Intelligent boiler of coffee maker

A coffee machine and boiler technology, applied in the field of coffee machine intelligent boiler, can solve problems such as large temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

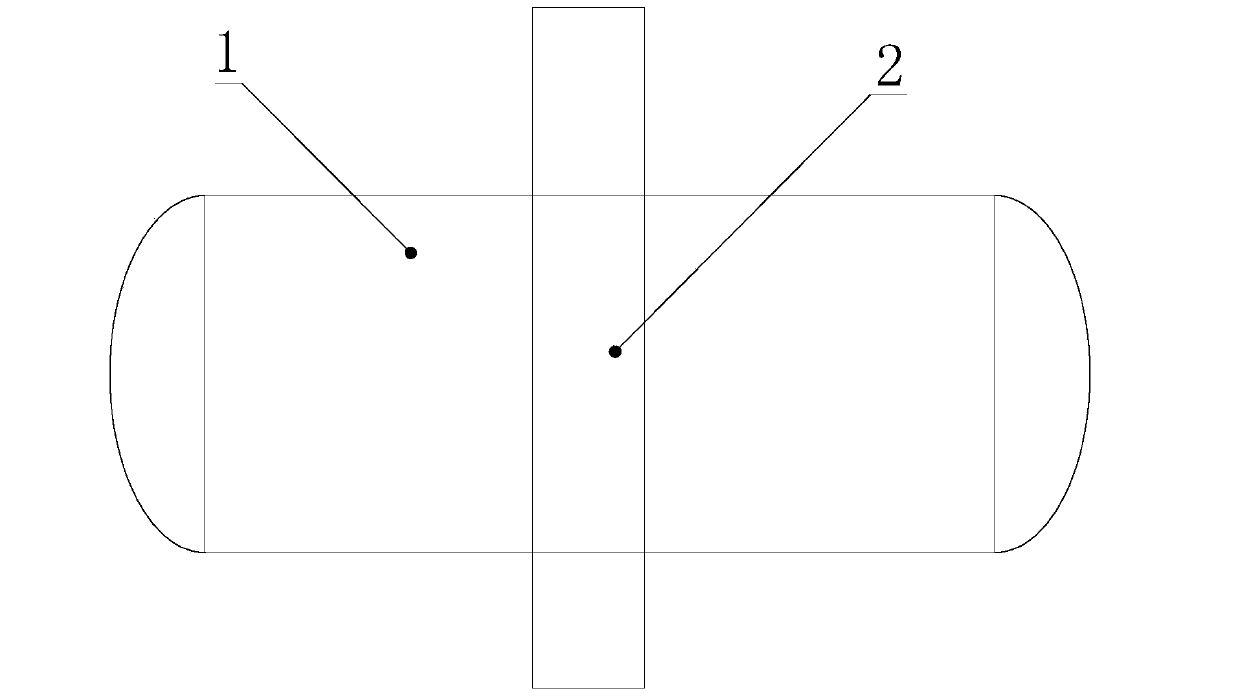

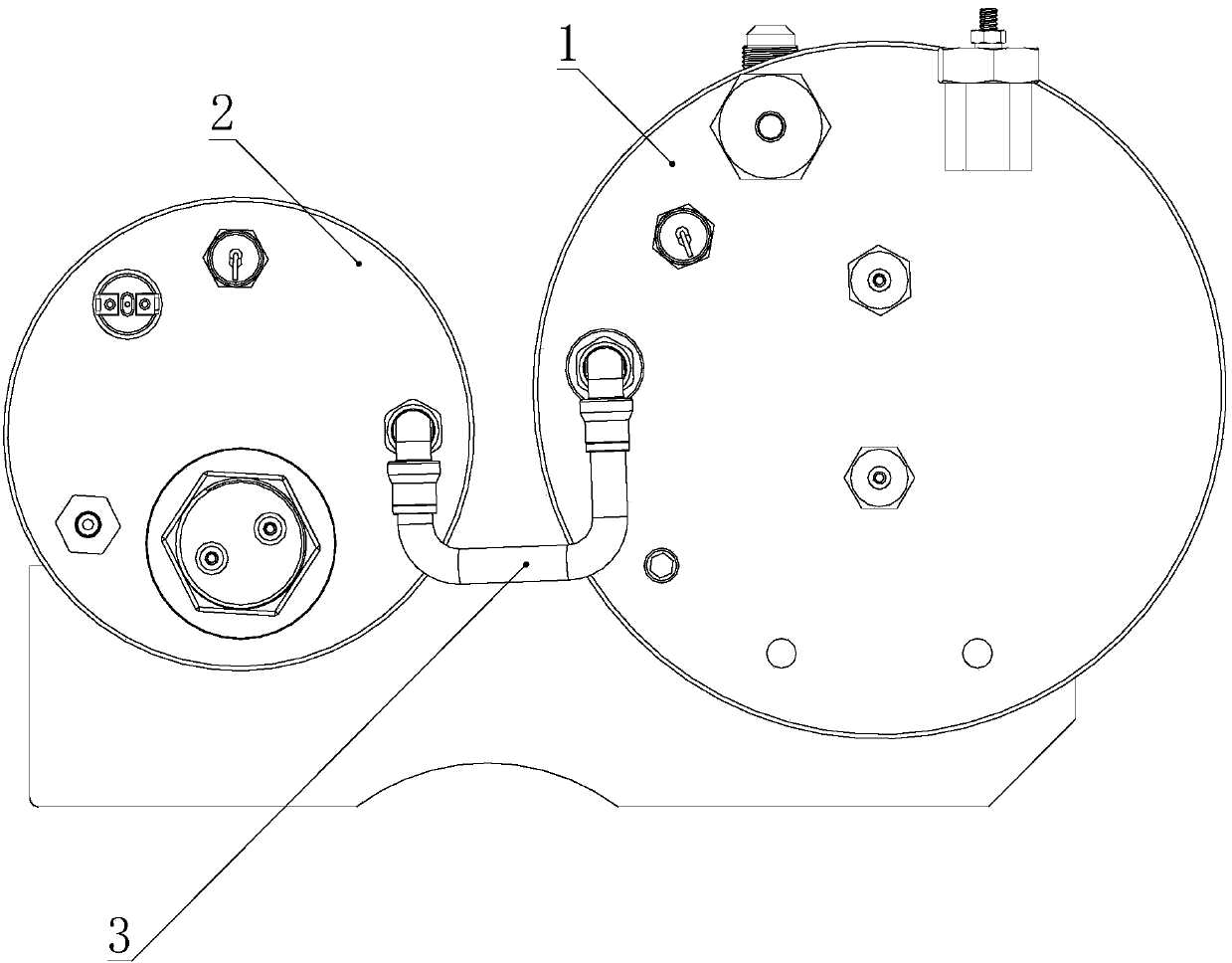

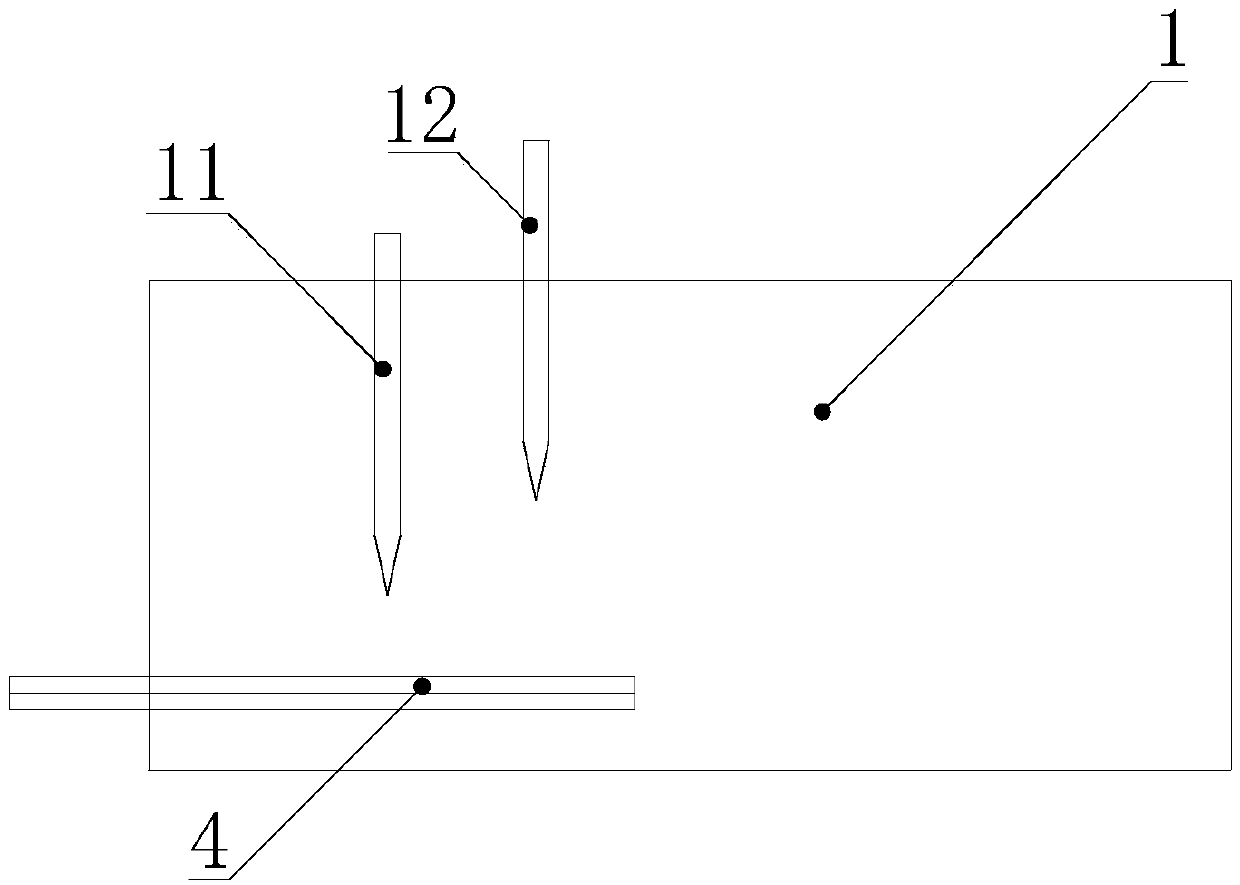

[0024] like Figure 2-Figure 3 as shown, figure 2 is a structural schematic diagram of the present invention; image 3 It is a structural schematic diagram of the water level probe of the present invention.

[0025] An intelligent boiler for a coffee machine, comprising a water inlet pipe 3 and a separately arranged steam boiler 1 and a coffee boiler 2, the water inlet pipe 3 passes through the inner cavity of the steam boiler 1 and communicates with the coffee boiler 2; the present invention has a preheating function, and does not With steam, the operator can freely set the steam pressure and water temperature without changing the total capacity and power. Let the operator know how much water is being used to make coffee. It is easier to standardize, speed up and unify coffee drinks.

[0026] The internal temperature of the steam boiler 1 is 80°C-85°C when it is working, which is suitable for the temperature values required by different types of coffee; the internal te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com