Moving coil high frequency booster pump

A booster pump, moving coil technology, applied in engine components, machines/engines, charging systems, etc., can solve the problems of low fuel pressure, complex structure, complex control, etc., and achieve the effect of improving efficiency and fuel pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

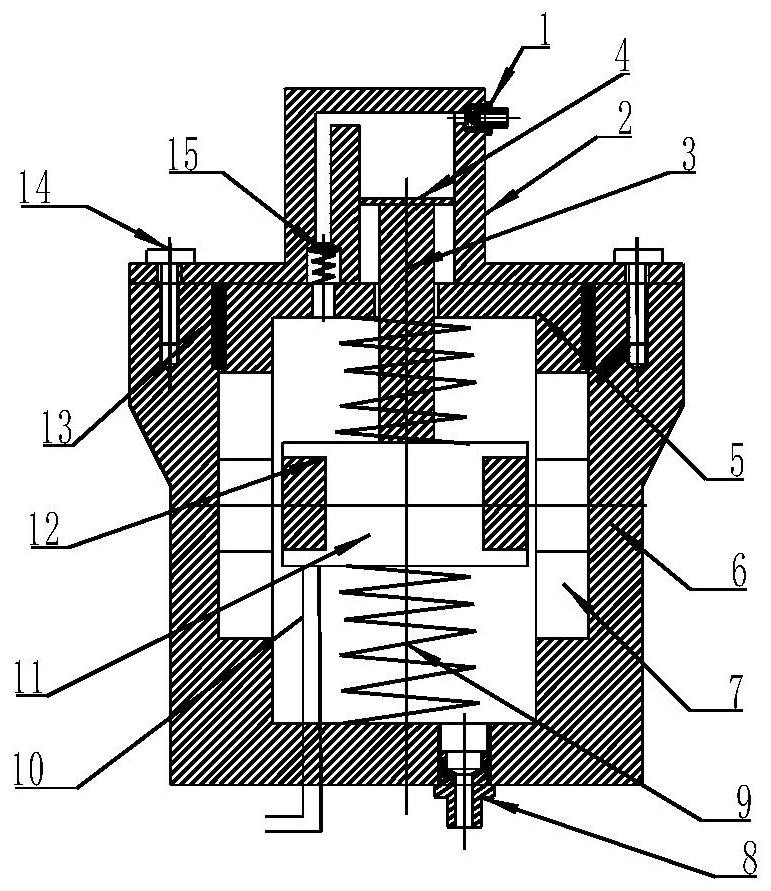

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

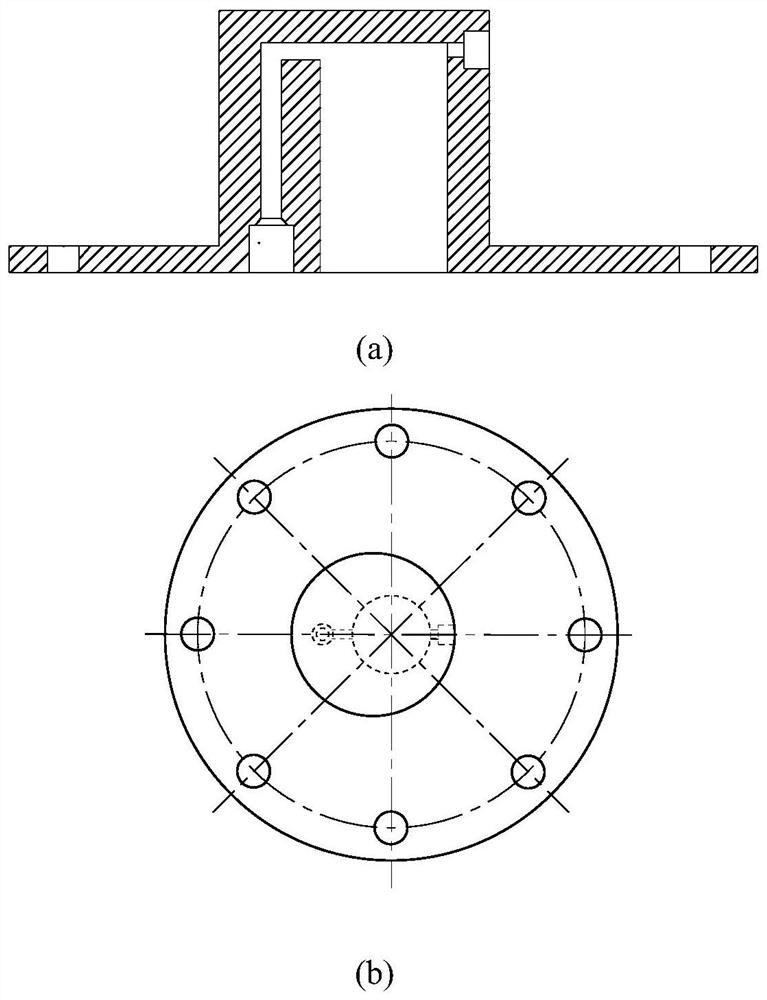

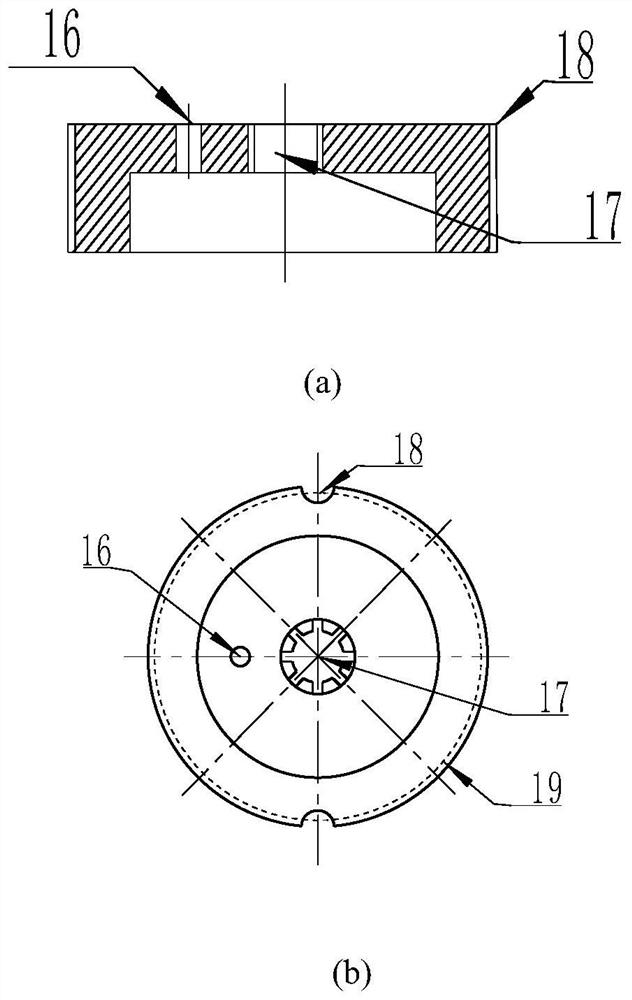

[0018] A moving-coil high-frequency booster pump, comprising an oil inlet 1, an oil cylinder 2, a piston rod 3, a piston 4, a magnetically conductive cover 5, a pump body 6, a permanent magnet 7, an oil outlet 8, a first spring, and a second spring 9. Power line 10, winding frame 11, coil 12, bolts 14, check valve 15, oil return hole 16, the oil cylinder and the pump body are connected by bolts, the magnetically conductive cover 5 is set at the port of the pump body 6, and the guide The magnetic cover and the pump body are connected by threads, image 3 The middle 19 is the middle diameter of the thread, and the oil cylinder is provided with a check valve, an oil inlet 1, a piston and a piston rod 3, and an oil return hole 16 is arranged on the magnetic conductive cover, and the check valve passes through the oil return hole 16 on the magnetic conductive cover. It com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com