavity is formed in the insert positioning part; a limiting ball and a spring are arranged in the storage cavity; the spring abuts against the limiting ball to enable the limiting ballto be in a working state; an electromagnet and a heating body are arranged in the insert positioning part; the electromagnet is electrified and then attracts the limiting ball so as to enable the limiting ball to be separated from the working state; after the heating body heats a heat conductive part, the heat is transmitted to the limiting ball through the spring so that a metal insert can be heated when the limiting ball works; a vent hole is formed in the bottom of the insert mounting groove and is connected with an air inlet part; and the air inlet part is connected to an air pump. Compared with the prior art, the injection mold with the insert positioning function has the advantages that the metal insert can be limited at a preset position, and therefore accidents caused by disengagement of the metal insert can be avoided.

Owner:ZHEJIANG BUSINESS TECH INST

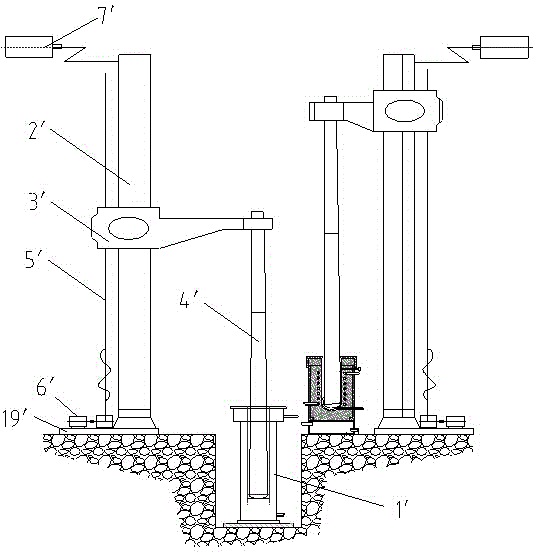

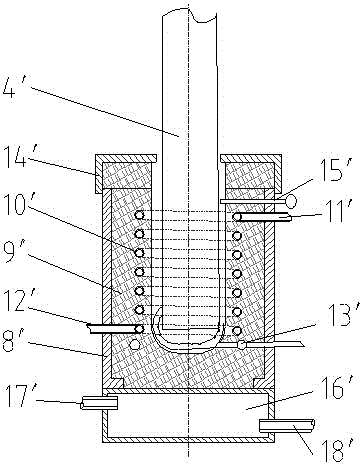

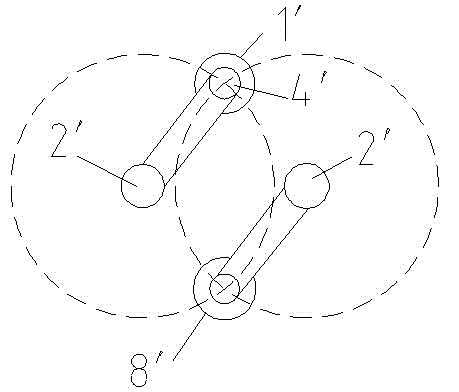

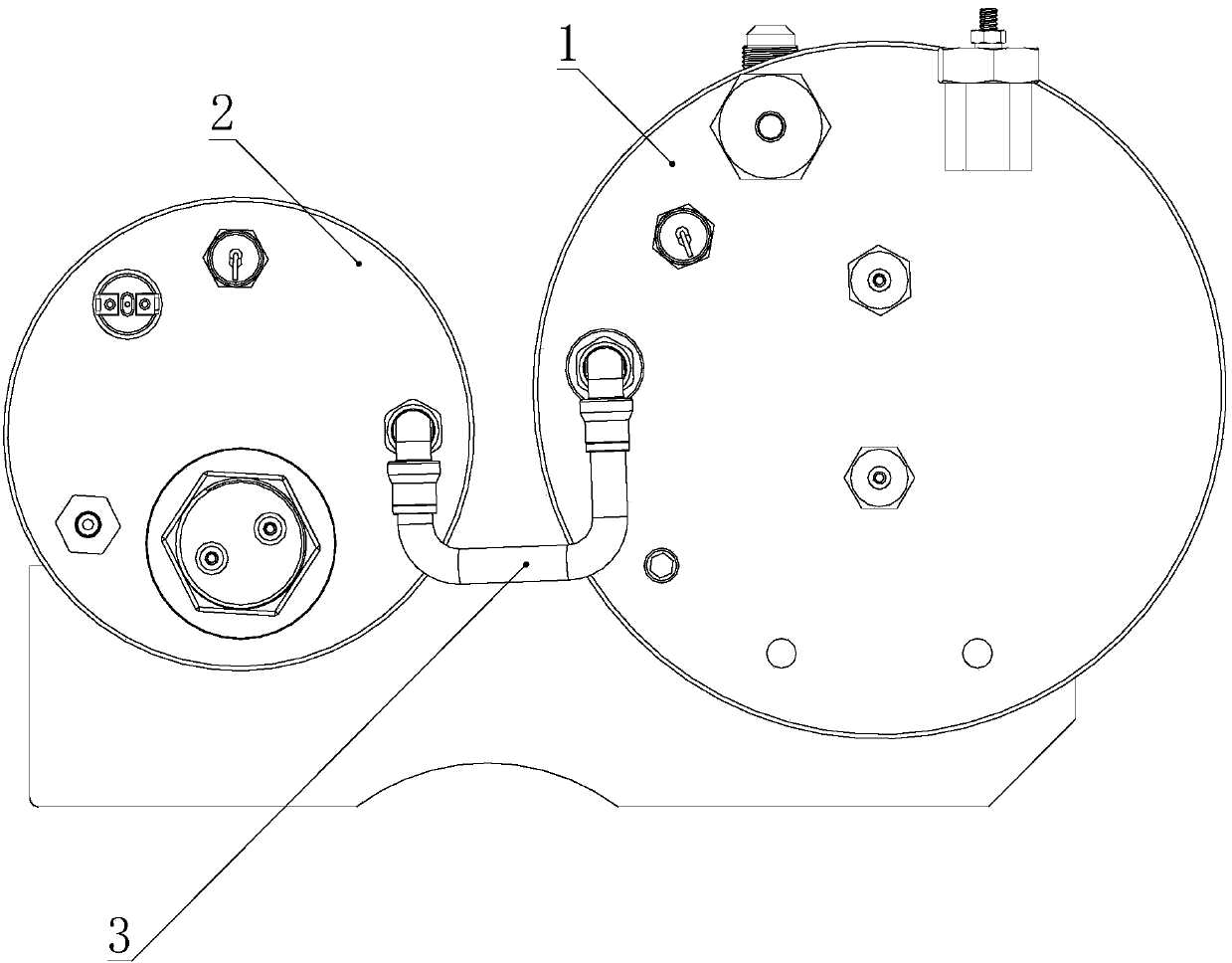

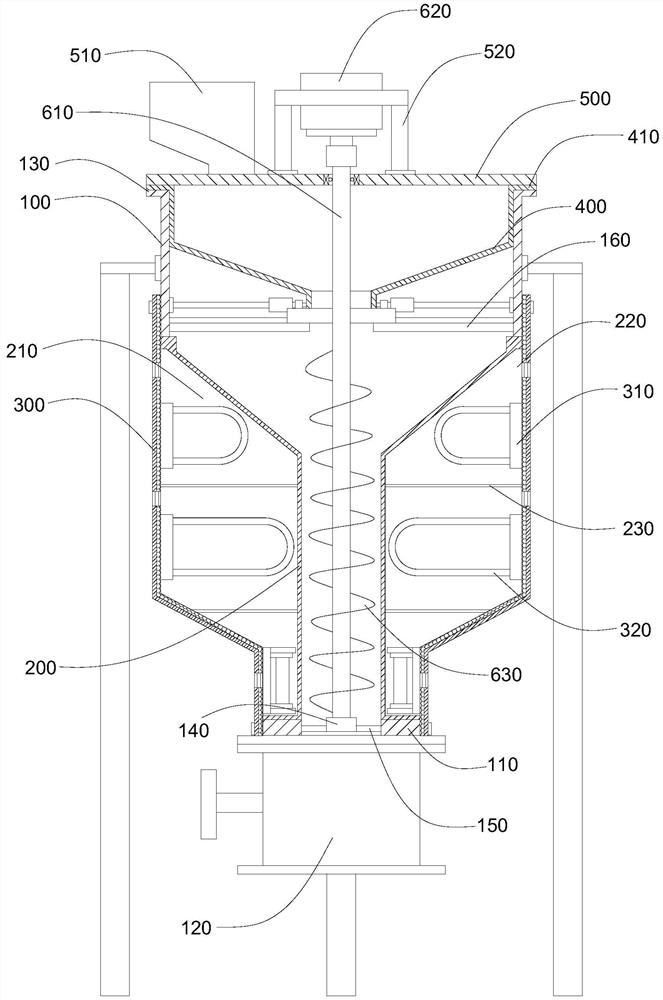

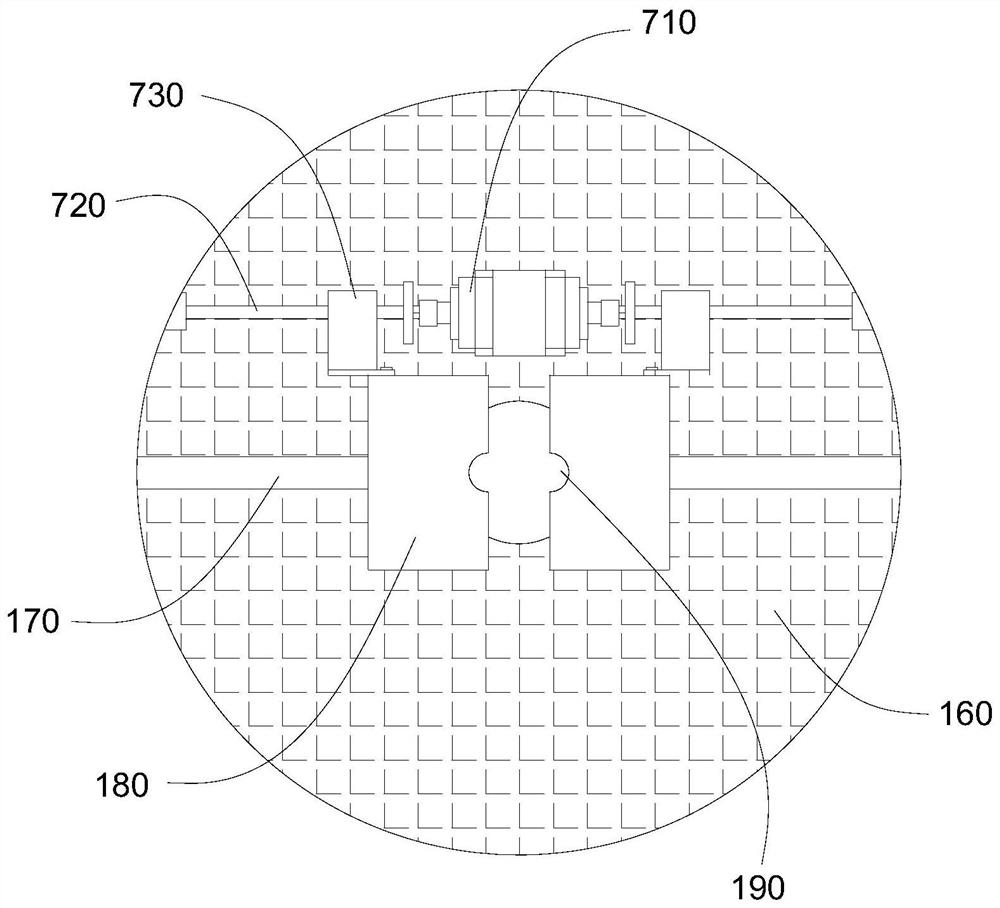

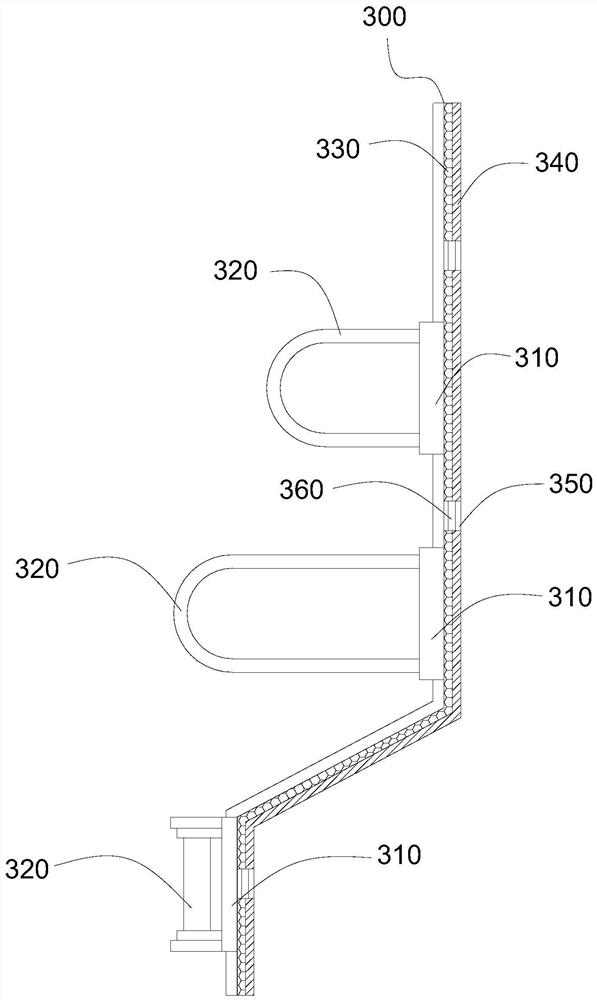

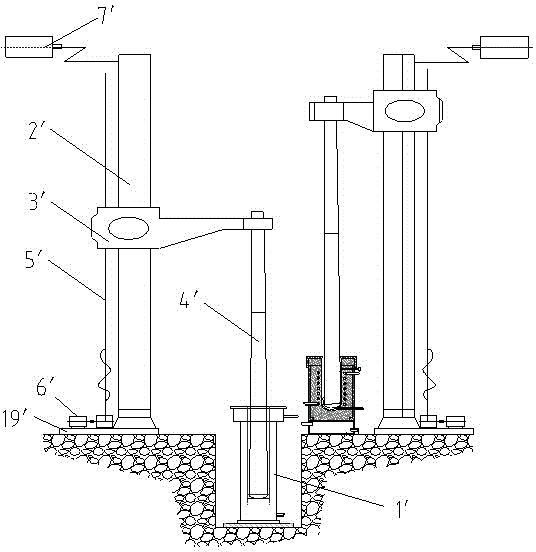

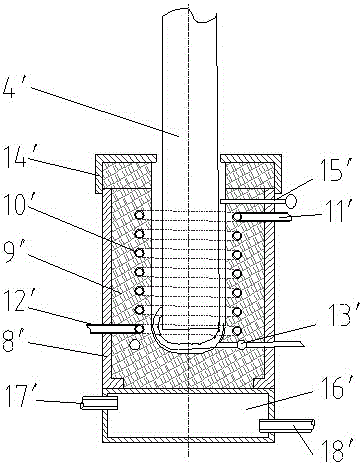

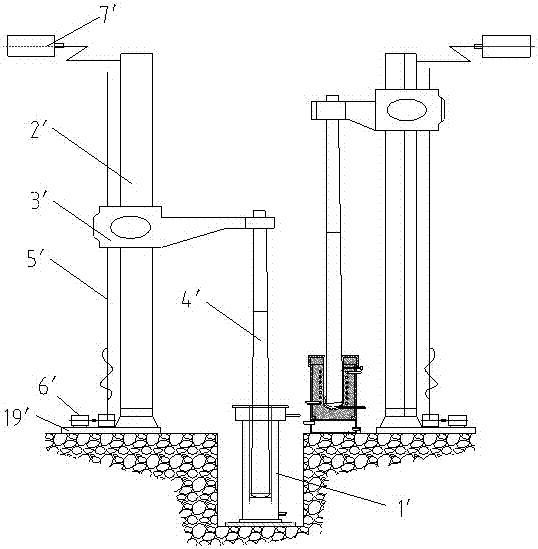

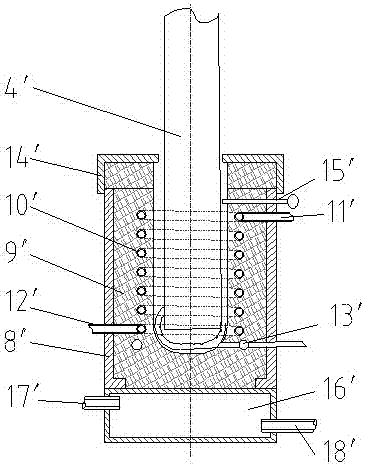

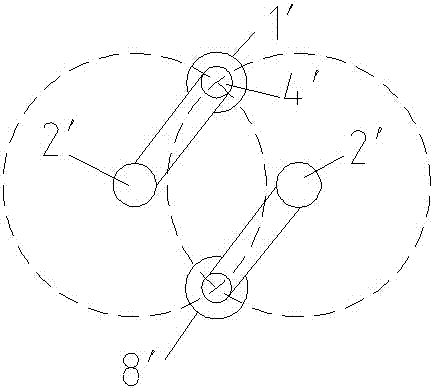

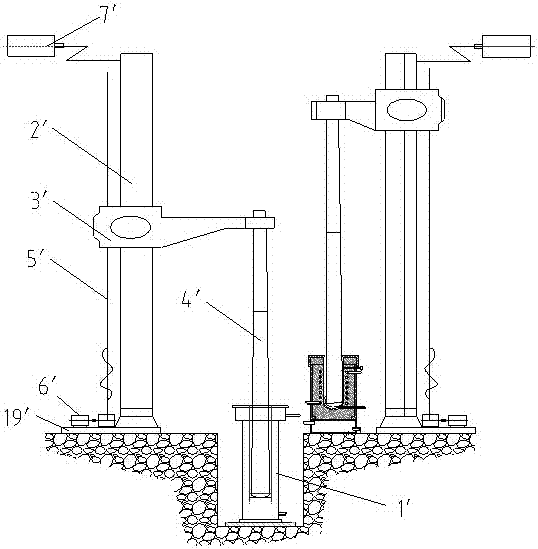

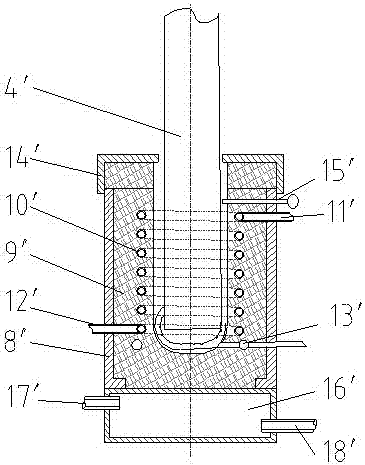

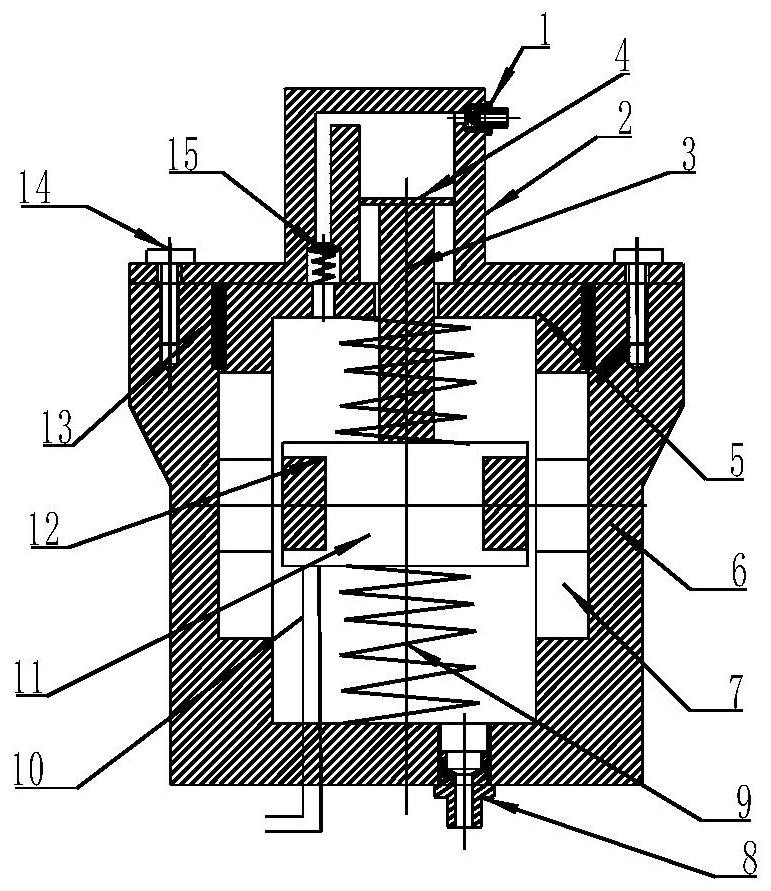

Electric furnace system for electroslag metallurgy

ActiveCN104831083ASimple and reasonable structureIncrease profitIncreasing energy efficiencySlagElectricity

