A plastic granule feeding machine

A technology of plastic granules and feeding machine, applied in the field of feeding machine, can solve the problems of complex structure of preheating feeding machine, prolonging the processing and production time, and inability to achieve the preheating effect, so as to achieve good preheating effect and shorten the processing and production time , The effect of facilitating heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

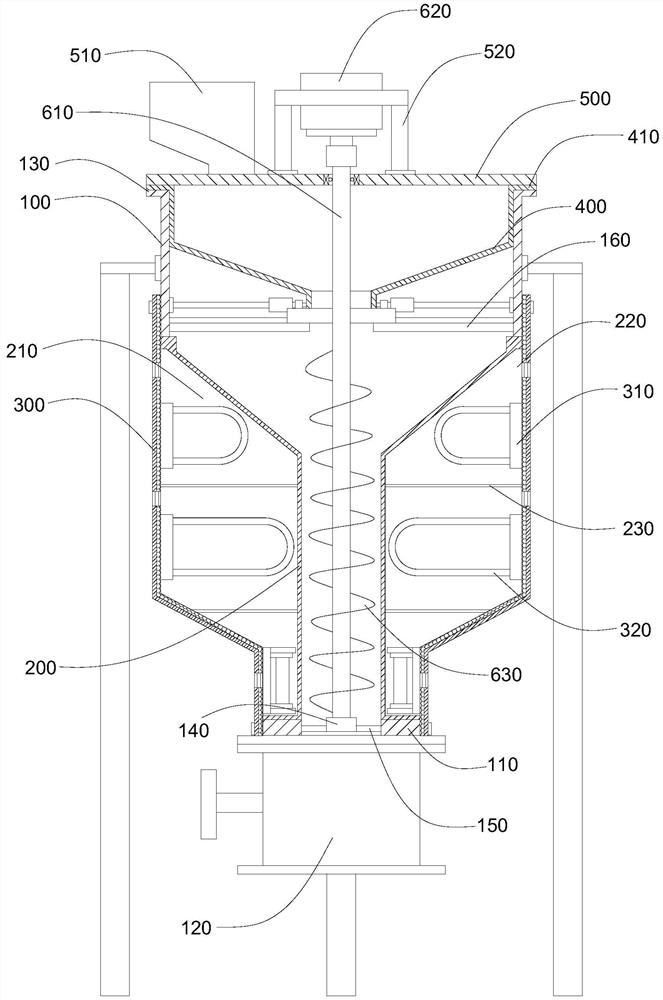

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

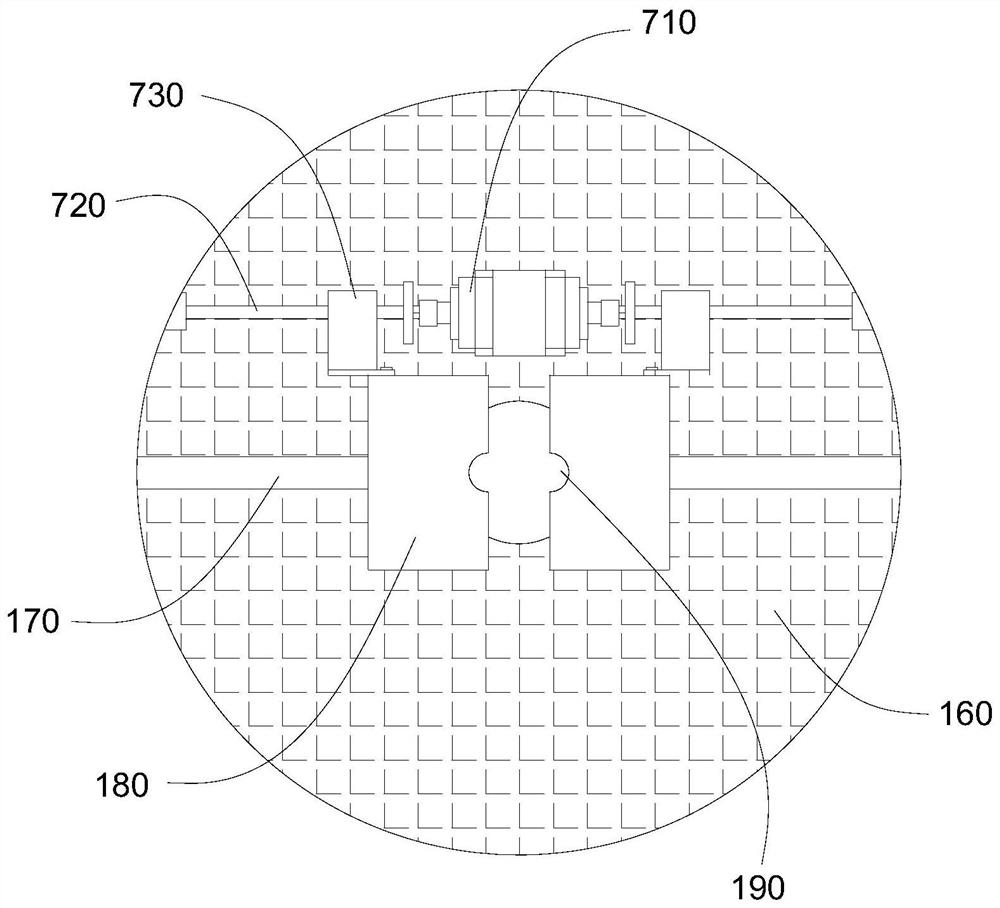

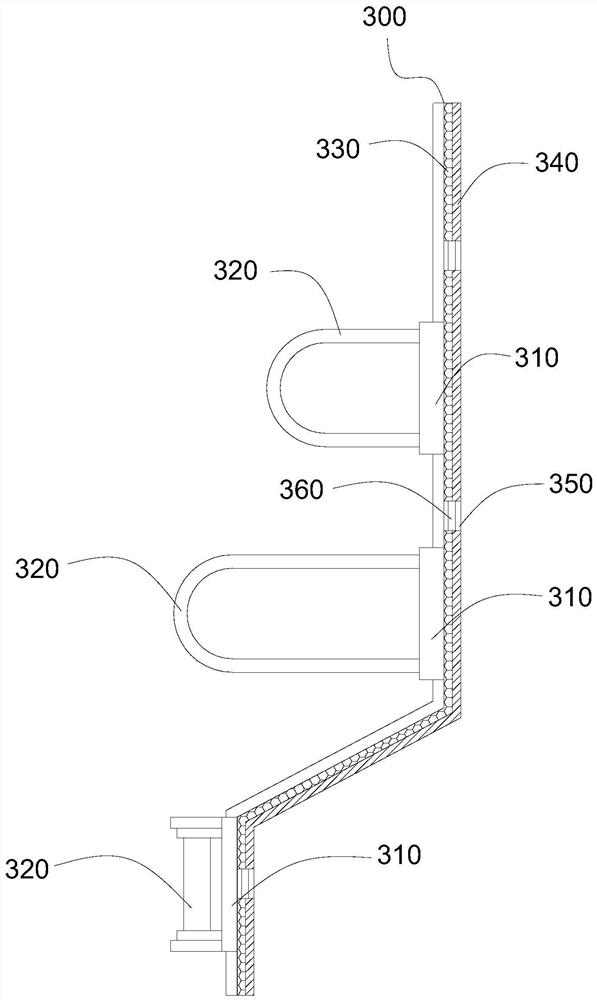

[0023] like figure 1 , figure 2 As shown, a plastic granule feeder is disclosed in a specific embodiment of the present invention, which includes a barrel body 100, the bottom of the barrel body 100 is connected with a feeding pipe 110, and the feeding pipe 110 is provided with a feeding pipe 110. Valve 120, the inner wall of the barrel body 100 is fixed with a plurality of vertically arranged heat conduction plates 200, the width of the heat conduction plates 200 is smaller than the radius length of the inner wall of the barrel body 100, and the plurality of heat conduction plates 200 wrap around the The axis of the barrel body 100 is distributed in a circular array, and the side wall of each heat conducting plate 200 away from the axis of the barrel body 100 is fixedly connected with the inner w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com