Pre-cleaning device and pre-cleaning method for glass production and processing

A pre-cleaning, glass technology, applied in the cleaning method using tools, cleaning method using liquid, cleaning method and utensils, etc., can solve the problems of low work efficiency, the efficiency of glass film cannot be guaranteed, etc., to ensure the firmness of bonding , Improve the effect of post-processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

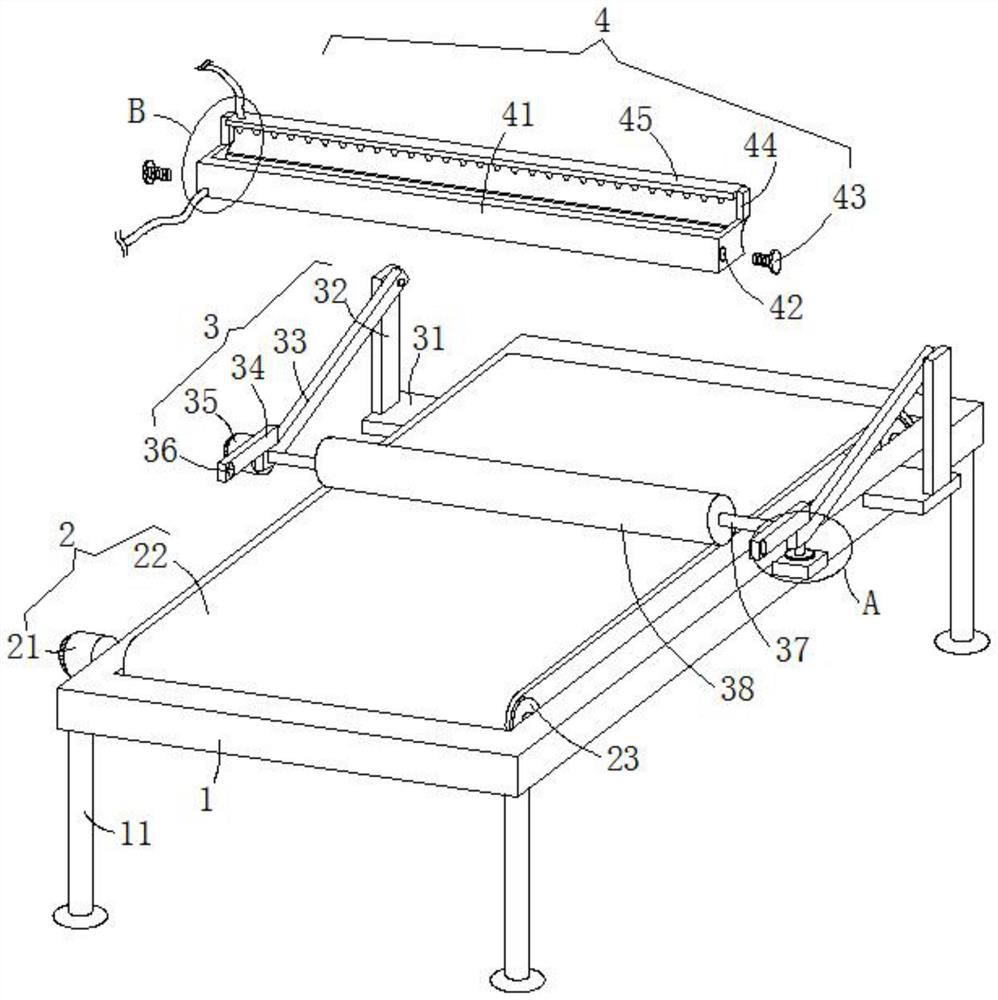

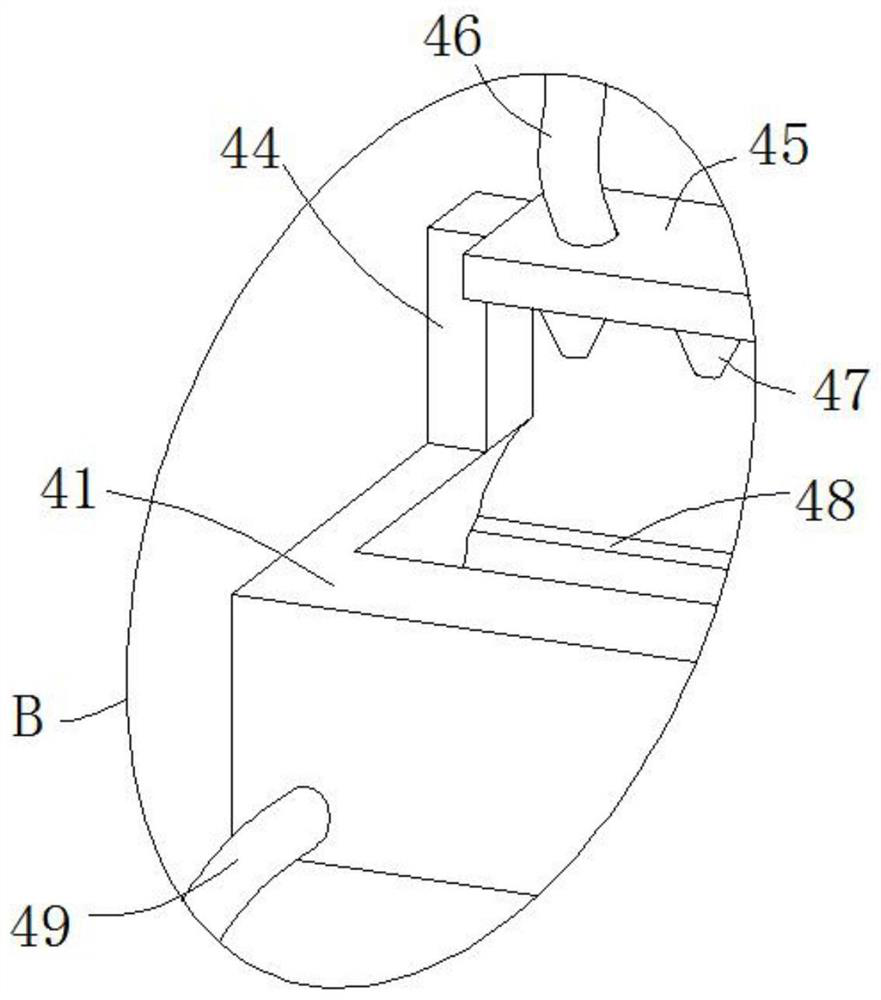

[0025] see Figure 1-3 , the present embodiment provides a pre-cleaning device and a pre-cleaning method for glass production and processing, including a support frame 1, a transmission mechanism 2, a film covering mechanism 3 and a cleaning mechanism 4, the transmission mechanism 2 is arranged in the inner cavity of the support frame 1, The coating mechanism 3 includes two support blocks 31, two support columns 32, two hinged rods 33, a first drive motor 35, two transmission rods 37, a cleaning roller 38 and two extension mounting rods 34, the cleaning mechanism 4 includes a waste liquid collection box 41, two support rods 44 and a rectangular hollow box 45.