The invention discloses an electric furnace system for electroslag metallurgy, comprising a crystallizer in a furnace shape and an electrode unit disposed on one side of the crystallizer. The lower end of the crystallizer is provided with a bottom water tank used for cooling. The electric furnace system further comprises an electrode preheater located on one side of the electrode unit; the electrode preheater comprises a shell; refractory insulating material is disposed within the shell, and the shell is centrally provided with a heating chamber which is vertically set, the upper end of which is open and which allows insertion of the lower end of an electrode; an inductive coil spirally and liftably around the heating chamber is buried in the refractory insulating material, forming a heater. The electric furnace system with a preheating function is high in smelting efficiency, good in safety, good in smelting effect, safe, efficient and energy saving; smelting quality of slag ingots is improved; the bottom water tank is convenient to maintain and change, maintenance cost is lower, and cooling efficiency is improved.

Owner:宝武特冶航研科技有限公司

Injection mold

The invention discloses an injection mold which comprises an insert mounting part. The insert mounting part is provided with threaded holes and is mounted on the mold through a threaded connection manner. An insert mounting groove is formed in the insert mounting part. An insert locating part is arranged on the side edge of the insert mounting groove. A containing cavity is formed in the insert locating part. A limiting ball and a spring are arranged in the containing cavity. The spring abuts against the limiting ball so that the limiting ball can be in a working state. A heating body is arranged in the insert locating part. A prospect hole is formed in the bottom of the insert mounting groove. A hydraulic oil cavity is formed in the insert mounting part. The prospect hole is connected with the hydraulic oil cavity. An ejection block and a piston block are arranged in the hydraulic oil cavity. An ejection rod is arranged on the ejection block. The ejection rod can stretch out of the prospect hole, and therefore a metal insert is jacked up. The piston block is connected with a push rod, the push rod is driven by a motor to work, and therefore the piston block is driven to move. Compared with the prior art, according to the injection mold, the metal insert can be stably limited at a preset position, and the situation that the metal insert is separated, and consequently accidents happen is avoided.

Owner:ZHEJIANG BUSINESS TECH INST

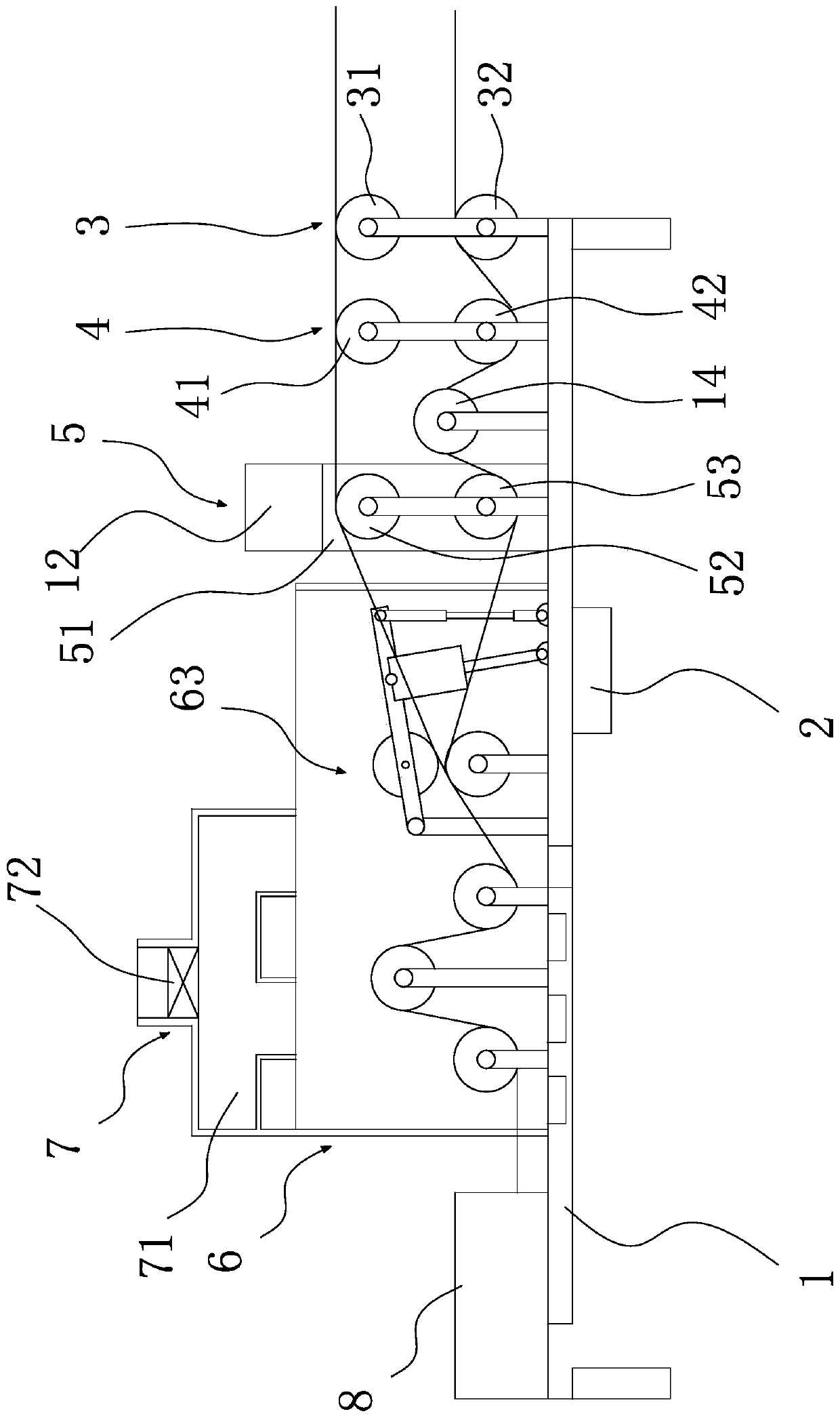

Glass fiber fabric compounding machine with pre-heating function

ActiveCN107116890AImprove activity stabilityEnsure safetyLamination ancillary operationsLaminationGlass fiberEngineering

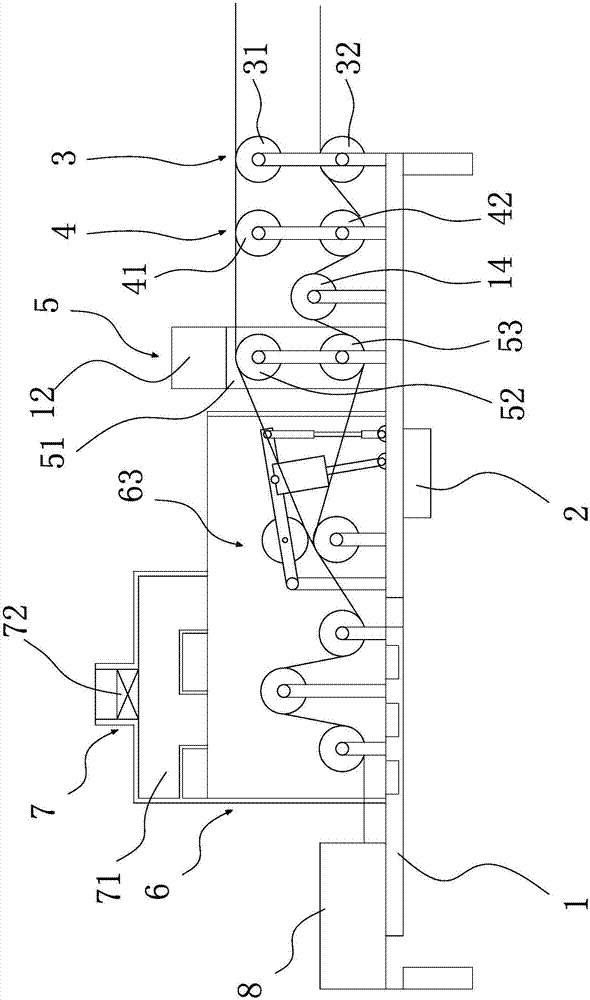

The invention provides a glass fiber fabric compounding machine with a pre-heating function and belongs to the technical field of machinery, aiming at solving the problem that an existing glass fiber fabric is easy to degum after being compounded. The glass fiber fabric compounding machine with the pre-heating function comprises a rack which is horizontally and transversely arranged, wherein a controller is arranged on the bottom surface of the rack; the rack is sequentially provided with a feeding device, a pre-heating device, a gumming device, a compound drying device, a heat dissipation device and a winding frame; the feeding device comprises a first feeding roller and a second feeding roller, which are independent to each other; the gumming device comprises a gumming box; the gumming box is internally provided with a first gumming roller and a second gumming roller; the pre-heating device comprises a first pre-heating roller and a second pre-heating roller. The glass fiber fabric compounding machine provided by the invention is used for pre-heating raw materials of the glass fiber fabric, so that glue can completely permeate into the raw materials of the glass fiber fabric in a gumming process, furthermore, the sticking fastness of the glass fiber fabric in a production process is ensured and the quality of the glass fiber fabric is improved.

Owner:浙江凯澳新材料有限公司

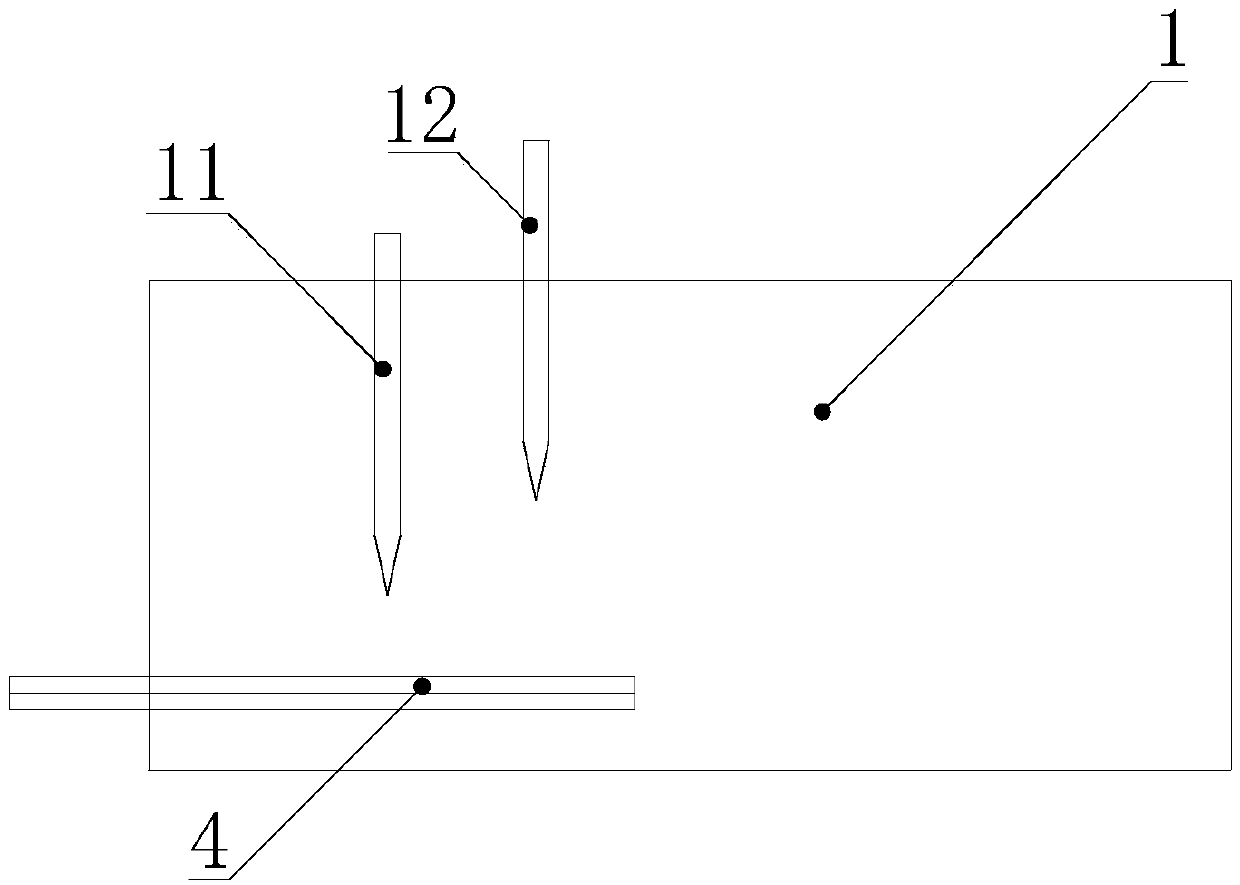

Plate drying machine with preheating function

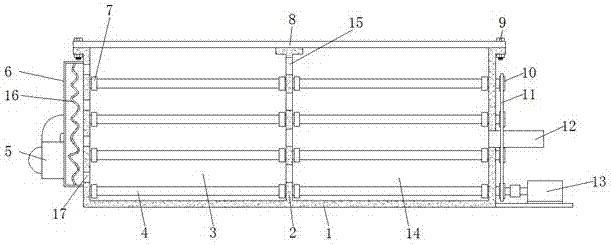

InactiveCN107192225AEasy accessEasy to removeDrying gas arrangementsDrying solid materialsPulp and paper industryExhaust pipe

The invention discloses a plate drying machine with the preheating function. The plate drying machine comprises a drying cabinet; the right side surface of the drying cabinet is provided with an exhaust pipe which communicates with an inner cavity of the drying cabinet; cabinet doors are arranged on two sides of the front surface and the back surface of the drying cabinet through hinges respectively; a partition plate which is vertically arranged and is welded to the inner wall of the drying cabinet is arranged in the middle of the inner cavity of the drying cabinet and divides the inner cavity of the drying cabinet into a drying cavity body and a preheating cavity body; and a first through groove communicating with the drying cavity body and the preheating cavity body is formed in the drying cabinet. The plate drying machine with the preheating function has the advantages that waste heat of hot air in the drying cavity body is discharged into the preheating cavity body for preheating plates, and therefore the waste heat can be fully utilized; due to the preheating effect of the exhaust pipe, the drying efficiency is high when the plates in the exhaust pipe are placed into the drying cavity body; and the shunting effect of second through grooves and the first through groove is utilized so that the bottom surfaces and the upper surfaces of the plates placed on rotating shafts can be heated, and therefore the drying efficiency can be improved.

Owner:黄永怀

Intelligent boiler of coffee maker

The invention discloses an intelligent boiler of a coffee maker. The intelligent boiler comprises a water inlet pipe, and a steam boiler and a coffee boiler which are arranged independently, and the water inlet pipe penetrates the inner cavity of the steam boiler to communicate with the coffee boiler. According to the intelligent boiler, the steam boiler and the coffee boiler are arranged independently, and the water inlet pipe penetrates the inner cavity of the steam boiler to communicate with the coffee boiler, the intelligent boiler is allowed to have a preheating function and is free of steam and an operator can set steam pressure and the temperature of water freely on conditions that total capacity and the total power are not changed; the operator can know the current temperature of the water for making coffee; the coffee is easier to made in standardized, rapid and uniform manners; the intelligent boiler is simple in structure and practical.

