an injection mold

A technology of injection molds and inserts, applied in the direction of coating, etc., can solve the problems of reducing product quality, unable to work, affecting production and processing work, etc., to achieve the effect of improving injection molding ability and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

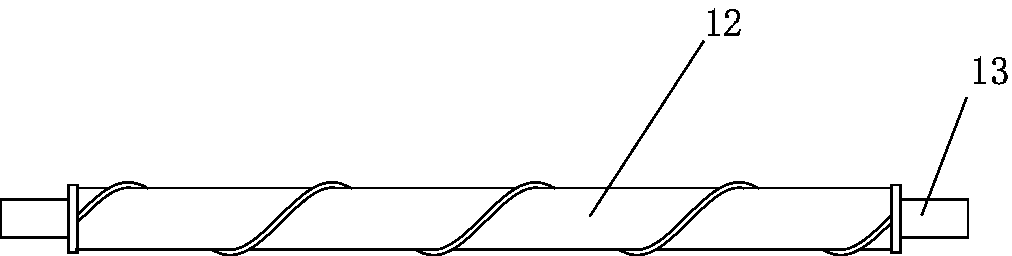

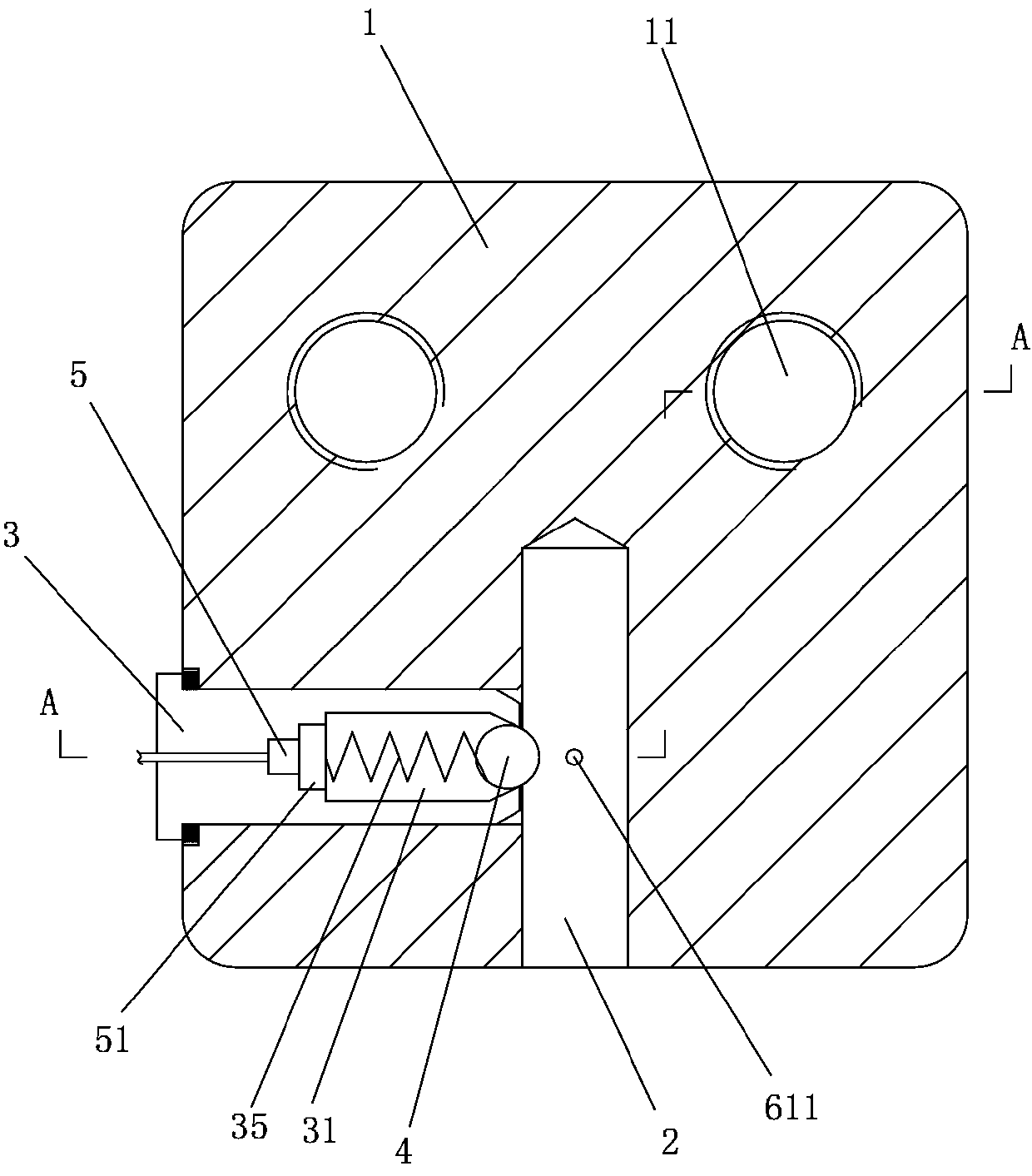

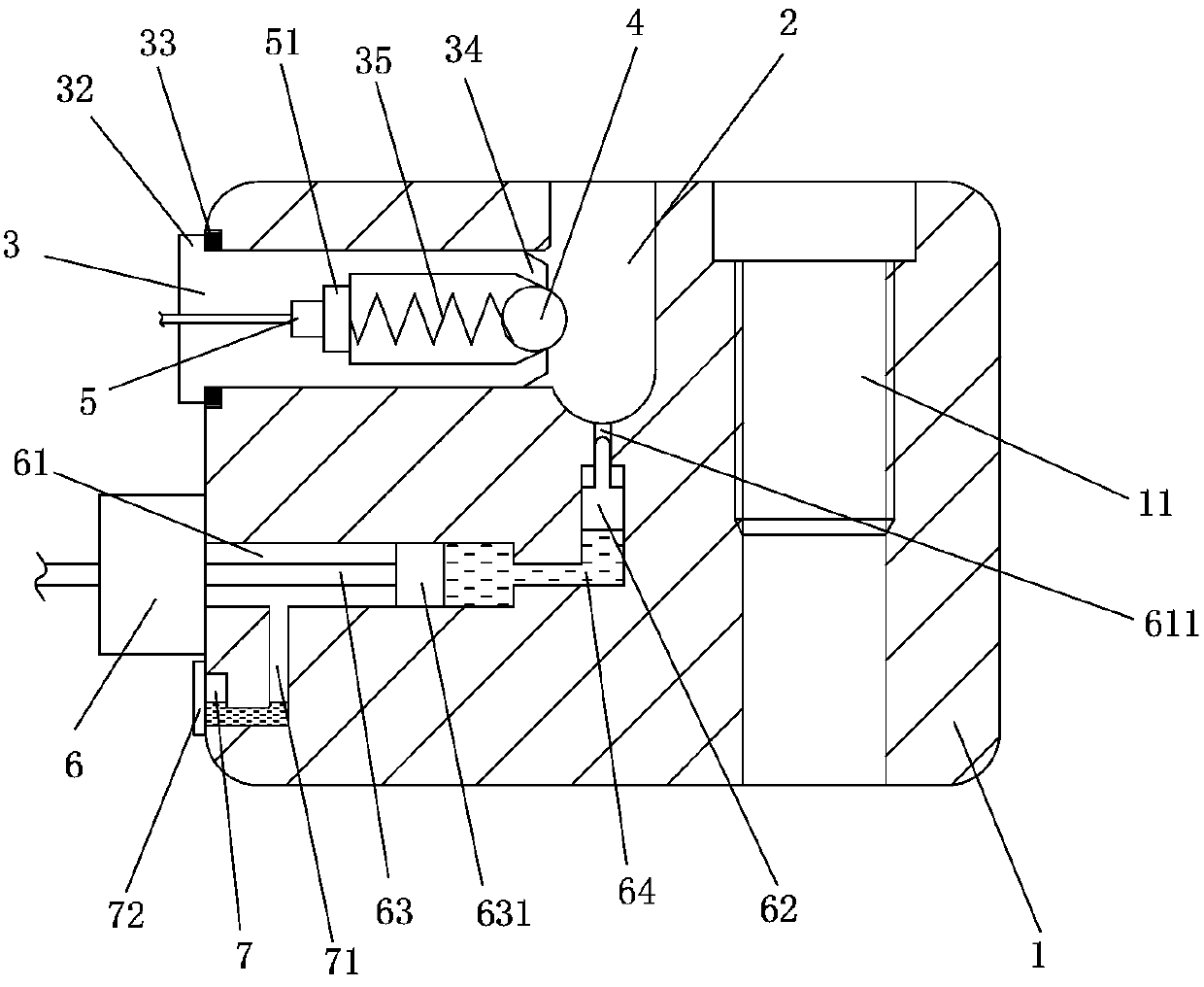

[0014] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail: Figure 1 to Figure 3 As shown, an injection mold includes an insert installation part 1. The insert installation part 1 is provided with a threaded hole 11 and is installed on the mold by a threaded connection. The insert installation part 1 is provided with an insert The mounting groove 2, the insert positioning part 3 is arranged on the side of the insert mounting groove 2, and the insert positioning part 3 is provided with a storage cavity 31, and a limit ball 4 and a spring are arranged in the storage cavity 31 35, the spring 35 bears against the limit ball 4 to make it in a working state, the insert positioning part 3 is provided with a heating body 5, and the heating body 5 heats the thermal conductor 51 and then passes through the spring 35 The heat is transferred to the limit ball 4 so that the limit ball 4 can heat the metal insert ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com