[0026] The transmission mechanism 2 includes two transmission rollers 23, a conveyor belt 22 and a second drive motor 21. The two transmission rollers 23 are respectively located at the left and right ends of the inner cavity of the support frame 1, and both rotate with the front and rear side walls of the inner cavity ...

Embodiment 2

[0033] see Figure 1-3 , further improvements have been made on the basis of Example 1:

[0034] The four corners of the bottom surface of the support frame 1 are vertically provided with support legs 11 , and the entire support frame 1 is supported by the support legs 11 .

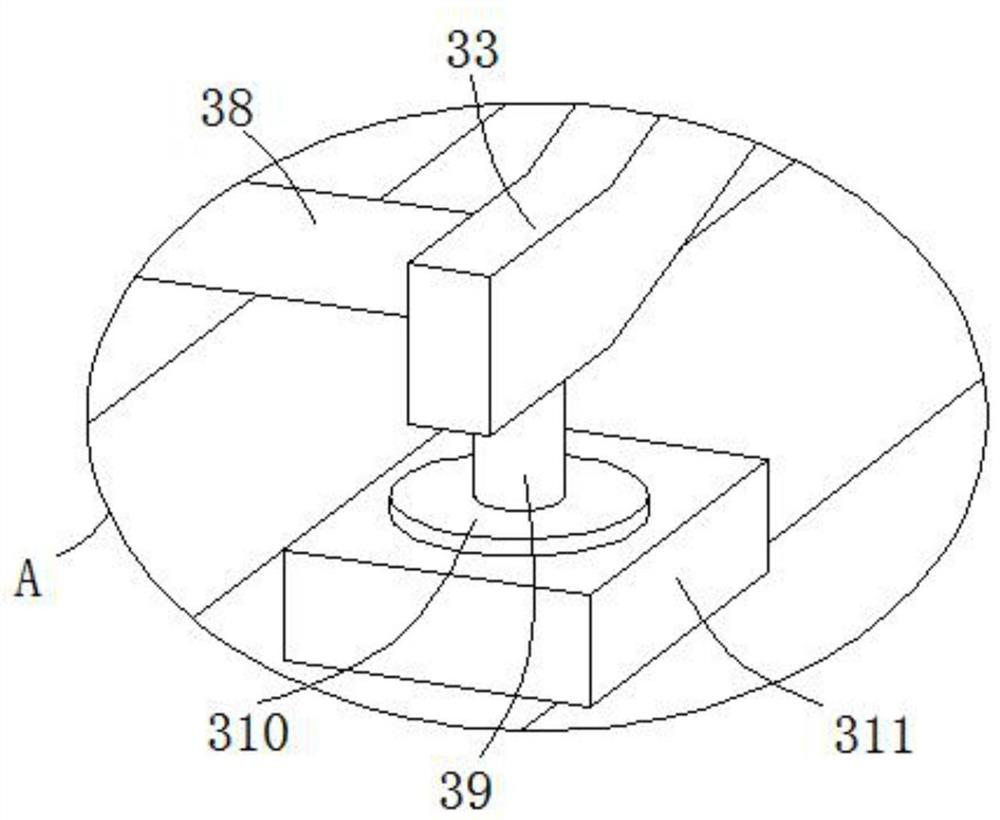

[0035] The bottom end of the tip of the front hinged rod 33 is vertically provided with a suspender 39, the bottom surface of the suspender 39 is provided with an iron plate 310, and the right side of the front end of the support frame 1 is provided with a magnet block 311 directly below the iron plate 310 , by arranging the magnet block 311 and the iron plate 310 that are attracted to each other, the two hinged rods 33 can be pressed down in real time around the hinge point, so as to ensure that the cleaning roller 38 is pressed on the glass to be cleaned in real time, so as to avoid glass failure. Clean enough to affect the later lamination operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com