Owner:XUZHOU ZHONGYI COFFEE EQUIP

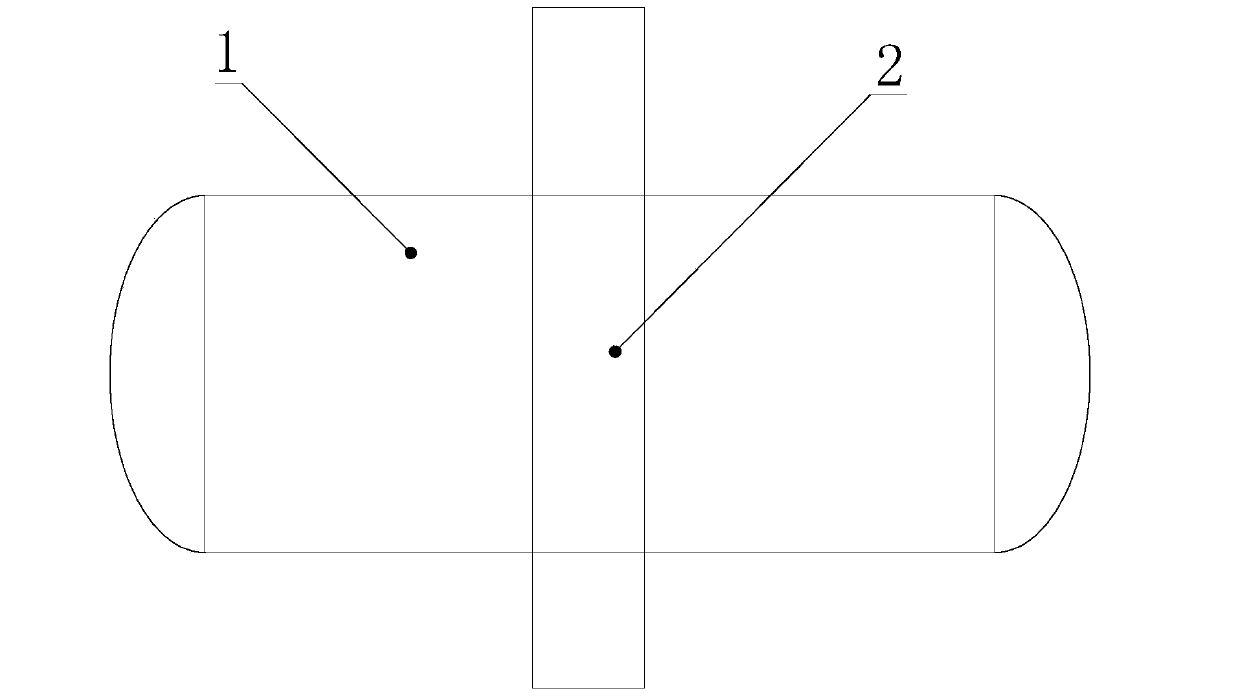

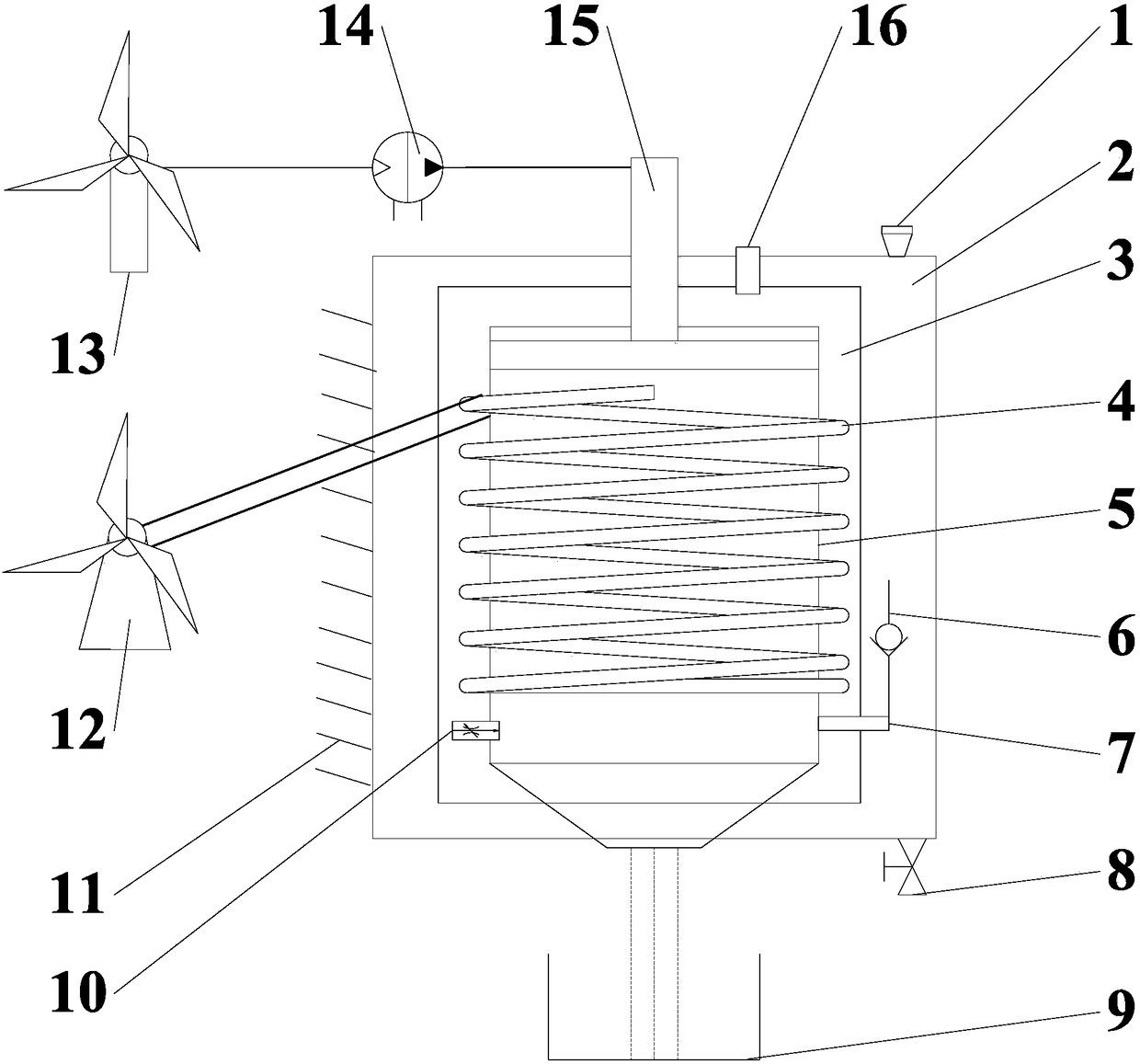

Sleeve type fresh water sea salt coproduction system

InactiveCN105836829AShorten the concentration timeFast outputSeawater treatmentFinal product manufactureWater vaporFresh water

The invention discloses a sleeve type fresh water sea salt coproduction system, which comprises a heating cylinder (5), a seawater storage layer (3) and a fresh water storage layer (2) in sequential arrangement from inside to outside, wherein a sealing piston (15) capable of doing vertical and reciprocating movement is arranged inside the heating cylinder (5); a piston rod of the sealing piston (15) sequentially passes out of the top ends of the heating cylinder (5), the seawater storage layer (3) and the fresh water storage layer (2) to be connected with a mechanical transmission mechanism (14); the bottom of the heating cylinder (5) is of a funnel-shaped structure; the funnel-shaped structure sequentially passes through the back ends of the seawater storage layer (3) and the fresh water storage layer (2), and then, an opening is right aligned with a salt storage tank (9); a sweater inlet and a water vapor outlet (7) are formed in the wall of the heating cylinder (5). The sleeve type fresh water sea salt coproduction system provided by the invention has the advantages that materials are taken in site; reproducible energy sources are used in a way of taking actions that suit local circumstances to realize the combined production of fresh water and sea salt; the structure is compact; the cost is low; the energy is saved; the environment is protected.

