Helical feeder

A technology of screw feeding and screw blades, which is applied in the field of screw feeders, can solve problems affecting production speed and production efficiency, increasing production costs, affecting the appearance or quality of finished products, and achieving high production efficiency, good sealing, and small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

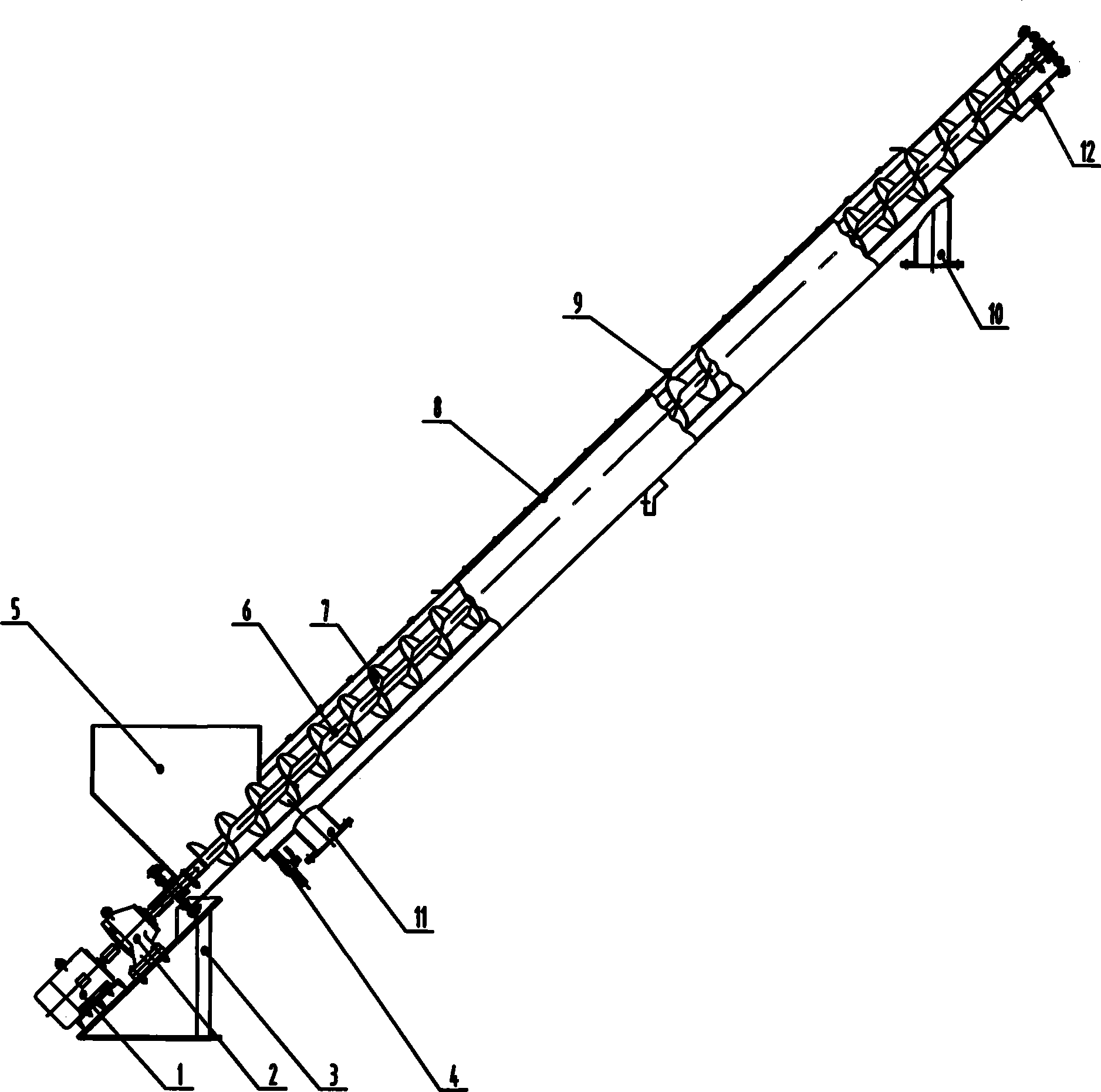

[0011] Referring to the drawings, a screw feeder includes a motor 1 , a reducer 2 , a motor frame 3 , a drain valve 4 , a screw feed shaft 6 , a screw blade 7 , a material channel and a casing 8 . The motor 1 is connected to the reducer 2 and the screw feeding shaft 6 in sequence. The screw feeding shaft 6 is installed in the material channel and the casing 8, and the screw feeding shaft 6 is provided with a spiral blade 7 along the axis. The material inlet 5 is installed on the upper part of the lower end of the material channel and the casing 8, the drain valve 4 and the gas outlet 11 are installed at the lower part, the observation port 9 is installed in the middle section of the material channel and the outer casing 8, and the gas inlet 10 and the material outlet 12 are installed at the upper end. A material inlet 12 is installed at the lower part, a motor frame 3 is installed under the material inlet 12 , and a motor 1 and a reducer 2 are installed on the motor frame 3 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com