A kind of preparation method of corrosion-resistant polyurethane press roll

A press roll, polyurethane technology, applied in the press part, other household utensils, papermaking, etc., can solve the problems of destroying the strength and surface finish of the press roll, affecting the dehydration efficiency of the press roll, corrosion, etc., to achieve good strength and solvent resistance, Enhanced strength and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing a corrosion-resistant polyurethane press roll in this embodiment comprises the following steps:

[0029] Step 1: Prepare Modified Polyurethane Resin

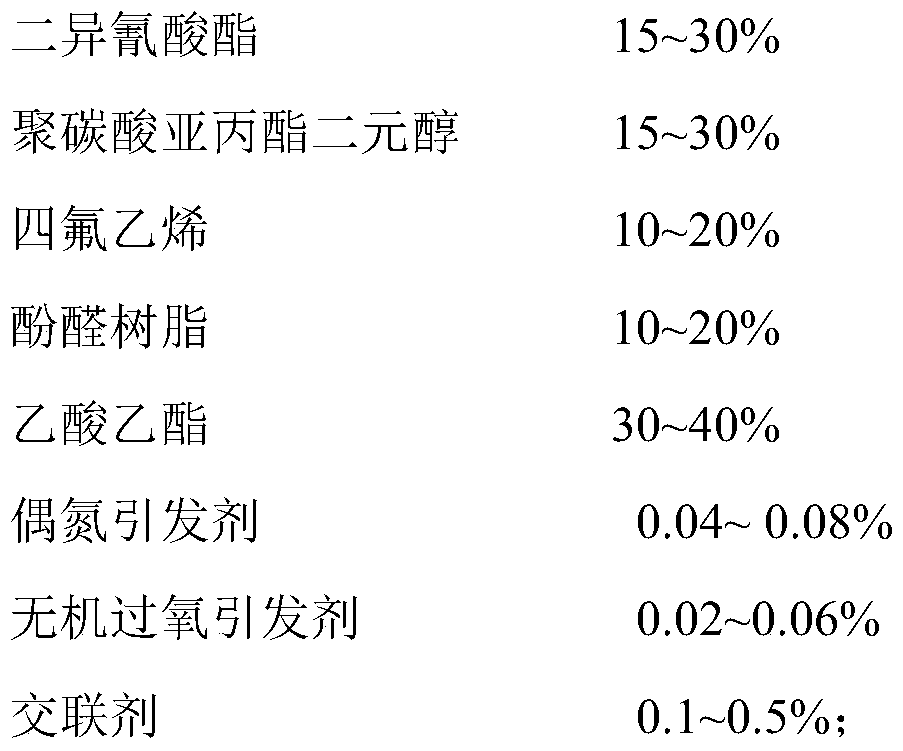

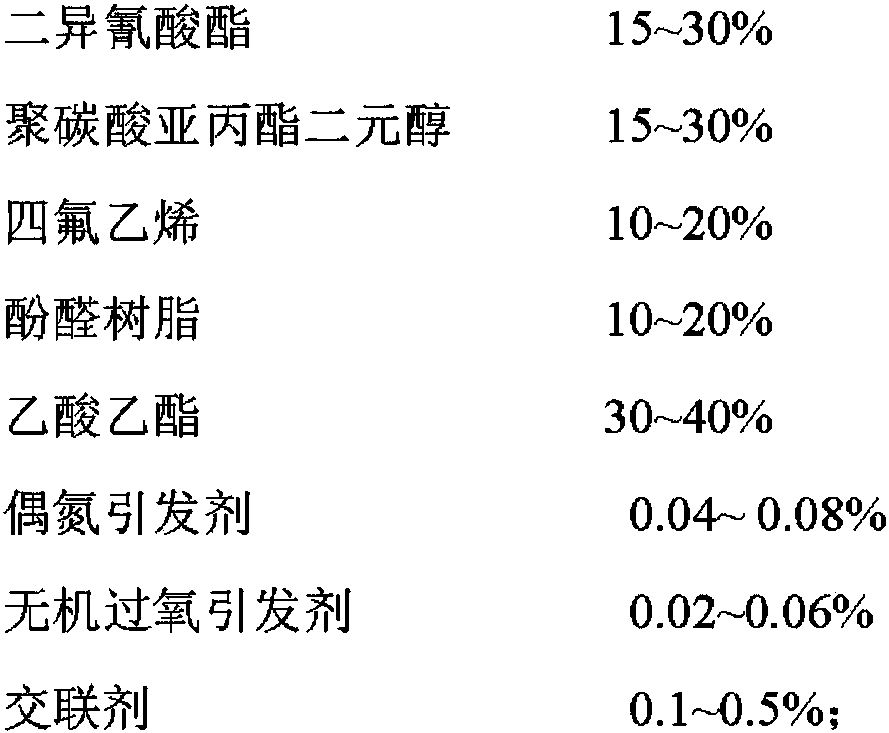

[0030] (1) Weigh the following raw materials in percentage by weight: 15% diisocyanate, 15% polypropylene carbonate diol, 20% tetrafluoroethylene, 19.84% phenolic resin, 30% ethyl acetate, 0.04% azo initiator , Inorganic peroxygen initiator 0.02%, crosslinking agent 0.1%.

[0031] (2) Vacuum dehydrate the polypropylene carbonate diol of formula quantity at 80 DEG C for 30 minutes, after dehydration, cool it down to normal temperature, then add the azo initiator of formula quantity, heat up to 70 DEG C while stirring, then Add the formulated amount of diisocyanate, and continue to stir and react at 70°C for 4 hours to obtain the first mixture; wherein, the azo initiator is a mixture of azobisisobutyronitrile and azobisisoheptanonitrile.

[0032] (3) Mix the tetrafluoroethylene with the formula quan...

Embodiment 2

[0041] A method for preparing a corrosion-resistant polyurethane press roll in this embodiment comprises the following steps:

[0042] Step 1: Prepare Modified Polyurethane Resin