Owner:HOHAI UNIV CHANGZHOU

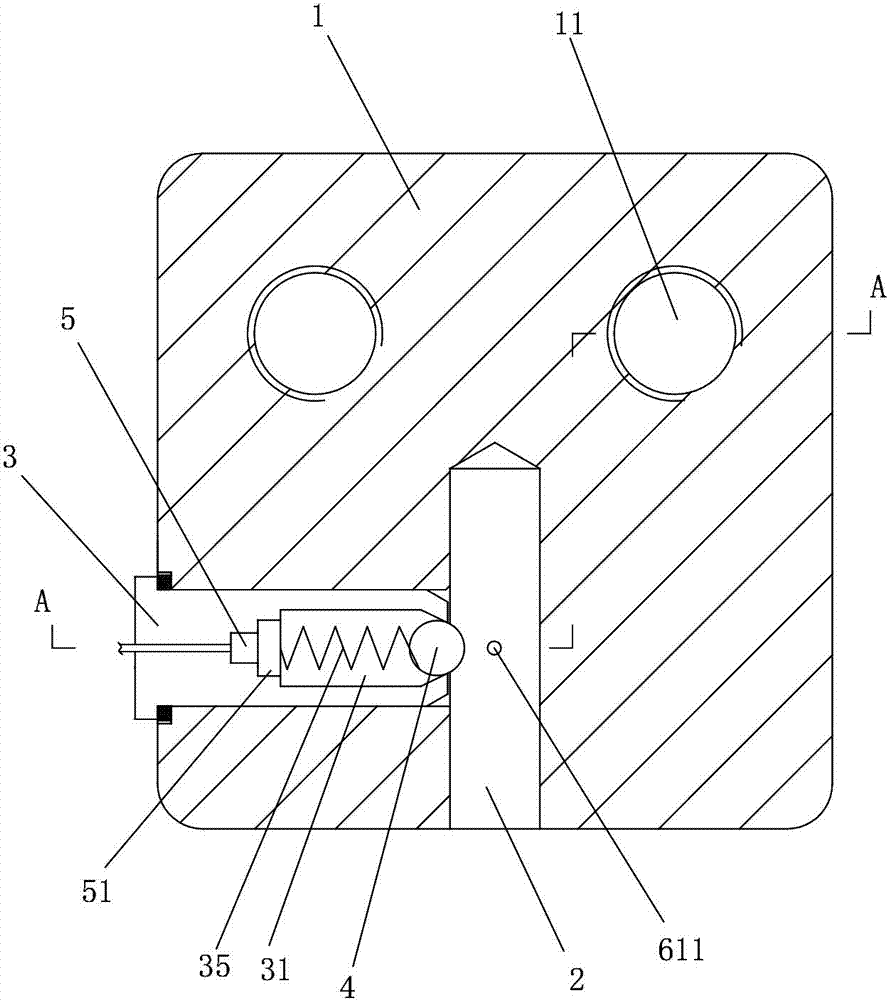

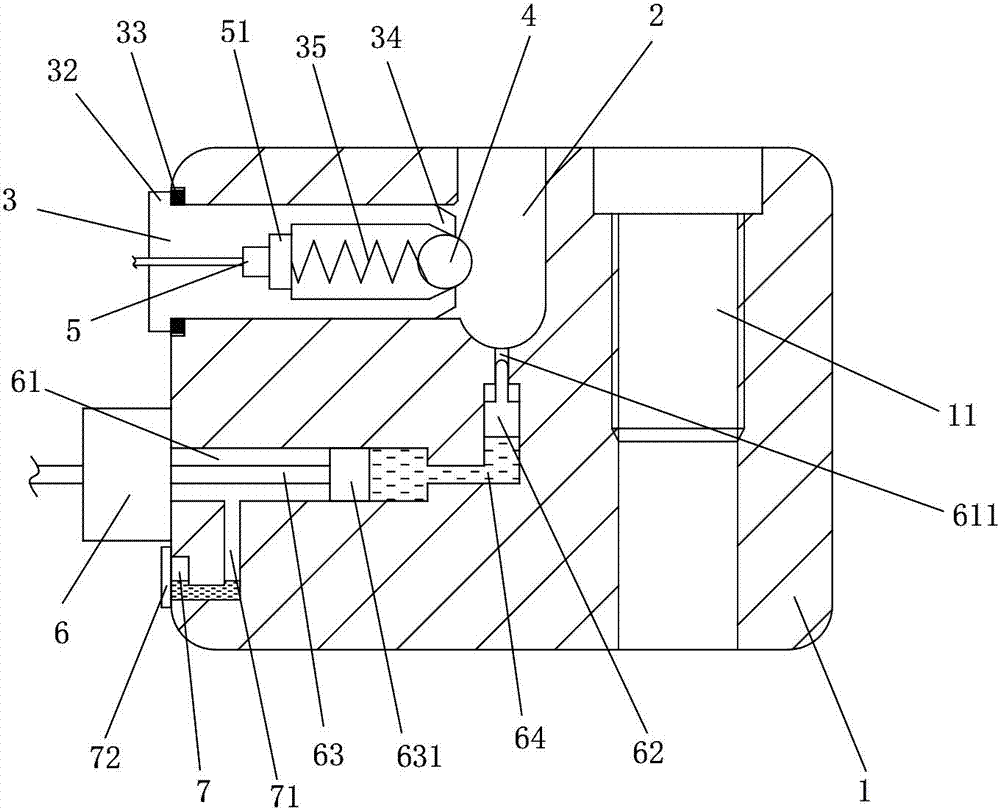

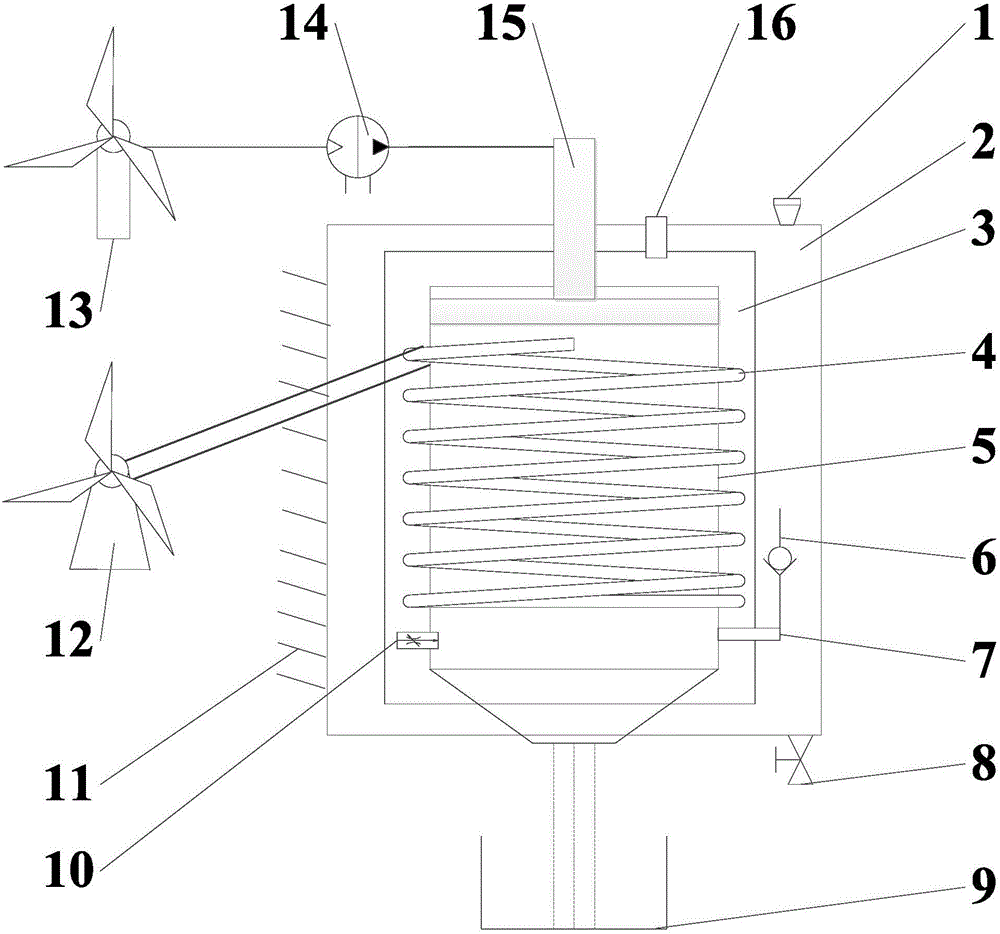

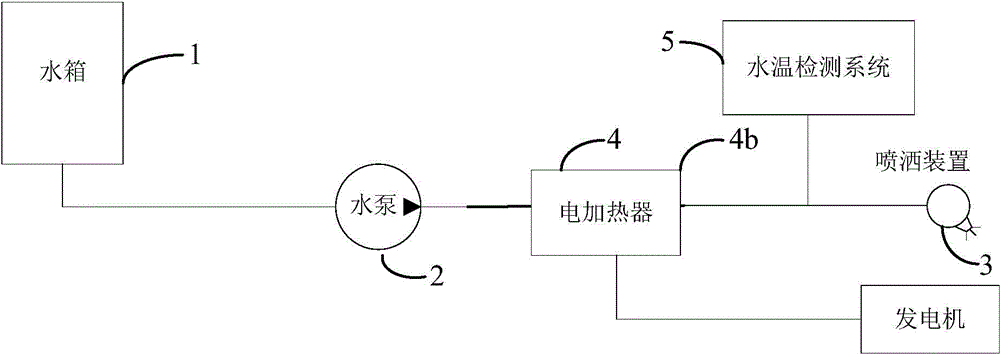

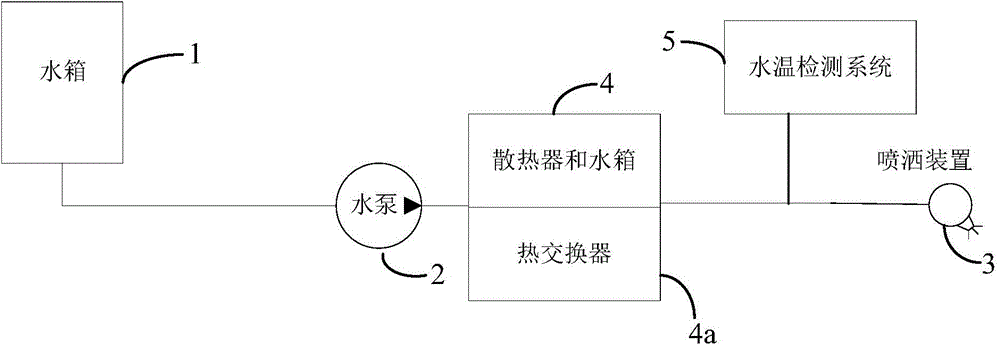

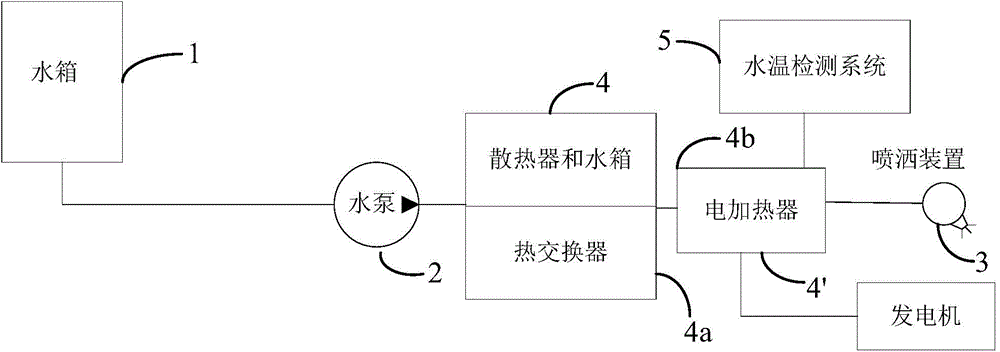

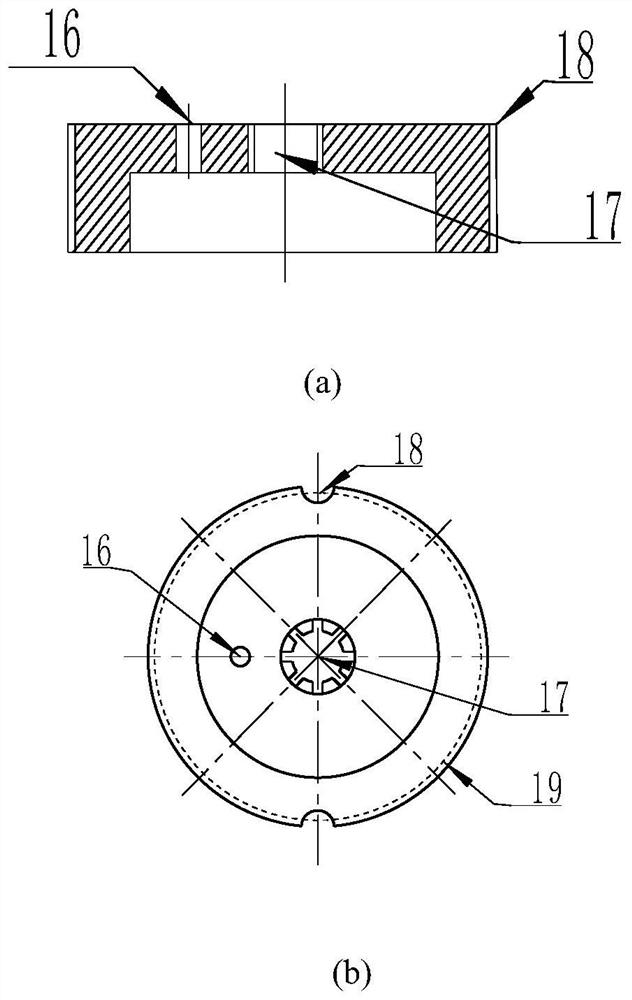

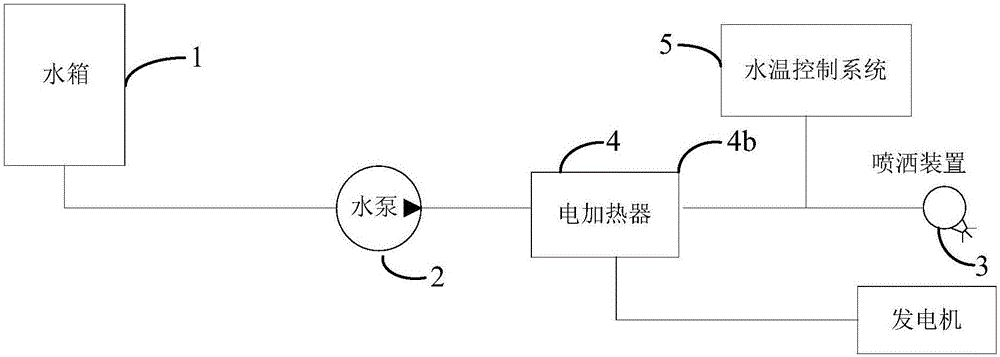

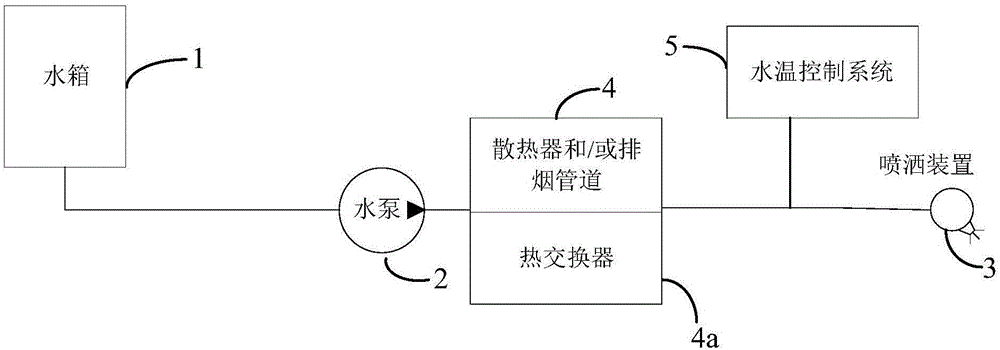

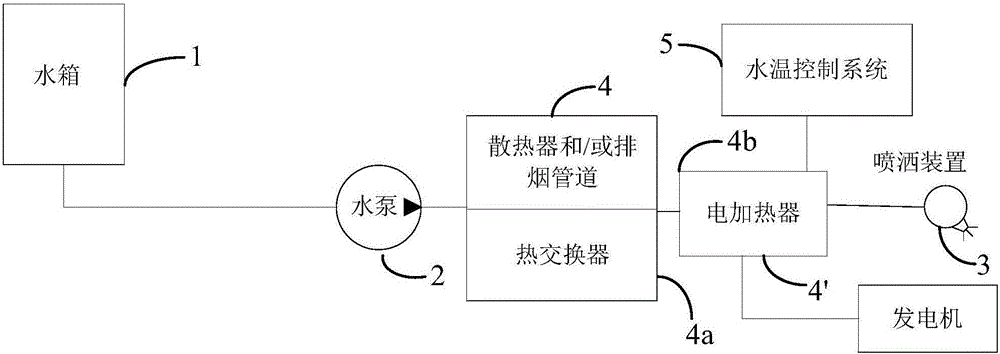

Road roller and water spraying system thereof

ActiveCN104099852AWith preheating functionAdapt to temperatureRoads maintainenceSprinkler systemControl system

The invention discloses a road roller and a water spraying system thereof. The water spraying system comprises a water tank, a water pump and a spraying device, and further comprises a preheating device, wherein the preheating device is arranged on a pipeline between the water pump and the spraying device, and is used for preheating the cold water sprayed by the spraying device; a water temperature control system is connected with the preheating device and is used for detecting the water temperature and controlling the flowing speed. The water spraying system provided with the preheating function can prevent cold water from being directly sprayed onto a vibration wheel of the road roller, so as to prevent the influence of vibration wheel on the pavement construction temperature, prevent the construction material from being stuck onto the vibration wheel to influence the construction quality and enhance the cleaning difficulty.

Owner:HUNAN SANY ROAD MACHINERY

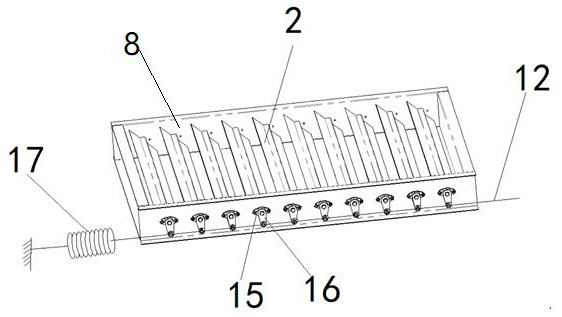

A plastic granule feeding machine

Owner:GANZHOU TONGZHOU PLASTIC MACHINERY

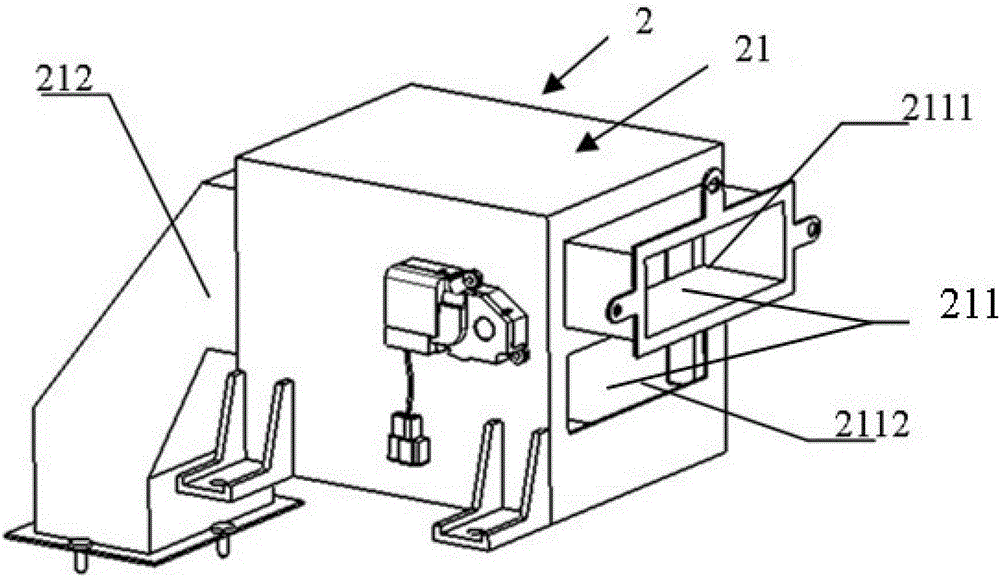

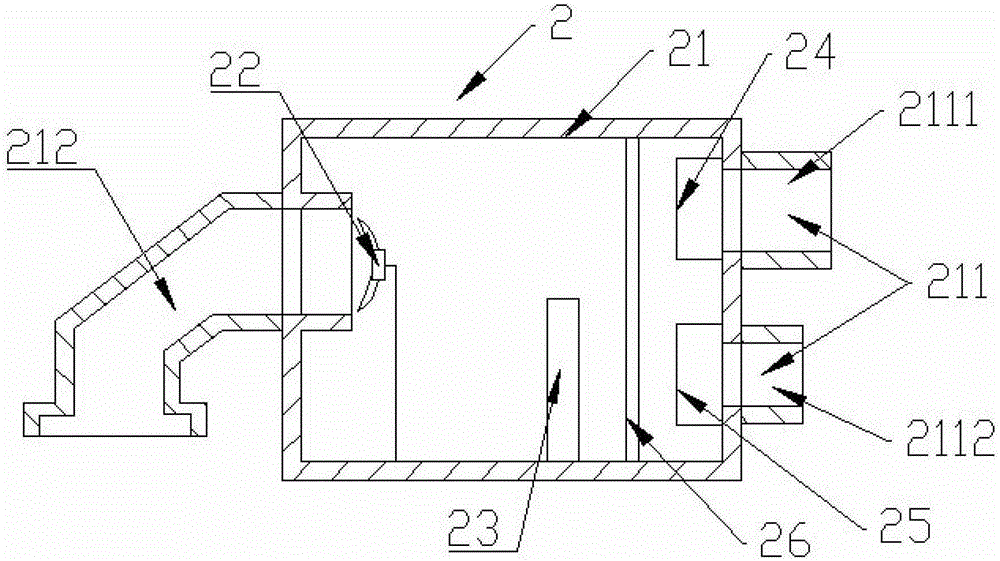

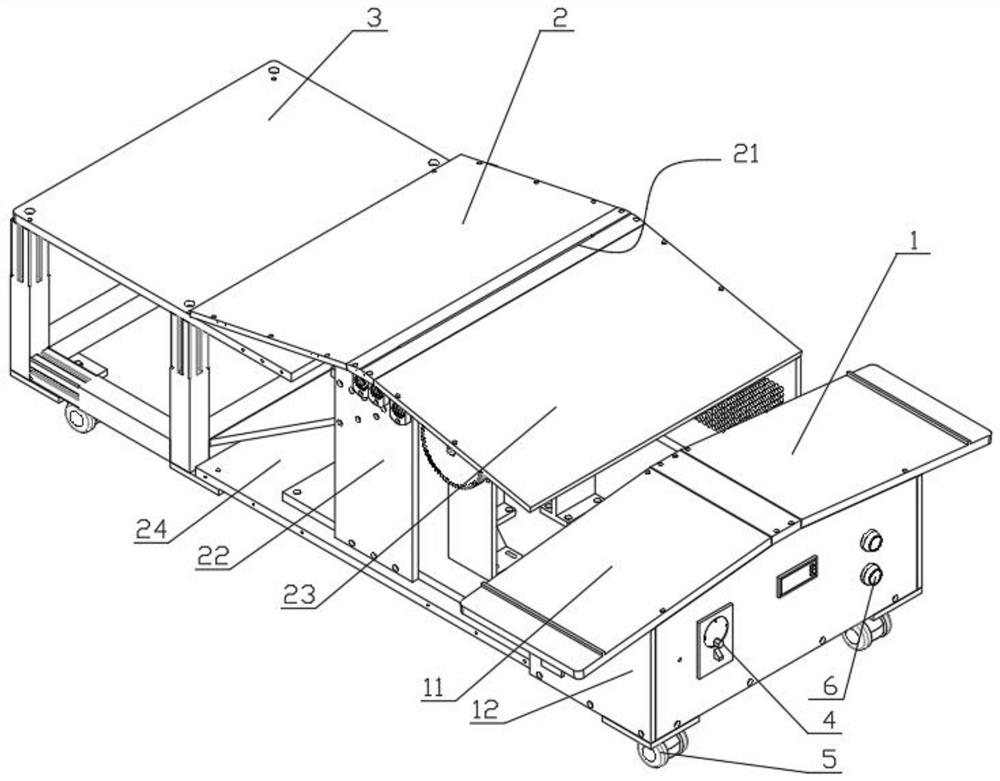

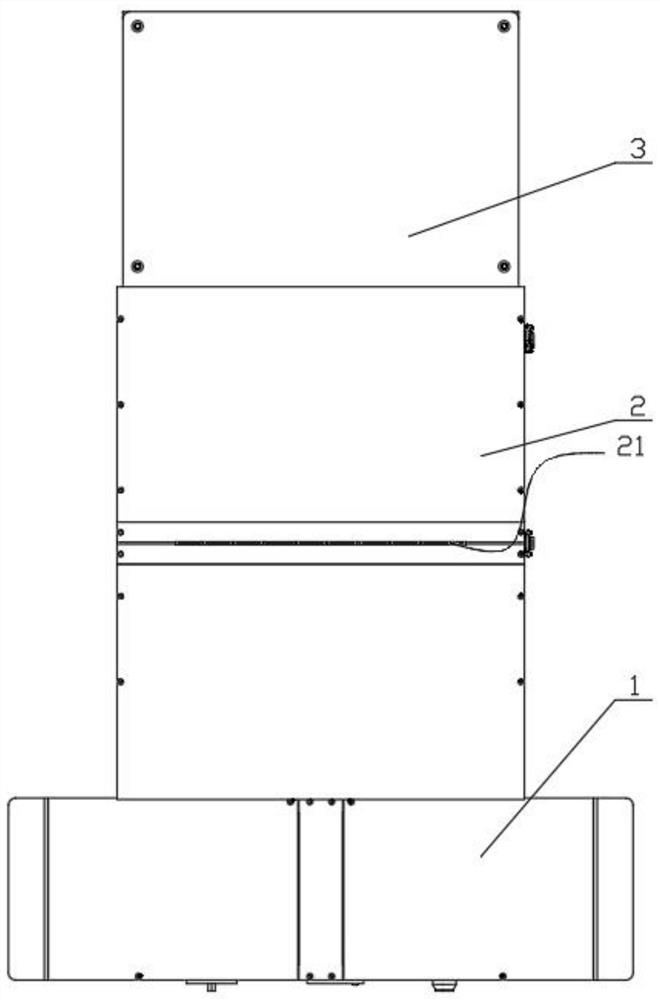

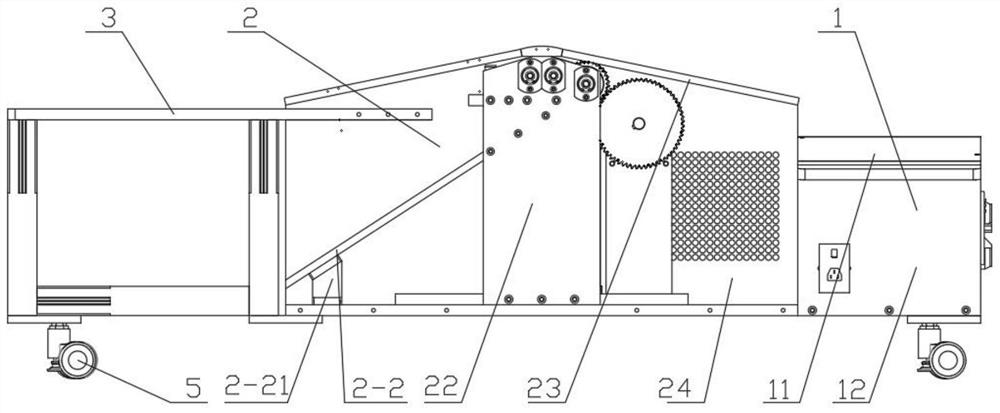

Electric vehicle air-cooled power battery thermal management device and control system

The invention relates to the field of electric automobiles and discloses an air-cooled power battery heat management device for an electric vehicle. The air-cooled power battery heat management device comprises a battery box for mounting a power battery, an air outlet ventilating group and a cycle ventilating group which are formed by connecting multiple ventilating boxes through pipelines, and an air inlet assembly and a cycle assembly, wherein the air outlet ventilating group is arranged in the battery box and is connected with the power battery in parallel; the cycle ventilating group is arranged at a position, which is far away from the air outlet ventilating group, in the battery box; the air inlet assembly absorbs air outside the battery box and blows air into the battery box through the air outlet ventilating group; the cycle assembly absorbs the air in the battery box through the cycle ventilating group, and the air is discharged out of the battery box. The air quantity and air speed of the air flowing in the battery box are uniform, and the problem of non-uniform cooling existing in a forced convection cooling mode in the prior art is solved. Furthermore, a heater is arranged in the cycle assembly, so that the power battery is preheated. The invention also provides a special control system. According to the control system, the power battery can be maintained to operate under optimal operating temperature conditions.

Owner:陈言平

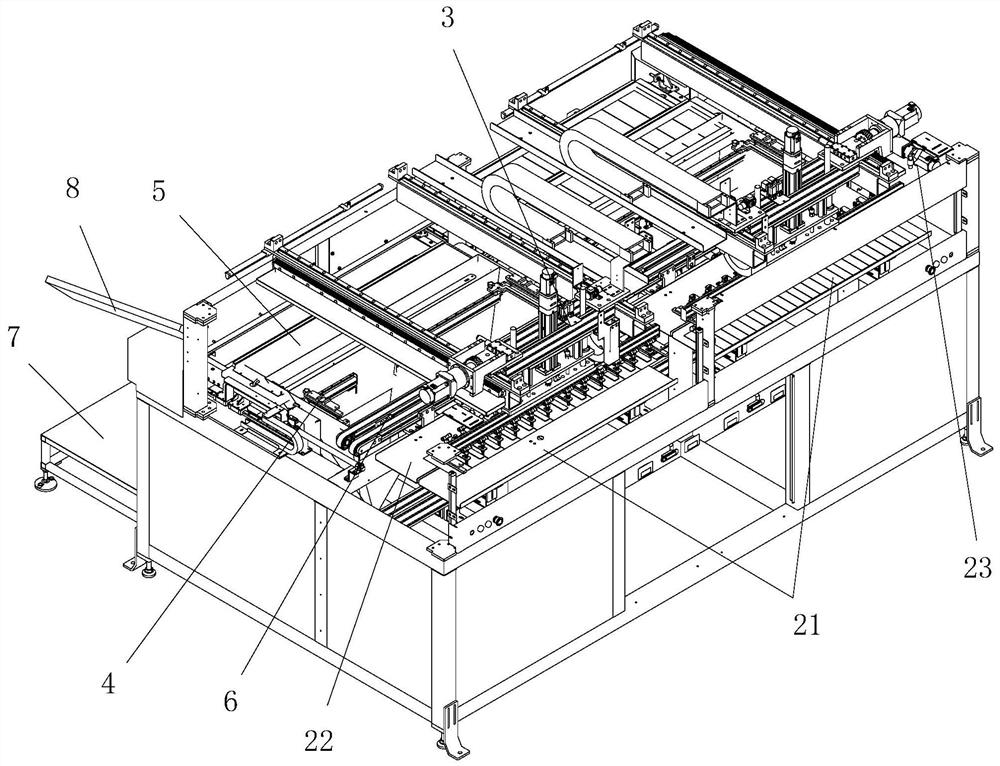

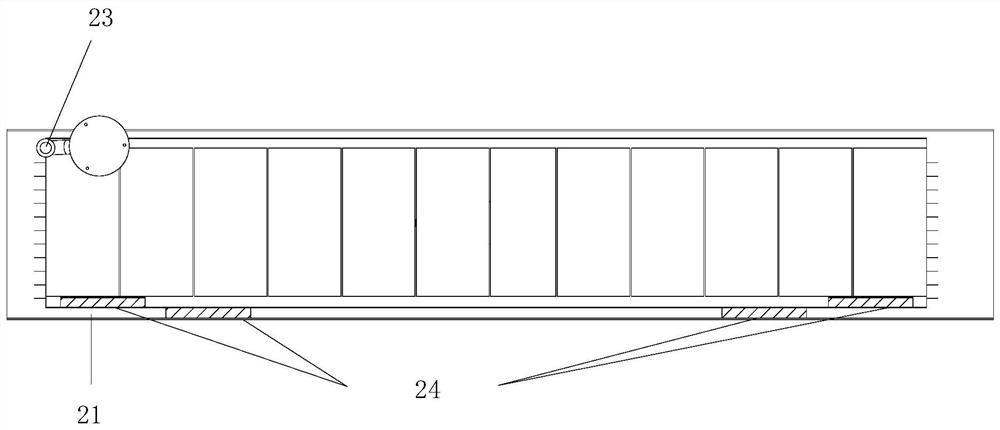

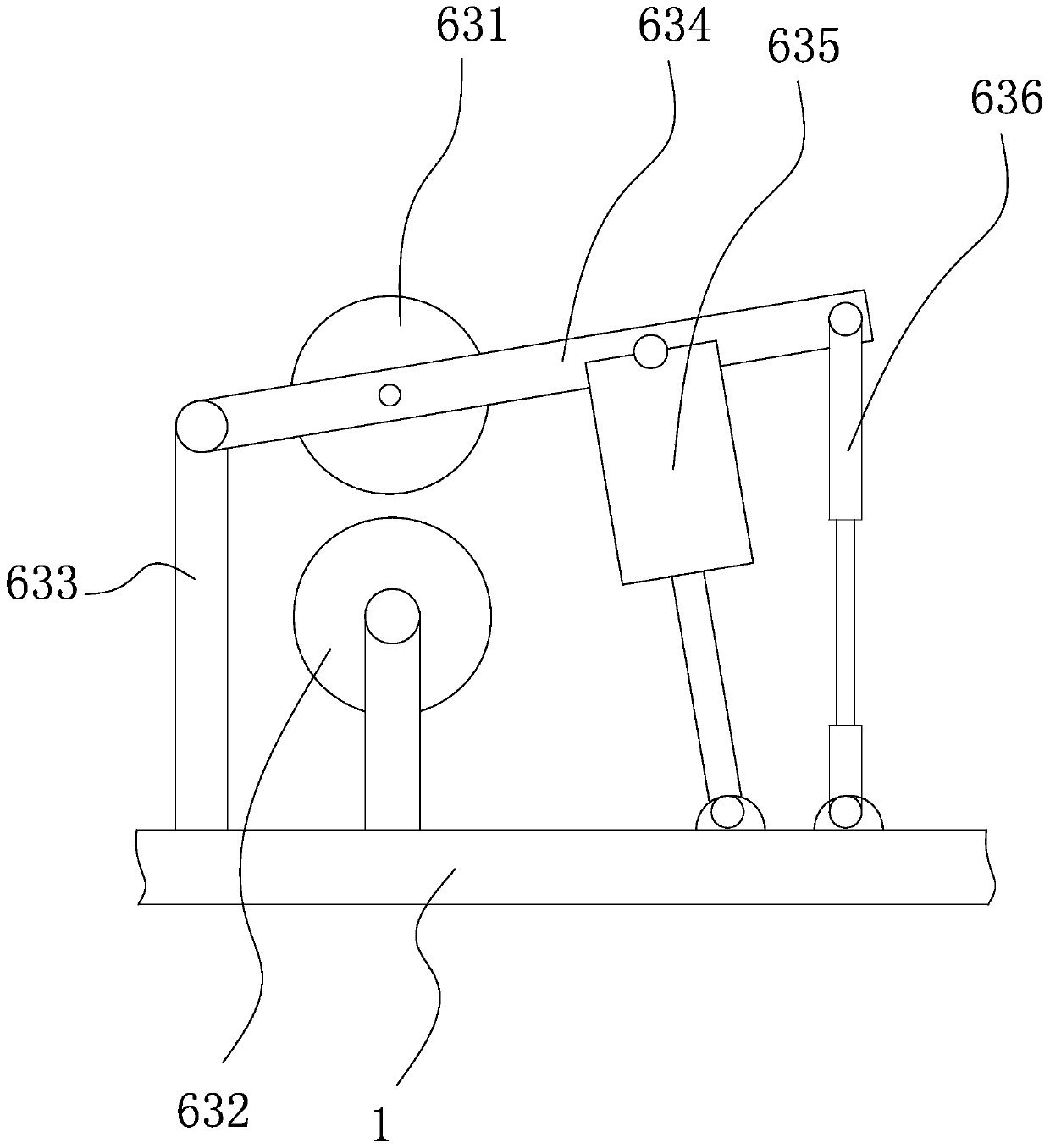

Paper folding device for corrugated carton

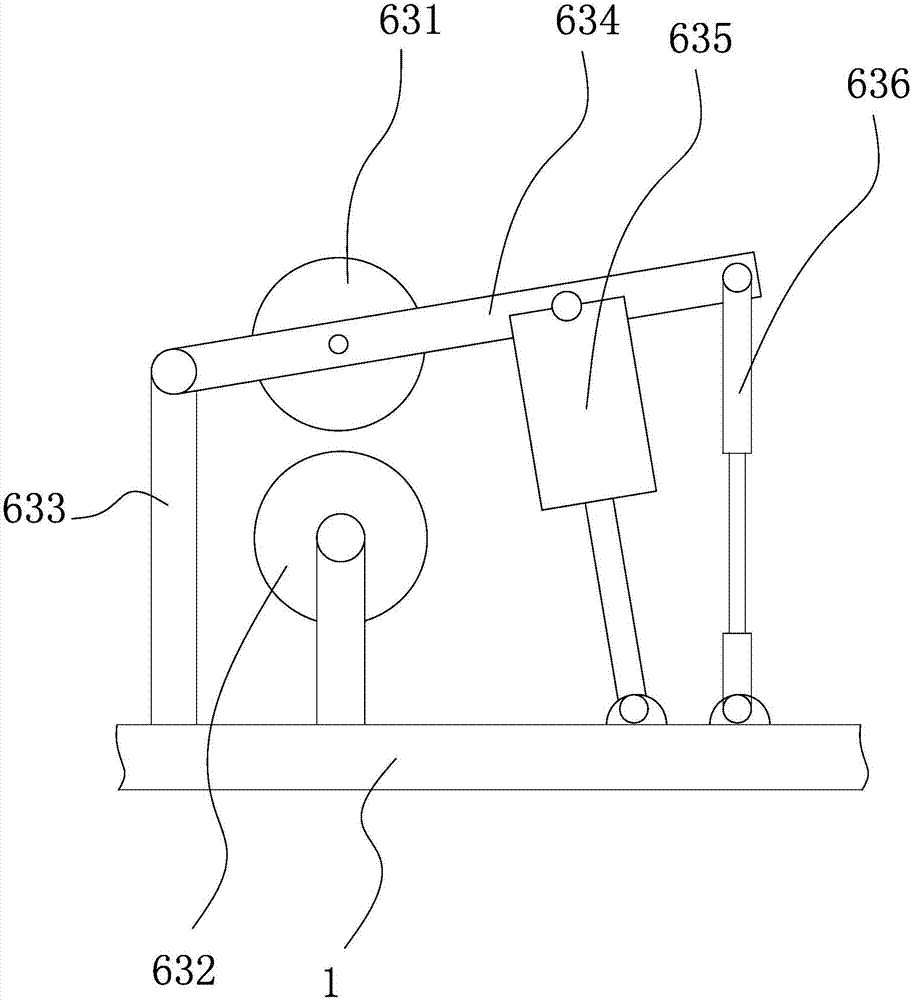

InactiveCN108147199AQuickly fold into shape and shapeWith preheating functionFolding thin materialsArticle deliveryCartonPaperboard

The invention provides a paper folding device for a corrugated carton. The paper folding device for the corrugated carton comprises a paper feeding mechanism, and a paper pressing mechanism and a paper folding mechanism which are arranged above the paper feeding mechanism. The paper pressing mechanism comprises a telescopic arm and a pressing plate connected with the telescopic arm. The paper folding mechanism is a folding mechanism working at 0-180 degrees and comprises guiding rods located on the two sides in the transverse direction, a pressing roller mounted on the guiding rods through sliding sleeves, and a transmission plate provided with power output and connected with the pressing roller. The pressing plate and the pressing roller have the preheating function. The paper folding device has the beneficial effects that corrugated paperboards can be folded by 0-180 degrees through the arranged paper folding mechanism, the application range is wider, the pressing plate and the pressing roller have the preheating function, and thus the corrugated paperboards can be rapidly folded, formed and shaped.

Owner:ZHUZHOU SINOVAN PACKAGING TECH

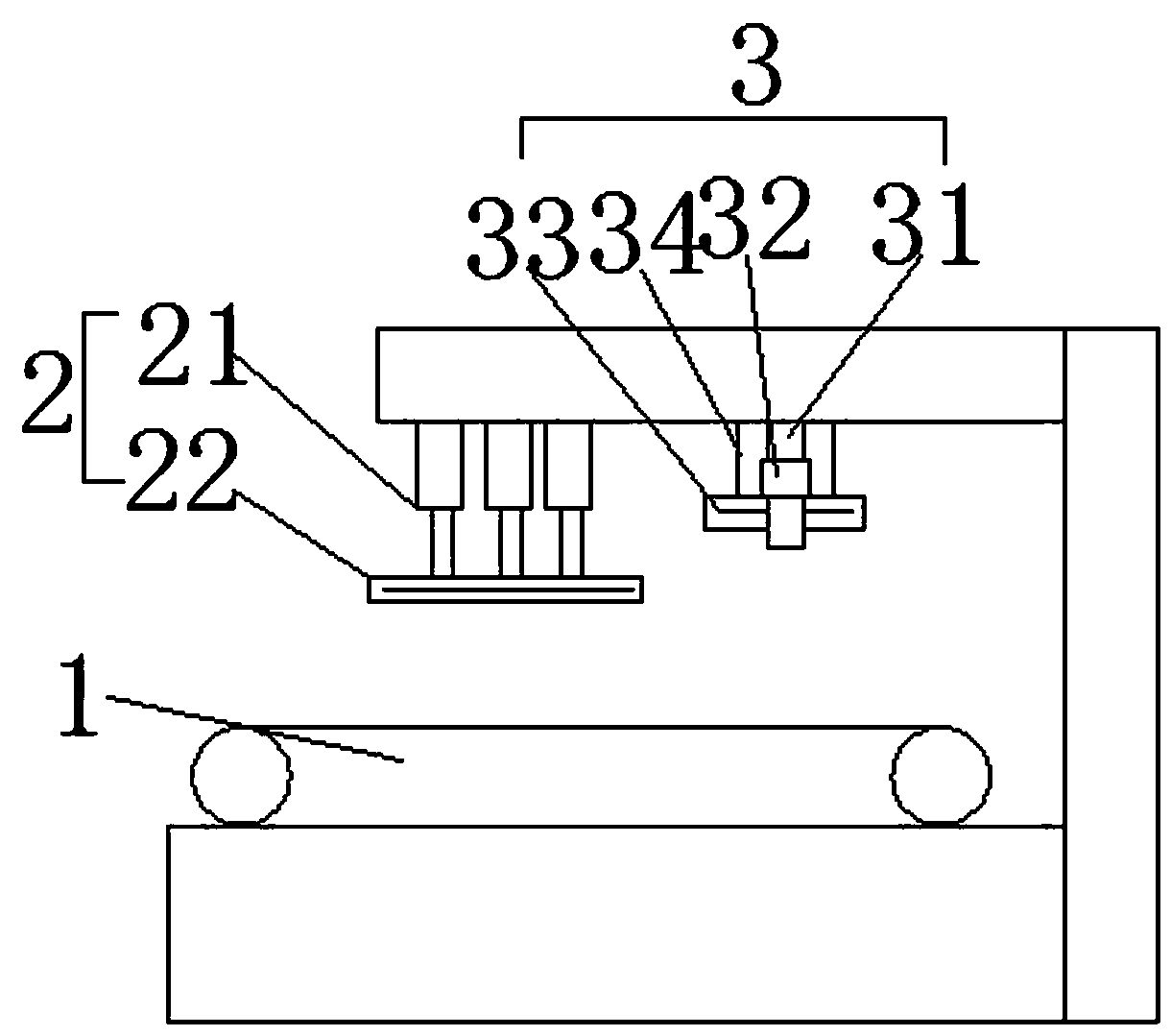

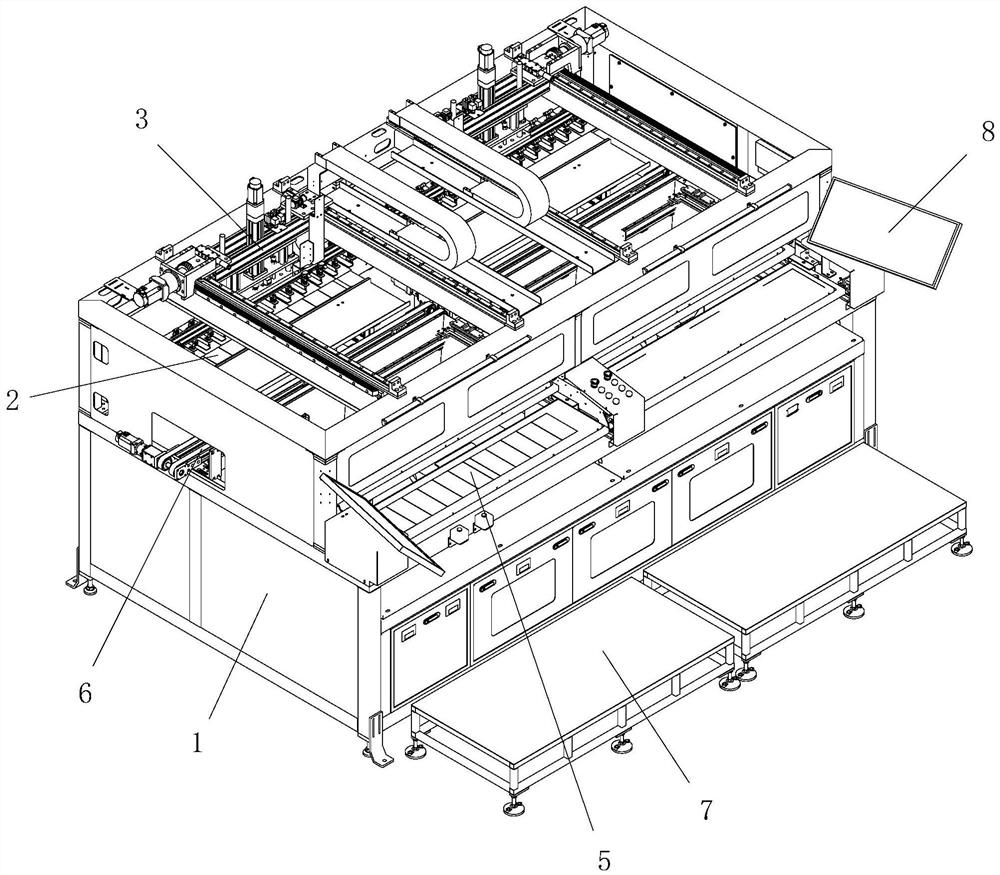

Battery string EL repair machine

PendingCN113707766AHigh degree of automationFast pace of reworkFinal product manufactureSemiconductor/solid-state device manufacturingSoftware engineeringDisplay device

The invention discloses a battery string EL repair machine which comprises a machine frame, an NG string feeding and positioning mechanism, a Y-axis and Z-axis transferring mechanism, an EL detection mechanism, an interchange type double repair table mechanism, a battery string conveying mechanism, a foot-pad pedal and an EL displayer, and the Y-axis and Z-axis transferring mechanism is installed on the portion, above the NG string feeding and positioning mechanism, of the machine frame. The Y-axis and Z-axis transfer mechanism transfers the NG string to an EL detection mechanism arranged on the workbench for testing, the workbench on the front side of the EL detection mechanism is provided with an interchangeable double-repair-table mechanism for receiving NG products, and the workbench on the rear side of the EL detection mechanism is provided with a battery string conveying mechanism for receiving OK products. By means of the mode, NG battery strings are repaired, distinguished feeding can be conducted according to A / B strings, leads can be accurately pressed for detection, the repairing table has the preheating function, the upper repairing table and the lower repairing table are switched, and the repairing rhythm is guaranteed.

Owner:SUZHOU SHENGCHENG SOLAR EQUIP

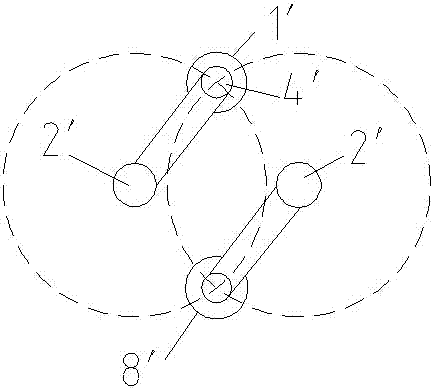

Electroslag smelting method

The invention discloses an electroslag smelting method. The electroslag smelting method is characterized in that two electrode devices are arranged beside a crystallizer and used for smelting in the crystallizer by turns, an electrode is installed on one electrode device and preheated when the other electrode device is used for smelting, an electrode of the electrode device used for smelting is moved away after smelting is completed, the preheated electrode is moved into the crystallizer for smelting after slag is fed again and the crystallizer is arranged well, and the process is repeated so as to achieve high-efficiency electroslag smelting. The electroslag smelting method has the advantages of high smelting efficiency and safety, excellent smelting effect, high efficiency, energy conservation, higher electroslag steel ingot smelting quality, great convenience in maintenance and replacement of the bottom water tank, lower maintenance cost and higher cooling efficiency.