[0043] (1) Weigh the following raw materials in percentage by weight: 30% diisocyanate, 15% polypropylene carbonate diol, 10% tetrafluoroethylene, 10% phenolic resin, 34.36% ethyl acetate, 0.08% azo initiator , Inorganic peroxygen initiator 0.06%, crosslinking agent 0.5%;

[0044] (2) Vacuum dehydrate the polypropylene carbonate diol of formula quantity at 120 DEG C for 40 minutes, after dehydration, cool it down to normal temperature, then add the azo initiator of formula quantity, heat up to 80 DEG C while stirring, then Adding a formulated amount of diisocyanate, continuing to stir and react at 80°C for 5 hours to obtain the first mixture; wherein, the azo initiator is one of azobisisoheptanonitrile and dimethyl azobisisobutyrate or a mixture of two or more.

[0045] (3) Mix the tetrafluoroeth...

Embodiment 3

[0054] A method for preparing a corrosion-resistant polyurethane press roll in this embodiment comprises the following steps:

[0055] Step 1: Prepare Modified Polyurethane Resin

[0056] (1) Weigh the following raw materials in percentage by weight: 17% of diisocyanate, 17% of polypropylene carbonate diol, 15% of tetrafluoroethylene, 15% of phenolic resin, 35.71% of ethyl acetate, 0.06% of azo initiator , Inorganic peroxygen initiator 0.03%, crosslinking agent 0.2%.

[0057] (2) Vacuum dehydrate the polypropylene carbonate diol of formula quantity at 100 DEG C for 35 minutes, cool it to normal temperature after dehydration, then add the azo initiator of formula quantity, heat up to 75 DEG C while stirring, then Add the formulated amount of diisocyanate, and continue to stir and react at 75° C. for 4.5 hours to obtain the first mixture; wherein, the azo initiator is azobisisobutyric acid.

[0058] (3) Mix the tetrafluoroethylene with the formulated amount of the inorganic pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com