Owner:宝武特冶航研科技有限公司

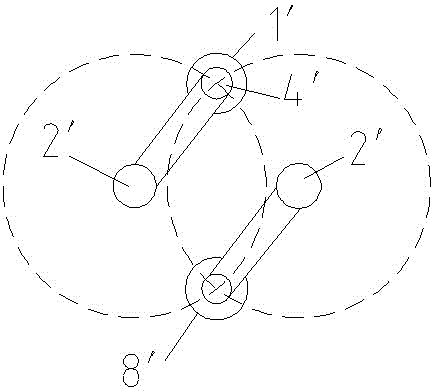

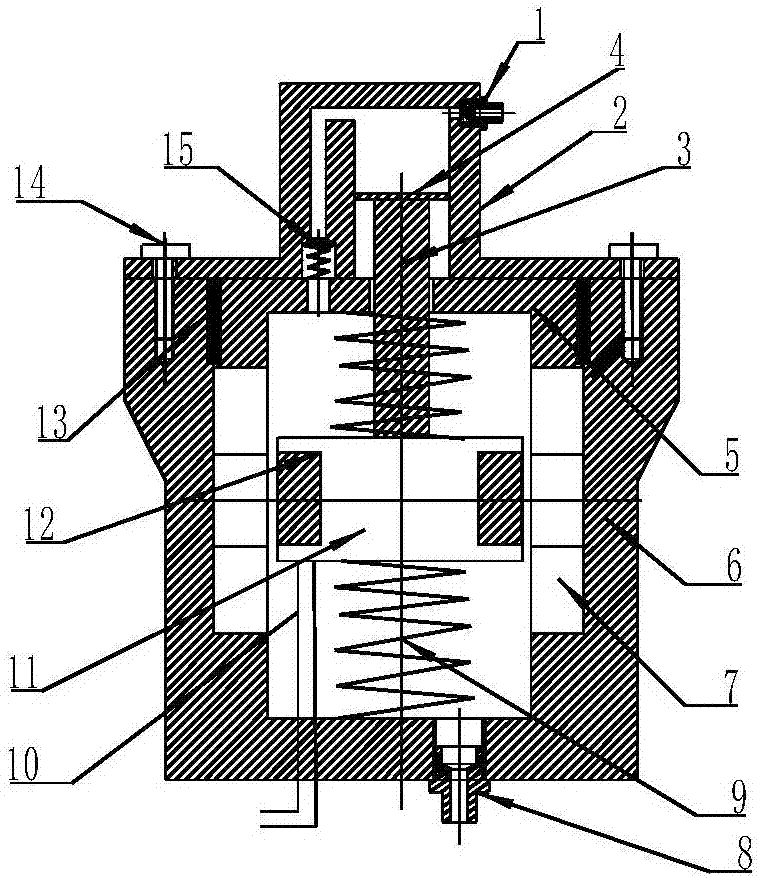

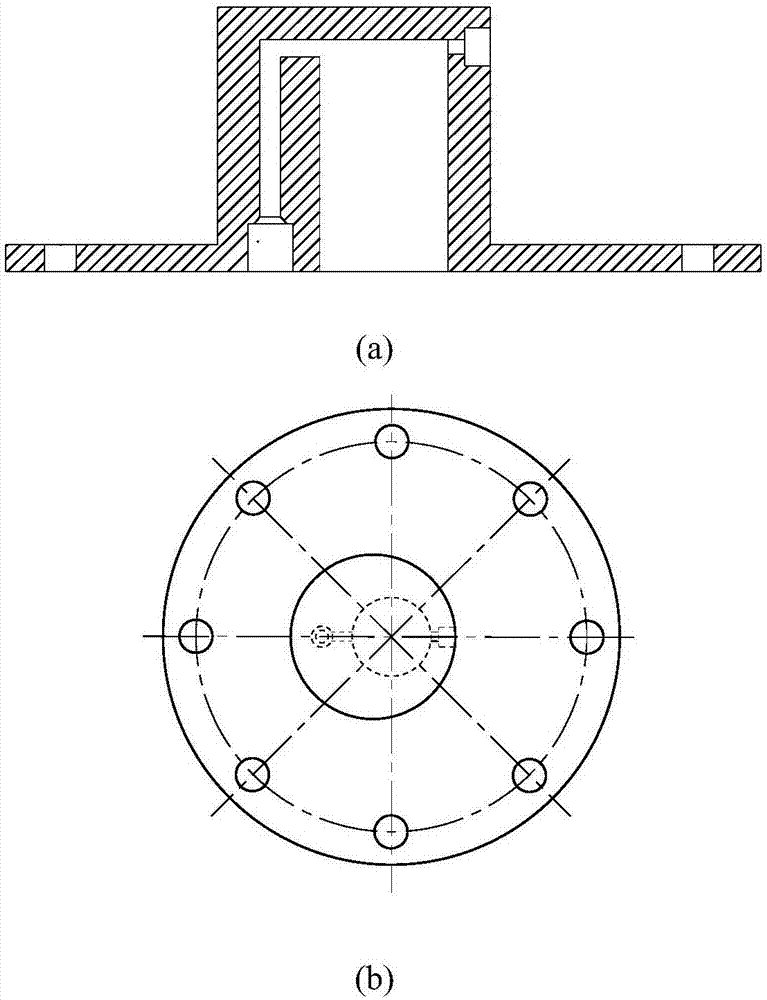

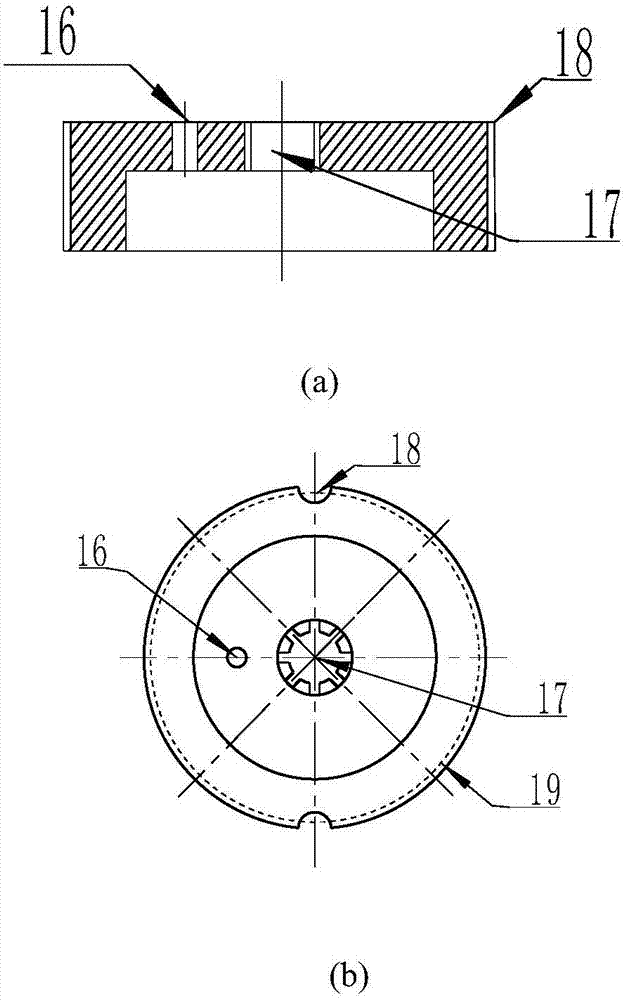

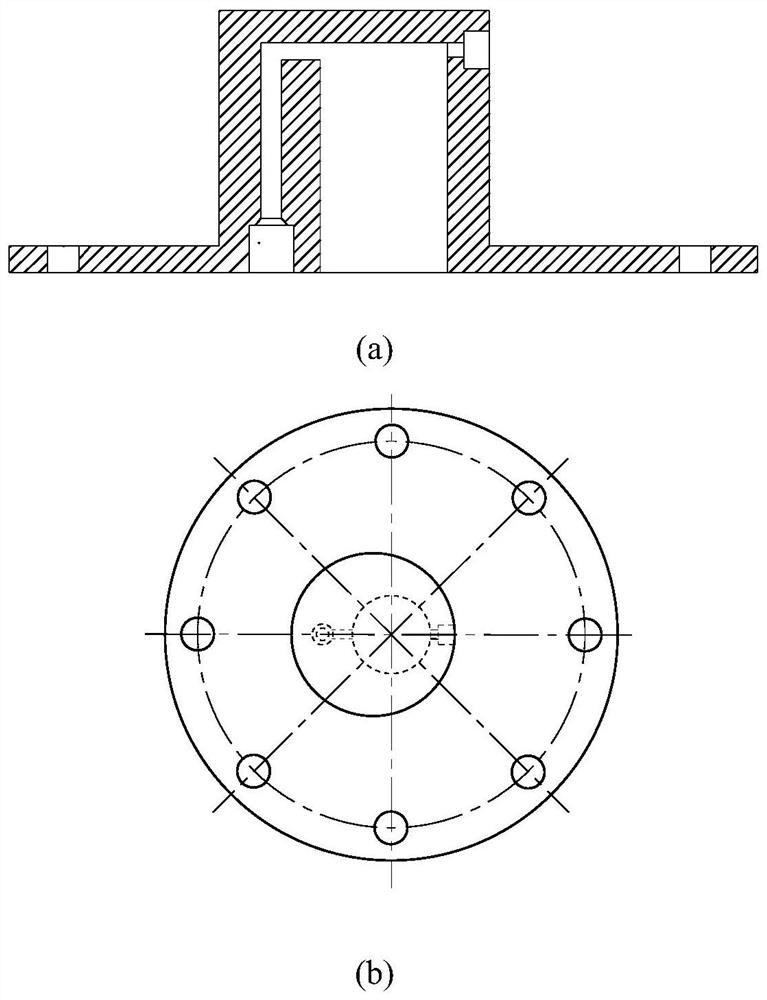

Moving coil type high frequency booster pump

ActiveCN107246342AWith preheating functionSmall pressure fluctuationsMachines/enginesThermal treatment of fuelHigh pressureConductor Coil

The invention discloses a moving coil type high frequency booster pump. The moving coil type high frequency booster pump comprises an oil inlet, an oil cylinder, a piston rod, a piston, a magnetic conductive cover, a pump body, permanent magnets, an oil outlet, a first spring, a second spring, a power line, a wire winding frame, a coil, a bolt, a one-way valve and an oil return hole, wherein the oil cylinder is connected with the pump body through the bolt; the magnetic conductive cover is arranged at the end opening of the pump body; the magnetic conductive cover is connected with the pump body through a thread; the one-way valve, the oil inlet, the piston and the piston rod are arranged on the oil cylinder; the oil return hole is formed in the magnetic conductive cover; the one-way valve communicates with the pump cavity through the oil return hole in the magnetic conductive cover; the first spring is arranged on the piston rod in the pump cavity in a sleeving manner; one end of the first spring is connected with the wire winding frame; one end of the second spring is connected with the wire winding frame, and the other end of the second spring is connected with the bottom of the pump body; the permanent magnets are arranged on the inner wall of the pump body; and the coil is wound on the wire winding frame. According to the moving coil type high frequency booster pump provided by the invention, the linear electromagnetic driving method is adopted, the structure is simple, the weight is light, the control is convenient, the driving capability is high, and a higher pressure can be further produced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

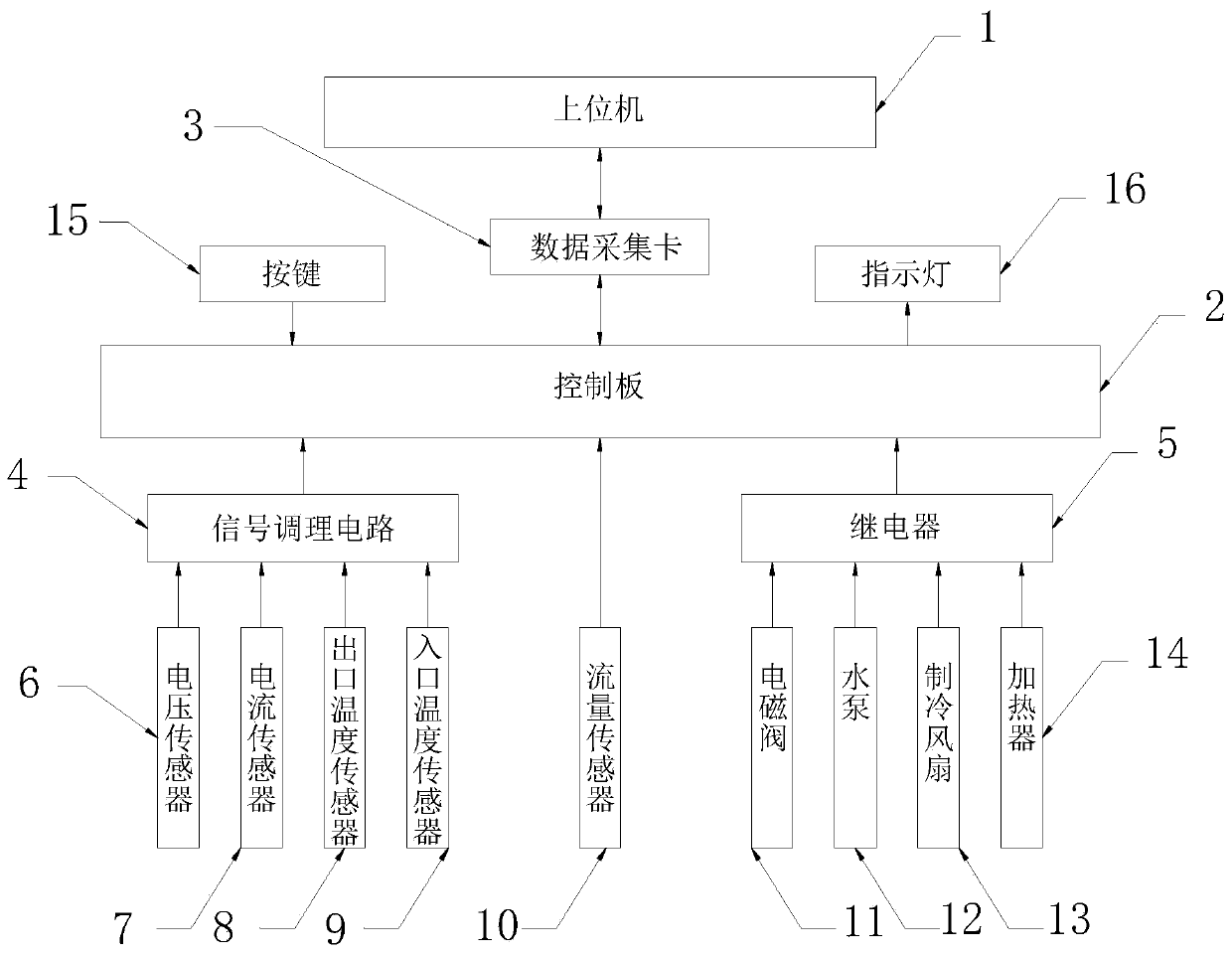

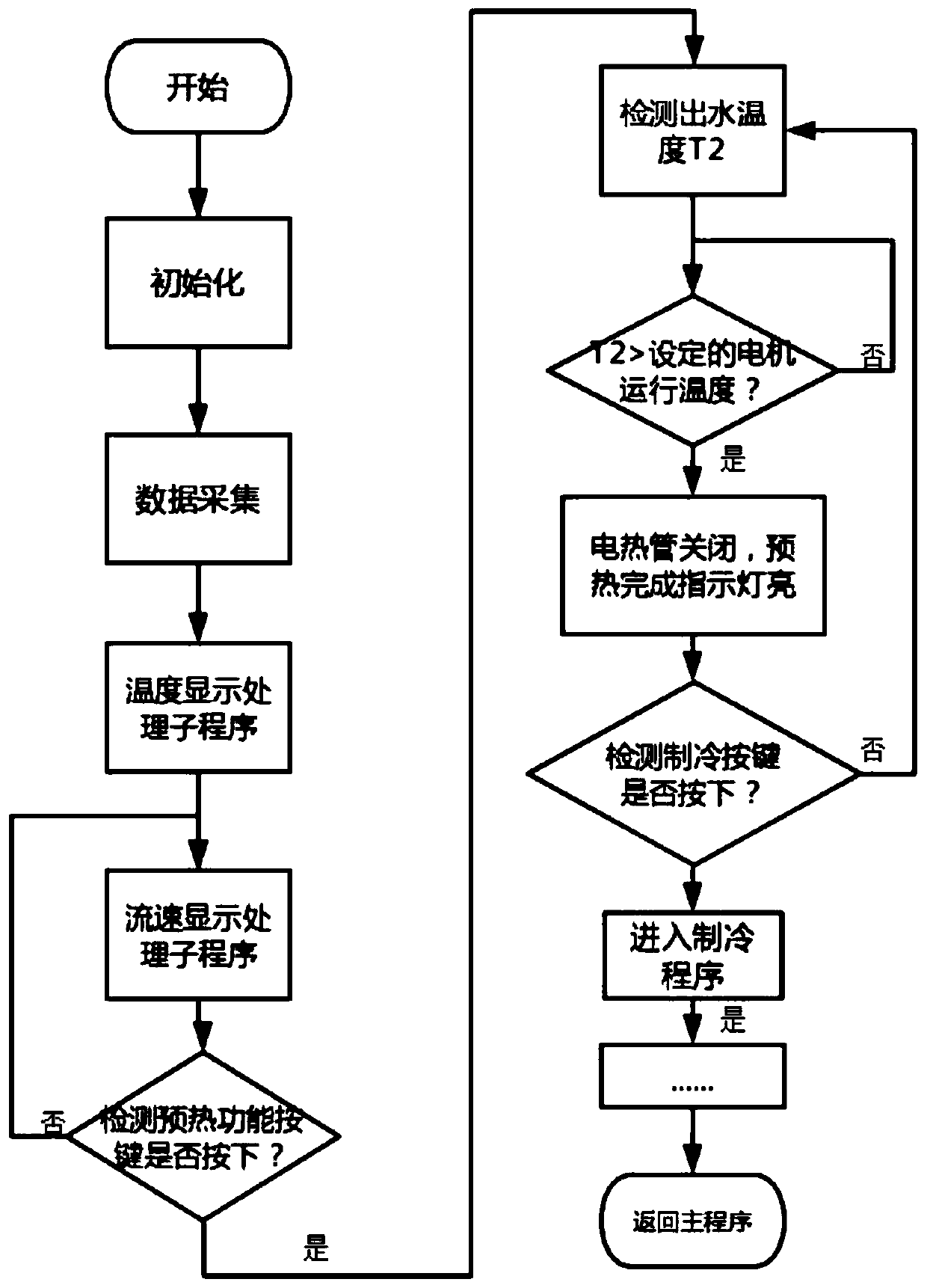

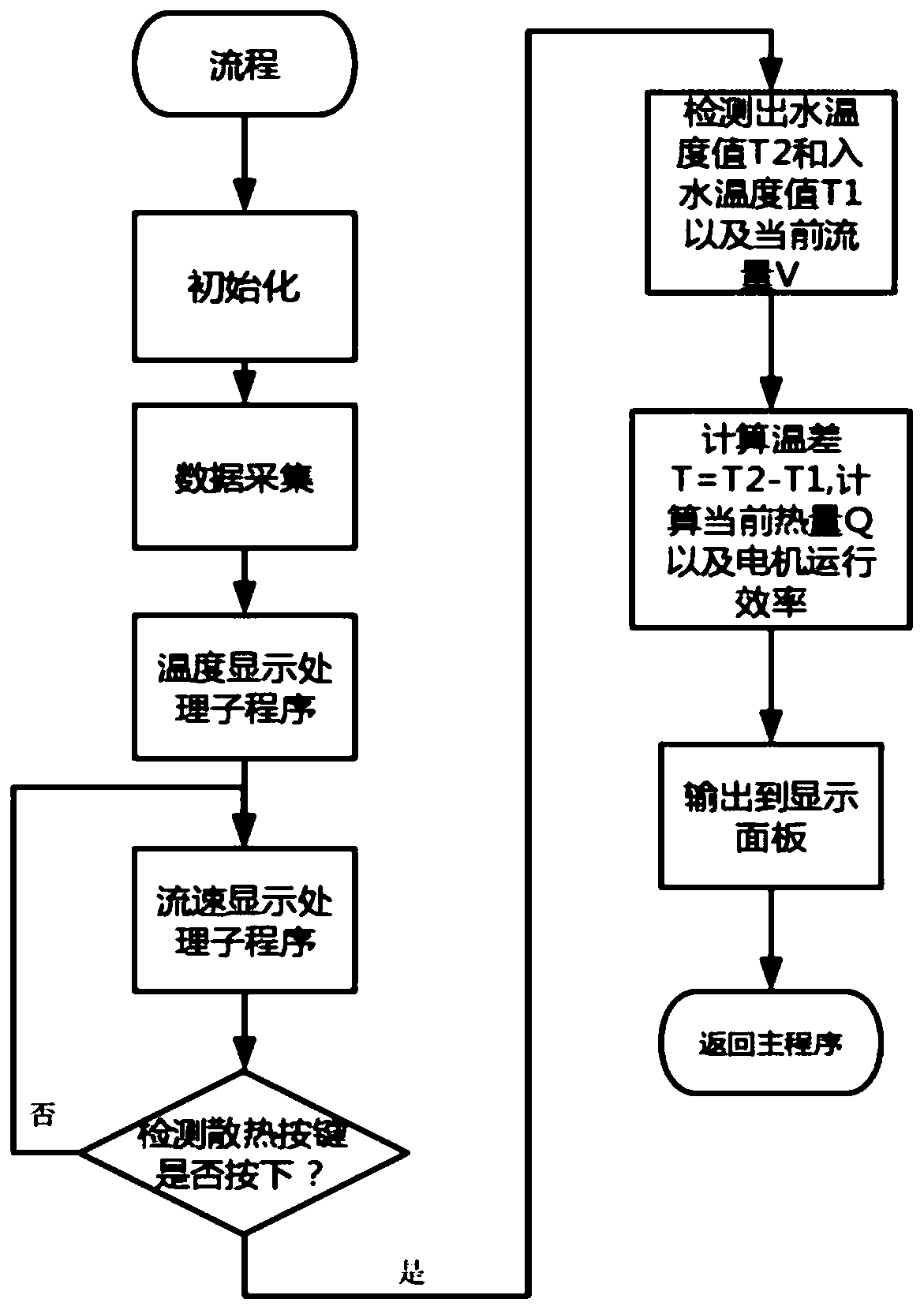

Motor power measurement and calculation system based on motor refrigeration

InactiveCN111562432AReduce wearGuaranteed safe operationManufacturing dynamo-electric machinesPower measurement by thermal methodsCurrent sensorData acquisition

The invention relates to the technical field of motor power measurement and calculation, and particularly discloses a motor power measurement and calculation system based on motor refrigeration. The system comprises an upper computer and a control panel. The upper computer is electrically connected with the control panel through a data acquisition card, and the control panel is electrically connected with a signal conditioning circuit, a relay, a flow sensor, a key and an indicator light; and the signal conditioning circuit is electrically connected with a voltage sensor, a current sensor anda temperature sensor, and the relay is connected with an electromagnetic valve, a water pump, a refrigeration fan and a heater. According to the invention, the heat power generated by motor operationis measured by using a cooling circulation system which must be adopted during motor operation, so that the motor operation power is calculated; the system also has a preheating function, and can preheat the motor when the environment temperature is too low, thereby reducing the wear of the motor, and guaranteeing the safe operation of the motor. Finally, a system which is low in cost, high in reliability and high in intelligent degree is formed.

Owner:HARBIN UNIV OF SCI & TECH

an injection mold

The invention discloses an injection mold which comprises an insert mounting part. The insert mounting part is provided with threaded holes and is mounted on the mold through a threaded connection manner. An insert mounting groove is formed in the insert mounting part. An insert locating part is arranged on the side edge of the insert mounting groove. A containing cavity is formed in the insert locating part. A limiting ball and a spring are arranged in the containing cavity. The spring abuts against the limiting ball so that the limiting ball can be in a working state. A heating body is arranged in the insert locating part. A prospect hole is formed in the bottom of the insert mounting groove. A hydraulic oil cavity is formed in the insert mounting part. The prospect hole is connected with the hydraulic oil cavity. An ejection block and a piston block are arranged in the hydraulic oil cavity. An ejection rod is arranged on the ejection block. The ejection rod can stretch out of the prospect hole, and therefore a metal insert is jacked up. The piston block is connected with a push rod, the push rod is driven by a motor to work, and therefore the piston block is driven to move. Compared with the prior art, according to the injection mold, the metal insert can be stably limited at a preset position, and the situation that the metal insert is separated, and consequently accidents happen is avoided.

Owner:ZHEJIANG BUSINESS TECH INST

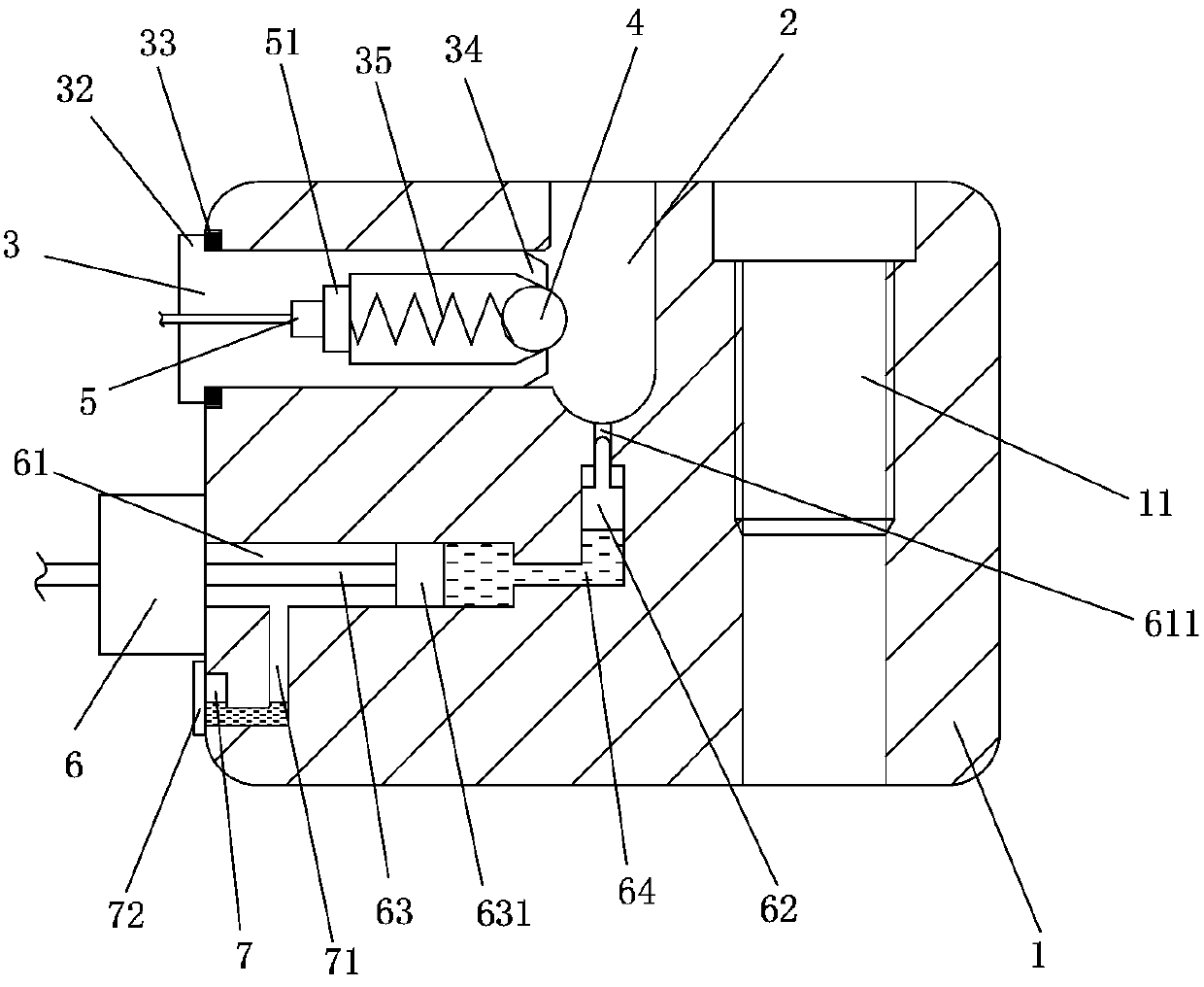

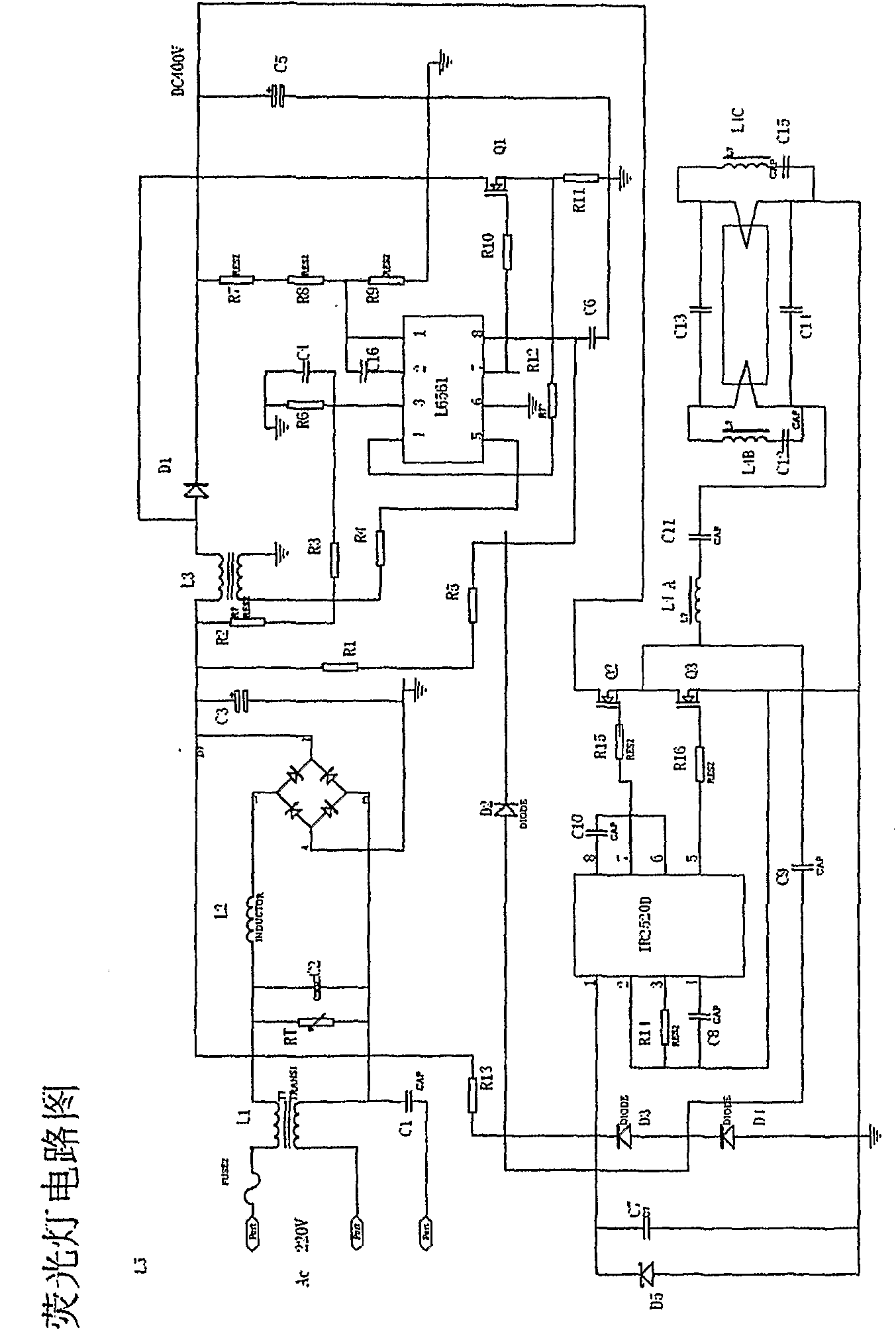

An electronic driver for a fluorescent lamp

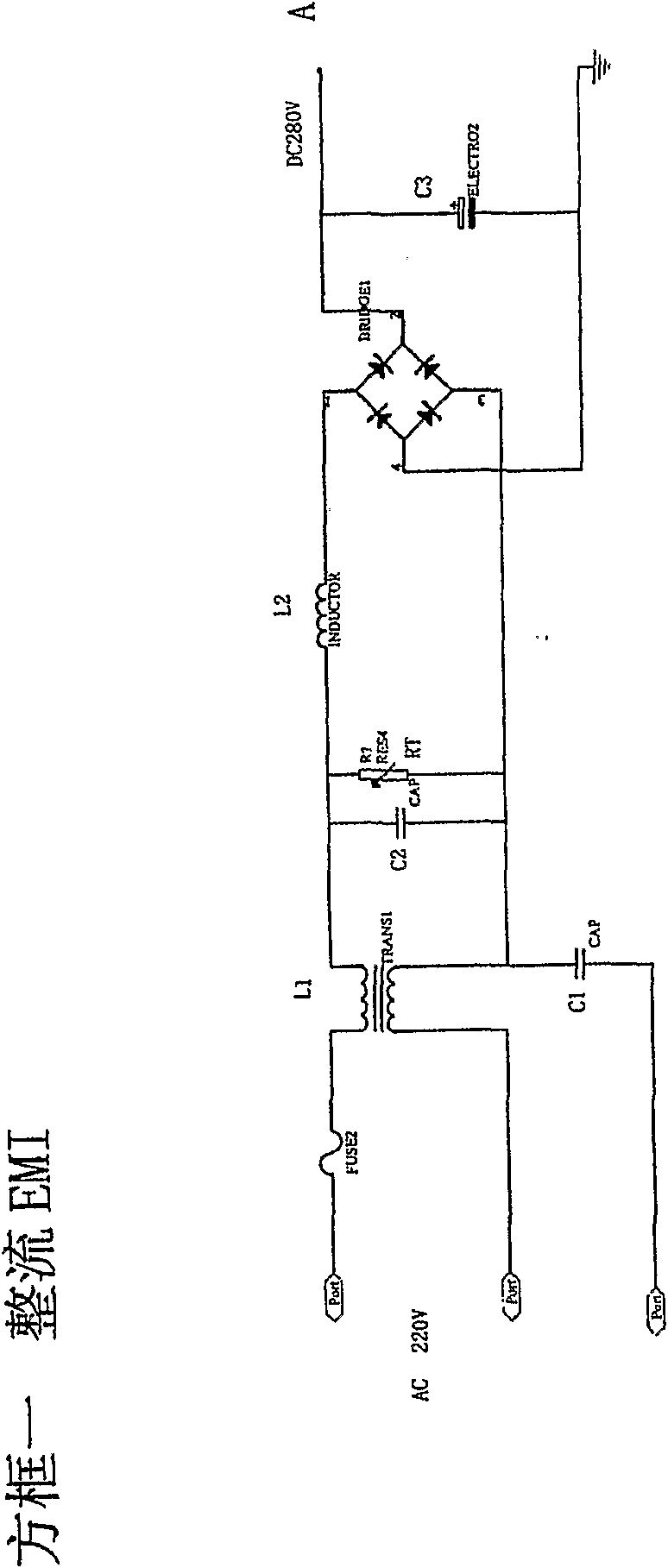

InactiveCN101427612BProtection against high frequency transientsStable output voltageElectrical apparatusElectric lighting sourcesOutput transformerDriver circuit

The present invention relates to an electric driver for fluorescent lamp, comprising an input circuit for rectifying and filtering an inputted alternating voltage with certain amplitude and a power factor correction circuit for further amplifying the voltage rectified and filtered by the input circuit to obtain a stable DC voltage with higher amplitude. The electric driver further comprises an output circuit for receiving the DC voltage outputted from the power factor correction circuit as its operating power supply, and providing the fluorescent lamp with an output without input transformer and without output transformer.

Owner:禤伟旗 +2

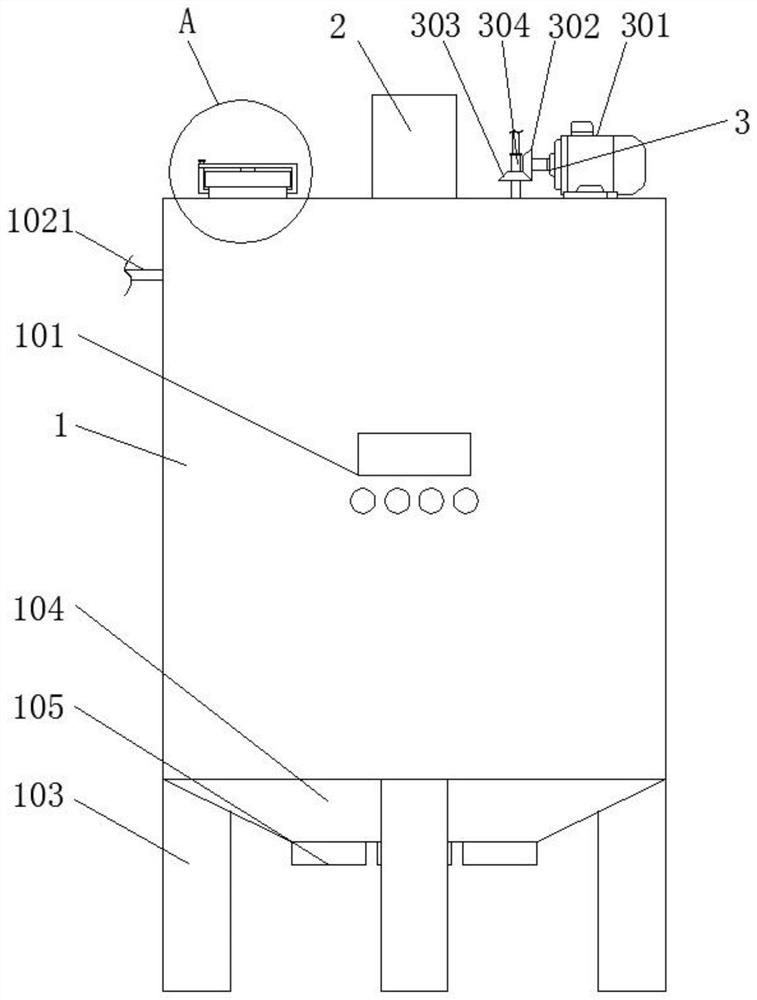

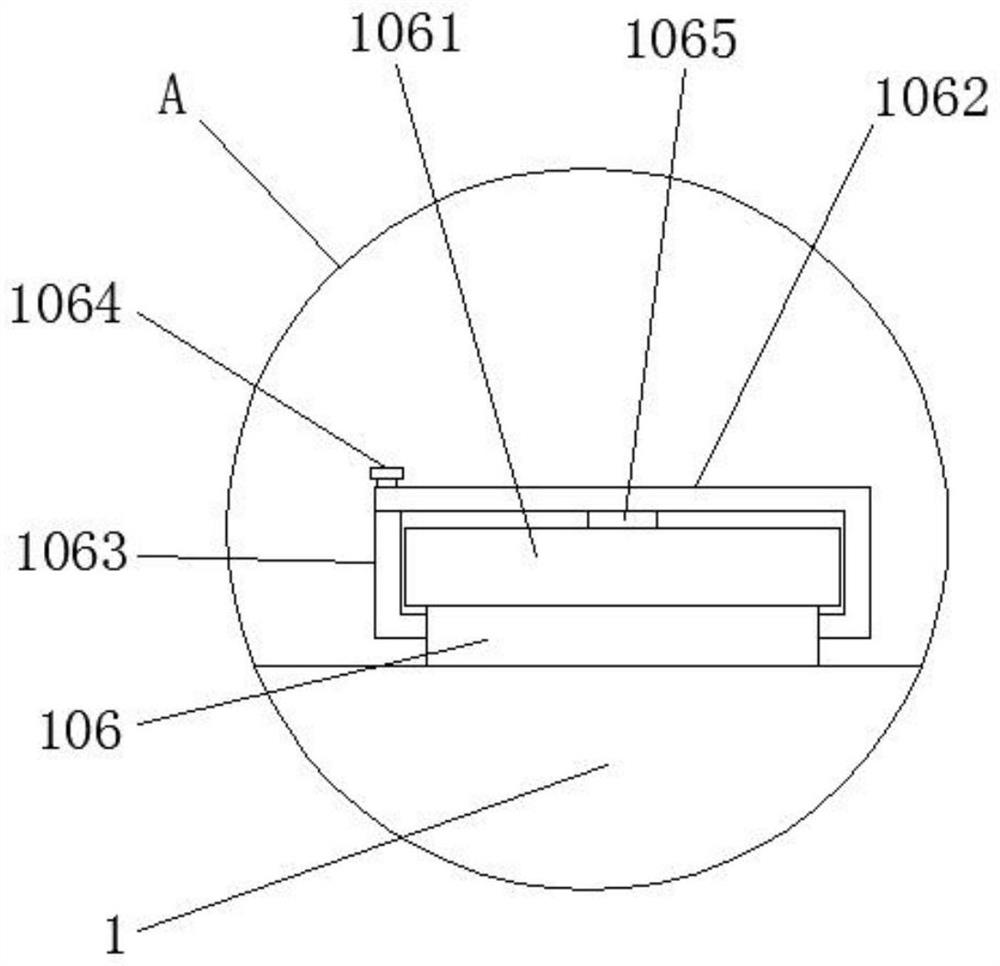

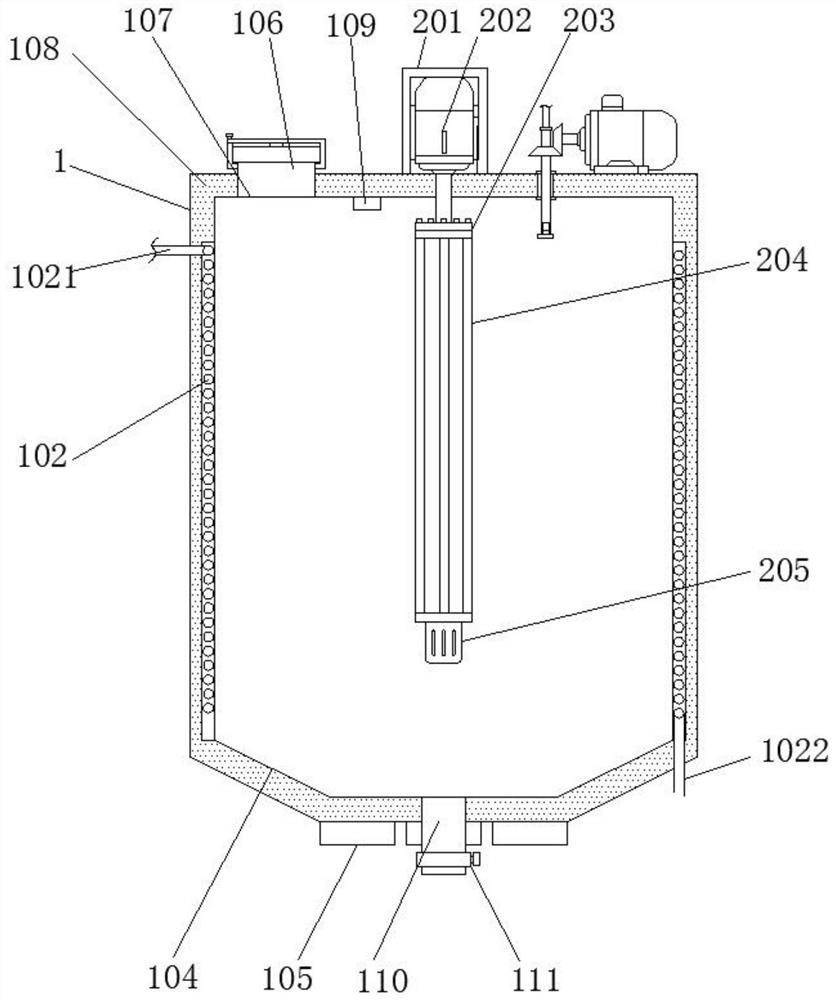

Emulsion cosmetic production emulsification tank with preheating function

PendingCN113522157AImprove efficiencyEasy to collectRotary stirring mixersMixing methodsElectric machineryEngineering

The invention discloses an emulsion cosmetic production emulsification tank with a preheating function. The emulsion cosmetic production emulsification tank comprises an emulsification tank body, an emulsification assembly and a cleaning assembly; the lower end of the emulsification tank body is an inclined tank bottom; a plurality of electric heating devices are fixedly mounted below the inclined tank bottom; a feeding port is formed in the left side of the top of the emulsification tank body; an inner shell is arranged in the emulsification tank body; a motor cover and a first motor of the emulsification assembly are arranged at the top of the emulsification tank body; a flange connector, a stirring shaft and an emulsifying machine of the emulsification assembly are arranged in the emulsification tank body; and the cleaning assembly is arranged at the top of the emulsification tank body. According to the emulsion cosmetic production emulsification tank with the preheating function, the electric heating device is arranged and installed at the bottom of the inclined tank bottom; and before materials are added into the emulsification tank body, the electric heating devices are started through the control panel to preheat the bottom of the emulsification tank body, and then the emulsification tank body is used for processing, so that the emulsification efficiency is improved.

Owner:江苏德康医疗器械有限公司

A kind of electroslag smelting method

The invention discloses an electroslag smelting method, which is characterized in that two sets of electrode devices are arranged beside a crystallizer, and then the two sets of electrode devices are smelted by using the crystallizer in turn, during the smelting process of one electrode device, the other electrode device The device performs the work of installing electrodes and preheating the electrodes. When the electrode device used for smelting is smelted and the electrodes are removed, re-feeding and the crystallizer are arranged, the preheated electrodes are moved into the crystallizer for smelting, and so on. Realize high-efficiency electroslag smelting. The invention has the advantages of high smelting efficiency, good safety, excellent smelting effect, safety, high efficiency and energy saving, and improves the smelting quality of electroslag steel ingots; at the same time, the bottom water tank is very convenient for maintenance and replacement, reduces maintenance costs, and improves cooling efficiency.

Owner:宝武特冶航研科技有限公司

Electroslag smelting electric furnace device

ActiveCN104831083BIncrease profitLow machining accuracy requirementsIncreasing energy efficiencyElectricitySlag

The invention discloses an electric furnace system for electroslag metallurgy, comprising a crystallizer in a furnace shape and an electrode unit disposed on one side of the crystallizer. The lower end of the crystallizer is provided with a bottom water tank used for cooling. The electric furnace system further comprises an electrode preheater located on one side of the electrode unit; the electrode preheater comprises a shell; refractory insulating material is disposed within the shell, and the shell is centrally provided with a heating chamber which is vertically set, the upper end of which is open and which allows insertion of the lower end of an electrode; an inductive coil spirally and liftably around the heating chamber is buried in the refractory insulating material, forming a heater. The electric furnace system with a preheating function is high in smelting efficiency, good in safety, good in smelting effect, safe, efficient and energy saving; smelting quality of slag ingots is improved; the bottom water tank is convenient to maintain and change, maintenance cost is lower, and cooling efficiency is improved.

Owner:宝武特冶航研科技有限公司

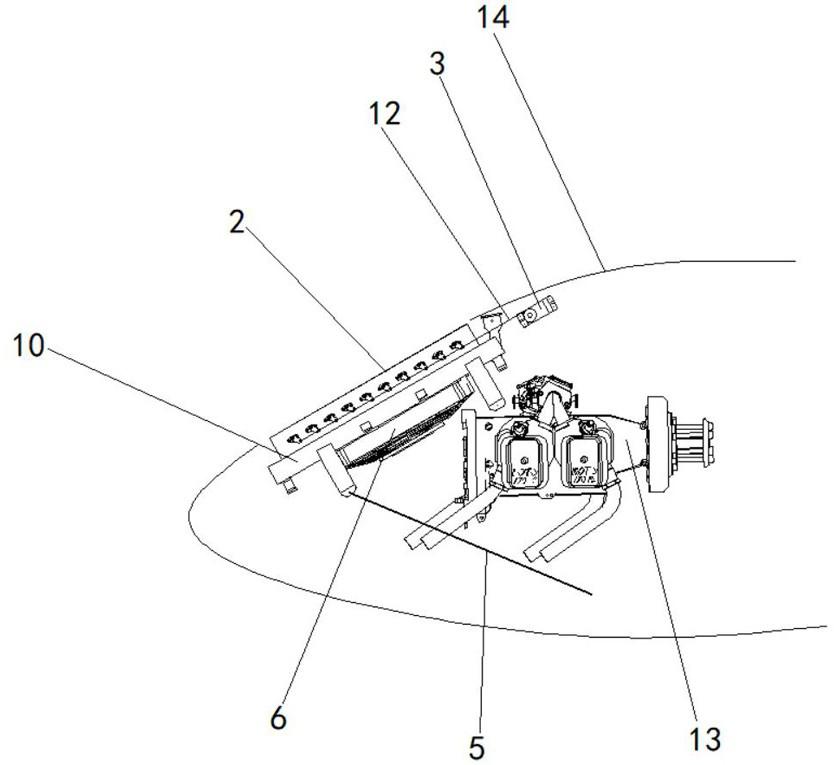

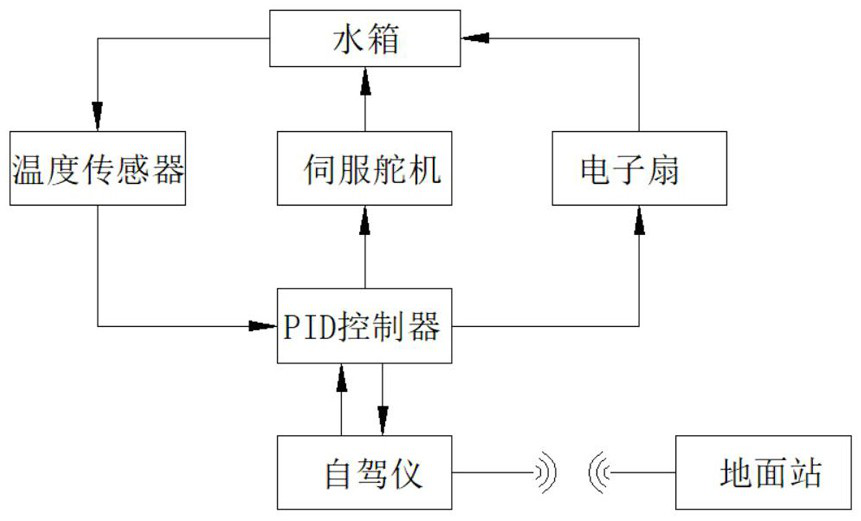

Intelligent temperature control system of UAV engine and its realization method

ActiveCN110318856BReduce loadImprove cooling efficiencyPower plant cooling arrangmentsCoolant flow controlCooling effectHeater Rod

The invention discloses an intelligent temperature control system of an unmanned aerial vehicle engine and an implementation method of the intelligent temperature control system, relates to the technical field of unmanned aerial vehicle engines, and in particular to an unmanned aerial vehicle engine liquid cooling (water cooling and oil cooling) temperature control system and an implementation method thereof. The intelligent temperature control system comprises an intelligent water tank assembly installed on a machine head portion of an unmanned aerial vehicle and a PID controller integrated in an unmanned aerial vehicle self-driving instrument, wherein the intelligent water tank assembly comprises a water tank, a shutter movable assembly arranged at the top of the water tank and an electronic fan arranged at the bottom of the water tank, the water tank is arranged above the engine and is connected with the engine, a temperature sensor is arranged at the water inlet of the water tank,a heating rod is arranged at the water outlet of the water tank, a servo motor in the heating rod, the temperature sensor, the shutter movable assembly and an electronic fan are connected with the PIDcontroller, and the PID controller completes real-time data transmission communication with the ground end through a radio station inside the unmanned aerial vehicle self-driving instrument. The system has the positive effect on improving the cooling effect of the unmanned aerial vehicle engine.

Owner:青岛未来创新高新技术有限公司

A film tearing device for curved glass cover plate of automobile instrument

ActiveCN112173324BWith preheating functionThe film tearing process is convenient and quickLamination ancillary operationsLaminationGlass coverEngineering

Owner:HEILONGJIANG TIANYOUWEI ELECTRONICS CO LTD

A sleeve-type freshwater sea-salt cogeneration system

InactiveCN105836829BShorten the concentration timeFast outputSeawater treatmentSpecific water treatment objectivesFresh water organismWater vapor

The invention discloses a sleeve type fresh water sea salt coproduction system, which comprises a heating cylinder (5), a seawater storage layer (3) and a fresh water storage layer (2) in sequential arrangement from inside to outside, wherein a sealing piston (15) capable of doing vertical and reciprocating movement is arranged inside the heating cylinder (5); a piston rod of the sealing piston (15) sequentially passes out of the top ends of the heating cylinder (5), the seawater storage layer (3) and the fresh water storage layer (2) to be connected with a mechanical transmission mechanism (14); the bottom of the heating cylinder (5) is of a funnel-shaped structure; the funnel-shaped structure sequentially passes through the back ends of the seawater storage layer (3) and the fresh water storage layer (2), and then, an opening is right aligned with a salt storage tank (9); a sweater inlet and a water vapor outlet (7) are formed in the wall of the heating cylinder (5). The sleeve type fresh water sea salt coproduction system provided by the invention has the advantages that materials are taken in site; reproducible energy sources are used in a way of taking actions that suit local circumstances to realize the combined production of fresh water and sea salt; the structure is compact; the cost is low; the energy is saved; the environment is protected.

Owner:HOHAI UNIV CHANGZHOU

Medicinal material drying device

InactiveCN110608596AFast drying operationEffective dryingDrying gas arrangementsDrying machines with progressive movementsPulp and paper industryMaterials processing

The invention relates to the technical field of medicinal material processing, in particular to a medicinal material drying device which comprises an oven and a conveying belt. The left side and the right side of the oven are each provided with an opening for the conveying belt to pass through. The top of the right side of the oven is provided with a hot air inlet. The bottom of the left side of the oven is provided with an air outlet. Carpet guide rollers for supporting the conveying belt are arranged in the oven. By means of the medicinal material drying device, a medicinal material can be rapidly dried; meanwhile the whole medicinal material drying device is simple in structure and low in cost; by further arranging partition plates, the hot air temperature is gradually increased in theconveying direction of the conveying belt, the medicinal material can be effectively dried and can also be slowly dried step by step instead of being directly dried at a high temperature, and the medicinal material drying device has a preheating function on the medicinal material and ensures the drying operation in the medicinal material.

Owner:四川聚泉生物科技有限公司

Moving coil high frequency booster pump

ActiveCN107246342BWith preheating functionSmall pressure fluctuationsMachines/enginesThermal treatment of fuelEngineeringOil intake

The present invention proposes a moving-coil high-frequency booster pump, which includes an oil inlet, an oil cylinder, a piston rod, a piston, a magnetically conductive cover, a pump body, a permanent magnet, an oil outlet, a first spring, a second spring, a power cord, Winding frame, coil, bolt, one-way valve, oil return hole, oil cylinder and pump body are connected by bolts, magnetically conductive cover is set at the port of pump body, magnetically conductive cover and pump body are connected by thread, and oil cylinder is provided with One-way valve, oil inlet, piston and piston rod, oil return hole is set on the magnetic conduction cover, the one-way valve communicates with the pump chamber through the oil return hole on the magnetic conduction cover, the first spring is sleeved in the pump chamber On the piston rod, one end of the first spring is connected to the winding frame, one end of the second spring is connected to the winding frame, and the other end is connected to the bottom of the pump body. The permanent magnet is arranged on the inner wall of the pump body, and the coil is wound on the winding frame. The moving-coil high-frequency booster pump of the present invention adopts the linear electromagnetic drive mode, has simple structure, light weight, convenient control, strong driving ability, and can generate higher pressure.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Road roller and its sprinkler system

ActiveCN104099852BWith preheating functionAdapt to temperatureRoads maintainenceControl systemSprinkler system

The invention discloses a road roller and a water spraying system thereof. The water spraying system comprises a water tank, a water pump and a spraying device, and further comprises a preheating device, wherein the preheating device is arranged on a pipeline between the water pump and the spraying device, and is used for preheating the cold water sprayed by the spraying device; a water temperature control system is connected with the preheating device and is used for detecting the water temperature and controlling the flowing speed. The water spraying system provided with the preheating function can prevent cold water from being directly sprayed onto a vibration wheel of the road roller, so as to prevent the influence of vibration wheel on the pavement construction temperature, prevent the construction material from being stuck onto the vibration wheel to influence the construction quality and enhance the cleaning difficulty.

Owner:HUNAN SANY ROAD MACHINERY

A glass fiber cloth composite machine with preheating function

ActiveCN107116890BImprove activity stabilityEnsure safetyLamination ancillary operationsLaminationGlass fiberEngineering

The invention provides a glass fiber fabric compounding machine with a pre-heating function and belongs to the technical field of machinery, aiming at solving the problem that an existing glass fiber fabric is easy to degum after being compounded. The glass fiber fabric compounding machine with the pre-heating function comprises a rack which is horizontally and transversely arranged, wherein a controller is arranged on the bottom surface of the rack; the rack is sequentially provided with a feeding device, a pre-heating device, a gumming device, a compound drying device, a heat dissipation device and a winding frame; the feeding device comprises a first feeding roller and a second feeding roller, which are independent to each other; the gumming device comprises a gumming box; the gumming box is internally provided with a first gumming roller and a second gumming roller; the pre-heating device comprises a first pre-heating roller and a second pre-heating roller. The glass fiber fabric compounding machine provided by the invention is used for pre-heating raw materials of the glass fiber fabric, so that glue can completely permeate into the raw materials of the glass fiber fabric in a gumming process, furthermore, the sticking fastness of the glass fiber fabric in a production process is ensured and the quality of the glass fiber fabric is improved.

Owner:浙江凯澳新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com